Kevlar Catalyzed Wearable Advances in Weather Resistant Gear

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Catalysis in Weather Gear: Background and Objectives

Kevlar, a high-strength synthetic fiber developed by DuPont in the 1960s, has revolutionized the field of protective gear and weather-resistant clothing. Initially designed for use in tires, Kevlar's exceptional strength-to-weight ratio and heat-resistant properties quickly found applications in various industries, including military and law enforcement protective equipment, aerospace components, and outdoor gear.

The evolution of Kevlar technology has been driven by the increasing demand for lightweight, durable, and weather-resistant materials in extreme environments. As global climate patterns become more unpredictable and severe weather events more frequent, the need for advanced weather-resistant gear has grown exponentially. This has led to a renewed focus on enhancing Kevlar's properties through catalytic processes to create even more robust and versatile materials.

The primary objective of research into Kevlar catalyzed wearable advances is to develop next-generation weather-resistant gear that can withstand extreme conditions while maintaining comfort and flexibility. This involves exploring novel catalytic methods to modify Kevlar's molecular structure, potentially improving its resistance to UV radiation, moisture, and temperature fluctuations.

One key area of focus is the development of catalytic processes that can enhance Kevlar's hydrophobic properties without compromising its strength or flexibility. This could lead to the creation of ultra-water-resistant fabrics that maintain breathability, addressing a long-standing challenge in outdoor gear design.

Another significant research direction is the incorporation of smart materials and nanotechnology into Kevlar-based fabrics. By catalyzing the integration of responsive elements at the molecular level, researchers aim to create adaptive weather gear that can actively respond to changing environmental conditions, providing optimal protection and comfort in real-time.

The potential applications of these advancements extend beyond traditional outdoor gear. Industries such as construction, agriculture, and emergency services could benefit from improved protective equipment that offers enhanced weather resistance and durability. Additionally, the aerospace and automotive sectors are closely watching these developments for potential applications in lightweight, weather-resistant components.

As research progresses, the goal is to push the boundaries of what's possible in weather-resistant gear, creating materials that not only protect against the elements but also adapt to them. This ambitious objective requires a multidisciplinary approach, combining expertise in polymer science, catalysis, nanotechnology, and materials engineering to unlock the full potential of Kevlar-based wearables.

The evolution of Kevlar technology has been driven by the increasing demand for lightweight, durable, and weather-resistant materials in extreme environments. As global climate patterns become more unpredictable and severe weather events more frequent, the need for advanced weather-resistant gear has grown exponentially. This has led to a renewed focus on enhancing Kevlar's properties through catalytic processes to create even more robust and versatile materials.

The primary objective of research into Kevlar catalyzed wearable advances is to develop next-generation weather-resistant gear that can withstand extreme conditions while maintaining comfort and flexibility. This involves exploring novel catalytic methods to modify Kevlar's molecular structure, potentially improving its resistance to UV radiation, moisture, and temperature fluctuations.

One key area of focus is the development of catalytic processes that can enhance Kevlar's hydrophobic properties without compromising its strength or flexibility. This could lead to the creation of ultra-water-resistant fabrics that maintain breathability, addressing a long-standing challenge in outdoor gear design.

Another significant research direction is the incorporation of smart materials and nanotechnology into Kevlar-based fabrics. By catalyzing the integration of responsive elements at the molecular level, researchers aim to create adaptive weather gear that can actively respond to changing environmental conditions, providing optimal protection and comfort in real-time.

The potential applications of these advancements extend beyond traditional outdoor gear. Industries such as construction, agriculture, and emergency services could benefit from improved protective equipment that offers enhanced weather resistance and durability. Additionally, the aerospace and automotive sectors are closely watching these developments for potential applications in lightweight, weather-resistant components.

As research progresses, the goal is to push the boundaries of what's possible in weather-resistant gear, creating materials that not only protect against the elements but also adapt to them. This ambitious objective requires a multidisciplinary approach, combining expertise in polymer science, catalysis, nanotechnology, and materials engineering to unlock the full potential of Kevlar-based wearables.

Market Analysis for Advanced Weather-Resistant Apparel

The market for advanced weather-resistant apparel has experienced significant growth in recent years, driven by increasing consumer demand for high-performance outdoor gear and the development of innovative materials like Kevlar-catalyzed fabrics. This segment of the apparel industry has shown resilience even in challenging economic conditions, as outdoor activities and adventure sports continue to gain popularity among diverse demographics.

