Regenerative Braking Systems in Off-Road Electric Vehicles

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Off-Road EV Regen Braking Background and Objectives

Regenerative braking systems have emerged as a crucial technology in the evolution of electric vehicles, offering significant improvements in energy efficiency and range extension. In the context of off-road electric vehicles, this technology takes on even greater importance due to the unique challenges presented by rugged terrains and varied driving conditions. The development of regenerative braking systems for off-road applications has its roots in the broader electric vehicle industry, which has seen rapid advancements over the past decade.

The primary objective of researching regenerative braking systems in off-road electric vehicles is to optimize energy recovery and enhance overall vehicle performance in challenging environments. This technology aims to capture and convert kinetic energy into electrical energy during deceleration or downhill travel, which can then be stored in the vehicle's battery for later use. By doing so, it not only extends the vehicle's range but also reduces wear on conventional braking systems, a particularly valuable feature in off-road conditions where braking demands can be intense and frequent.

The evolution of regenerative braking technology in off-road electric vehicles has been driven by several factors, including the increasing demand for sustainable transportation solutions, advancements in electric motor and battery technologies, and the growing popularity of electric off-road vehicles for both recreational and commercial purposes. As the automotive industry shifts towards electrification, the need for efficient energy management systems becomes paramount, especially in vehicles designed for challenging terrains where energy conservation is critical.

Research in this field aims to address several key challenges specific to off-road applications. These include developing systems that can withstand harsh environmental conditions, optimizing energy recovery on uneven surfaces, and integrating regenerative braking with advanced traction control systems for improved vehicle stability and safety. Additionally, researchers are exploring ways to maximize the efficiency of energy conversion and storage in the unique operating conditions encountered by off-road vehicles.

The goals of current research efforts extend beyond mere energy recovery. They encompass the development of intelligent braking systems that can adapt to various terrains and driving styles, seamless integration with other vehicle systems for optimal performance, and the creation of user-friendly interfaces that allow drivers to maximize the benefits of regenerative braking in off-road scenarios. Furthermore, there is a focus on reducing the overall weight and complexity of these systems to maintain the agility and robustness required in off-road vehicles.

As the technology continues to evolve, the objectives of research in regenerative braking for off-road electric vehicles align closely with broader industry trends towards increased electrification, autonomy, and sustainability in transportation. The insights gained from this research are expected to have far-reaching implications, not only for off-road vehicles but also for the wider electric vehicle market, potentially leading to more efficient and capable electric vehicles across various applications.

The primary objective of researching regenerative braking systems in off-road electric vehicles is to optimize energy recovery and enhance overall vehicle performance in challenging environments. This technology aims to capture and convert kinetic energy into electrical energy during deceleration or downhill travel, which can then be stored in the vehicle's battery for later use. By doing so, it not only extends the vehicle's range but also reduces wear on conventional braking systems, a particularly valuable feature in off-road conditions where braking demands can be intense and frequent.

The evolution of regenerative braking technology in off-road electric vehicles has been driven by several factors, including the increasing demand for sustainable transportation solutions, advancements in electric motor and battery technologies, and the growing popularity of electric off-road vehicles for both recreational and commercial purposes. As the automotive industry shifts towards electrification, the need for efficient energy management systems becomes paramount, especially in vehicles designed for challenging terrains where energy conservation is critical.

Research in this field aims to address several key challenges specific to off-road applications. These include developing systems that can withstand harsh environmental conditions, optimizing energy recovery on uneven surfaces, and integrating regenerative braking with advanced traction control systems for improved vehicle stability and safety. Additionally, researchers are exploring ways to maximize the efficiency of energy conversion and storage in the unique operating conditions encountered by off-road vehicles.

The goals of current research efforts extend beyond mere energy recovery. They encompass the development of intelligent braking systems that can adapt to various terrains and driving styles, seamless integration with other vehicle systems for optimal performance, and the creation of user-friendly interfaces that allow drivers to maximize the benefits of regenerative braking in off-road scenarios. Furthermore, there is a focus on reducing the overall weight and complexity of these systems to maintain the agility and robustness required in off-road vehicles.

