Polycarbonate in Smart Home Technologies

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate in Smart Home: Background and Objectives

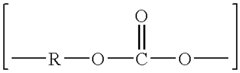

Polycarbonate, a versatile thermoplastic polymer, has emerged as a key material in the rapidly evolving field of smart home technologies. The integration of polycarbonate into smart home devices and systems represents a significant technological advancement, combining the material's unique properties with the demands of modern, connected living spaces.

The development of polycarbonate can be traced back to the 1950s, but its application in smart home technologies is a relatively recent phenomenon. This evolution aligns with the broader trend of home automation and the Internet of Things (IoT), which has gained momentum over the past decade. The convergence of polycarbonate's material science with smart home innovation has opened up new possibilities for product design, functionality, and user experience.

The primary objective of incorporating polycarbonate into smart home technologies is to enhance the performance, durability, and aesthetic appeal of devices while maintaining cost-effectiveness. Polycarbonate's exceptional impact resistance, optical clarity, and thermal stability make it an ideal candidate for a wide range of smart home applications, from touchscreens and sensor housings to structural components of larger devices.

As the smart home market continues to expand, driven by consumer demand for convenience, energy efficiency, and enhanced security, the role of advanced materials like polycarbonate becomes increasingly critical. The technology aims to leverage polycarbonate's properties to create smarter, more resilient, and visually appealing devices that seamlessly integrate into modern living spaces.

The ongoing research and development in this field focus on several key areas. These include improving the material's resistance to environmental factors, enhancing its compatibility with various smart home technologies, and exploring new manufacturing techniques to optimize production processes. Additionally, there is a growing emphasis on developing sustainable and recyclable polycarbonate formulations to align with the increasing environmental consciousness in consumer electronics.

The trajectory of polycarbonate use in smart home technologies is closely tied to advancements in material science, miniaturization of electronic components, and the evolution of IoT protocols. As these fields progress, the potential applications for polycarbonate in smart homes are expected to expand, potentially revolutionizing how we interact with our living environments.

The development of polycarbonate can be traced back to the 1950s, but its application in smart home technologies is a relatively recent phenomenon. This evolution aligns with the broader trend of home automation and the Internet of Things (IoT), which has gained momentum over the past decade. The convergence of polycarbonate's material science with smart home innovation has opened up new possibilities for product design, functionality, and user experience.

The primary objective of incorporating polycarbonate into smart home technologies is to enhance the performance, durability, and aesthetic appeal of devices while maintaining cost-effectiveness. Polycarbonate's exceptional impact resistance, optical clarity, and thermal stability make it an ideal candidate for a wide range of smart home applications, from touchscreens and sensor housings to structural components of larger devices.

As the smart home market continues to expand, driven by consumer demand for convenience, energy efficiency, and enhanced security, the role of advanced materials like polycarbonate becomes increasingly critical. The technology aims to leverage polycarbonate's properties to create smarter, more resilient, and visually appealing devices that seamlessly integrate into modern living spaces.

The ongoing research and development in this field focus on several key areas. These include improving the material's resistance to environmental factors, enhancing its compatibility with various smart home technologies, and exploring new manufacturing techniques to optimize production processes. Additionally, there is a growing emphasis on developing sustainable and recyclable polycarbonate formulations to align with the increasing environmental consciousness in consumer electronics.

The trajectory of polycarbonate use in smart home technologies is closely tied to advancements in material science, miniaturization of electronic components, and the evolution of IoT protocols. As these fields progress, the potential applications for polycarbonate in smart homes are expected to expand, potentially revolutionizing how we interact with our living environments.

Smart Home Market Demand Analysis

The smart home market has experienced significant growth in recent years, driven by increasing consumer demand for convenience, energy efficiency, and enhanced home security. As polycarbonate becomes more prevalent in smart home technologies, it is crucial to analyze the market demand for these innovative solutions.

The global smart home market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other industries. This growth is fueled by several factors, including the rising adoption of Internet of Things (IoT) devices, advancements in artificial intelligence and machine learning, and the increasing availability of affordable smart home products.

Consumer preferences are shifting towards integrated smart home ecosystems that offer seamless connectivity and control over various household functions. This trend has led to a surge in demand for smart devices such as thermostats, lighting systems, security cameras, and voice-controlled assistants. Polycarbonate, with its unique properties, is well-positioned to meet the material requirements of these devices.

