Application Of Turbine Engines With Advanced Ceramic Matrix Composites

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Matrix Composites Turbine Engine Technology Background and Goals

The primary objective of this research is to explore the potential applications of turbine engines incorporating advanced ceramic matrix composites (CMCs). CMCs are a class of materials that combine ceramic reinforcements with a ceramic matrix, offering superior properties such as high-temperature resistance, low density, and excellent mechanical strength compared to traditional metallic materials.

This section will delve into the current state of CMC technology and the challenges faced in its implementation in turbine engines. It will also provide an overview of the geographical distribution of research and development efforts in this field, highlighting the key players and their contributions. By understanding the present landscape, we can identify the critical technological hurdles that need to be overcome to unlock the full potential of CMC-based turbine engines.

This section will delve into the current state of CMC technology and the challenges faced in its implementation in turbine engines. It will also provide an overview of the geographical distribution of research and development efforts in this field, highlighting the key players and their contributions. By understanding the present landscape, we can identify the critical technological hurdles that need to be overcome to unlock the full potential of CMC-based turbine engines.

Ceramic Matrix Composites Turbine Engine Market Demand Analysis

- Increasing Demand for Lightweight Materials

The aerospace and automotive industries are driving the demand for lightweight, high-performance materials to improve fuel efficiency and reduce emissions. Ceramic matrix composites (CMCs) offer superior strength-to-weight ratios compared to traditional materials. - Emerging Applications in Harsh Environments

CMCs exhibit excellent thermal and chemical resistance, making them suitable for applications in harsh environments, such as turbine engines, industrial furnaces, and chemical processing equipment. - Potential for Cost Reduction

As manufacturing processes for CMCs mature, the cost of production is expected to decrease, further expanding their market potential in various industries. - Regulatory Drivers

Stringent environmental regulations and emission standards are driving the adoption of more efficient and environmentally friendly technologies, creating opportunities for CMCs in sectors like power generation and transportation.

Ceramic Matrix Composites Turbine Engine Technology Status and Challenges

- Ceramic Matrix Composites (CMCs)

CMCs are advanced materials with a ceramic matrix reinforced by ceramic fibers, offering superior properties like high-temperature resistance, low density, and high strength-to-weight ratio. - Evolution of CMCs

The development of CMCs has progressed through various generations, from initial oxide-based systems to more advanced non-oxide CMCs with improved thermal and mechanical properties. - Current Applications

CMCs are increasingly used in high-temperature applications, such as turbine engine components (combustors, nozzles, and shrouds), aerospace thermal protection systems, and industrial furnace linings. - Challenges and Limitations

Key challenges include high manufacturing costs, complex processing techniques, limited damage tolerance, and environmental degradation at extreme temperatures.

Ceramic Matrix Composites Turbine Engine Current Technical Solutions

01 Ceramic Matrix Composites for Turbine Engine Components

Ceramic matrix composites (CMCs) are advanced materials used in turbine engine components like blades, vanes, and combustor liners, offering superior high-temperature strength, oxidation resistance, and thermal insulation properties compared to metallic materials.- Ceramic Matrix Composites for Turbine Components: Ceramic matrix composites (CMCs) are advanced materials used in turbine components like blades, vanes, and combustors, offering superior high-temperature strength, oxidation resistance, and low density compared to metallic materials, enabling improved turbine engine performance and efficiency.

- Turbine Blade Manufacturing with CMCs: Various methods and techniques are disclosed for manufacturing turbine blades using CMCs, including processes for forming CMC preforms, infiltrating preforms with ceramic matrices, and applying coatings or protective layers.

- CMC Turbine Vanes and Combustor Components: CMCs are also utilized in turbine vanes and combustor components, improving thermal efficiency, reducing cooling requirements, and extending component life.

- Coatings and Protective Layers for CMC Components: Various coatings and protective layers, such as environmental barrier coatings (EBCs), thermal barrier coatings (TBCs), and oxidation-resistant coatings, are applied to CMC turbine components to enhance performance and durability.

- Repair and Maintenance of CMC Turbine Components: Methods and techniques are disclosed for repairing and maintaining CMC turbine components after exposure to high-temperature and oxidizing environments, including processes for removing damaged coatings, refurbishing the CMC substrate, and reapplying protective coatings.

