Application Of Turbine Engines With Ceramic Matrix Composites

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Matrix Composite Turbine Engine Background and Objectives

The primary objective of this research is to explore the potential applications of turbine engines incorporating ceramic matrix composites (CMCs). CMCs are advanced materials that offer superior thermal and mechanical properties compared to traditional metallic alloys, making them attractive for high-temperature applications in turbine engines.

This section will provide an overview of the technological background and goals related to CMC turbine engines. It will discuss the historical development of turbine engine materials, highlighting the limitations of conventional materials and the need for more robust alternatives like CMCs. Additionally, it will outline the specific performance targets and design objectives that CMC turbine engines aim to achieve, such as higher operating temperatures, improved fuel efficiency, and extended component lifetimes.

This section will provide an overview of the technological background and goals related to CMC turbine engines. It will discuss the historical development of turbine engine materials, highlighting the limitations of conventional materials and the need for more robust alternatives like CMCs. Additionally, it will outline the specific performance targets and design objectives that CMC turbine engines aim to achieve, such as higher operating temperatures, improved fuel efficiency, and extended component lifetimes.

Ceramic Matrix Composite Turbine Engine Market Demand Analysis

- Market Potential

The market for ceramic matrix composite (CMC) turbine engines is expected to witness significant growth due to their superior properties, such as high-temperature resistance, lightweight, and corrosion resistance. These advantages make CMCs attractive for aerospace, power generation, and automotive applications. - Aerospace Industry

The aerospace industry is a major driver for CMC turbine engines, as they offer improved fuel efficiency, reduced emissions, and extended service life compared to traditional metallic components. The demand for more efficient and environmentally friendly aircraft engines is driving the adoption of CMCs. - Power Generation

CMC turbine engines are also finding applications in the power generation sector, where their high-temperature capabilities and corrosion resistance can lead to increased efficiency and reduced maintenance costs in gas turbines and other power generation systems. - Automotive Industry

The automotive industry is exploring the use of CMC turbine engines in turbochargers and other high-temperature applications, as they can withstand extreme conditions and improve engine performance and efficiency. - Market Trends

The market for CMC turbine engines is expected to grow steadily, driven by increasing demand for lightweight and high-performance materials, as well as stricter environmental regulations and the need for energy-efficient solutions across various industries.

Ceramic Matrix Composite Turbine Engine Technology Status and Challenges

- Historical Development

Ceramic matrix composites (CMCs) have evolved from early carbon-carbon composites to advanced silicon carbide (SiC) and oxide-based materials, offering superior high-temperature capabilities. - Current Challenges

Key challenges include improving oxidation resistance, thermal shock resistance, and manufacturing processes for complex geometries while reducing costs. - Geographical Distribution

Major CMC research and development activities are concentrated in the United States, Europe, and Japan, driven by aerospace and energy applications.

Ceramic Matrix Composite Turbine Engine Current Technical Solutions

01 Ceramic matrix composites for turbine components

Ceramic matrix composites (CMCs) are used in turbine components like blades, vanes, and combustor liners due to their high-temperature resistance, low density, and improved strength over traditional materials. These CMCs can withstand extreme temperatures and provide enhanced durability in turbine engines.- CMCs for turbine engine components: Ceramic matrix composites (CMCs) are used in turbine engine components like blades, vanes, combustors, and nozzles. CMCs offer superior high-temperature strength, oxidation resistance, and low density compared to traditional metallic materials, making them suitable for hot sections of turbine engines.

- CMC coatings for turbine engine components: Turbine engine components can be coated with CMCs to provide protection against high temperatures, oxidation, and erosion. The CMC coatings act as a thermal barrier and improve the durability and lifespan of the underlying component.

- Manufacturing processes for CMC turbine engine components: Various manufacturing processes are employed to produce turbine engine components from CMCs, such as chemical vapor infiltration, polymer infiltration and pyrolysis, and melt infiltration. These processes involve infiltrating a ceramic matrix with a reinforcing material to create a composite structure.

