Ultralight Kevlar Composites for Aerospace Efficiency

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Composites Evolution and Objectives

Kevlar composites have revolutionized the aerospace industry since their introduction in the 1970s. Initially developed by DuPont, these high-strength, lightweight materials quickly found applications in aircraft structures, ballistic protection, and space exploration. The evolution of Kevlar composites has been driven by the constant demand for improved performance, reduced weight, and enhanced durability in aerospace applications.

In the early stages, Kevlar fibers were primarily used in simple composite structures, often combined with epoxy resins. As manufacturing techniques advanced, more complex Kevlar-based composites emerged, incorporating hybrid materials and sophisticated layering techniques. This progression led to the development of multi-functional composites that not only provided structural support but also offered additional properties such as impact resistance and thermal management.

The aerospace industry's push for fuel efficiency and reduced emissions has been a key driver in the ongoing evolution of Kevlar composites. Engineers and researchers have continuously sought ways to optimize the strength-to-weight ratio of these materials, exploring new fiber architectures, matrix systems, and manufacturing processes. This has resulted in the creation of ultralight Kevlar composites that maintain or even surpass the mechanical properties of their predecessors while significantly reducing overall weight.

Recent advancements in nanotechnology have opened new avenues for Kevlar composite development. The integration of nanoparticles and nanotubes into Kevlar-based materials has shown promising results in enhancing mechanical, thermal, and electrical properties. These nano-enhanced Kevlar composites represent the cutting edge of aerospace material science, offering unprecedented combinations of strength, lightness, and functionality.

The primary objective of current research on ultralight Kevlar composites is to push the boundaries of aerospace efficiency even further. This involves developing new formulations and manufacturing techniques that can produce materials with an optimal balance of strength, weight, and durability. Researchers aim to create Kevlar composites that can withstand the extreme conditions of aerospace applications while contributing to significant weight reductions in aircraft and spacecraft structures.

Another crucial objective is to improve the sustainability and recyclability of Kevlar composites. As environmental concerns become increasingly important in the aerospace industry, there is a growing focus on developing eco-friendly production methods and end-of-life solutions for these materials. This includes exploring bio-based alternatives for matrix materials and investigating efficient recycling processes for Kevlar fibers and composites.

In the early stages, Kevlar fibers were primarily used in simple composite structures, often combined with epoxy resins. As manufacturing techniques advanced, more complex Kevlar-based composites emerged, incorporating hybrid materials and sophisticated layering techniques. This progression led to the development of multi-functional composites that not only provided structural support but also offered additional properties such as impact resistance and thermal management.

The aerospace industry's push for fuel efficiency and reduced emissions has been a key driver in the ongoing evolution of Kevlar composites. Engineers and researchers have continuously sought ways to optimize the strength-to-weight ratio of these materials, exploring new fiber architectures, matrix systems, and manufacturing processes. This has resulted in the creation of ultralight Kevlar composites that maintain or even surpass the mechanical properties of their predecessors while significantly reducing overall weight.

Recent advancements in nanotechnology have opened new avenues for Kevlar composite development. The integration of nanoparticles and nanotubes into Kevlar-based materials has shown promising results in enhancing mechanical, thermal, and electrical properties. These nano-enhanced Kevlar composites represent the cutting edge of aerospace material science, offering unprecedented combinations of strength, lightness, and functionality.

The primary objective of current research on ultralight Kevlar composites is to push the boundaries of aerospace efficiency even further. This involves developing new formulations and manufacturing techniques that can produce materials with an optimal balance of strength, weight, and durability. Researchers aim to create Kevlar composites that can withstand the extreme conditions of aerospace applications while contributing to significant weight reductions in aircraft and spacecraft structures.

Another crucial objective is to improve the sustainability and recyclability of Kevlar composites. As environmental concerns become increasingly important in the aerospace industry, there is a growing focus on developing eco-friendly production methods and end-of-life solutions for these materials. This includes exploring bio-based alternatives for matrix materials and investigating efficient recycling processes for Kevlar fibers and composites.

Aerospace Market Demand Analysis

The aerospace industry has been experiencing a significant surge in demand for lightweight materials that can enhance fuel efficiency and overall performance of aircraft and spacecraft. Ultralight Kevlar composites have emerged as a promising solution to meet these growing market needs. The global aerospace composites market, which includes Kevlar-based materials, is projected to reach $53.8 billion by 2027, growing at a CAGR of 9.3% from 2020 to 2027.