As the technology continues to evolve, the objectives of research in regenerative braking for off-road electric vehicles align closely with broader industry trends towards increased electrification, autonomy, and sustainability in transportation. The insights gained from this research are expected to have far-reaching implications, not only for off-road vehicles but also for the wider electric vehicle market, potentially leading to more efficient and capable electric vehicles across various applications.

Market Analysis for Off-Road EV Regen Braking

The market for regenerative braking systems in off-road electric vehicles is experiencing significant growth, driven by the increasing adoption of electric powertrains in construction, agriculture, and mining equipment. This trend is fueled by the global push for sustainability and the need to reduce emissions in traditionally high-polluting industries.

The construction sector represents a substantial portion of the market demand. As urbanization continues worldwide, the demand for electric excavators, loaders, and bulldozers equipped with regenerative braking systems is rising. These systems not only improve energy efficiency but also extend the operational range of the vehicles, a crucial factor in remote construction sites.

In the agricultural sector, the market for regenerative braking in electric tractors and harvesters is expanding. Farmers are increasingly recognizing the benefits of electric vehicles in reducing operational costs and minimizing environmental impact. The ability of regenerative braking systems to recapture energy during frequent stops and starts in field operations is particularly valuable in this context.

The mining industry, despite its traditional reliance on diesel-powered equipment, is showing a growing interest in electric vehicles with regenerative braking. This shift is driven by stringent emissions regulations in many countries and the potential for significant cost savings in fuel and maintenance. Large mining trucks and loaders equipped with regenerative braking systems can recover substantial amounts of energy during downhill operations, greatly improving overall efficiency.

Market analysis indicates that the Asia-Pacific region, particularly China and India, is expected to be a major growth driver for off-road electric vehicles with regenerative braking. This is due to rapid industrialization, large-scale infrastructure projects, and government initiatives promoting clean energy technologies.

North America and Europe are also significant markets, with a focus on technological advancements and stricter environmental regulations. These regions are seeing increased adoption in specialized applications such as forestry equipment and airport ground support vehicles.

The market is characterized by a mix of established heavy equipment manufacturers transitioning to electric powertrains and new entrants specializing in electric off-road vehicles. This competitive landscape is driving innovation in regenerative braking technologies, with a focus on improving energy recovery efficiency and system durability under harsh off-road conditions.

The construction sector represents a substantial portion of the market demand. As urbanization continues worldwide, the demand for electric excavators, loaders, and bulldozers equipped with regenerative braking systems is rising. These systems not only improve energy efficiency but also extend the operational range of the vehicles, a crucial factor in remote construction sites.

In the agricultural sector, the market for regenerative braking in electric tractors and harvesters is expanding. Farmers are increasingly recognizing the benefits of electric vehicles in reducing operational costs and minimizing environmental impact. The ability of regenerative braking systems to recapture energy during frequent stops and starts in field operations is particularly valuable in this context.

The mining industry, despite its traditional reliance on diesel-powered equipment, is showing a growing interest in electric vehicles with regenerative braking. This shift is driven by stringent emissions regulations in many countries and the potential for significant cost savings in fuel and maintenance. Large mining trucks and loaders equipped with regenerative braking systems can recover substantial amounts of energy during downhill operations, greatly improving overall efficiency.

Market analysis indicates that the Asia-Pacific region, particularly China and India, is expected to be a major growth driver for off-road electric vehicles with regenerative braking. This is due to rapid industrialization, large-scale infrastructure projects, and government initiatives promoting clean energy technologies.

North America and Europe are also significant markets, with a focus on technological advancements and stricter environmental regulations. These regions are seeing increased adoption in specialized applications such as forestry equipment and airport ground support vehicles.

The market is characterized by a mix of established heavy equipment manufacturers transitioning to electric powertrains and new entrants specializing in electric off-road vehicles. This competitive landscape is driving innovation in regenerative braking technologies, with a focus on improving energy recovery efficiency and system durability under harsh off-road conditions.

