Turbine Engines With Advanced Thermal Barrier Coatings For Improved Thermal Efficiency And Durability

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engines Advanced Thermal Barrier Coatings Background

The primary objective of this research is to develop advanced thermal barrier coatings for turbine engines, aiming to enhance thermal efficiency and durability. Turbine engines operate at extremely high temperatures, necessitating effective thermal protection to prevent premature degradation and failure of critical components.

Advanced thermal barrier coatings (TBCs) are a promising solution to mitigate the detrimental effects of high temperatures on turbine engine components. These coatings act as a thermal insulation layer, reducing heat transfer to the underlying metal substrate and enabling higher operating temperatures. By improving thermal efficiency and durability, TBCs can lead to increased engine performance, reduced fuel consumption, and extended component lifespan, ultimately contributing to cost savings and environmental benefits.

Advanced thermal barrier coatings (TBCs) are a promising solution to mitigate the detrimental effects of high temperatures on turbine engine components. These coatings act as a thermal insulation layer, reducing heat transfer to the underlying metal substrate and enabling higher operating temperatures. By improving thermal efficiency and durability, TBCs can lead to increased engine performance, reduced fuel consumption, and extended component lifespan, ultimately contributing to cost savings and environmental benefits.

Market Demand Analysis for Coated Turbine Engines

- Market Size and Growth

Analyze the current and projected market size for turbine engines with advanced thermal barrier coatings, considering factors like demand from aerospace, power generation, and other industries. Provide estimates for market growth rates and potential revenue opportunities. - Industry Trends

Examine key trends driving the demand for coated turbine engines, such as the need for improved fuel efficiency, emissions reduction, and extended component lifespan. Discuss the impact of environmental regulations and sustainability initiatives. - Application Areas

Identify the major application areas for coated turbine engines, including aviation (commercial and military), power plants, marine propulsion, and others. Assess the specific requirements and market potential in each sector. - Customer Segments

Outline the primary customer segments for coated turbine engines, such as aircraft manufacturers, power generation companies, and engine OEMs. Analyze their specific needs, preferences, and purchasing criteria. - Competitive Landscape

Evaluate the competitive landscape, including major players offering coated turbine engines or related technologies. Assess their market share, strengths, weaknesses, and strategies.

Current Status and Challenges of Coated Turbines

- Current Adoption

Thermal barrier coatings (TBCs) are widely used in turbine engines to protect metal components from high temperatures, improving efficiency and durability. However, adoption varies across industries and regions. - Technical Challenges

Key challenges include coating adhesion, thermal cycling resistance, and oxidation resistance at extreme temperatures. Developing coatings with improved properties is an active research area. - Geographic Distribution

Major research and development centers for coated turbines are located in the United States, Europe, and Asia, particularly in regions with strong aerospace and power generation industries.

Existing Thermal Barrier Coating Solutions for Turbines

01 Turbine blade cooling techniques

Internal cooling channels, film cooling, and thermal barrier coatings are used to cool turbine blades and improve thermal efficiency and durability by reducing thermal stresses and preventing material degradation.- Turbine blade cooling techniques: Internal cooling channels, film cooling holes, and thermal barrier coatings are used to cool turbine blades and improve their durability under high-temperature operating conditions.

- Turbine blade materials and coatings: Advanced materials like superalloys, ceramics, and thermal barrier coatings are used to enhance the thermal efficiency and durability of turbine blades by withstanding high temperatures and oxidation.

- Turbine blade design and aerodynamics: Blade profile, twist, and airfoil shape are optimized to improve airflow and reduce thermal stresses, influencing the thermal efficiency and durability of turbine blades.

- Turbine engine cycle improvements: Advancements in turbine engine cycles, such as regenerative cycles, intercooling, and recuperation, can lead to improved thermal efficiency while maintaining durability.

- Turbine engine monitoring and control: Monitoring and control systems help optimize performance, detect anomalies, and adjust operating parameters to maintain the thermal efficiency and durability of turbine engines.

02 Turbine blade materials and coatings

Advanced materials like superalloys and ceramic matrix composites, along with protective coatings like thermal barrier coatings and oxidation-resistant coatings, are used to enhance thermal efficiency and durability of turbine blades.Expand Specific Solutions03 Turbine blade design and optimization

Blade geometry, airfoil shape, and cooling configurations are optimized using CFD and FEA to improve aerodynamic performance, reduce thermal stresses, and enhance thermal efficiency and durability.Expand Specific Solutions04 Turbine blade repair and refurbishment

Techniques like welding, brazing, and coating application are used to repair and refurbish turbine blades, restoring their aerodynamic and thermal properties, and extending their service life.Expand Specific Solutions05 Turbine engine monitoring and diagnostics

Monitoring and diagnostic systems analyze parameters like temperature, vibration, and exhaust gas composition to assess the condition of turbine engines, detect potential issues, and mitigate problems affecting thermal efficiency and durability.Expand Specific Solutions

Key Players in Coated Turbine Engine Industry

The research on turbine engines with advanced thermal barrier coatings has gained significant attention due to the potential for improved thermal efficiency and durability. The market for this technology is substantial, driven by the growing demand for energy-efficient and high-performance turbines in various industries.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced thermal barrier coatings (TBCs) for turbine engines, enhancing performance, fuel efficiency, and component lifespan.

