Innovative Solutions For Reducing Friction In Check Valves

Check Valve Friction Reduction: Technology Background And Goals

The analysis will encompass a thorough examination of the current state of the art, pinpointing major technical challenges and bottlenecks that impede further progress. Additionally, it will shed light on the geographical distribution of expertise and resources within this field, highlighting regions or institutions that have made significant contributions.

Check Valve Market Demand Analysis

- Market Size and Growth

Analyze the current and projected market size for check valve products, considering factors like industrial applications, infrastructure development, and replacement demand. Provide quantitative data on market value and growth rates. - Industry Trends

Identify key trends shaping the check valve market, such as the adoption of new materials, design innovations, and regulatory changes. Discuss how these trends influence market demand and customer preferences. - Application Analysis

Examine the demand for check valves across various industries, including oil and gas, water and wastewater treatment, power generation, and chemical processing. Highlight the specific requirements and challenges in each application area. - Regional Dynamics

Assess the regional distribution of check valve demand, considering factors like industrialization levels, infrastructure investments, and local regulations. Identify high-growth regions and potential emerging markets. - Customer Segmentation

Analyze the different customer segments within the check valve market, such as original equipment manufacturers (OEMs), end-users, and aftermarket customers. Understand their unique needs and purchasing behaviors.

Check Valve Friction Reduction: Technology Status And Challenges

- Valve Design Limitations

Current valve designs face challenges in reducing friction, leading to increased wear, energy losses, and maintenance requirements. - Material Constraints

Commonly used valve materials have inherent limitations in terms of surface roughness and lubricity, contributing to friction issues. - Flow Dynamics

Complex fluid dynamics within valves, including turbulence and cavitation, can exacerbate friction and erosion problems. - Scaling and Fouling

Buildup of deposits or scaling on valve surfaces can significantly increase friction and impair valve performance. - Sealing Challenges

Achieving effective sealing while minimizing friction remains a challenge, particularly in high-pressure or high-temperature applications.

Current Technical Solutions

01 Friction-Reducing Designs

Various check valve designs aim to reduce friction and improve flow efficiency by optimizing valve seat geometry, using low-friction materials, or incorporating features that minimize turbulence and resistance to fluid flow.- Optimized Valve Design: Various check valve designs aim to reduce friction and improve flow efficiency by optimizing valve components, materials, or configurations to minimize resistance and turbulence during fluid flow.

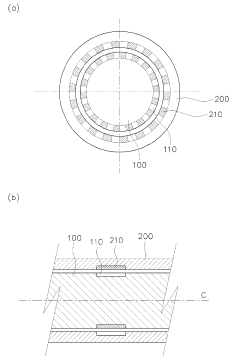

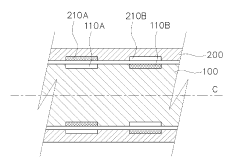

- Surface Treatments: Surface treatments or coatings can be applied to check valve components to reduce friction and wear, involving low-friction materials or textures on valve surfaces in contact with the fluid.

- Valve Seat and Sealing Mechanisms: Optimized valve seat designs and sealing mechanisms contribute to reduced friction and improved sealing performance, utilizing specialized geometries, materials, or configurations to minimize friction and leakage.

- Low-Friction Materials: The selection of low-friction materials, such as certain polymers or composites, for check valve components can reduce friction between moving parts and improve overall valve performance.

- Turbulence and Flow Resistance Minimization: Check valve designs that minimize turbulence and flow resistance, through optimized flow paths, streamlined geometries, or other features, can contribute to reduced friction and promote smooth and efficient fluid flow.

02 Fluid System Applications

Check valves are widely used in various fluid systems, such as hydraulic, pneumatic, and piping networks, to prevent backflow and ensure proper directional flow, with designs and materials tailored to specific application requirements.Expand Specific Solutions03 Materials and Coatings

The choice of materials and coatings for check valves, including metals, polymers, and composites, with coatings applied to enhance surface properties, can influence their performance, durability, and resistance to friction and wear.Expand Specific Solutions04 Sealing Mechanisms

Effective sealing mechanisms, such as elastomeric seals or metal-to-metal sealing surfaces, are crucial for check valves to prevent backflow and leakage while minimizing friction and providing a reliable seal.Expand Specific Solutions05 Testing and Performance Evaluation

Various testing methods and performance evaluation techniques are employed to assess the functionality, reliability, and efficiency of check valves under different operating conditions, including flow rates, pressures, and temperatures.Expand Specific Solutions

Technology Main Player Analysis

Honeywell International Technologies Ltd.