Energy efficiency remains a top priority for homeowners, driving the demand for smart energy management systems. Polycarbonate's thermal insulation properties make it an ideal material for energy-efficient smart home devices, such as smart windows and climate control systems. The market for these energy-saving solutions is expected to grow significantly as consumers become more environmentally conscious and seek ways to reduce their utility bills.

Home security is another key driver of smart home technology adoption. The demand for smart security systems, including doorbell cameras, motion sensors, and smart locks, has risen sharply. Polycarbonate's durability and impact resistance make it an excellent choice for these security devices, contributing to their reliability and longevity.

The aging population in many countries has created a growing market for smart home technologies that support independent living for seniors. Polycarbonate-based smart home devices can play a crucial role in health monitoring, fall detection, and medication management systems, addressing the needs of this demographic.

As smart home technology becomes more mainstream, there is an increasing demand for aesthetically pleasing devices that blend seamlessly with home decor. Polycarbonate's versatility in terms of color, texture, and finish allows manufacturers to create visually appealing smart home products that cater to diverse consumer preferences.

The COVID-19 pandemic has accelerated the adoption of smart home technologies, as people spend more time at home and prioritize hygiene and touchless interactions. This has led to increased demand for voice-controlled devices and automated systems, many of which can benefit from polycarbonate's properties.

In conclusion, the smart home market presents significant opportunities for polycarbonate applications. The material's unique characteristics align well with the demands of this rapidly growing industry, positioning it as a key component in the development of innovative smart home technologies.

The global smart home market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other industries. This growth is fueled by several factors, including the rising adoption of Internet of Things (IoT) devices, advancements in artificial intelligence and machine learning, and the increasing availability of affordable smart home products.

Consumer preferences are shifting towards integrated smart home ecosystems that offer seamless connectivity and control over various household functions. This trend has led to a surge in demand for smart devices such as thermostats, lighting systems, security cameras, and voice-controlled assistants. Polycarbonate, with its unique properties, is well-positioned to meet the material requirements of these devices.

Energy efficiency remains a top priority for homeowners, driving the demand for smart energy management systems. Polycarbonate's thermal insulation properties make it an ideal material for energy-efficient smart home devices, such as smart windows and climate control systems. The market for these energy-saving solutions is expected to grow significantly as consumers become more environmentally conscious and seek ways to reduce their utility bills.

Home security is another key driver of smart home technology adoption. The demand for smart security systems, including doorbell cameras, motion sensors, and smart locks, has risen sharply. Polycarbonate's durability and impact resistance make it an excellent choice for these security devices, contributing to their reliability and longevity.

The aging population in many countries has created a growing market for smart home technologies that support independent living for seniors. Polycarbonate-based smart home devices can play a crucial role in health monitoring, fall detection, and medication management systems, addressing the needs of this demographic.

As smart home technology becomes more mainstream, there is an increasing demand for aesthetically pleasing devices that blend seamlessly with home decor. Polycarbonate's versatility in terms of color, texture, and finish allows manufacturers to create visually appealing smart home products that cater to diverse consumer preferences.

The COVID-19 pandemic has accelerated the adoption of smart home technologies, as people spend more time at home and prioritize hygiene and touchless interactions. This has led to increased demand for voice-controlled devices and automated systems, many of which can benefit from polycarbonate's properties.

In conclusion, the smart home market presents significant opportunities for polycarbonate applications. The material's unique characteristics align well with the demands of this rapidly growing industry, positioning it as a key component in the development of innovative smart home technologies.

Current State and Challenges of Polycarbonate Usage

Polycarbonate has gained significant traction in smart home technologies due to its unique combination of properties. Currently, this versatile material is widely used in various smart home devices, including smart displays, touchscreens, and sensor housings. Its transparency, impact resistance, and thermal stability make it an ideal choice for these applications.

In the smart lighting sector, polycarbonate is extensively utilized for LED light diffusers and covers. Its ability to transmit light while providing durability has led to its widespread adoption in smart bulbs and fixtures. The material's moldability allows for intricate designs, enhancing both functionality and aesthetics in smart lighting solutions.

