PVDF-Based Flexible And Stretchable Devices

Technology Background And Goals

This report aims to provide a comprehensive overview of the development history and evolution trends in the field of PVDF-based flexible and stretchable devices. This section will delve into the key milestones and technological advancements that have shaped this domain, shedding light on the driving forces behind its progress. Additionally, it will clearly outline the anticipated technological goals and desired outcomes that serve as the guiding principles for future research and development efforts in this area.

By establishing a solid foundation through an in-depth examination of the technology's background and objectives, this section aims to set the stage for a more nuanced understanding of the market demands, current technological landscape, and potential innovative directions that will be explored in subsequent sections of the report.

Market Demand Analysis

- Market Size and Growth

Analyze the current and projected market size for PVDF-based flexible and stretchable devices, considering various application areas such as wearable electronics, soft robotics, and energy harvesting. Provide quantitative data on market value and growth rates. - Application Domains

Identify the key application domains driving the demand for PVDF-based devices, such as healthcare, consumer electronics, automotive, and aerospace. Discuss the specific needs and requirements of each domain that PVDF-based devices can address. - Consumer Trends

Examine consumer trends and preferences that influence the demand for flexible and stretchable devices, such as the desire for lightweight, conformable, and durable products. Assess the impact of these trends on the adoption of PVDF-based solutions. - Competitive Landscape

Analyze the competitive landscape, including alternative technologies or materials that may compete with PVDF-based devices. Evaluate the strengths and weaknesses of PVDF-based solutions compared to these alternatives. - Market Challenges

Identify potential challenges or barriers to the widespread adoption of PVDF-based devices, such as cost, scalability, or regulatory hurdles. Discuss strategies to overcome these challenges and facilitate market growth.

Technology Status And Challenges

- Technological Maturity

PVDF-based flexible and stretchable devices have reached a relatively mature stage, with various applications in sensors, actuators, and energy harvesting systems. - Key Challenges

Challenges include improving mechanical durability, enhancing electromechanical coupling efficiency, and developing scalable manufacturing processes. - Geographical Distribution

Research and development efforts are distributed globally, with major contributions from the United States, Europe, China, and South Korea.

Current Technical Solutions

01 Flexible and Stretchable PVDF Devices

Polyvinylidene fluoride (PVDF) can be used to fabricate flexible and stretchable devices like sensors, actuators, and energy harvesters that can withstand bending, stretching, and deformation without compromising functionality.- Stretchable and Flexible PVDF Devices: Techniques like stretchable substrates, conductive polymers, and serpentine/wrinkled structures enable the fabrication of wearable and conformable PVDF-based devices for sensors, energy harvesters, and actuators.

- PVDF-based Stretchable Energy Harvesters: PVDF-based energy harvesters with stretchable and flexible properties can convert mechanical energy from human motion or environmental vibrations into electrical energy, enabling self-powered wearable systems.

- Stretchable and Flexible PVDF Sensors: PVDF-based sensors with stretchable and flexible characteristics can detect and measure physical quantities like strain, pressure, or temperature while conforming to curved or deformable surfaces, suitable for wearable health monitoring, soft robotics, and human-machine interfaces.

- Fabrication of Stretchable PVDF Devices: Various fabrication techniques, including printing, patterning, and integration with stretchable substrates or conductive materials, enable the production of high-performance and conformable PVDF-based devices.

- Stretchable and Flexible PVDF Actuators: PVDF-based actuators with stretchable and flexible properties can generate mechanical motion or force in response to electrical stimuli, suitable for soft robotics, wearable devices, and biomedical systems.