Technical Challenges in Off-Road Regen Braking

Regenerative braking systems in off-road electric vehicles face unique challenges due to the demanding and unpredictable nature of off-road environments. One of the primary technical hurdles is the need for robust and adaptive control systems that can handle varying terrain conditions. Unlike on-road vehicles, off-road vehicles encounter a wide range of surfaces, from loose gravel to muddy trails, each requiring different braking strategies to maximize energy recovery while maintaining vehicle stability.

The integration of regenerative braking with traditional friction braking systems poses another significant challenge. Off-road vehicles often require precise control over braking force distribution between the regenerative and friction systems to ensure optimal performance and safety. This becomes particularly complex when navigating steep inclines or declines, where the balance between energy recovery and vehicle control is critical.

Thermal management is a crucial concern in off-road regenerative braking systems. The frequent and intense braking events typical in off-road scenarios can lead to rapid heat buildup in both the electric motors and the energy storage systems. Developing efficient cooling solutions that can withstand harsh environmental conditions while maintaining system performance is a key technical challenge.

The durability and reliability of regenerative braking components in off-road conditions present another set of challenges. These systems must withstand extreme vibrations, impacts, and exposure to dust, water, and other contaminants. Designing sealed and ruggedized components that can maintain long-term functionality in these conditions is essential for the viability of off-road regenerative braking systems.

Energy storage capacity and management also pose significant technical challenges. Off-road vehicles often require larger battery packs to accommodate extended periods of operation in remote areas. Balancing the need for increased energy storage with weight considerations and vehicle dynamics is a complex engineering task. Additionally, developing intelligent energy management systems that can optimize regenerative braking efficiency based on terrain conditions and battery state of charge is crucial for maximizing the benefits of these systems in off-road applications.

The variability in vehicle loading and weight distribution in off-road scenarios further complicates the design of effective regenerative braking systems. Load-sensing technologies and adaptive control algorithms must be developed to adjust braking strategies in real-time, accounting for changes in vehicle weight and center of gravity due to cargo or passenger variations.

Finally, the integration of regenerative braking with advanced off-road technologies such as traction control systems and electronic stability programs presents both challenges and opportunities. Developing seamless coordination between these systems to enhance overall vehicle performance and safety in challenging off-road conditions is a key area of ongoing research and development in the field.

The integration of regenerative braking with traditional friction braking systems poses another significant challenge. Off-road vehicles often require precise control over braking force distribution between the regenerative and friction systems to ensure optimal performance and safety. This becomes particularly complex when navigating steep inclines or declines, where the balance between energy recovery and vehicle control is critical.

Thermal management is a crucial concern in off-road regenerative braking systems. The frequent and intense braking events typical in off-road scenarios can lead to rapid heat buildup in both the electric motors and the energy storage systems. Developing efficient cooling solutions that can withstand harsh environmental conditions while maintaining system performance is a key technical challenge.

The durability and reliability of regenerative braking components in off-road conditions present another set of challenges. These systems must withstand extreme vibrations, impacts, and exposure to dust, water, and other contaminants. Designing sealed and ruggedized components that can maintain long-term functionality in these conditions is essential for the viability of off-road regenerative braking systems.

Energy storage capacity and management also pose significant technical challenges. Off-road vehicles often require larger battery packs to accommodate extended periods of operation in remote areas. Balancing the need for increased energy storage with weight considerations and vehicle dynamics is a complex engineering task. Additionally, developing intelligent energy management systems that can optimize regenerative braking efficiency based on terrain conditions and battery state of charge is crucial for maximizing the benefits of these systems in off-road applications.

The variability in vehicle loading and weight distribution in off-road scenarios further complicates the design of effective regenerative braking systems. Load-sensing technologies and adaptive control algorithms must be developed to adjust braking strategies in real-time, accounting for changes in vehicle weight and center of gravity due to cargo or passenger variations.