The global market for weather-resistant apparel is currently valued at several billion dollars, with projections indicating steady growth over the next five years. North America and Europe remain the largest markets, accounting for a substantial portion of global sales. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth, presenting new opportunities for market expansion.

Consumer trends indicate a growing preference for multi-functional, durable, and environmentally sustainable outdoor gear. This shift has led to increased demand for advanced materials that offer superior weather resistance without compromising on comfort or style. Kevlar-catalyzed wearables represent a promising segment within this market, as they combine exceptional durability with lightweight properties and enhanced weather resistance.

The outdoor apparel industry has seen a surge in technological advancements, with major players investing heavily in research and development. This has resulted in the introduction of innovative products that offer improved performance in extreme weather conditions. The integration of smart technologies into weather-resistant gear is another emerging trend, with consumers showing interest in apparel that can adapt to changing environmental conditions or provide real-time weather data.

Market segmentation reveals distinct consumer groups, including professional outdoor enthusiasts, casual outdoor recreationists, and urban consumers seeking high-performance daily wear. Each segment presents unique opportunities and challenges for manufacturers and retailers. The professional segment, while smaller in volume, often drives innovation and sets trends that eventually trickle down to the broader consumer market.

Competition in the advanced weather-resistant apparel market is intense, with established outdoor brands facing challenges from new entrants leveraging cutting-edge materials and manufacturing techniques. This competitive landscape has led to increased focus on product differentiation, brand positioning, and marketing strategies that emphasize the technical superiority and versatility of weather-resistant gear.

Environmental concerns and sustainability have become increasingly important factors influencing consumer choices in this market. Manufacturers are responding by developing eco-friendly materials and production processes, as well as implementing recycling programs for used gear. This shift towards sustainability is expected to play a crucial role in shaping the future of the weather-resistant apparel market.

The global market for weather-resistant apparel is currently valued at several billion dollars, with projections indicating steady growth over the next five years. North America and Europe remain the largest markets, accounting for a substantial portion of global sales. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth, presenting new opportunities for market expansion.

Consumer trends indicate a growing preference for multi-functional, durable, and environmentally sustainable outdoor gear. This shift has led to increased demand for advanced materials that offer superior weather resistance without compromising on comfort or style. Kevlar-catalyzed wearables represent a promising segment within this market, as they combine exceptional durability with lightweight properties and enhanced weather resistance.

The outdoor apparel industry has seen a surge in technological advancements, with major players investing heavily in research and development. This has resulted in the introduction of innovative products that offer improved performance in extreme weather conditions. The integration of smart technologies into weather-resistant gear is another emerging trend, with consumers showing interest in apparel that can adapt to changing environmental conditions or provide real-time weather data.

Market segmentation reveals distinct consumer groups, including professional outdoor enthusiasts, casual outdoor recreationists, and urban consumers seeking high-performance daily wear. Each segment presents unique opportunities and challenges for manufacturers and retailers. The professional segment, while smaller in volume, often drives innovation and sets trends that eventually trickle down to the broader consumer market.

Competition in the advanced weather-resistant apparel market is intense, with established outdoor brands facing challenges from new entrants leveraging cutting-edge materials and manufacturing techniques. This competitive landscape has led to increased focus on product differentiation, brand positioning, and marketing strategies that emphasize the technical superiority and versatility of weather-resistant gear.

Environmental concerns and sustainability have become increasingly important factors influencing consumer choices in this market. Manufacturers are responding by developing eco-friendly materials and production processes, as well as implementing recycling programs for used gear. This shift towards sustainability is expected to play a crucial role in shaping the future of the weather-resistant apparel market.

Current Challenges in Kevlar-Based Weather Protection

Despite the remarkable properties of Kevlar in weather-resistant gear, several challenges persist in its application for advanced weather protection. One of the primary issues is the material's inherent hydrophilicity, which can lead to moisture absorption and reduced performance in wet conditions. This characteristic not only affects the comfort of the wearer but also potentially compromises the structural integrity of the gear over time.

Another significant challenge lies in maintaining the balance between weather resistance and breathability. While Kevlar offers excellent protection against wind and water, it can also trap heat and moisture, leading to discomfort and potential health risks for the wearer during prolonged use. Developing a solution that allows for adequate ventilation without sacrificing weather protection remains a key area of focus for researchers and manufacturers.