For smart home security systems, polycarbonate is employed in camera housings, motion sensors, and control panels. Its weather resistance and toughness ensure longevity and reliability in outdoor applications, while its electrical insulating properties make it suitable for internal components.

Despite its widespread use, the integration of polycarbonate in smart home technologies faces several challenges. One primary concern is the material's susceptibility to scratching, which can affect the clarity of displays and camera lenses over time. Manufacturers are exploring various coatings and surface treatments to mitigate this issue, but a fully satisfactory solution remains elusive.

Another challenge lies in the recycling and sustainability of polycarbonate. As smart home devices become more prevalent, the environmental impact of their materials becomes increasingly important. While polycarbonate is recyclable, the process is complex and often not economically viable, leading to concerns about e-waste accumulation.

The rising costs of raw materials and energy have also impacted the production of polycarbonate, potentially affecting its affordability in smart home applications. Manufacturers are seeking ways to optimize production processes and explore alternative formulations to maintain cost-effectiveness without compromising performance.

Furthermore, as smart home devices become more sophisticated, there is a growing demand for materials with enhanced properties. This includes improved heat dissipation for devices with higher processing power, better flame retardancy for safety-critical applications, and increased UV resistance for outdoor devices. While polycarbonate performs well in many aspects, meeting these evolving requirements presents ongoing challenges for material scientists and engineers.

In conclusion, while polycarbonate has established itself as a key material in smart home technologies, addressing these challenges will be crucial for its continued dominance in the field. Innovations in material science and manufacturing processes will play a vital role in overcoming these hurdles and expanding the potential of polycarbonate in future smart home applications.

In the smart lighting sector, polycarbonate is extensively utilized for LED light diffusers and covers. Its ability to transmit light while providing durability has led to its widespread adoption in smart bulbs and fixtures. The material's moldability allows for intricate designs, enhancing both functionality and aesthetics in smart lighting solutions.

For smart home security systems, polycarbonate is employed in camera housings, motion sensors, and control panels. Its weather resistance and toughness ensure longevity and reliability in outdoor applications, while its electrical insulating properties make it suitable for internal components.

Despite its widespread use, the integration of polycarbonate in smart home technologies faces several challenges. One primary concern is the material's susceptibility to scratching, which can affect the clarity of displays and camera lenses over time. Manufacturers are exploring various coatings and surface treatments to mitigate this issue, but a fully satisfactory solution remains elusive.

Another challenge lies in the recycling and sustainability of polycarbonate. As smart home devices become more prevalent, the environmental impact of their materials becomes increasingly important. While polycarbonate is recyclable, the process is complex and often not economically viable, leading to concerns about e-waste accumulation.

The rising costs of raw materials and energy have also impacted the production of polycarbonate, potentially affecting its affordability in smart home applications. Manufacturers are seeking ways to optimize production processes and explore alternative formulations to maintain cost-effectiveness without compromising performance.

Furthermore, as smart home devices become more sophisticated, there is a growing demand for materials with enhanced properties. This includes improved heat dissipation for devices with higher processing power, better flame retardancy for safety-critical applications, and increased UV resistance for outdoor devices. While polycarbonate performs well in many aspects, meeting these evolving requirements presents ongoing challenges for material scientists and engineers.

In conclusion, while polycarbonate has established itself as a key material in smart home technologies, addressing these challenges will be crucial for its continued dominance in the field. Innovations in material science and manufacturing processes will play a vital role in overcoming these hurdles and expanding the potential of polycarbonate in future smart home applications.

Existing Polycarbonate Solutions for Smart Home Devices

01 Synthesis and modification of polycarbonates

Various methods for synthesizing and modifying polycarbonates are explored, including novel catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.- Synthesis and modification of polycarbonates: Various methods for synthesizing and modifying polycarbonates are explored, including new catalysts, reaction conditions, and additives to improve properties such as molecular weight, thermal stability, and optical clarity. These techniques aim to enhance the overall performance and versatility of polycarbonate materials for different applications.

- Polycarbonate blends and composites: Development of polycarbonate blends and composites with other polymers or additives to achieve specific properties. These formulations can improve impact resistance, flame retardancy, or other characteristics while maintaining the desirable features of polycarbonates. The blending process and composition ratios are crucial for optimizing the final material properties.