02 Manufacturing Processes for CMC Turbine Components

Various manufacturing processes, including chemical vapor infiltration, polymer impregnation and pyrolysis, and additive manufacturing techniques, are employed to produce CMC turbine components with desired properties like high strength, low porosity, and tailored microstructures.Expand Specific Solutions03 Coatings and Surface Treatments for CMC Turbine Components

To enhance performance and durability, various coatings and surface treatments are applied to CMC turbine components, including environmental barrier coatings (EBCs) for oxidation and corrosion protection, thermal barrier coatings (TBCs) for thermal insulation, and surface modifications for improved erosion resistance.Expand Specific Solutions04 Design and Optimization of CMC Turbine Components

The design and optimization of CMC turbine components involve material selection, component geometry, and structural analysis, with computational modeling and simulation techniques employed to predict performance and durability under various operating conditions.Expand Specific Solutions05 Repair and Maintenance of CMC Turbine Components

Techniques for repairing and maintaining CMC turbine components, such as patching, infiltration, and surface treatments, are being developed to extend their service life due to degradation from high operating temperatures and harsh environments.Expand Specific Solutions

Ceramic Matrix Composites Turbine Engine Key Players Analysis

The research on turbine engines with advanced ceramic matrix composites is rapidly evolving, driven by higher operating temperatures and efficiency needs in aerospace and power industries. Major players like Rolls-Royce, Safran, General Electric, and Siemens invest heavily in developing and commercializing these materials. While early-stage, companies like XiAn Xinyao Ceramic Composite Materials Co. Ltd., Nanjing University of Aeronautics & Astronautics, and Northwestern Polytechnical University collaborate with industry leaders to accelerate ceramic matrix composites adoption in turbine engines.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced ceramic matrix composite (CMC) materials for turbine engines, offering higher temperature capabilities, improved durability, and reduced weight compared to traditional metallic components.

Strengths: Extensive CMC experience, strong R&D capabilities, proven CMC integration. Weaknesses: High manufacturing costs, limited production capacity.

Safran Aircraft Engines SAS

Technical Solution: Safran has been actively researching and developing CMCs for turbine engine applications, utilizing silicon carbide fibers in a silicon carbide matrix, offering improved thermal and mechanical properties.

Strengths: Expertise in aerospace materials, engine design, strong R&D, successful CMC integration. Weaknesses: Limited production capacity, potential supply chain challenges.