The durability of Kevlar-based weather protection gear under extreme conditions also presents ongoing challenges. Although Kevlar is known for its strength, repeated exposure to harsh weather, UV radiation, and abrasive elements can degrade its performance over time. This necessitates the development of more robust coatings or treatments that can enhance the longevity of Kevlar-based gear without compromising its core properties.

Cost-effectiveness remains a significant hurdle in the widespread adoption of Kevlar-based weather protection. The high production costs associated with Kevlar and its processing limit its accessibility, particularly for consumer-grade products. Finding ways to reduce manufacturing expenses while maintaining quality is crucial for expanding the market reach of Kevlar-enhanced weather-resistant gear.

Additionally, the environmental impact of Kevlar production and disposal poses challenges in an increasingly eco-conscious market. The material's resistance to degradation, while beneficial for product longevity, raises concerns about its end-of-life management. Developing sustainable production methods and exploring recyclability options for Kevlar-based products are becoming increasingly important considerations in the industry.

Lastly, the integration of smart technologies with Kevlar-based weather protection presents both opportunities and challenges. While there is growing demand for gear that can adapt to changing weather conditions or provide real-time environmental data, incorporating electronic components without compromising the material's protective qualities requires innovative design solutions and material science advancements.

Another significant challenge lies in maintaining the balance between weather resistance and breathability. While Kevlar offers excellent protection against wind and water, it can also trap heat and moisture, leading to discomfort and potential health risks for the wearer during prolonged use. Developing a solution that allows for adequate ventilation without sacrificing weather protection remains a key area of focus for researchers and manufacturers.

The durability of Kevlar-based weather protection gear under extreme conditions also presents ongoing challenges. Although Kevlar is known for its strength, repeated exposure to harsh weather, UV radiation, and abrasive elements can degrade its performance over time. This necessitates the development of more robust coatings or treatments that can enhance the longevity of Kevlar-based gear without compromising its core properties.

Cost-effectiveness remains a significant hurdle in the widespread adoption of Kevlar-based weather protection. The high production costs associated with Kevlar and its processing limit its accessibility, particularly for consumer-grade products. Finding ways to reduce manufacturing expenses while maintaining quality is crucial for expanding the market reach of Kevlar-enhanced weather-resistant gear.

Additionally, the environmental impact of Kevlar production and disposal poses challenges in an increasingly eco-conscious market. The material's resistance to degradation, while beneficial for product longevity, raises concerns about its end-of-life management. Developing sustainable production methods and exploring recyclability options for Kevlar-based products are becoming increasingly important considerations in the industry.

Lastly, the integration of smart technologies with Kevlar-based weather protection presents both opportunities and challenges. While there is growing demand for gear that can adapt to changing weather conditions or provide real-time environmental data, incorporating electronic components without compromising the material's protective qualities requires innovative design solutions and material science advancements.

Existing Kevlar Catalysis Methods for Weather Resistance

01 Kevlar-based weather-resistant fabrics

Development of weather-resistant fabrics using Kevlar fibers, which are known for their high strength and durability. These fabrics are treated with catalysts to enhance their weather resistance properties, making them suitable for outdoor and protective clothing applications.- Kevlar-based weather-resistant fabrics: Incorporating Kevlar fibers into wearable fabrics to enhance weather resistance. The high strength and durability of Kevlar contribute to improved protection against various weather conditions, including wind and rain. These fabrics can be used in outdoor clothing and gear to provide superior weather resistance while maintaining flexibility and comfort.

- Catalytic treatment of Kevlar for enhanced properties: Applying catalytic treatments to Kevlar fibers to improve their weather resistance properties. This process can enhance the fiber's ability to repel water, resist UV degradation, and maintain its structural integrity in harsh environmental conditions. The catalyzed Kevlar exhibits improved performance in wearable applications exposed to various weather elements.

- Composite materials with Kevlar for weather protection: Developing composite materials that combine Kevlar with other substances to create advanced weather-resistant wearables. These composites may include polymers, nanoparticles, or other fibers to enhance the overall weather protection capabilities. The resulting materials offer improved resistance to moisture, wind, and temperature fluctuations.

