Optimizing Flow Geometry Of Check Valves To Improve Flow Efficiency

Check Valve Flow Geometry Optimization: Technology Background And Goals

The research will delve into the intricate relationship between valve geometry, fluid dynamics, and flow patterns, leveraging advanced computational fluid dynamics (CFD) simulations and experimental data. Potential areas of focus include streamlining the valve body contours, optimizing the valve opening mechanism, and minimizing turbulence and flow separation. Innovative design approaches, such as biomimetic or additive manufacturing techniques, may also be explored to unlock new possibilities in flow optimization.

Check Valve Market Demand Analysis

- Growing Demand for Check Valves Check valves are essential components in various industries, including oil and gas, water treatment, and chemical processing. The market demand for check valves is driven by the expansion of these industries and the need for efficient fluid control systems.

- Replacement and Maintenance Needs Existing infrastructure and aging equipment require regular maintenance and replacement of check valves, contributing to a steady demand in the market.

- Emphasis on Energy Efficiency With increasing focus on energy efficiency and cost savings, there is a growing demand for check valves that can minimize pressure losses and improve flow efficiency, reducing overall energy consumption.

- Regulatory Compliance Stringent regulations and safety standards in various industries necessitate the use of high-quality check valves, driving demand for reliable and compliant products.

- Emerging Markets and Industrialization Rapid industrialization and infrastructure development in emerging economies are fueling the demand for check valves in new construction projects and industrial facilities.

Check Valve Flow Geometry Optimization: Technology Status And Challenges

- Valve Design Evolution

Tracing the development of check valve designs, from traditional swing and lift check valves to advanced designs like tilting disc, double-door, and nozzle check valves. - Flow Efficiency Challenges

Identifying key challenges in optimizing flow efficiency, such as minimizing pressure drop, preventing flow reversal, and reducing turbulence and cavitation. - Material and Manufacturing Constraints

Discussing material selection and manufacturing limitations that impact valve performance, durability, and cost-effectiveness. - Computational Fluid Dynamics (CFD) Modeling

Highlighting the role of CFD simulations in analyzing flow patterns, optimizing valve geometries, and predicting performance under various operating conditions.

Current Technical Solutions

01 Optimized Valve Design

Optimize design features like streamlined valve body shapes, valve seat geometries, and reduced flow obstructions to enhance flow efficiency and minimize pressure drops and turbulence.- Optimized Valve Design: Enhance flow efficiency through streamlined valve body shapes, optimized valve seat geometries, and reduced flow obstructions to minimize pressure drops and turbulence.

- Low-Friction Materials: Utilize low-friction materials, such as certain polymers or coatings, to reduce surface roughness and minimize flow resistance, resulting in improved flow characteristics.

- Optimized Flow Paths: Optimize the configuration of valve components and flow paths, including streamlined flow channels, minimized obstructions, and optimized valve opening/closing mechanisms for improved flow efficiency.

- Proper Sizing and Scaling: Design valves with appropriate dimensions and flow capacities to match application requirements, minimizing pressure drops and maximizing flow rates for optimal flow efficiency.

- Integration with Flow Control Systems: Integrate check valves with flow control systems, including valve actuation mechanisms, flow monitoring, and intelligent control algorithms to dynamically adjust valve operation based on flow conditions for optimized efficiency.

02 Low-Friction Materials

Select low-friction materials, such as certain polymers or coatings, to reduce surface roughness and minimize flow resistance, improving flow efficiency.Expand Specific Solutions03 Optimized Valve Configurations

Choose appropriate valve configurations, like swing, lift, or ball types, based on application requirements to optimize flow characteristics and efficiency.Expand Specific Solutions04 Proper Sizing and Positioning

Optimize valve sizing and positioning within the flow system, considering factors like pipe diameter, flow rates, and valve placement to minimize pressure drops and turbulence, improving flow efficiency.Expand Specific Solutions05 Maintenance and Monitoring

Implement regular maintenance and monitoring of check valves, including inspections, cleaning, and component replacement, to prevent issues like leakage or sticking that can impact flow efficiency over time.Expand Specific Solutions

Main Player Analysis

Ford Global Technologies LLC

BorgWarner, Inc.

Key Technology Interpretation

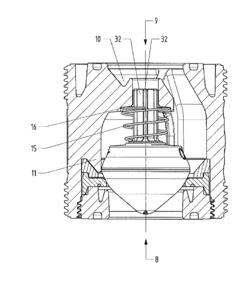

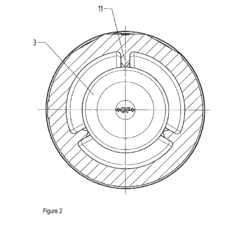

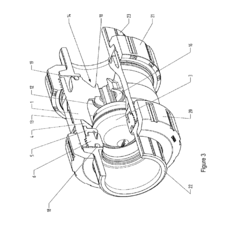

- The use of a closing element with a flow-optimized shape in zone a, which allows for low resistance in the conduit or valve. this shape ensures a uniform distribution of flow and prevents vibration and noise generation.

- The arrangement of zone a, which has a radius that automatically distributes flow in a completely uniform manner, at the tip or front of the closing element. this helps to further optimize the flow coefficient and minimize resistance.

- The use of a domed shape in zone b of the closing element, which provides optimum sealing when the valve is closed. this design ensures reliable sealing and prevents backflow when the valve is open.

- The integration of zone c, which has a radius that gradually transitions from the domed shape in zone b to a short straight line, serving as a flow guiding element. this feature helps to minimize turbulence and reduce vibration and fluttering, further improving the flow coefficient.

Check Valve Flow Geometry Optimization Economic Analysis

Regulatory Landscape for Valve Manufacturing

The regulatory landscape for valve manufacturing encompasses a comprehensive set of standards, guidelines, and directives that govern the design, production, and quality assurance of valves across various industries. These regulations are established by international organizations, government agencies, and industry associations to ensure the safety, reliability, and performance of valves in critical applications.

One of the primary regulatory bodies is the International Organization for Standardization (ISO), which has developed a series of standards specifically for industrial valves. The ISO 16138 standard, for instance, provides requirements for the design, manufacturing, and testing of industrial valves, ensuring consistent quality and performance across different manufacturers.

In addition to international standards, regional and national regulations play a crucial role in the valve manufacturing industry. In the United States, the American Society of Mechanical Engineers (ASME) has established the ASME Boiler and Pressure Vessel Code, which includes specific sections dedicated to valves used in pressure systems. Compliance with these codes is often mandatory for valves used in critical applications, such as power generation, oil and gas, and chemical processing.

The European Union has implemented the Pressure Equipment Directive (PED), which sets essential safety requirements for pressure equipment, including valves, intended for use within the European Economic Area. Manufacturers must ensure that their valves comply with the PED requirements and carry the CE marking, indicating conformity with the relevant European directives.

Industry-specific regulations also play a significant role in valve manufacturing. For example, the American Petroleum Institute (API) has developed standards for valves used in the oil and gas industry, such as API 600 for steel gate valves and API 594 for check valves. These standards cover design, material selection, testing, and quality control requirements specific to the harsh environments encountered in the oil and gas sector.

Environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, also impact valve manufacturing by restricting the use of certain hazardous materials and substances in the production process.

Compliance with these regulations is essential for valve manufacturers to ensure the safety and reliability of their products, as well as to gain access to global markets. Failure to adhere to these standards and directives can result in legal consequences, product recalls, and damage to a company's reputation.