PVDF-Based Energy Harvesting Systems For Improving Energy Conversion Efficiency

Technology Background And Goals

The background section will delve into the historical evolution of PVDF-based energy harvesting systems, tracing their origins and highlighting the key milestones that have shaped their progress. It will also outline the specific technological goals and targets that this research aims to achieve, such as improving energy conversion efficiency, increasing durability, or expanding the range of applications.

Market Demand Analysis

- Market Size and Growth

The global market for PVDF-based energy harvesting systems is expected to witness significant growth in the coming years, driven by the increasing demand for sustainable and efficient energy solutions. - Key Application Areas

PVDF-based energy harvesting systems find applications in various sectors, including:- Wearable electronics and IoT devices

- Structural health monitoring systems

- Automotive and aerospace industries

- Wireless sensor networks

- Regional Market Dynamics

The market demand for PVDF-based energy harvesting systems varies across different regions, with North America and Europe being the early adopters. However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing investments in sustainable energy technologies and the presence of major manufacturing hubs. - Drivers and Restraints

- Drivers: Growing demand for self-powered devices, increasing focus on energy efficiency, and advancements in PVDF materials and manufacturing processes.

- Restraints: High initial costs, limited awareness, and challenges in integrating PVDF-based systems with existing infrastructure.

- Competitive Landscape

The PVDF-based energy harvesting market is highly competitive, with several established players and emerging startups. Key players include [Company A], [Company B], and [Company C], among others. Strategic partnerships, mergers and acquisitions, and product innovations are expected to shape the competitive landscape in the coming years.

Technology Status And Challenges

- PVDF Material Properties

Polyvinylidene fluoride (PVDF) is a semi-crystalline polymer with excellent piezoelectric, pyroelectric, and ferroelectric properties, making it suitable for energy harvesting applications. - Current Challenges

Key challenges include low energy conversion efficiency, limited mechanical durability, and difficulties in integrating PVDF into practical devices. - Efficiency Limitations

The piezoelectric coefficient and dielectric constant of PVDF are relatively low, limiting its energy conversion efficiency compared to other piezoelectric materials. - Mechanical Durability

PVDF films can suffer from fatigue and degradation under repeated mechanical stress, affecting their long-term performance and reliability. - Integration Challenges

Incorporating PVDF into energy harvesting systems requires careful design and fabrication techniques to ensure efficient energy transfer and minimize losses.

Current Technical Solutions

01 PVDF-based Piezoelectric Energy Harvesters

PVDF (Polyvinylidene fluoride) is a piezoelectric material that converts mechanical energy into electrical energy. PVDF-based energy harvesting systems utilize this property to generate electrical energy from various sources like vibrations, strain, or pressure, and can be used in wearable devices, structural health monitoring, and energy harvesting from ambient sources.- PVDF-based Piezoelectric Energy Harvesters: PVDF (Polyvinylidene fluoride) is a piezoelectric material that converts mechanical energy into electrical energy. PVDF-based energy harvesting systems utilize this property to generate power from various sources like vibrations, strain, or pressure. These systems find applications in wearable devices, structural health monitoring, and wireless sensor networks.

- Enhancing Conversion Efficiency: To improve the energy conversion efficiency of PVDF-based systems, techniques like optimizing material properties, device structure, electrode configurations, and incorporating nanofillers or nanocomposites into the PVDF matrix can be employed to enhance piezoelectric properties and efficiency.

- Wearable and Implantable Applications: PVDF-based energy harvesters can be designed for wearable and implantable devices, converting mechanical energy from body movements or biological processes into electrical energy. This can power sensors, electronics, or medical devices, reducing the need for batteries or external power sources.

- Integration with Energy Storage: PVDF-based energy harvesters can be integrated with energy storage systems like batteries or supercapacitors for efficient storage and management of the harvested energy, enabling its use in various applications.

- Structural Health Monitoring: PVDF-based energy harvesting systems can be employed for structural health monitoring, converting mechanical energy from structural vibrations or deformations into electrical energy to power sensors and electronics for monitoring structural integrity and detecting potential damage or defects.