The demand for ultralight Kevlar composites in the aerospace sector is primarily driven by the industry's relentless pursuit of weight reduction and improved fuel efficiency. Commercial airlines are under increasing pressure to reduce their carbon footprint and operating costs, with fuel expenses accounting for a substantial portion of their overall expenditure. By incorporating ultralight Kevlar composites into aircraft structures, manufacturers can achieve weight savings of up to 20-30% compared to traditional materials, translating to significant fuel savings and reduced emissions.

Military aerospace applications also contribute to the growing demand for ultralight Kevlar composites. The defense sector requires materials that offer high strength-to-weight ratios for advanced fighter jets, unmanned aerial vehicles (UAVs), and satellite systems. Kevlar composites provide excellent ballistic protection while maintaining low weight, making them ideal for military aircraft and spacecraft applications.

The space exploration sector is another key driver of demand for ultralight Kevlar composites. As space agencies and private companies aim to reduce launch costs and increase payload capacity, lightweight materials become crucial. Kevlar composites are being increasingly used in satellite structures, spacecraft components, and even in space habitats due to their exceptional strength, low weight, and resistance to extreme temperatures.

The growing trend of electric and hybrid-electric aircraft is also fueling the demand for ultralight Kevlar composites. These innovative aircraft designs require materials that can offset the additional weight of batteries and electric propulsion systems. Kevlar composites offer an excellent solution to this challenge, enabling manufacturers to create more efficient and environmentally friendly aircraft.

Furthermore, the maintenance, repair, and overhaul (MRO) segment of the aerospace industry is showing increased interest in ultralight Kevlar composites. As older aircraft are retrofitted with lighter materials to improve fuel efficiency and extend their service life, the demand for these advanced composites is expected to rise.

In conclusion, the aerospace market demand for ultralight Kevlar composites is robust and multifaceted, driven by the need for fuel efficiency, environmental sustainability, and enhanced performance across commercial, military, and space exploration sectors. As the industry continues to evolve and innovate, the role of these advanced materials in shaping the future of aerospace technology is set to expand significantly.

The demand for ultralight Kevlar composites in the aerospace sector is primarily driven by the industry's relentless pursuit of weight reduction and improved fuel efficiency. Commercial airlines are under increasing pressure to reduce their carbon footprint and operating costs, with fuel expenses accounting for a substantial portion of their overall expenditure. By incorporating ultralight Kevlar composites into aircraft structures, manufacturers can achieve weight savings of up to 20-30% compared to traditional materials, translating to significant fuel savings and reduced emissions.

Military aerospace applications also contribute to the growing demand for ultralight Kevlar composites. The defense sector requires materials that offer high strength-to-weight ratios for advanced fighter jets, unmanned aerial vehicles (UAVs), and satellite systems. Kevlar composites provide excellent ballistic protection while maintaining low weight, making them ideal for military aircraft and spacecraft applications.

The space exploration sector is another key driver of demand for ultralight Kevlar composites. As space agencies and private companies aim to reduce launch costs and increase payload capacity, lightweight materials become crucial. Kevlar composites are being increasingly used in satellite structures, spacecraft components, and even in space habitats due to their exceptional strength, low weight, and resistance to extreme temperatures.

The growing trend of electric and hybrid-electric aircraft is also fueling the demand for ultralight Kevlar composites. These innovative aircraft designs require materials that can offset the additional weight of batteries and electric propulsion systems. Kevlar composites offer an excellent solution to this challenge, enabling manufacturers to create more efficient and environmentally friendly aircraft.

Furthermore, the maintenance, repair, and overhaul (MRO) segment of the aerospace industry is showing increased interest in ultralight Kevlar composites. As older aircraft are retrofitted with lighter materials to improve fuel efficiency and extend their service life, the demand for these advanced composites is expected to rise.

In conclusion, the aerospace market demand for ultralight Kevlar composites is robust and multifaceted, driven by the need for fuel efficiency, environmental sustainability, and enhanced performance across commercial, military, and space exploration sectors. As the industry continues to evolve and innovate, the role of these advanced materials in shaping the future of aerospace technology is set to expand significantly.