- Polycarbonate processing techniques: Advanced processing techniques for polycarbonates, including extrusion, injection molding, and film formation. These methods focus on improving the manufacturing efficiency, reducing defects, and enhancing the surface quality of polycarbonate products. Specialized equipment and process parameters are developed to optimize the production of various polycarbonate forms.

- Polycarbonate applications in electronics: Utilization of polycarbonates in electronic applications, such as in the production of circuit boards, housings for electronic devices, and optical components. The focus is on developing polycarbonate formulations with enhanced electrical properties, heat resistance, and dimensional stability to meet the demanding requirements of modern electronics.

- Recycling and sustainability of polycarbonates: Methods for recycling polycarbonate materials and developing more sustainable production processes. This includes chemical recycling techniques, the use of bio-based monomers, and the development of additives to enhance the biodegradability of polycarbonates. The aim is to reduce the environmental impact of polycarbonate production and waste management.

02 Polycarbonate blends and composites

Development of polycarbonate blends and composites with other polymers or additives to achieve improved mechanical properties, flame retardancy, or specific functionalities. These formulations often involve careful selection of components and processing methods to optimize the final material characteristics for targeted applications.Expand Specific Solutions03 Optical applications of polycarbonates

Utilization of polycarbonates in optical applications, such as lenses, displays, and light-guiding components. This includes modifications to enhance optical properties, reduce haze, improve light transmission, and develop specialized grades for specific optical requirements in various industries.Expand Specific Solutions04 Polycarbonate processing and manufacturing techniques

Advancements in processing and manufacturing techniques for polycarbonates, including extrusion, injection molding, and film formation. These developments focus on improving efficiency, reducing defects, and enhancing the quality of final products while optimizing production costs and environmental impact.Expand Specific Solutions05 Sustainable and bio-based polycarbonates

Research and development of sustainable and bio-based alternatives to traditional polycarbonates, focusing on renewable resources and environmentally friendly production methods. This includes the exploration of new monomers, polymerization techniques, and end-of-life considerations to create more eco-friendly polycarbonate materials.Expand Specific Solutions

Key Players in Polycarbonate and Smart Home Industries

The research on polycarbonate use in smart home technologies is in a growth phase, with the market expanding rapidly due to increasing adoption of IoT devices and smart home systems. The global market size for polycarbonate in smart home applications is projected to grow significantly over the next few years. Technologically, polycarbonate applications are advancing, with companies like SABIC, Covestro, and Bayer AG leading innovation in material development. These firms are focusing on enhancing polycarbonate properties for improved durability, heat resistance, and transparency, crucial for smart home devices. Other players like Mitsubishi Engineering-Plastics and Kingfa Sci. & Tech. are also contributing to the technological maturity of polycarbonate solutions in this sector.

SABIC Global Technologies BV

Technical Solution: SABIC has developed LEXAN™ polycarbonate resins specifically for smart home technologies. Their innovative approach includes flame-retardant grades that meet UL94 V-0 standards at thin wall sections, crucial for compact smart devices[1]. SABIC's polycarbonate solutions offer high impact strength and heat resistance, allowing for durable and sleek designs in smart home products. They've also introduced transparent grades with high light transmission, enabling the integration of LED displays and touch interfaces in smart home control panels[2]. SABIC's polycarbonates feature enhanced UV stability, ensuring long-lasting performance in outdoor smart home applications like security cameras and lighting fixtures[3].

Strengths: High impact resistance, flame retardancy, and design flexibility. Weaknesses: Higher cost compared to some alternative materials, potential for yellowing over time in certain applications.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered Makrolon® polycarbonate resins tailored for smart home devices. Their technology focuses on creating thin-wall molding capabilities, allowing for miniaturization of smart sensors and IoT devices[1]. Covestro's polycarbonates offer excellent dimensional stability and high flow characteristics, enabling complex geometries in smart home product designs. They've developed grades with enhanced chemical resistance to withstand cleaning agents commonly used in households[2]. Covestro has also introduced polycarbonate blends that provide improved acoustic properties, crucial for smart speakers and voice-activated devices. Their materials feature low-halogen formulations, addressing the growing demand for more environmentally friendly smart home products[3].

Strengths: Excellent balance of physical properties, good processability, and eco-friendly formulations. Weaknesses: Relatively high material cost, limited resistance to certain chemicals without special grades.

