Turbine Engines With Advanced Cooling Systems For Improved Performance And Efficiency

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Advanced Cooling Systems Turbine Engine Background

The primary objective of this research is to develop advanced cooling systems for turbine engines, enabling improved performance and efficiency. Turbine engines operate at extremely high temperatures, necessitating effective cooling mechanisms to prevent component degradation and ensure optimal operation. This section explores the current state of cooling technologies, identifies key challenges, and outlines potential avenues for innovation.

Existing cooling systems often rely on air-cooling techniques, which can be limited in their effectiveness and efficiency. Advanced cooling systems aim to leverage novel materials, designs, and heat transfer mechanisms to enhance cooling capabilities while minimizing energy consumption and weight penalties. Potential solutions may involve the integration of advanced heat exchangers, phase-change materials, or innovative thermal management strategies tailored to the specific operating conditions of turbine engines.

Existing cooling systems often rely on air-cooling techniques, which can be limited in their effectiveness and efficiency. Advanced cooling systems aim to leverage novel materials, designs, and heat transfer mechanisms to enhance cooling capabilities while minimizing energy consumption and weight penalties. Potential solutions may involve the integration of advanced heat exchangers, phase-change materials, or innovative thermal management strategies tailored to the specific operating conditions of turbine engines.

Advanced Cooling Systems Market Demand Analysis

- Market Size and Growth

The market for advanced cooling systems in turbine engines is expected to witness substantial growth driven by the increasing demand for higher efficiency and reduced emissions in the aviation and power generation industries. - Key Applications

Advanced cooling systems find applications in aircraft engines, industrial gas turbines, and power generation turbines, enabling higher operating temperatures for improved performance and fuel efficiency. - Emerging Trends

Trends shaping the market include the development of advanced materials for cooling components, integration of additive manufacturing techniques, and the adoption of advanced cooling techniques like impingement cooling and transpiration cooling. - Regional Dynamics

North America and Europe are leading markets due to stringent emission regulations and the presence of major aerospace and power generation companies. Asia-Pacific is an emerging market driven by the growing demand for energy and the expansion of the aviation industry.

Current Cooling Technologies Status and Challenges

- Air Cooling Systems

Widely used in gas turbines, relying on compressed air to cool hot components. Effective but limited cooling capacity. - Liquid Cooling Systems

Employ liquid coolants like water or oil to extract heat from turbine components. Higher cooling capacity but more complex. - Thermal Barrier Coatings

Ceramic coatings applied to turbine blades and vanes to insulate and protect from high temperatures. Limited lifespan and potential spallation issues. - Film Cooling

Injects coolant air through small holes in turbine blades to create an insulating film. Effective but can disrupt aerodynamics. - Impingement Cooling

Directs jets of coolant onto the internal surfaces of turbine components. Efficient but complex geometry required.

State-of-the-Art Cooling Solutions for Turbine Engines

01 Cooling system design for turbine engines

Innovative cooling system designs for turbine engines, involving air or liquid coolants, and optimized flow paths and configurations to enhance heat transfer and cooling effectiveness.- Cooling system design for turbine engines: Innovative cooling system designs for turbine engines, involving air or liquid coolants and optimized cooling channels or passages within turbine components, to enhance performance and efficiency.

- Thermal management and heat transfer: Techniques for managing and transferring heat in turbine engines, particularly in hot sections like combustors and turbine blades, using thermal barrier coatings, impingement cooling, or other methods to improve heat dissipation and protect critical components.

- Cooling air supply and distribution: Methods and systems for supplying and distributing cooling air within turbine engines, including compressor bleed air or other sources, directed to specific components or areas for efficient cooling and performance.

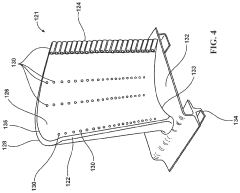

- Turbine blade cooling techniques: Specialized cooling techniques for turbine blades subjected to high temperatures, involving internal cooling channels, film cooling, or other methods to maintain blade integrity and prevent failure.

- Cooling system monitoring and control: Systems and methods for monitoring and controlling cooling systems in turbine engines, using sensors, feedback loops, and control algorithms to optimize cooling performance and efficiency.

02 Thermal management and heat dissipation

Techniques for managing and dissipating heat generated in turbine engines, particularly in hot sections, using specialized coatings, insulation materials, or heat exchangers to control and remove excess heat.Expand Specific Solutions03 Cooling air flow and distribution

Methods and systems for optimizing the flow and distribution of cooling air within turbine engines, particularly for cooling critical components like turbine blades and vanes, using specialized air flow paths, impingement cooling, or film cooling techniques.Expand Specific Solutions04 Turbine blade and vane cooling

Specialized cooling techniques for turbine blades and vanes exposed to extremely high temperatures, involving internal cooling channels, film cooling holes, or the use of specialized materials and coatings to improve heat dissipation.Expand Specific Solutions05 Cooling system integration and control

Approaches for integrating and controlling the cooling systems of turbine engines, including the use of sensors, control algorithms, and feedback mechanisms to optimize cooling performance and efficiency under various operating conditions.Expand Specific Solutions

Key Players in Advanced Turbine Cooling

The turbine engine market is mature, driven by aerospace and power generation industries. While cooling technology is well-established, key players like United Technologies Corp., Rolls-Royce Plc, General Electric Company, Honeywell International Technologies Ltd., and RTX Corp. continuously innovate to enhance performance and efficiency.