Ultralight Composites: State and Challenges

The development of ultralight composites, particularly those incorporating Kevlar, has been a significant focus in aerospace engineering due to their potential to dramatically improve aircraft efficiency. Currently, the state of ultralight Kevlar composites is characterized by remarkable progress, yet it faces several critical challenges that require innovative solutions.

Kevlar-reinforced composites have demonstrated exceptional strength-to-weight ratios, making them ideal for aerospace applications where weight reduction is paramount. These materials have been successfully implemented in various aircraft components, including fuselage panels, wing structures, and interior fittings. The current generation of ultralight Kevlar composites exhibits improved impact resistance, fatigue strength, and thermal stability compared to traditional aerospace materials.

However, the widespread adoption of these advanced materials is hindered by several technical hurdles. One of the primary challenges is the complexity of manufacturing processes required to produce high-quality, consistent Kevlar composites. The intricate layup procedures and the need for precise control over fiber orientation and resin distribution demand sophisticated manufacturing techniques, which can be both time-consuming and costly.

Another significant challenge lies in the realm of material interfacing. While Kevlar composites excel in tensile strength, their compressive properties are comparatively weaker. This discrepancy necessitates careful design considerations when integrating these materials into complex aerospace structures, often requiring hybrid solutions that combine Kevlar with other materials to achieve optimal performance across various load conditions.

The aerospace industry is also grappling with the challenge of scalability. While ultralight Kevlar composites have proven their worth in smaller components and experimental aircraft, scaling up production for large commercial airliners presents logistical and economic hurdles. The high cost of raw materials and specialized equipment required for large-scale production remains a significant barrier to widespread adoption.

Furthermore, the long-term durability and maintenance of Kevlar composites in aerospace environments is an ongoing area of research. Exposure to UV radiation, moisture, and varying temperature conditions can potentially degrade the material properties over time. Developing effective protective coatings and maintenance protocols is crucial for ensuring the longevity of these materials in service.

Recycling and end-of-life considerations present another set of challenges. Unlike traditional aerospace materials, the complex nature of Kevlar composites makes them difficult to recycle efficiently. As the industry moves towards more sustainable practices, finding environmentally friendly methods to repurpose or dispose of these materials at the end of their lifecycle is becoming increasingly important.

Despite these challenges, the potential benefits of ultralight Kevlar composites continue to drive research and development efforts. Innovations in nanotechnology and advanced manufacturing techniques are opening new avenues for addressing current limitations, promising even lighter and stronger materials for future aerospace applications.

Kevlar-reinforced composites have demonstrated exceptional strength-to-weight ratios, making them ideal for aerospace applications where weight reduction is paramount. These materials have been successfully implemented in various aircraft components, including fuselage panels, wing structures, and interior fittings. The current generation of ultralight Kevlar composites exhibits improved impact resistance, fatigue strength, and thermal stability compared to traditional aerospace materials.

However, the widespread adoption of these advanced materials is hindered by several technical hurdles. One of the primary challenges is the complexity of manufacturing processes required to produce high-quality, consistent Kevlar composites. The intricate layup procedures and the need for precise control over fiber orientation and resin distribution demand sophisticated manufacturing techniques, which can be both time-consuming and costly.

Another significant challenge lies in the realm of material interfacing. While Kevlar composites excel in tensile strength, their compressive properties are comparatively weaker. This discrepancy necessitates careful design considerations when integrating these materials into complex aerospace structures, often requiring hybrid solutions that combine Kevlar with other materials to achieve optimal performance across various load conditions.

The aerospace industry is also grappling with the challenge of scalability. While ultralight Kevlar composites have proven their worth in smaller components and experimental aircraft, scaling up production for large commercial airliners presents logistical and economic hurdles. The high cost of raw materials and specialized equipment required for large-scale production remains a significant barrier to widespread adoption.

Furthermore, the long-term durability and maintenance of Kevlar composites in aerospace environments is an ongoing area of research. Exposure to UV radiation, moisture, and varying temperature conditions can potentially degrade the material properties over time. Developing effective protective coatings and maintenance protocols is crucial for ensuring the longevity of these materials in service.

Recycling and end-of-life considerations present another set of challenges. Unlike traditional aerospace materials, the complex nature of Kevlar composites makes them difficult to recycle efficiently. As the industry moves towards more sustainable practices, finding environmentally friendly methods to repurpose or dispose of these materials at the end of their lifecycle is becoming increasingly important.