Core Innovations in Polycarbonate for Smart Home Technologies

Coatings for polycarbonate windows

PatentInactiveUS20070231577A1

Innovation

- A dual-cure coating composition that includes a radiation-curable component, a thermally curable binder, and a thermally curable crosslinking agent, along with UV-absorbing additives, applied to the polycarbonate substrate, which cures using both actinic radiation and thermal energy, ensuring excellent adhesion and optical clarity without the need for intermediate primers.

Polycarbonate compositions having improved chemical resistance, articles formed thereof, and methods of manufacture

PatentActiveUS20200369875A1

Innovation

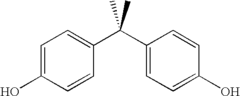

- A polycarbonate composition comprising 10 to 99 wt % of bisphenol A polycarbonate homopolymers and a poly(carbonate-siloxane) with a siloxane content of 30 to 70 wt %, optionally including a silicone-based impact modifier, to enhance chemical resistance and mechanical properties.

Environmental Impact and Sustainability Considerations

The use of polycarbonate in smart home technologies has significant environmental implications that must be carefully considered. Polycarbonate, a versatile thermoplastic polymer, offers numerous advantages in terms of durability, transparency, and impact resistance. However, its production and disposal processes raise important sustainability concerns.

The manufacturing of polycarbonate involves energy-intensive processes and the use of potentially harmful chemicals, such as bisphenol A (BPA). These factors contribute to a considerable carbon footprint and potential environmental risks. As smart home technologies continue to proliferate, the increased demand for polycarbonate could exacerbate these environmental impacts if not properly managed.

Recycling polycarbonate presents both challenges and opportunities. While the material is technically recyclable, the presence of additives and coatings in smart home devices can complicate the recycling process. Developing more efficient recycling technologies and implementing effective collection systems are crucial steps towards mitigating the environmental impact of polycarbonate use in this sector.

The longevity of polycarbonate products in smart home applications can be viewed as a double-edged sword from an environmental perspective. On one hand, the durability of polycarbonate reduces the need for frequent replacements, potentially lowering overall resource consumption. On the other hand, this durability means that polycarbonate products may persist in the environment for extended periods if not properly disposed of or recycled.

Efforts to improve the sustainability of polycarbonate use in smart home technologies are ongoing. Research into bio-based alternatives and the development of more environmentally friendly production methods show promise. Additionally, the implementation of circular economy principles in the design and lifecycle management of smart home devices could significantly reduce the environmental footprint of polycarbonate use.

The energy efficiency of smart home technologies enabled by polycarbonate components must also be considered. While these devices may contribute to overall household energy savings, the embodied energy in their production and the potential for increased electronic waste pose environmental challenges that need to be addressed.

As the smart home industry evolves, there is a growing emphasis on eco-design principles. This approach considers the environmental impact of products throughout their entire lifecycle, from raw material extraction to end-of-life disposal. Incorporating these principles into the development of polycarbonate-based smart home technologies can lead to more sustainable products and practices.

The manufacturing of polycarbonate involves energy-intensive processes and the use of potentially harmful chemicals, such as bisphenol A (BPA). These factors contribute to a considerable carbon footprint and potential environmental risks. As smart home technologies continue to proliferate, the increased demand for polycarbonate could exacerbate these environmental impacts if not properly managed.

Recycling polycarbonate presents both challenges and opportunities. While the material is technically recyclable, the presence of additives and coatings in smart home devices can complicate the recycling process. Developing more efficient recycling technologies and implementing effective collection systems are crucial steps towards mitigating the environmental impact of polycarbonate use in this sector.

The longevity of polycarbonate products in smart home applications can be viewed as a double-edged sword from an environmental perspective. On one hand, the durability of polycarbonate reduces the need for frequent replacements, potentially lowering overall resource consumption. On the other hand, this durability means that polycarbonate products may persist in the environment for extended periods if not properly disposed of or recycled.

Efforts to improve the sustainability of polycarbonate use in smart home technologies are ongoing. Research into bio-based alternatives and the development of more environmentally friendly production methods show promise. Additionally, the implementation of circular economy principles in the design and lifecycle management of smart home devices could significantly reduce the environmental footprint of polycarbonate use.