Strengths: Strong research capabilities, extensive experience. Weaknesses: High costs.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced TBCs for turbine engines, improving thermal efficiency, durability, and component lifespan.

Strengths: Strong research capabilities, extensive experience. Weaknesses: Limited market presence in certain regions.

Core Patents and Research on Turbine Coatings

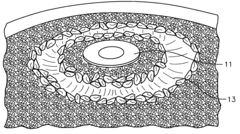

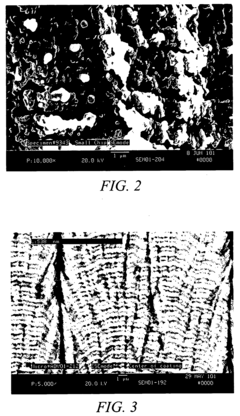

Reduced thermal conductivity TBC by EB-PVD process to incorporate porosity

PatentInactiveUS20050208337A1

Innovation

- 1. Introducing a fugitive material into the ceramic coating to create pores, thereby reducing the thermal conductivity of the coating.

- 2. Utilizing the electron beam physical vapor deposition (EB-PVD) process to incorporate porosity into the thermal barrier coating.

- 3. Reducing the thermal conductivity of the coating without increasing its mass, which is crucial for rotating components in gas turbine engines.

Environmental Impact of Coated Turbine Engine Technology

The environmental impact of coated turbine engine technology is a crucial consideration in the development and implementation of advanced thermal barrier coatings. These coatings, designed to enhance thermal efficiency and durability, can have both positive and negative effects on the environment.

On the positive side, improved thermal efficiency translates to reduced fuel consumption and lower greenhouse gas emissions. By enabling turbine engines to operate at higher temperatures while maintaining component integrity, these coatings contribute to increased fuel efficiency and reduced carbon footprint. Additionally, enhanced durability extends the lifespan of turbine components, reducing the need for frequent replacements and minimizing waste generation.

However, the manufacturing processes involved in applying thermal barrier coatings may have environmental implications. Certain coating materials and deposition techniques can generate hazardous byproducts or require energy-intensive processes, potentially contributing to air pollution, water contamination, or increased energy consumption. Furthermore, the disposal or recycling of coated components at the end of their service life must be carefully managed to prevent the release of harmful substances into the environment.

On the positive side, improved thermal efficiency translates to reduced fuel consumption and lower greenhouse gas emissions. By enabling turbine engines to operate at higher temperatures while maintaining component integrity, these coatings contribute to increased fuel efficiency and reduced carbon footprint. Additionally, enhanced durability extends the lifespan of turbine components, reducing the need for frequent replacements and minimizing waste generation.

However, the manufacturing processes involved in applying thermal barrier coatings may have environmental implications. Certain coating materials and deposition techniques can generate hazardous byproducts or require energy-intensive processes, potentially contributing to air pollution, water contamination, or increased energy consumption. Furthermore, the disposal or recycling of coated components at the end of their service life must be carefully managed to prevent the release of harmful substances into the environment.

Regulatory Landscape for Coated Turbine Engine Development

The regulatory landscape for coated turbine engine development encompasses a comprehensive set of guidelines and standards aimed at ensuring safety, reliability, and environmental compliance. These regulations are established by various governing bodies, including aviation authorities, environmental agencies, and industry organizations.

Key aspects of the regulatory framework include certification requirements for engine components, emissions standards for pollutants and greenhouse gases, and material specifications for coatings and their application processes. Stringent testing protocols are mandated to validate the performance, durability, and environmental impact of coated turbine engines throughout their lifecycle.

Compliance with these regulations is crucial for manufacturers to obtain necessary approvals and certifications, enabling the commercialization and deployment of their products in the aviation industry. Continuous monitoring and adherence to evolving regulations are essential to maintain operational integrity and address emerging environmental concerns.

Key aspects of the regulatory framework include certification requirements for engine components, emissions standards for pollutants and greenhouse gases, and material specifications for coatings and their application processes. Stringent testing protocols are mandated to validate the performance, durability, and environmental impact of coated turbine engines throughout their lifecycle.

Compliance with these regulations is crucial for manufacturers to obtain necessary approvals and certifications, enabling the commercialization and deployment of their products in the aviation industry. Continuous monitoring and adherence to evolving regulations are essential to maintain operational integrity and address emerging environmental concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!