02 Improving Conversion Efficiency

To enhance the energy conversion efficiency of PVDF-based systems, techniques like optimizing material properties, device structure, electrode configurations, and incorporating nanostructures or composite materials with PVDF can be employed to improve piezoelectric properties and efficiency.Expand Specific Solutions03 Wearable and Implantable Applications

PVDF-based energy harvesting systems can be integrated into wearable and implantable devices to power them using energy from body movements or ambient vibrations, providing a sustainable and self-powered solution for applications like health monitoring, fitness tracking, and medical implants.Expand Specific Solutions04 Structural Health Monitoring

PVDF-based energy harvesting systems can be employed for structural health monitoring in various structures like buildings, bridges, and aircraft, generating electrical energy from vibrations or strain experienced by the structures, enabling self-powered sensor networks for monitoring and maintenance.Expand Specific Solutions05 Ambient Energy Harvesting

PVDF-based energy harvesting systems can be designed to capture energy from various ambient sources like wind, ocean waves, or human motion, providing a sustainable and renewable source of energy for powering low-power devices or charging batteries in remote or off-grid locations.Expand Specific Solutions

Main Player Analysis

Stmicroelectronics Srl

Texas Instruments Incorporated

Key Technology Interpretation

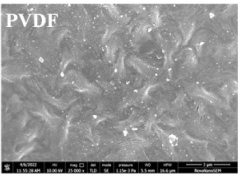

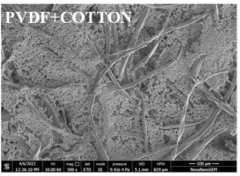

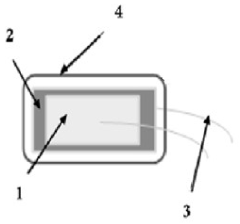

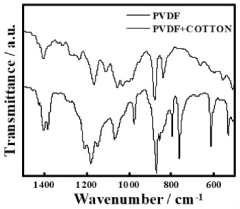

- The composite-based energy harvesting device is prepared by sandwiching PVDF with PVDF-cotton in a metallic foil and electrode, followed by encapsulation with poly(dimethyl siloxane) and curing agent.

- The use of PVDF-cotton composite as a sandwiched layer in the energy harvesting device provides better flexibility and mechanical properties.

- The encapsulation with poly(dimethyl siloxane) and curing agent provides protection and durability to the energy harvesting device.

PVDF-Based Energy Harvesting Efficiency Improvement Economic Analysis

PVDF-based energy harvesting systems have the potential to significantly impact various sectors of the economy. These systems can generate electricity from ambient vibrations and mechanical stress, offering a sustainable and cost-effective energy solution. The implementation of PVDF-based technologies in industries such as automotive, aerospace, and consumer electronics could lead to reduced energy costs and increased energy efficiency, ultimately contributing to economic growth.

In the manufacturing sector, the adoption of PVDF-based energy harvesting systems could revolutionize production processes, leading to improved productivity and reduced operational costs. Additionally, the development and commercialization of these systems could create new job opportunities in research, engineering, and manufacturing, stimulating economic growth in the renewable energy sector.

Furthermore, the integration of PVDF-based energy harvesting systems in smart cities and infrastructure projects could lead to substantial energy savings and improved resource management. This could result in reduced public spending on energy and maintenance, allowing for reallocation of funds to other critical areas of the economy. As the technology matures and becomes more widely adopted, it has the potential to contribute significantly to sustainable economic development and energy independence.

PVDF-Based Energy Harvesting Efficiency Improvement Policy And Regulatory Impact

The regulatory landscape for PVDF-based energy harvesting systems is evolving as governments recognize the potential of this technology in sustainable energy generation. Several countries have implemented policies to support research and development in piezoelectric materials, including PVDF. These policies often include funding initiatives, tax incentives, and grants for companies and research institutions working on innovative energy harvesting solutions.

In the European Union, the Horizon Europe program has allocated significant resources to support projects focused on advanced materials for energy applications, including PVDF-based systems. Similarly, the United States Department of Energy has launched initiatives to accelerate the development and commercialization of energy harvesting technologies, with PVDF systems being a key area of interest.

However, the regulatory framework for implementing PVDF-based energy harvesting systems in practical applications is still developing. Standardization bodies are working to establish guidelines for safety, performance, and reliability of these systems. As the technology matures, it is expected that more specific regulations will be implemented to ensure the safe and effective integration of PVDF-based energy harvesting systems into various applications, such as wearable devices, smart buildings, and transportation infrastructure.