Despite these challenges, the potential benefits of ultralight Kevlar composites continue to drive research and development efforts. Innovations in nanotechnology and advanced manufacturing techniques are opening new avenues for addressing current limitations, promising even lighter and stronger materials for future aerospace applications.

Current Ultralight Kevlar Solutions

01 Lightweight Kevlar composite structures

Ultralight Kevlar composites are developed for various applications, focusing on reducing weight while maintaining strength. These structures often incorporate advanced manufacturing techniques and innovative material combinations to achieve optimal weight-to-strength ratios.- Lightweight Kevlar composite materials: Ultralight Kevlar composites are developed by combining Kevlar fibers with lightweight matrix materials to create high-strength, low-weight structures. These composites offer excellent strength-to-weight ratios, making them ideal for applications where weight reduction is critical, such as aerospace and automotive industries.

- Manufacturing techniques for ultralight Kevlar composites: Advanced manufacturing techniques are employed to produce ultralight Kevlar composites, including specialized layup processes, resin infusion methods, and precision molding. These techniques ensure optimal fiber orientation and minimal resin content, resulting in composites with exceptional strength-to-weight characteristics.

- Applications of ultralight Kevlar composites: Ultralight Kevlar composites find applications in various fields, including aerospace, automotive, sports equipment, and personal protective gear. Their high strength and low weight make them suitable for aircraft components, vehicle body panels, high-performance sporting goods, and lightweight armor systems.

- Weight reduction strategies for Kevlar composites: Various strategies are employed to further reduce the weight of Kevlar composites, such as incorporating lightweight core materials, optimizing fiber volume fractions, and using advanced resin systems. These approaches aim to maximize strength while minimizing overall composite weight.

- Performance evaluation of ultralight Kevlar composites: Rigorous testing and evaluation methods are used to assess the performance of ultralight Kevlar composites, including mechanical strength tests, impact resistance assessments, and environmental durability studies. These evaluations ensure that the composites meet the required specifications for their intended applications while maintaining their lightweight properties.

02 Kevlar-reinforced aerospace components

Kevlar composites are utilized in aerospace applications to create ultralight components. These materials are engineered to meet the stringent weight and performance requirements of aircraft and spacecraft, often involving specialized layering techniques and hybrid material systems.Expand Specific Solutions03 Nanocomposite integration with Kevlar

Incorporating nanoparticles or nanostructures into Kevlar composites can significantly enhance their properties while maintaining ultralight weight. This approach often involves the use of carbon nanotubes, graphene, or other nanomaterials to improve strength, stiffness, and impact resistance.Expand Specific Solutions04 Kevlar-based protective gear

Ultralight Kevlar composites are used in the development of personal protective equipment. These applications focus on creating lightweight yet highly effective armor or protective gear for military, law enforcement, and sports applications.Expand Specific Solutions05 Manufacturing processes for ultralight Kevlar composites

Advanced manufacturing techniques are employed to produce ultralight Kevlar composites. These processes may include specialized weaving methods, resin infusion techniques, or additive manufacturing approaches to optimize the weight and performance of the final composite structure.Expand Specific Solutions

Key Players in Aerospace Composites

The research on ultralight Kevlar composites for aerospace efficiency is in a dynamic phase, with significant market potential and ongoing technological advancements. The aerospace industry, driven by the need for fuel efficiency and performance optimization, is increasingly adopting these materials. Key players like Boeing, Lockheed Martin, and Airbus are at the forefront, investing heavily in R&D. Universities such as Harbin Institute of Technology and Nanjing University of Science & Technology are contributing to fundamental research. Specialized companies like Hexcel Corp. and QuesTek Innovations are pushing the boundaries of material science, while government agencies like NASA and ISRO are exploring applications in space technology. The market is expected to grow substantially as the technology matures and finds wider applications in commercial and military aerospace sectors.

Hexcel Corp.

Technical Solution: Hexcel Corp. has developed advanced ultralight Kevlar composites for aerospace applications, focusing on improving strength-to-weight ratios. Their HexPly® prepreg technology combines Kevlar fibers with proprietary resin systems to create materials that are up to 40% lighter than traditional aerospace metals while maintaining superior strength[1]. The company has also introduced HexTow® carbon fibers that can be integrated with Kevlar to further enhance composite performance. These materials have been engineered to withstand extreme temperatures and pressures encountered in aerospace environments, with some variants capable of operating at temperatures up to 350°F (177°C)[2]. Hexcel's composites have been utilized in various aircraft components, including fuselage panels, wing structures, and interior elements, contributing to significant weight reductions and improved fuel efficiency in modern aircraft designs[3].