Finally, the integration of regenerative braking with advanced off-road technologies such as traction control systems and electronic stability programs presents both challenges and opportunities. Developing seamless coordination between these systems to enhance overall vehicle performance and safety in challenging off-road conditions is a key area of ongoing research and development in the field.

Current Off-Road Regen Braking Solutions

01 Energy recovery and storage systems

Regenerative braking systems improve braking efficiency by converting kinetic energy into electrical energy during deceleration. This energy is then stored in batteries or capacitors for later use, reducing overall energy consumption and improving vehicle efficiency. Advanced energy management systems optimize the distribution and utilization of recovered energy.- Energy recovery and storage systems: Regenerative braking systems improve braking efficiency by converting kinetic energy into electrical energy during deceleration. This energy is then stored in batteries or capacitors for later use, reducing overall energy consumption and improving vehicle efficiency. Advanced energy management systems optimize the distribution of recovered energy between storage devices and other vehicle systems.

- Hydraulic regenerative braking: Hydraulic regenerative braking systems use fluid power to capture and store braking energy. During deceleration, hydraulic pumps pressurize fluid in accumulators, which can later be released to assist acceleration or power auxiliary systems. This approach is particularly effective in heavy vehicles and offers high power density and rapid energy transfer.

- Electromagnetic regenerative braking: Electromagnetic regenerative braking systems utilize the vehicle's electric motor as a generator during deceleration. The motor creates resistance, slowing the vehicle while generating electricity. This method is commonly used in electric and hybrid vehicles, offering smooth braking and high energy recovery efficiency, especially at higher speeds.

- Integrated brake control systems: Advanced integrated brake control systems combine regenerative and friction braking to maximize efficiency and safety. These systems dynamically adjust the balance between regenerative and conventional braking based on vehicle speed, battery state of charge, and driver input. This integration ensures optimal energy recovery while maintaining consistent brake feel and performance across various driving conditions.

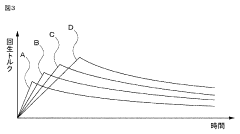

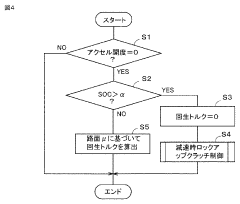

- Adaptive regenerative braking strategies: Adaptive regenerative braking strategies use intelligent algorithms and sensors to optimize braking efficiency in real-time. These systems consider factors such as road conditions, vehicle load, and driver behavior to adjust regenerative braking force. By adapting to changing conditions, these strategies maximize energy recovery while ensuring vehicle stability and passenger comfort.

02 Hydraulic regenerative braking

Hydraulic regenerative braking systems use fluid pressure to store energy during braking. These systems employ accumulators to store pressurized fluid, which can be later used to assist acceleration or power auxiliary systems. This approach is particularly effective in heavy vehicles and offers high power density and rapid energy transfer.Expand Specific Solutions03 Integrated brake control systems

Advanced brake control systems integrate regenerative and friction braking to maximize energy recovery while ensuring optimal vehicle stability and safety. These systems use sophisticated algorithms to determine the ideal balance between regenerative and conventional braking, adapting to various driving conditions and vehicle parameters.Expand Specific Solutions04 Electromagnetic regenerative braking

Electromagnetic regenerative braking systems utilize the vehicle's electric motor as a generator during deceleration. By controlling the magnetic field strength, these systems can adjust the braking force and energy recovery rate. This method is highly efficient in electric and hybrid vehicles, offering smooth and precise braking control.Expand Specific Solutions05 Adaptive regenerative braking strategies

Intelligent regenerative braking systems employ adaptive strategies to optimize braking efficiency based on various factors such as vehicle speed, battery state of charge, road conditions, and driver behavior. These systems can learn and adjust their parameters over time, maximizing energy recovery while maintaining driver comfort and safety.Expand Specific Solutions