- Repair and refurbishment of CMC turbine engine components: Methods and techniques are developed for repairing and refurbishing turbine engine components made from CMCs. These processes involve removing damaged areas, applying repair materials, and heat treatment to restore structural integrity and performance.

- Design and optimization of CMC turbine engine components: Turbine engine components made from CMCs are designed and optimized for specific operating conditions, such as high temperatures, pressure loads, and erosive environments. Factors like material composition, fiber orientation, and component geometry are considered to achieve desired performance characteristics.

02 CMC turbine blade designs

Turbine blades are designed with CMCs to improve performance and durability in high-temperature environments. These CMC blades can operate at higher temperatures, reducing the need for complex cooling systems and improving engine efficiency.Expand Specific Solutions03 CMC coatings for turbine components

Turbine components like combustor liners and vanes can be coated with CMCs to provide thermal protection and improve resistance to oxidation and corrosion at high temperatures.Expand Specific Solutions04 Manufacturing processes for CMC turbine components

Various manufacturing processes are used to produce turbine components from CMCs, including chemical vapor infiltration, polymer infiltration and pyrolysis, and additive manufacturing methods like 3D printing.Expand Specific Solutions05 Repair and maintenance of CMC turbine components

Techniques and methods are developed for repairing and maintaining turbine components made from CMCs, including processes for patching or replacing damaged areas and restoring structural integrity and thermal protection capabilities.Expand Specific Solutions

Ceramic Matrix Composite Turbine Engine Key Player Analysis

The research on the application of turbine engines with ceramic matrix composites is a highly competitive field, driven by the need for more efficient and durable engines in the aerospace and power generation industries. The market size is substantial and growing, with major players like Rolls-Royce, General Electric, Safran, and United Technologies investing heavily in this technology. The technology itself is still in the development and early adoption stage, with companies like XiAn Xinyao Ceramic Composite Materials Co. Ltd., Nanjing University of Aeronautics & Astronautics, and Safran Ceramics SA leading the way in terms of technical maturity and commercialization efforts.

Rolls-Royce Plc

Technical Solution: Rolls-Royce uses silicon carbide fibers in a silicon carbide matrix for CMC turbine engines, enabling higher operating temperatures, improved fuel efficiency, and reduced emissions.

Strengths: Extensive experience, strong R&D capabilities, proven CMC development. Weaknesses: High manufacturing costs, scaling up production challenges.

Safran Aircraft Engines SAS

Technical Solution: Safran's SiC/SiC CMC technology utilizes silicon carbide fibers in a silicon carbide matrix, offering superior high-temperature capabilities and improved engine performance. They have integrated CMC components into their LEAP engine program.

Strengths: Extensive experience, strong R&D capabilities, proven CMC development. Weaknesses: Potential high costs associated with CMC production.

Ceramic Matrix Composite Turbine Engine Core Technology Interpretation

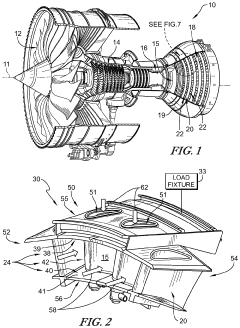

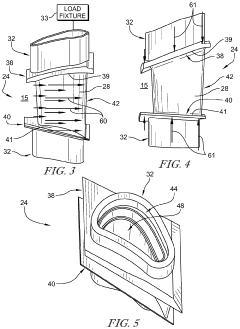

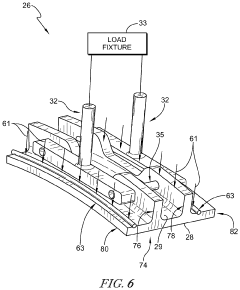

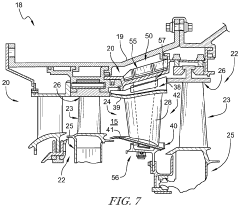

Gas turbine engine with pre-conditioned ceramic matrix composite components

PatentActiveUS11933195B2

Innovation

- A method of pre-conditioning ceramic matrix composite components to reduce or eliminate wear and crack propagation in the components when used in gas turbine engines.