Robert Bosch GmbH

Key Technology Interpretation

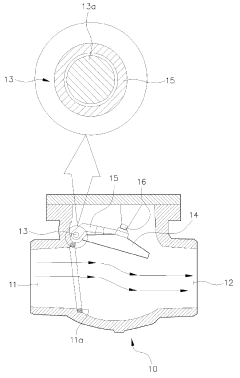

- The swing check valve incorporates a hinge pin with a first magnetic body and a hinge arm with a second magnetic body of opposite polarity, which reduces friction on the hinge unit when the valve disc vibrates or shakes.

- The magnetic repulsion between the first and second magnetic bodies helps prevent friction and wear on the hinge unit, improving the valve's durability and service life.

- The magnetic repulsion mechanism is a passive system that does not require external power or control, simplifying the valve design and operation.

Regulatory and Compliance Factors

Regulatory and compliance factors play a crucial role in the development and implementation of technologies aimed at reducing friction in check valves. These factors encompass a wide range of legal, safety, and environmental considerations that must be carefully addressed to ensure the successful adoption and deployment of such technologies.

One of the primary regulatory aspects is adherence to industry standards and codes. Check valves are widely used in various industries, including oil and gas, chemical processing, power generation, and water treatment. Each industry has its own set of standards and regulations governing the design, manufacturing, and operation of check valves. Compliance with these standards is essential to ensure the safety and reliability of the valves, as well as to meet the specific requirements of the respective industries.

Environmental regulations are another critical factor to consider. Technologies aimed at reducing friction in check valves may involve the use of specialized materials, coatings, or lubricants. These materials must be evaluated for their environmental impact, including their potential for leaching, toxicity, and biodegradability. Compliance with environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, is mandatory for products intended for use in various markets.

Safety considerations are paramount in the design and implementation of friction-reducing technologies for check valves. These valves are often used in high-pressure and high-temperature applications, where failure could result in catastrophic consequences. Technologies that reduce friction must be thoroughly tested and validated to ensure they do not compromise the structural integrity, pressure rating, or temperature tolerance of the valves. Compliance with safety standards, such as those set by the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), is essential.

Intellectual property rights and patent protection are also important factors to consider. Technologies aimed at reducing friction in check valves may involve proprietary innovations or patented solutions. Proper due diligence must be conducted to ensure that the proposed technologies do not infringe on existing patents or intellectual property rights. Additionally, companies may seek to protect their innovations through patent filings, which can provide a competitive advantage and enable licensing opportunities.

In summary, regulatory and compliance factors play a critical role in the development and implementation of technologies aimed at reducing friction in check valves. Adherence to industry standards, environmental regulations, safety considerations, and intellectual property rights is essential for ensuring the successful adoption and deployment of these technologies while mitigating potential risks and liabilities.

Environmental Impact Considerations

Environmental impact considerations are crucial when developing technologies aimed at reducing friction in check valves. The manufacturing processes, materials used, and the operational phase of these valves can have significant implications for the environment.

One key aspect to consider is the energy consumption and carbon footprint associated with the production and operation of check valves with reduced friction. While these valves may offer improved efficiency and reduced energy losses during operation, their manufacturing processes may involve energy-intensive techniques or the use of materials with high embodied energy. A comprehensive life cycle assessment should be conducted to evaluate the overall environmental impact, taking into account the entire value chain from raw material extraction to end-of-life disposal or recycling.

Additionally, the materials used in the construction of these valves should be carefully evaluated for their environmental impact. The use of hazardous or non-biodegradable materials can pose risks to the environment during manufacturing, operation, and disposal phases. Efforts should be made to explore eco-friendly alternatives or implement effective recycling and waste management strategies to minimize the environmental footprint.

Furthermore, the potential impact on water resources should be considered, especially in applications where check valves are used in water distribution systems or industrial processes involving water. Leakage or contamination from these valves can lead to water pollution, affecting aquatic ecosystems and human health. Rigorous testing and monitoring protocols should be implemented to ensure the safe and responsible use of these valves in water-related applications.

It is also essential to consider the potential for noise pollution associated with the operation of check valves with reduced friction. While these valves may offer improved flow characteristics, they may also generate higher levels of noise, which can have adverse effects on the surrounding environment and human well-being. Appropriate noise mitigation measures, such as sound insulation or vibration damping, should be explored to minimize the impact of noise pollution.

Overall, a comprehensive environmental impact assessment should be conducted throughout the entire life cycle of check valves with reduced friction, from design and manufacturing to operation and disposal. Collaboration with environmental experts, regulatory bodies, and stakeholders is crucial to ensure that the development and implementation of these technologies align with sustainable practices and environmental protection goals.