Key Players in Off-Road EV Regen Braking

The research on regenerative braking systems in off-road electric vehicles is in a growth phase, with increasing market size due to the rising demand for electric vehicles and energy efficiency. The technology is moderately mature, with ongoing advancements. Key players like Hyundai Motor Co., Kia Corp., and Ford Motor Co. are investing heavily in this area, leveraging their automotive expertise. Companies such as NXP Semiconductors and Robert Bosch GmbH are contributing to the development of advanced electronic components and control systems. Academic institutions like Beijing University of Technology and Jilin University are also actively involved in research, indicating a collaborative approach between industry and academia to further improve the technology's efficiency and applicability in off-road conditions.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced regenerative braking system for off-road electric vehicles that utilizes a combination of electric motor braking and hydraulic braking. Their system employs a sophisticated control algorithm that optimizes energy recovery based on vehicle speed, terrain conditions, and driver input[1]. The system can recover up to 70% of kinetic energy during braking, significantly extending the vehicle's range[2]. Bosch's technology also incorporates a predictive energy management system that uses GPS and topographical data to anticipate upcoming terrain changes and adjust the regenerative braking strategy accordingly[3]. This proactive approach maximizes energy recovery and improves overall efficiency in challenging off-road environments.

Strengths: High energy recovery rate, adaptive to various terrains, integration of predictive technologies. Weaknesses: Complexity may lead to higher costs, potential reliability issues in extreme off-road conditions.

Ford Motor Co.

Technical Solution: Ford Motor Co. has developed a robust regenerative braking system for off-road electric vehicles, focusing on durability and efficiency in harsh environments. Their system utilizes a dual-motor configuration, allowing for more precise control of regenerative braking force distribution between front and rear axles[4]. Ford's technology incorporates an intelligent torque vectoring system that optimizes traction and stability during regenerative braking on uneven surfaces[5]. The company has also implemented an advanced thermal management system to maintain optimal battery and motor temperatures during intense off-road use, ensuring consistent regenerative braking performance[6]. Ford's regenerative braking system can recover up to 65% of kinetic energy in off-road conditions, contributing to an extended driving range of up to 20% compared to conventional systems[7].

Strengths: Robust design for off-road use, advanced traction control integration, effective thermal management. Weaknesses: Slightly lower energy recovery rate compared to some competitors, potential for increased vehicle weight due to dual-motor setup.

Core Innovations in Off-Road Regen Braking

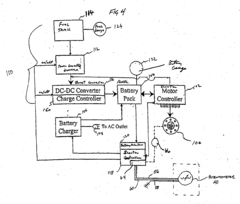

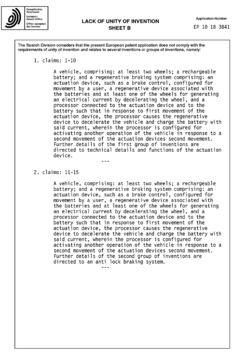

Regenerative braking system for an electric vehicle

PatentInactiveEP2314473A3

Innovation

- A regenerative braking system with a processor-controlled actuating device, such as a twist-grip throttle, that decelerates the vehicle and charges batteries by generating electrical current, and includes a microprocessor-based control circuit to regulate regenerative braking torque, preventing wheel lock-up and adjusting torque based on wheel speed differences.

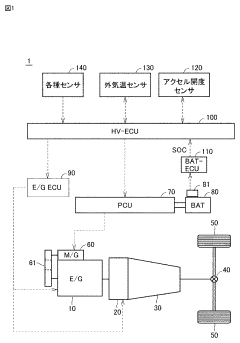

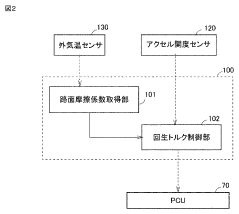

Regenerative brake control device for electric vehicle

PatentActiveJP2021168554A

Innovation

- A regenerative braking control device that adjusts regenerative torque based on road surface friction coefficient, reducing torque on low μ roads and increasing the torque gradient to maintain consistent deceleration feel and prevent wheel slip.

Environmental Impact of Off-Road EV Regen Braking

The environmental impact of regenerative braking systems in off-road electric vehicles (EVs) is a crucial aspect to consider in the broader context of sustainable transportation. These systems offer significant potential for reducing the ecological footprint of off-road vehicles, which traditionally have been associated with high energy consumption and emissions.