- The use of ceramic matrix composite materials in gas turbine engine components, which can offer improved high-temperature performance and weight reduction compared to traditional materials.

- The ability to extend the service life and reliability of ceramic matrix composite components in gas turbine engines through the pre-conditioning treatment.

Ceramic Matrix Composite Turbine Engine Environmental Impact Assessment

Ceramic matrix composites (CMCs) have emerged as a promising material for turbine engine applications due to their superior properties, including high-temperature resistance, low density, and excellent mechanical strength. The environmental impact assessment of CMC turbine engines is a crucial aspect that needs to be addressed.

During the manufacturing process, the production of CMCs involves various energy-intensive processes and the use of hazardous materials, which can contribute to greenhouse gas emissions and environmental pollution. However, the lightweight nature of CMCs can lead to improved fuel efficiency and reduced emissions during the operational phase of turbine engines.

The end-of-life disposal or recycling of CMC components also presents challenges. While CMCs are generally considered inert and non-toxic, the presence of certain constituents, such as silicon carbide fibers, may require specialized handling and disposal methods to mitigate potential environmental risks. Developing effective recycling techniques for CMCs could help minimize waste and promote a more sustainable lifecycle for these advanced materials.

During the manufacturing process, the production of CMCs involves various energy-intensive processes and the use of hazardous materials, which can contribute to greenhouse gas emissions and environmental pollution. However, the lightweight nature of CMCs can lead to improved fuel efficiency and reduced emissions during the operational phase of turbine engines.

The end-of-life disposal or recycling of CMC components also presents challenges. While CMCs are generally considered inert and non-toxic, the presence of certain constituents, such as silicon carbide fibers, may require specialized handling and disposal methods to mitigate potential environmental risks. Developing effective recycling techniques for CMCs could help minimize waste and promote a more sustainable lifecycle for these advanced materials.

Ceramic Matrix Composite Turbine Engine Regulatory and Policy Landscape

The regulatory and policy landscape surrounding ceramic matrix composite (CMC) turbine engines is a complex and evolving area. Governments and regulatory bodies worldwide are actively working to establish standards and guidelines to ensure the safe and responsible development and deployment of these advanced propulsion systems. Key considerations include material certification, emissions regulations, and airworthiness requirements.

In the United States, agencies like the Federal Aviation Administration (FAA) and the Environmental Protection Agency (EPA) play a pivotal role in shaping the regulatory framework. The FAA's focus is on ensuring the airworthiness and safety of CMC turbine engines, while the EPA oversees emissions standards and environmental impact assessments. Similarly, in Europe, the European Union Aviation Safety Agency (EASA) and the European Commission's Directorate-General for Mobility and Transport (DG MOVE) are actively involved in developing regulations and policies for CMC turbine engines.

Beyond national and regional regulations, international organizations such as the International Civil Aviation Organization (ICAO) and the United Nations Framework Convention on Climate Change (UNFCCC) also influence the policy landscape. ICAO's standards and recommended practices (SARPs) provide a global framework for aviation safety and environmental protection, while the UNFCCC's efforts to mitigate climate change may impact emissions targets and incentives for more efficient propulsion technologies like CMC turbine engines.

In the United States, agencies like the Federal Aviation Administration (FAA) and the Environmental Protection Agency (EPA) play a pivotal role in shaping the regulatory framework. The FAA's focus is on ensuring the airworthiness and safety of CMC turbine engines, while the EPA oversees emissions standards and environmental impact assessments. Similarly, in Europe, the European Union Aviation Safety Agency (EASA) and the European Commission's Directorate-General for Mobility and Transport (DG MOVE) are actively involved in developing regulations and policies for CMC turbine engines.

Beyond national and regional regulations, international organizations such as the International Civil Aviation Organization (ICAO) and the United Nations Framework Convention on Climate Change (UNFCCC) also influence the policy landscape. ICAO's standards and recommended practices (SARPs) provide a global framework for aviation safety and environmental protection, while the UNFCCC's efforts to mitigate climate change may impact emissions targets and incentives for more efficient propulsion technologies like CMC turbine engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!