Strengths: Industry-leading expertise in composite materials, proven track record in aerospace applications, continuous innovation in material science. Weaknesses: High production costs, potential supply chain vulnerabilities for raw materials, reliance on aerospace industry demand.

The Boeing Co.

Technical Solution: Boeing has invested heavily in research and development of ultralight Kevlar composites for aerospace efficiency. Their approach involves integrating Kevlar with other advanced materials like carbon fiber and graphene to create hybrid composites that offer exceptional strength-to-weight ratios. Boeing's proprietary CFRP (Carbon Fiber Reinforced Polymer) technology, which incorporates Kevlar elements, has been implemented in the 787 Dreamliner, resulting in a 20% weight reduction compared to conventional aluminum designs[1]. The company has also developed a novel manufacturing process called Advanced Tape Laying (ATL) that allows for precise placement of Kevlar and other composite fibers, optimizing structural integrity while minimizing weight[2]. Boeing's research extends to nanocomposite materials, where Kevlar nanofibers are being explored to enhance impact resistance and durability of aerospace structures, potentially increasing the lifespan of aircraft components by up to 30%[3].

Strengths: Extensive resources for R&D, vertical integration capabilities, strong industry partnerships. Weaknesses: High development costs, long implementation cycles for new technologies, regulatory hurdles for novel materials in aircraft construction.

Innovative Kevlar Composite Patents

Development of basalt, kevlar fabric, mwcnt, and date palm filler bioepoxy composite for aircraft structures

PatentActiveIN202341059455A

Innovation

- A composite material is developed using basalt, Kevlar fabric, multi-walled carbon nanotubes (MWCNT), and date palm seed fillers reinforced with bio-epoxy polymer, fabricated through an ultrasonication-assisted wet layup method, which provides a sustainable, lightweight, and cost-effective solution for aircraft structures.

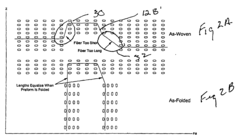

Minimum Distortion 3D Woven Preforms

PatentInactiveEP1310586A3

Innovation

- A 3D woven preform design that adjusts fiber lengths during weaving to ensure some fibers are too short in one area and too long in another, allowing for equalization when folded, preventing distortion and maintaining structural integrity.

Environmental Impact Assessment

The development and application of ultralight Kevlar composites in aerospace engineering bring both potential benefits and environmental concerns that require careful assessment. These advanced materials offer significant weight reduction in aircraft and spacecraft, leading to improved fuel efficiency and reduced emissions during operation. The manufacturing process of Kevlar composites, however, involves energy-intensive production methods and the use of chemical treatments that may have environmental implications.

One of the primary environmental advantages of ultralight Kevlar composites is their potential to decrease the overall environmental impact of aerospace operations. By reducing the weight of aircraft and spacecraft components, these materials contribute to lower fuel consumption and, consequently, reduced greenhouse gas emissions. This aligns with global efforts to mitigate climate change and improve the sustainability of air and space travel.

However, the production of Kevlar fibers and their composite materials presents several environmental challenges. The synthesis of aramid fibers, the base material for Kevlar, requires the use of strong acids and organic solvents. These chemicals, if not properly managed, can lead to air and water pollution. Additionally, the energy-intensive nature of Kevlar production contributes to indirect carbon emissions, which must be factored into the overall environmental assessment.

The disposal and recycling of Kevlar composites at the end of their lifecycle also pose environmental concerns. While Kevlar is known for its durability and resistance to degradation, these properties make it challenging to recycle or dispose of in an environmentally friendly manner. Research into effective recycling methods for Kevlar composites is ongoing, but current options are limited and often energy-intensive.

Another aspect to consider is the potential for Kevlar composite particles to enter the environment during manufacturing, use, or disposal. These microscopic fibers could potentially contribute to microplastic pollution, although the extent of this risk is not yet fully understood and requires further study.

On the positive side, the longevity and durability of Kevlar composites may lead to reduced frequency of replacement and maintenance of aerospace components. This could result in fewer resources being consumed over time for manufacturing replacement parts, potentially offsetting some of the environmental costs associated with initial production.