Ceramic Matrix Composites Turbine Engine Core Technology Interpretation

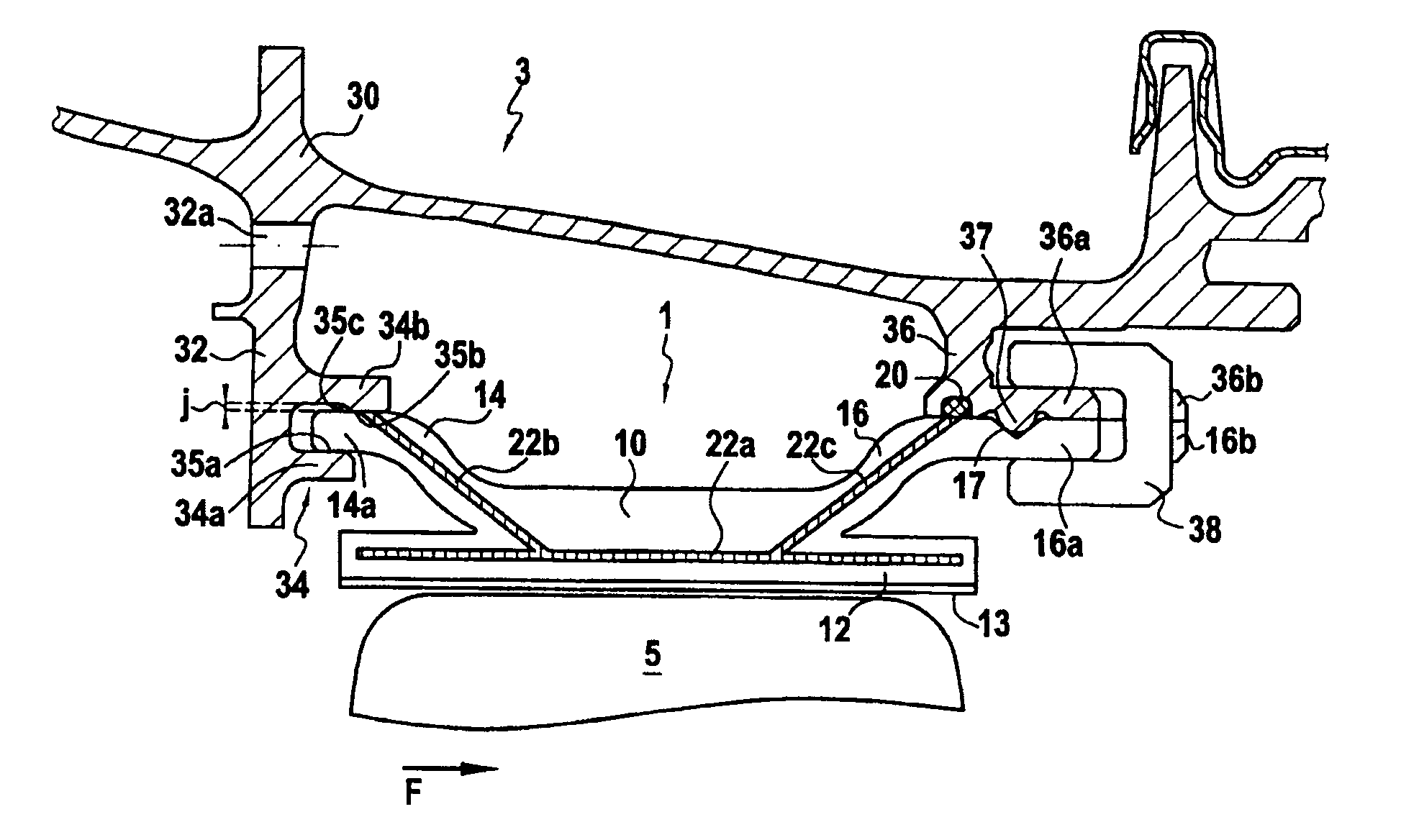

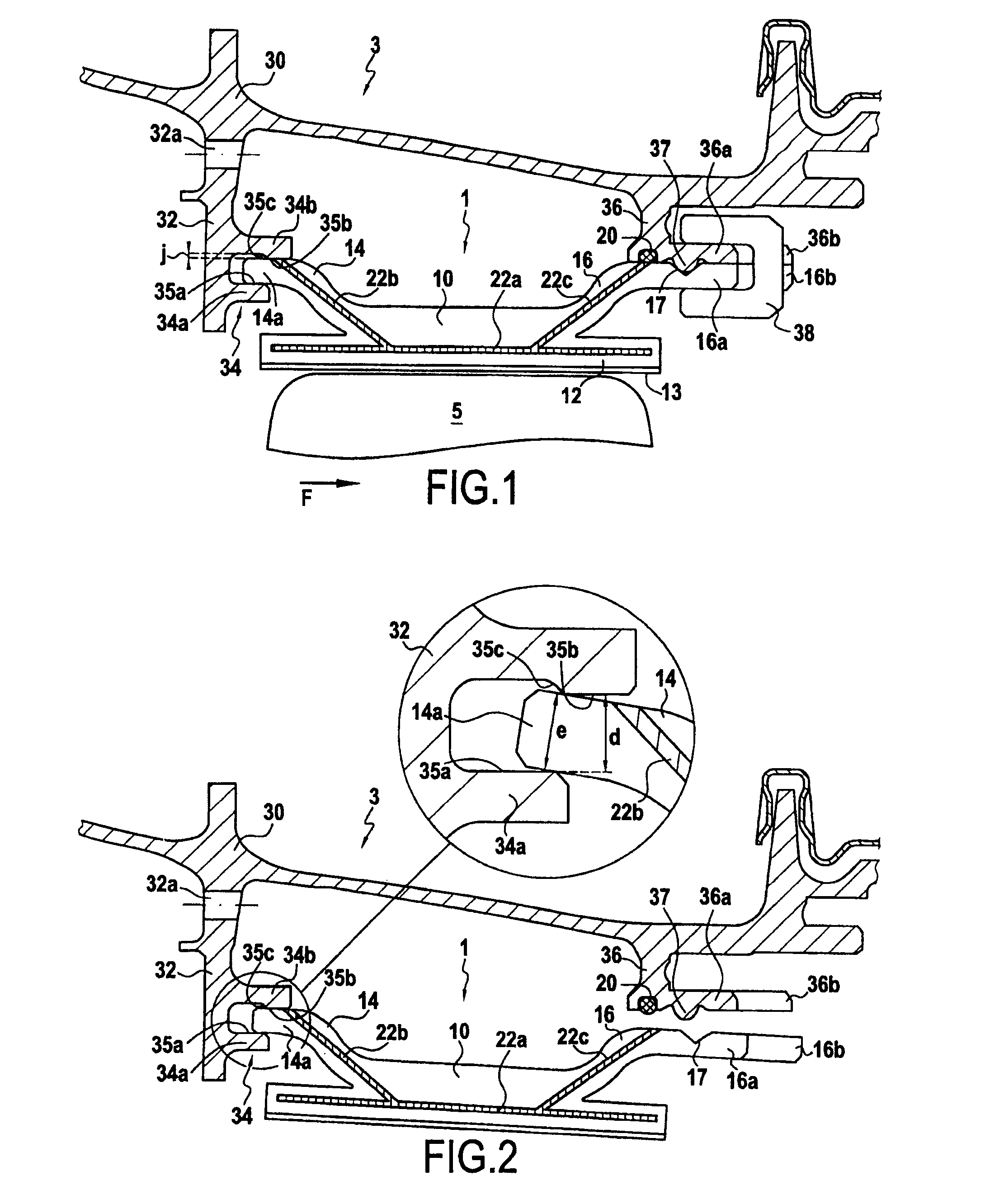

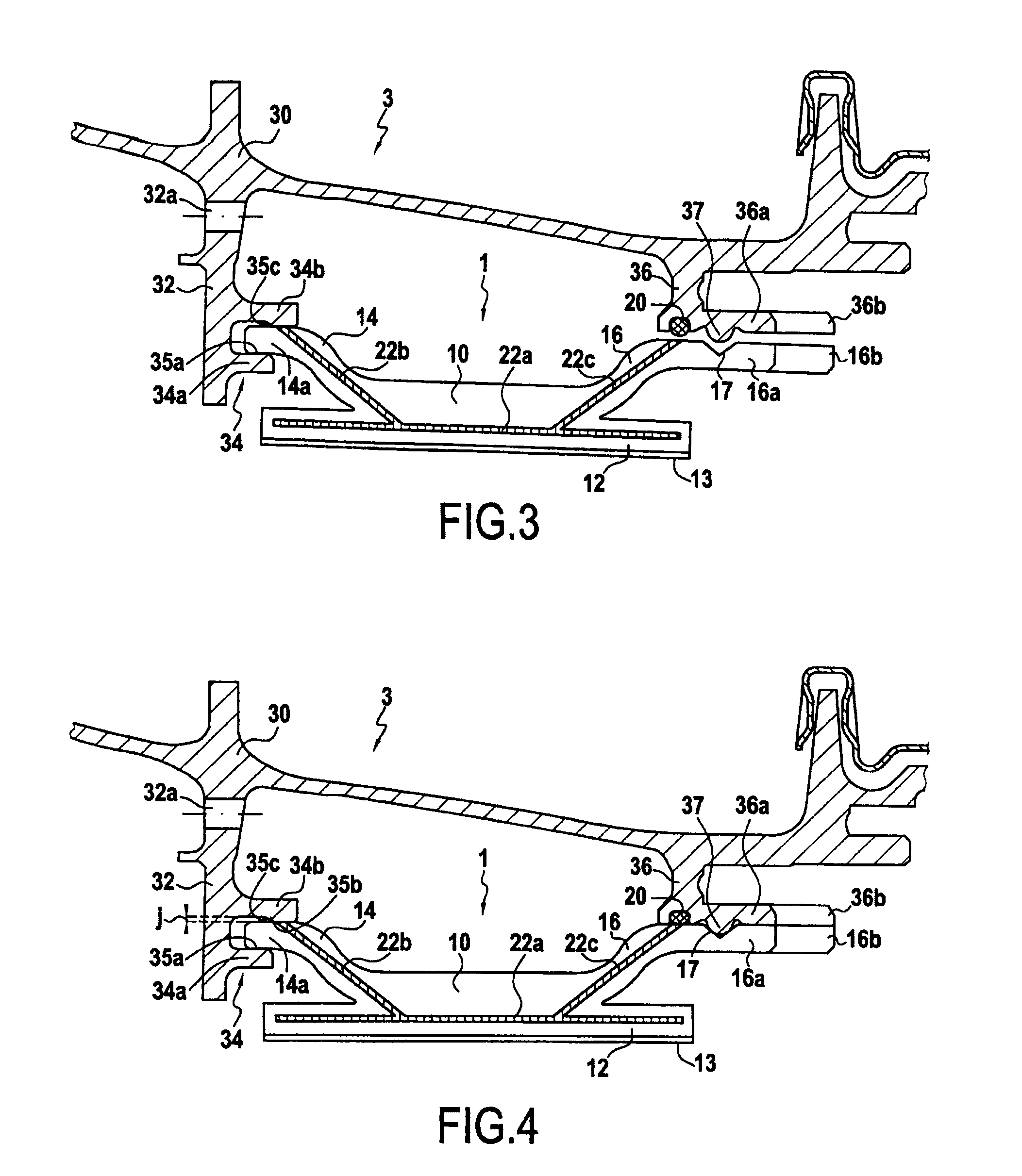

Turbine ring assembly

PatentActiveUS20120027572A1

Innovation

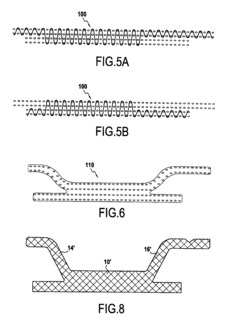

- The turbine ring assembly comprises a ring support structure and a plurality of ring sectors made of a single piece of ceramic matrix composite material.