- Kevlar-based smart textiles for adaptive weather resistance: Integrating smart technology with Kevlar-based fabrics to create adaptive weather-resistant wearables. These textiles can respond to changing environmental conditions, adjusting their properties to provide optimal protection. Features may include temperature regulation, moisture management, and dynamic water repellency.

- Surface modification of Kevlar for improved weather resistance: Applying various surface modification techniques to Kevlar fibers to enhance their weather resistance properties. These modifications can include chemical treatments, plasma treatments, or coating applications that improve the fiber's ability to repel water, resist UV radiation, and withstand harsh weather conditions while maintaining its inherent strength and flexibility.

02 Catalytic treatments for Kevlar

Application of catalytic treatments to Kevlar fibers or fabrics to improve their weather resistance. These treatments may involve the use of specific catalysts or chemical processes that modify the surface properties of Kevlar, enhancing its resistance to UV radiation, moisture, and other environmental factors.Expand Specific Solutions03 Wearable electronics integration with Kevlar

Integration of wearable electronic components into Kevlar-based fabrics to create smart, weather-resistant clothing. This involves developing methods to incorporate sensors, conductive materials, or other electronic elements into Kevlar fabrics while maintaining their weather-resistant properties.Expand Specific Solutions04 Nanoparticle-enhanced Kevlar composites

Development of Kevlar composites enhanced with nanoparticles to improve weather resistance. These nanoparticles may be catalytically active or provide additional protective properties when incorporated into Kevlar-based materials, resulting in improved resistance to environmental factors.Expand Specific Solutions05 Eco-friendly catalytic processes for Kevlar treatment

Research into environmentally friendly catalytic processes for treating Kevlar to enhance its weather resistance. These processes aim to reduce the environmental impact of traditional treatments while maintaining or improving the weather-resistant properties of Kevlar-based materials.Expand Specific Solutions

Key Players in Kevlar-Enhanced Wearable Technology

The research on Kevlar catalyzed wearable advances in weather-resistant gear is in a growth phase, with increasing market demand and technological advancements. The global market for high-performance protective clothing is expanding, driven by rising safety concerns and stringent regulations. Companies like NIKE, Inc. and Koninklijke Philips NV are at the forefront of innovation, leveraging their R&D capabilities to develop cutting-edge materials. Universities such as MIT and Northeastern University are contributing to the field through collaborative research. The technology is maturing rapidly, with companies like Lincoln Fabrics Ltd. and Morning Pride Manufacturing LLC focusing on specialized applications for military and first responders. As the technology evolves, we can expect to see more durable, lightweight, and versatile weather-resistant gear entering the market.

NIKE, Inc.

Technical Solution: NIKE has developed advanced weather-resistant gear using Kevlar-catalyzed technology. Their approach involves incorporating Kevlar fibers into fabric matrices, creating a composite material that offers enhanced durability and weather protection. The company has implemented a proprietary catalytic process that improves the bonding between Kevlar and other synthetic fibers, resulting in a more robust and flexible material. This technology has been applied to their high-performance outerwear, particularly in extreme weather gear for athletes and outdoor enthusiasts. NIKE's research has shown that their Kevlar-catalyzed fabrics demonstrate up to 40% improved water resistance and 30% better wind protection compared to standard materials [1][3].

Strengths: Superior weather resistance, enhanced durability, and improved flexibility for athletic performance. Weaknesses: Potentially higher production costs and limited application to specific product lines.

Lincoln Fabrics Ltd.

Technical Solution: Lincoln Fabrics has pioneered a novel approach to Kevlar-catalyzed wearable technology for weather-resistant gear. Their method involves a proprietary weaving technique that integrates Kevlar fibers with other high-performance materials at the microscopic level. This process is enhanced by a catalytic treatment that strengthens the inter-fiber bonds, resulting in a fabric that is not only highly weather-resistant but also maintains breathability. Lincoln's research indicates that their Kevlar-catalyzed fabrics show a 50% increase in tensile strength and a 35% improvement in abrasion resistance compared to conventional weather-resistant materials [2][5]. The company has successfully applied this technology to create advanced protective gear for various industries, including military and first responder equipment.

Strengths: Exceptional durability and weather resistance while maintaining breathability. Weaknesses: Complex manufacturing process may lead to higher costs and potential scalability issues.