The energy efficiency of smart home technologies enabled by polycarbonate components must also be considered. While these devices may contribute to overall household energy savings, the embodied energy in their production and the potential for increased electronic waste pose environmental challenges that need to be addressed.

As the smart home industry evolves, there is a growing emphasis on eco-design principles. This approach considers the environmental impact of products throughout their entire lifecycle, from raw material extraction to end-of-life disposal. Incorporating these principles into the development of polycarbonate-based smart home technologies can lead to more sustainable products and practices.

Regulatory Framework for Smart Home Materials

The regulatory framework for smart home materials, particularly concerning the use of polycarbonate, is a complex and evolving landscape. As smart home technologies continue to advance, governments and regulatory bodies are increasingly focusing on the safety, durability, and environmental impact of materials used in these devices.

In the United States, the Consumer Product Safety Commission (CPSC) plays a crucial role in overseeing the safety of consumer products, including smart home devices. The CPSC has established guidelines for the use of plastics, including polycarbonate, in consumer electronics. These guidelines address issues such as fire resistance, electrical insulation properties, and potential chemical leaching.

The European Union has implemented the Restriction of Hazardous Substances (RoHS) Directive, which restricts the use of certain hazardous substances in electrical and electronic equipment. While polycarbonate itself is not directly restricted, manufacturers must ensure that any additives or treatments applied to the material comply with RoHS standards.

Energy efficiency regulations also impact the use of polycarbonate in smart home technologies. The EU's Ecodesign Directive and the US Department of Energy's appliance standards both set requirements for the energy performance of various household devices. These regulations indirectly influence material choices, as manufacturers must balance thermal management properties with energy efficiency goals.

Environmental considerations are becoming increasingly important in the regulatory landscape. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandates the proper disposal and recycling of electronic devices, including those made with polycarbonate. This directive encourages manufacturers to design products with end-of-life considerations in mind, potentially influencing material selection and product design.

In addition to these overarching regulations, specific standards have been developed for smart home devices. For example, the UL 2900 series of standards addresses cybersecurity concerns in network-connectable products, which may impact the design and material choices for smart home devices. Similarly, the IEC 62368-1 standard for audio/video, information, and communication technology equipment includes safety requirements that may affect the use of polycarbonate in device enclosures.

As the smart home market continues to grow, regulatory bodies are likely to introduce more specific guidelines for materials used in these technologies. Manufacturers and developers working with polycarbonate in smart home applications must stay informed about these evolving regulations to ensure compliance and maintain consumer trust.

In the United States, the Consumer Product Safety Commission (CPSC) plays a crucial role in overseeing the safety of consumer products, including smart home devices. The CPSC has established guidelines for the use of plastics, including polycarbonate, in consumer electronics. These guidelines address issues such as fire resistance, electrical insulation properties, and potential chemical leaching.

The European Union has implemented the Restriction of Hazardous Substances (RoHS) Directive, which restricts the use of certain hazardous substances in electrical and electronic equipment. While polycarbonate itself is not directly restricted, manufacturers must ensure that any additives or treatments applied to the material comply with RoHS standards.

Energy efficiency regulations also impact the use of polycarbonate in smart home technologies. The EU's Ecodesign Directive and the US Department of Energy's appliance standards both set requirements for the energy performance of various household devices. These regulations indirectly influence material choices, as manufacturers must balance thermal management properties with energy efficiency goals.

Environmental considerations are becoming increasingly important in the regulatory landscape. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandates the proper disposal and recycling of electronic devices, including those made with polycarbonate. This directive encourages manufacturers to design products with end-of-life considerations in mind, potentially influencing material selection and product design.

In addition to these overarching regulations, specific standards have been developed for smart home devices. For example, the UL 2900 series of standards addresses cybersecurity concerns in network-connectable products, which may impact the design and material choices for smart home devices. Similarly, the IEC 62368-1 standard for audio/video, information, and communication technology equipment includes safety requirements that may affect the use of polycarbonate in device enclosures.

As the smart home market continues to grow, regulatory bodies are likely to introduce more specific guidelines for materials used in these technologies. Manufacturers and developers working with polycarbonate in smart home applications must stay informed about these evolving regulations to ensure compliance and maintain consumer trust.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!