- The use of ceramic matrix composite materials for the ring sectors allows them to maintain their mechanical properties at high temperatures.

- The ceramic matrix composite ring sectors are suitable for use in gas turbine aeroengines, where high operating temperatures are required for improved efficiency and reduced emissions.

Ceramic Matrix Composites Turbine Engine Manufacturing Process Analysis

Ceramic matrix composites (CMCs) have emerged as a promising material for turbine engine applications due to their superior properties, including high-temperature resistance, low density, and excellent mechanical strength. The manufacturing process of CMC turbine engine components involves several critical steps:

Fiber Preform Fabrication: This initial stage involves creating a preform structure using ceramic fibers, often arranged in a specific pattern or weave. Common techniques include filament winding, braiding, or weaving. The preform provides the desired shape and reinforcement architecture for the final component.

Matrix Infiltration: The ceramic matrix material, typically silicon carbide or oxides, is infiltrated into the fiber preform through various methods like chemical vapor infiltration (CVI), polymer impregnation and pyrolysis (PIP), or reactive melt infiltration (RMI). This step ensures the fibers are fully encapsulated and bonded with the matrix, creating a dense and robust composite structure.

Post-Processing: After infiltration, the CMC component may undergo additional treatments, such as machining, surface coatings, or heat treatments, to achieve the desired dimensional accuracy, surface finish, and final material properties. These steps are crucial for optimizing the component's performance and durability in the harsh turbine engine environment.

Fiber Preform Fabrication: This initial stage involves creating a preform structure using ceramic fibers, often arranged in a specific pattern or weave. Common techniques include filament winding, braiding, or weaving. The preform provides the desired shape and reinforcement architecture for the final component.

Matrix Infiltration: The ceramic matrix material, typically silicon carbide or oxides, is infiltrated into the fiber preform through various methods like chemical vapor infiltration (CVI), polymer impregnation and pyrolysis (PIP), or reactive melt infiltration (RMI). This step ensures the fibers are fully encapsulated and bonded with the matrix, creating a dense and robust composite structure.

Post-Processing: After infiltration, the CMC component may undergo additional treatments, such as machining, surface coatings, or heat treatments, to achieve the desired dimensional accuracy, surface finish, and final material properties. These steps are crucial for optimizing the component's performance and durability in the harsh turbine engine environment.

Ceramic Matrix Composites Turbine Engine Regulatory and Environmental Considerations

Ceramic matrix composites (CMCs) have emerged as a promising material for turbine engine applications due to their superior properties, including high-temperature resistance, low density, and excellent mechanical strength. However, the widespread adoption of CMCs in turbine engines faces regulatory and environmental challenges that must be addressed.

From a regulatory standpoint, the introduction of new materials like CMCs into turbine engines requires extensive testing and certification processes to ensure compliance with safety and performance standards set by aviation authorities. These regulations aim to mitigate potential risks associated with material failures or unforeseen behavior under extreme operating conditions.

Additionally, the environmental impact of CMCs throughout their lifecycle, including manufacturing, operation, and disposal, must be carefully evaluated. While CMCs offer potential benefits in terms of improved fuel efficiency and reduced emissions during operation, their production processes and end-of-life management may raise concerns regarding energy consumption, greenhouse gas emissions, and waste management. Addressing these environmental considerations is crucial for the sustainable adoption of CMCs in turbine engine applications.

From a regulatory standpoint, the introduction of new materials like CMCs into turbine engines requires extensive testing and certification processes to ensure compliance with safety and performance standards set by aviation authorities. These regulations aim to mitigate potential risks associated with material failures or unforeseen behavior under extreme operating conditions.

Additionally, the environmental impact of CMCs throughout their lifecycle, including manufacturing, operation, and disposal, must be carefully evaluated. While CMCs offer potential benefits in terms of improved fuel efficiency and reduced emissions during operation, their production processes and end-of-life management may raise concerns regarding energy consumption, greenhouse gas emissions, and waste management. Addressing these environmental considerations is crucial for the sustainable adoption of CMCs in turbine engine applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!