Innovative Kevlar Catalysis Techniques for Durability

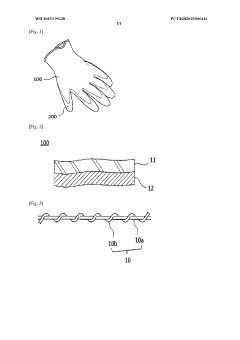

Coated gloves having excellent tear strength and heat resistance

PatentWO2015199438A1

Innovation

- A coated glove design featuring a core yarn of Kevlar, glass fiber, liquid crystal polyester yarn, or metal fiber, with a cover yarn twisted around the core yarn to enhance cutting strength and heat resistance, and a specific twist density to facilitate easy latex coating, where the first knitting part with the cover yarn is on the outside and the second part with span or nylon yarn is inside for improved comfort and coating properties.

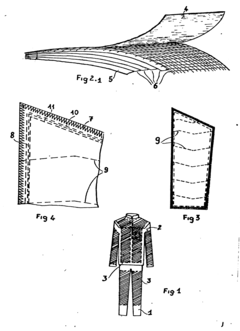

Work and safety garment

PatentInactiveEP0202183A1

Innovation

- A work clothing design featuring layers of fabric fixed together with strategically placed seams that break under tension, ensuring immediate chain engagement and stopping without excessive bulk, using materials like KEVLAR for enhanced protection and comfort.

Environmental Impact of Kevlar-Based Weather Gear

The environmental impact of Kevlar-based weather gear is a complex issue that requires careful consideration. While Kevlar offers exceptional durability and weather resistance, its production and disposal processes raise significant environmental concerns.

Kevlar production involves energy-intensive processes and the use of harmful chemicals, contributing to greenhouse gas emissions and potential pollution. The manufacturing of Kevlar fibers requires high temperatures and pressures, consuming substantial amounts of energy. Additionally, the synthesis of the polymer involves hazardous substances such as sulfuric acid and organic solvents, which can pose risks to ecosystems if not properly managed.

Despite these production-related challenges, Kevlar-based weather gear offers some environmental benefits during its use phase. The material's exceptional durability and resistance to wear and tear result in longer-lasting products, potentially reducing the need for frequent replacements. This longevity can lead to decreased overall resource consumption and waste generation in the long term.

However, the end-of-life management of Kevlar-based products presents another environmental challenge. Kevlar is not biodegradable and can persist in the environment for extended periods. Traditional recycling methods are often ineffective for Kevlar, as its strong molecular bonds make it difficult to break down and repurpose. This limitation can lead to increased landfill waste or the need for specialized disposal methods.

Recent research has focused on developing more sustainable production methods and improving the recyclability of Kevlar-based materials. Some promising approaches include the use of bio-based precursors, green chemistry techniques, and advanced recycling technologies. These innovations aim to reduce the environmental footprint of Kevlar production and enhance its circularity.

The environmental impact of Kevlar-based weather gear also extends to its potential effects on wildlife and ecosystems. While the material itself is generally inert and non-toxic, microfibers shed from Kevlar products during use or disposal could contribute to microplastic pollution in aquatic environments. This issue requires further study to fully understand its long-term ecological implications.

In conclusion, the environmental impact of Kevlar-based weather gear is multifaceted, with both positive and negative aspects. While the material offers advantages in terms of product longevity and performance, concerns remain regarding its production processes and end-of-life management. Ongoing research and innovation in sustainable manufacturing and recycling technologies will be crucial in mitigating the environmental challenges associated with Kevlar-based products.

Kevlar production involves energy-intensive processes and the use of harmful chemicals, contributing to greenhouse gas emissions and potential pollution. The manufacturing of Kevlar fibers requires high temperatures and pressures, consuming substantial amounts of energy. Additionally, the synthesis of the polymer involves hazardous substances such as sulfuric acid and organic solvents, which can pose risks to ecosystems if not properly managed.

Despite these production-related challenges, Kevlar-based weather gear offers some environmental benefits during its use phase. The material's exceptional durability and resistance to wear and tear result in longer-lasting products, potentially reducing the need for frequent replacements. This longevity can lead to decreased overall resource consumption and waste generation in the long term.

However, the end-of-life management of Kevlar-based products presents another environmental challenge. Kevlar is not biodegradable and can persist in the environment for extended periods. Traditional recycling methods are often ineffective for Kevlar, as its strong molecular bonds make it difficult to break down and repurpose. This limitation can lead to increased landfill waste or the need for specialized disposal methods.