Regenerative braking in off-road EVs contributes to improved energy efficiency by recapturing kinetic energy that would otherwise be lost as heat during conventional braking. This energy recovery process leads to extended battery life and increased range, reducing the frequency of charging cycles and, consequently, the overall energy demand from the grid. The reduced energy consumption translates directly into lower greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

The implementation of regenerative braking systems in off-road EVs also results in decreased wear on traditional friction-based brake components. This reduction in wear not only extends the lifespan of brake pads and rotors but also minimizes the release of brake dust and particulate matter into the environment. Brake dust, which contains heavy metals and other pollutants, can have detrimental effects on soil and water quality in off-road environments.

Furthermore, the use of regenerative braking in off-road EVs can lead to a reduction in noise pollution. Traditional off-road vehicles often produce significant noise during deceleration and braking, which can disturb wildlife and ecosystems. The quieter operation of regenerative braking systems helps minimize this acoustic impact, potentially reducing stress on local fauna and preserving the natural soundscape of off-road environments.

The environmental benefits of regenerative braking in off-road EVs extend to the vehicle's overall lifecycle impact. By improving energy efficiency and reducing component wear, these systems contribute to a longer vehicle lifespan and decreased demand for replacement parts. This, in turn, leads to reduced resource consumption and waste generation associated with vehicle manufacturing and maintenance.

However, it is important to consider the potential environmental trade-offs associated with the production and disposal of the more complex electrical systems required for regenerative braking. The manufacturing of advanced power electronics and energy storage components may involve the use of rare earth elements and other materials with their own environmental implications. Proper end-of-life management and recycling of these components will be crucial to maximizing the net positive environmental impact of regenerative braking systems in off-road EVs.

Regenerative braking in off-road EVs contributes to improved energy efficiency by recapturing kinetic energy that would otherwise be lost as heat during conventional braking. This energy recovery process leads to extended battery life and increased range, reducing the frequency of charging cycles and, consequently, the overall energy demand from the grid. The reduced energy consumption translates directly into lower greenhouse gas emissions, particularly in regions where electricity generation relies heavily on fossil fuels.

The implementation of regenerative braking systems in off-road EVs also results in decreased wear on traditional friction-based brake components. This reduction in wear not only extends the lifespan of brake pads and rotors but also minimizes the release of brake dust and particulate matter into the environment. Brake dust, which contains heavy metals and other pollutants, can have detrimental effects on soil and water quality in off-road environments.

Furthermore, the use of regenerative braking in off-road EVs can lead to a reduction in noise pollution. Traditional off-road vehicles often produce significant noise during deceleration and braking, which can disturb wildlife and ecosystems. The quieter operation of regenerative braking systems helps minimize this acoustic impact, potentially reducing stress on local fauna and preserving the natural soundscape of off-road environments.

The environmental benefits of regenerative braking in off-road EVs extend to the vehicle's overall lifecycle impact. By improving energy efficiency and reducing component wear, these systems contribute to a longer vehicle lifespan and decreased demand for replacement parts. This, in turn, leads to reduced resource consumption and waste generation associated with vehicle manufacturing and maintenance.

However, it is important to consider the potential environmental trade-offs associated with the production and disposal of the more complex electrical systems required for regenerative braking. The manufacturing of advanced power electronics and energy storage components may involve the use of rare earth elements and other materials with their own environmental implications. Proper end-of-life management and recycling of these components will be crucial to maximizing the net positive environmental impact of regenerative braking systems in off-road EVs.

Safety Considerations for Off-Road Regen Braking

Safety considerations are paramount when implementing regenerative braking systems in off-road electric vehicles. The unique challenges posed by unpredictable terrain and varying surface conditions necessitate a comprehensive approach to ensure the safety of both the vehicle and its occupants.