02 PVDF-based Stretchable Wearable Electronics

PVDF-based materials can be utilized in the development of stretchable and wearable electronic devices that can conform to the human body and maintain performance under deformations, suitable for wearable sensors, energy harvesters, and flexible displays.Expand Specific Solutions03 Stretchable PVDF Energy Harvesting Devices

PVDF's piezoelectric properties allow it to generate electrical energy from mechanical deformations, enabling the development of stretchable energy harvesting devices that can convert mechanical energy from sources like human motion or vibrations.Expand Specific Solutions04 Stretchable PVDF Sensors and Actuators

PVDF can be used to develop stretchable sensors and actuators that can detect and respond to stimuli like pressure, strain, or temperature changes, suitable for integration into wearable systems, flexible structures, robotics, healthcare, and human-machine interfaces.Expand Specific Solutions05 Fabrication of Stretchable PVDF Devices

Various fabrication techniques like electrospinning, 3D printing, and patterning methods can be employed to create stretchable PVDF-based device structures with precise control over material properties and device geometries.Expand Specific Solutions

Main Player Analysis

Arkema France SA

BOE Technology Group Co., Ltd.

Key Technology Interpretation

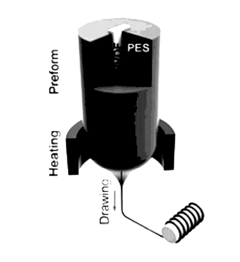

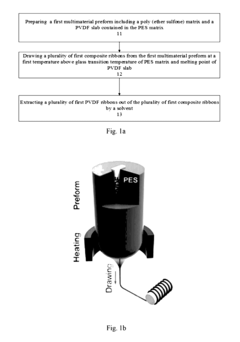

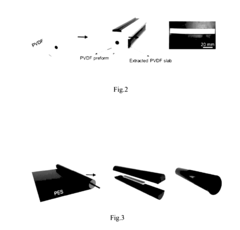

- The use of a fiber drawing method to produce pvdf ribbon, which allows for the production of ribbon with spontaneous high piezoelectricity, high aspect ratio, excellent uniformity, and desired geometry. this method also provides a low cost production method for pvdf ribbon, making it suitable for large-scale, commercially feasible applications.

PVDF-Based Devices Environmental Impact Analysis

The environmental impact of PVDF-based flexible and stretchable devices is a multifaceted issue that requires careful consideration. PVDF (Polyvinylidene fluoride) is a highly durable and non-biodegradable polymer, posing challenges for environmental sustainability. Production and disposal processes can contribute to environmental pollution if not managed properly. During manufacturing, the energy consumption and potential emissions associated with producing PVDF and fabricating devices must be considered, as they can have significant ecological footprints.

Moreover, while PVDF-based devices provide considerable benefits in terms of flexibility and resilience, their increased use necessitates a balanced approach to lifecycle management to mitigate potential negative impacts. Recycling and upcycling of PVDF and related components are crucial strategies; however, these processes are not yet fully developed or widely implemented. Advancements in this area could reduce waste and enhance sustainability.

Additionally, it is vital to investigate alternative, eco-friendly materials that offer similar properties to PVDF for future applications, potentially decreasing reliance on non-renewable and environmentally taxing resources. Understanding these impacts and exploring innovative solutions will be essential in promoting the responsible and sustainable use of PVDF-based technologies.

PVDF-Based Devices Regulatory And Policy Impact

The integration of PVDF-based flexible and stretchable devices into the regulatory and policy framework is a crucial consideration for their successful development and commercialization. Current regulations in electronics and material use dictate strict compliance with environmental and safety standards, which impact the production and disposal of these devices. The versatility of PVDF materials in applications such as sensors, wearable technology, and medical devices necessitates a comprehensive understanding of existing policies governing electronics and healthcare products. Potential policy changes in areas like sustainability and consumer safety could significantly influence the market landscape.

Additionally, harmonization across different markets is essential due to the global nature of technology deployment. Variability in regulatory standards between regions such as the EU, the US, and Asia could present challenges in standardizing PVDF device manufacturing processes and certification requirements. As governments increasingly prioritize circular economy principles, PVDF device manufacturers might need to adapt business models to address recycling and reuse, driven by policy incentives and penalties. Close monitoring of regulatory developments will be essential to maintain competitive advantage and ensure compliance, ultimately fostering innovation in PVDF-based technology sectors.