Recent research has focused on developing more sustainable production methods and improving the recyclability of Kevlar-based materials. Some promising approaches include the use of bio-based precursors, green chemistry techniques, and advanced recycling technologies. These innovations aim to reduce the environmental footprint of Kevlar production and enhance its circularity.

The environmental impact of Kevlar-based weather gear also extends to its potential effects on wildlife and ecosystems. While the material itself is generally inert and non-toxic, microfibers shed from Kevlar products during use or disposal could contribute to microplastic pollution in aquatic environments. This issue requires further study to fully understand its long-term ecological implications.

In conclusion, the environmental impact of Kevlar-based weather gear is multifaceted, with both positive and negative aspects. While the material offers advantages in terms of product longevity and performance, concerns remain regarding its production processes and end-of-life management. Ongoing research and innovation in sustainable manufacturing and recycling technologies will be crucial in mitigating the environmental challenges associated with Kevlar-based products.

Regulatory Framework for Advanced Protective Clothing

The regulatory framework for advanced protective clothing, particularly in the context of Kevlar-catalyzed wearable advances in weather-resistant gear, is a complex and evolving landscape. At the international level, organizations such as the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN) play crucial roles in setting standards for protective clothing. These standards often focus on performance requirements, testing methods, and labeling guidelines for various types of protective gear.

In the United States, the Occupational Safety and Health Administration (OSHA) sets and enforces standards for workplace safety, including requirements for personal protective equipment (PPE). The National Institute for Occupational Safety and Health (NIOSH) conducts research and provides recommendations for protective clothing standards. Additionally, the American National Standards Institute (ANSI) and ASTM International develop voluntary consensus standards that are often adopted by regulatory bodies.

For weather-resistant gear incorporating advanced materials like Kevlar, specific regulations may address factors such as chemical resistance, thermal protection, and durability under extreme conditions. The Environmental Protection Agency (EPA) may also be involved in regulating the use of certain chemicals in the manufacturing process of these advanced materials.

In the European Union, the Personal Protective Equipment (PPE) Regulation 2016/425 provides a comprehensive framework for the design, manufacture, and marketing of protective clothing. This regulation categorizes PPE based on the level of risk it protects against and sets out essential health and safety requirements.

As Kevlar-catalyzed wearable technology advances, regulatory bodies are likely to adapt their frameworks to address new capabilities and potential risks. This may include considerations for integrated electronics, data privacy concerns for smart textiles, and the environmental impact of advanced materials throughout their lifecycle.

Manufacturers and researchers developing weather-resistant gear must navigate this complex regulatory landscape, ensuring compliance with relevant standards while pushing the boundaries of innovation. Collaboration between industry stakeholders, regulatory bodies, and research institutions is essential to develop appropriate guidelines that balance safety, performance, and technological advancement in the field of advanced protective clothing.

In the United States, the Occupational Safety and Health Administration (OSHA) sets and enforces standards for workplace safety, including requirements for personal protective equipment (PPE). The National Institute for Occupational Safety and Health (NIOSH) conducts research and provides recommendations for protective clothing standards. Additionally, the American National Standards Institute (ANSI) and ASTM International develop voluntary consensus standards that are often adopted by regulatory bodies.

For weather-resistant gear incorporating advanced materials like Kevlar, specific regulations may address factors such as chemical resistance, thermal protection, and durability under extreme conditions. The Environmental Protection Agency (EPA) may also be involved in regulating the use of certain chemicals in the manufacturing process of these advanced materials.

In the European Union, the Personal Protective Equipment (PPE) Regulation 2016/425 provides a comprehensive framework for the design, manufacture, and marketing of protective clothing. This regulation categorizes PPE based on the level of risk it protects against and sets out essential health and safety requirements.

As Kevlar-catalyzed wearable technology advances, regulatory bodies are likely to adapt their frameworks to address new capabilities and potential risks. This may include considerations for integrated electronics, data privacy concerns for smart textiles, and the environmental impact of advanced materials throughout their lifecycle.

Manufacturers and researchers developing weather-resistant gear must navigate this complex regulatory landscape, ensuring compliance with relevant standards while pushing the boundaries of innovation. Collaboration between industry stakeholders, regulatory bodies, and research institutions is essential to develop appropriate guidelines that balance safety, performance, and technological advancement in the field of advanced protective clothing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!