One of the primary safety concerns is the potential for wheel lock-up during regenerative braking on low-friction surfaces. Off-road environments often include loose gravel, mud, or snow, which can significantly reduce traction. To address this issue, advanced anti-lock braking systems (ABS) specifically designed for regenerative braking must be integrated. These systems should be capable of rapidly modulating the regenerative braking force to prevent wheel lock-up and maintain vehicle stability.

Another critical safety aspect is the management of energy recuperation on steep descents. Off-road vehicles frequently encounter significant elevation changes, and excessive regenerative braking on long downhill sections can lead to overcharging of the battery system. This poses a risk of thermal runaway and potential battery failure. To mitigate this danger, intelligent battery management systems must be implemented to monitor battery state of charge and temperature, automatically adjusting the regenerative braking intensity to prevent overcharging.

The variability of off-road surfaces also necessitates adaptive regenerative braking strategies. The system should be capable of detecting surface conditions and adjusting the braking force accordingly. This may involve integrating sensors to measure wheel slip, vehicle pitch, and yaw rates, allowing the system to optimize braking performance across different terrains.

Furthermore, the integration of regenerative braking with traditional friction brakes requires careful consideration in off-road applications. A seamless transition between regenerative and friction braking is essential to maintain vehicle control, especially during emergency maneuvers. This calls for sophisticated brake-by-wire systems that can precisely coordinate the two braking mechanisms.

Driver awareness and training are also crucial safety components. Off-road regenerative braking systems may behave differently from conventional braking systems, particularly in challenging terrain. Clear, intuitive driver interfaces should be developed to provide real-time feedback on the regenerative braking system's status and performance. Additionally, comprehensive driver training programs should be implemented to ensure operators are fully aware of the system's capabilities and limitations in various off-road scenarios.

Lastly, fail-safe mechanisms must be incorporated to handle potential system malfunctions. This includes redundant control systems, fault detection algorithms, and mechanical backup systems to ensure safe vehicle operation even in the event of regenerative braking system failure. Regular maintenance and diagnostic procedures should also be established to proactively identify and address potential safety issues before they become critical.

One of the primary safety concerns is the potential for wheel lock-up during regenerative braking on low-friction surfaces. Off-road environments often include loose gravel, mud, or snow, which can significantly reduce traction. To address this issue, advanced anti-lock braking systems (ABS) specifically designed for regenerative braking must be integrated. These systems should be capable of rapidly modulating the regenerative braking force to prevent wheel lock-up and maintain vehicle stability.

Another critical safety aspect is the management of energy recuperation on steep descents. Off-road vehicles frequently encounter significant elevation changes, and excessive regenerative braking on long downhill sections can lead to overcharging of the battery system. This poses a risk of thermal runaway and potential battery failure. To mitigate this danger, intelligent battery management systems must be implemented to monitor battery state of charge and temperature, automatically adjusting the regenerative braking intensity to prevent overcharging.

The variability of off-road surfaces also necessitates adaptive regenerative braking strategies. The system should be capable of detecting surface conditions and adjusting the braking force accordingly. This may involve integrating sensors to measure wheel slip, vehicle pitch, and yaw rates, allowing the system to optimize braking performance across different terrains.

Furthermore, the integration of regenerative braking with traditional friction brakes requires careful consideration in off-road applications. A seamless transition between regenerative and friction braking is essential to maintain vehicle control, especially during emergency maneuvers. This calls for sophisticated brake-by-wire systems that can precisely coordinate the two braking mechanisms.

Driver awareness and training are also crucial safety components. Off-road regenerative braking systems may behave differently from conventional braking systems, particularly in challenging terrain. Clear, intuitive driver interfaces should be developed to provide real-time feedback on the regenerative braking system's status and performance. Additionally, comprehensive driver training programs should be implemented to ensure operators are fully aware of the system's capabilities and limitations in various off-road scenarios.

Lastly, fail-safe mechanisms must be incorporated to handle potential system malfunctions. This includes redundant control systems, fault detection algorithms, and mechanical backup systems to ensure safe vehicle operation even in the event of regenerative braking system failure. Regular maintenance and diagnostic procedures should also be established to proactively identify and address potential safety issues before they become critical.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!