United Technologies Corp.

Technical Solution: United Technologies Corp., through Pratt & Whitney, develops advanced cooling systems using ceramic matrix composites, thermal barrier coatings, and innovative designs for improved thermal management and efficiency.

Strengths: Extensive experience, advanced materials and manufacturing capabilities. Weaknesses: Integration challenges with existing platforms.

Rolls-Royce Plc

Technical Solution: Rolls-Royce optimizes cooling air flow paths and distribution, incorporating impingement and film cooling techniques for efficient cooling of critical components, enabling higher turbine inlet temperatures and performance.

Strengths: Expertise in aerodynamics and thermal management, strong research capabilities. Weaknesses: Challenges in integrating new cooling technologies.

Patented Cooling Technologies for Turbine Performance

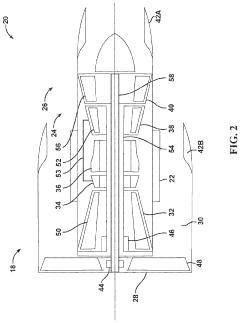

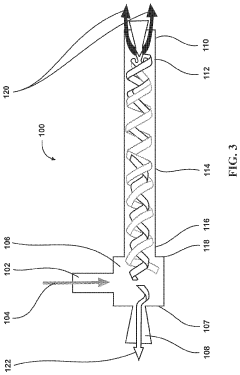

Turbine cooling system with energy separation

PatentActiveUS12012895B1

Innovation

- The cooling system utilizes energy separation to increase efficiency, which is a unique approach compared to conventional cooling systems.

- The cooling system is specifically designed for gas turbine engines, addressing the need for improved cooling as operating temperatures increase due to higher power requirements.

- The cooling system aims to improve overall engine performance by reducing energy consumption and enhancing cooling performance.

Regulatory Landscape for Turbine Emission Standards

The regulatory landscape for turbine emission standards is a complex and evolving area, driven by the need to balance environmental concerns with operational and economic considerations. Governments and regulatory bodies around the world have implemented various emission standards and guidelines to mitigate the environmental impact of turbine engines, particularly in the aviation and power generation sectors.

These standards typically focus on limiting the emissions of harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter (PM). Stringent emission limits have been established for different engine categories, based on factors like engine size, application, and technology level.

Major regulatory frameworks include the International Civil Aviation Organization's (ICAO) standards for aircraft engines, the Environmental Protection Agency's (EPA) regulations for stationary turbines in the United States, and the European Union's Industrial Emissions Directive (IED) for power plants. These regulations are periodically reviewed and updated to reflect technological advancements and evolving environmental priorities. Compliance with emission standards often requires the implementation of advanced combustion technologies, fuel optimization strategies, and emission control systems. Manufacturers must demonstrate their engines' conformity through rigorous testing and certification processes, ensuring transparency and accountability in the industry.

Major regulatory frameworks include the International Civil Aviation Organization's (ICAO) standards for aircraft engines, the Environmental Protection Agency's (EPA) regulations for stationary turbines in the United States, and the European Union's Industrial Emissions Directive (IED) for power plants. These regulations are periodically reviewed and updated to reflect technological advancements and evolving environmental priorities. Compliance with emission standards often requires the implementation of advanced combustion technologies, fuel optimization strategies, and emission control systems. Manufacturers must demonstrate their engines' conformity through rigorous testing and certification processes, ensuring transparency and accountability in the industry.

Economic Viability of Advanced Turbine Cooling Systems

The economic viability of advanced turbine cooling systems is a critical factor in their widespread adoption and commercialization. These systems aim to enhance the performance and efficiency of turbine engines by enabling higher operating temperatures, which can lead to increased power output and reduced fuel consumption. However, the implementation of advanced cooling technologies often comes with significant upfront costs and operational expenses.

A comprehensive cost-benefit analysis is essential to evaluate the economic feasibility of these systems. This analysis should consider the initial investment required for research, development, and implementation, as well as the ongoing costs associated with maintenance, repairs, and potential system upgrades. Additionally, the potential fuel savings and performance gains must be quantified and weighed against these expenses to determine the overall economic impact.

Furthermore, market demand and competitive landscape play a crucial role in assessing the economic viability. The potential for increased revenue streams through improved engine performance and reduced operating costs should be evaluated within the context of the target market segments and the competitive positioning of the advanced cooling systems. Factors such as industry regulations, environmental concerns, and consumer preferences may also influence the economic viability and adoption rates of these technologies.

A comprehensive cost-benefit analysis is essential to evaluate the economic feasibility of these systems. This analysis should consider the initial investment required for research, development, and implementation, as well as the ongoing costs associated with maintenance, repairs, and potential system upgrades. Additionally, the potential fuel savings and performance gains must be quantified and weighed against these expenses to determine the overall economic impact.

Furthermore, market demand and competitive landscape play a crucial role in assessing the economic viability. The potential for increased revenue streams through improved engine performance and reduced operating costs should be evaluated within the context of the target market segments and the competitive positioning of the advanced cooling systems. Factors such as industry regulations, environmental concerns, and consumer preferences may also influence the economic viability and adoption rates of these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!