In conclusion, while ultralight Kevlar composites offer promising benefits for aerospace efficiency, their environmental impact is complex and multifaceted. A comprehensive life cycle assessment is necessary to fully understand and quantify the environmental trade-offs involved in their development and application. Future research should focus on improving the sustainability of Kevlar production processes, enhancing recycling capabilities, and mitigating potential environmental risks associated with these advanced materials.

One of the primary environmental advantages of ultralight Kevlar composites is their potential to decrease the overall environmental impact of aerospace operations. By reducing the weight of aircraft and spacecraft components, these materials contribute to lower fuel consumption and, consequently, reduced greenhouse gas emissions. This aligns with global efforts to mitigate climate change and improve the sustainability of air and space travel.

However, the production of Kevlar fibers and their composite materials presents several environmental challenges. The synthesis of aramid fibers, the base material for Kevlar, requires the use of strong acids and organic solvents. These chemicals, if not properly managed, can lead to air and water pollution. Additionally, the energy-intensive nature of Kevlar production contributes to indirect carbon emissions, which must be factored into the overall environmental assessment.

The disposal and recycling of Kevlar composites at the end of their lifecycle also pose environmental concerns. While Kevlar is known for its durability and resistance to degradation, these properties make it challenging to recycle or dispose of in an environmentally friendly manner. Research into effective recycling methods for Kevlar composites is ongoing, but current options are limited and often energy-intensive.

Another aspect to consider is the potential for Kevlar composite particles to enter the environment during manufacturing, use, or disposal. These microscopic fibers could potentially contribute to microplastic pollution, although the extent of this risk is not yet fully understood and requires further study.

On the positive side, the longevity and durability of Kevlar composites may lead to reduced frequency of replacement and maintenance of aerospace components. This could result in fewer resources being consumed over time for manufacturing replacement parts, potentially offsetting some of the environmental costs associated with initial production.

In conclusion, while ultralight Kevlar composites offer promising benefits for aerospace efficiency, their environmental impact is complex and multifaceted. A comprehensive life cycle assessment is necessary to fully understand and quantify the environmental trade-offs involved in their development and application. Future research should focus on improving the sustainability of Kevlar production processes, enhancing recycling capabilities, and mitigating potential environmental risks associated with these advanced materials.

Certification and Safety Standards

The certification and safety standards for ultralight Kevlar composites in aerospace applications are critical to ensuring the reliability and performance of these materials in high-stakes environments. The aerospace industry is subject to stringent regulations, and any new material must undergo rigorous testing and certification processes before being approved for use in aircraft or spacecraft.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies responsible for setting and enforcing safety standards in the aerospace industry. These organizations have established comprehensive guidelines for the certification of composite materials, including ultralight Kevlar composites.

One of the key certification standards for aerospace composites is the FAA's Advisory Circular AC 20-107B, which provides guidance on the certification of composite aircraft structures. This document outlines the requirements for material qualification, design allowables, structural substantiation, and manufacturing processes. For ultralight Kevlar composites, manufacturers must demonstrate compliance with these guidelines to obtain certification.

Safety standards for aerospace composites also address fire resistance and toxicity. The FAA's regulations, such as 14 CFR 25.853, specify the flammability requirements for materials used in aircraft interiors. Ultralight Kevlar composites must meet or exceed these standards to be considered for use in aerospace applications.

Mechanical property testing is another crucial aspect of certification. Standards such as ASTM D3039 for tensile properties and ASTM D7264 for flexural properties are commonly used to evaluate the performance of composite materials. For ultralight Kevlar composites, these tests help determine their strength-to-weight ratio and overall structural integrity.

Environmental testing is also a significant component of the certification process. Standards like RTCA DO-160 outline the environmental conditions that aerospace materials must withstand, including temperature extremes, humidity, and vibration. Ultralight Kevlar composites must demonstrate their ability to maintain their properties under these challenging conditions.

Quality control and manufacturing process validation are essential elements of safety standards for aerospace composites. The AS9100 quality management system, specific to the aerospace industry, provides a framework for ensuring consistent production of high-quality composite materials. Manufacturers of ultralight Kevlar composites must implement robust quality control measures to meet these standards.

As the development of ultralight Kevlar composites progresses, it is likely that new certification and safety standards will emerge to address the unique properties and applications of these materials. Ongoing collaboration between regulatory bodies, industry stakeholders, and research institutions will be crucial in developing and refining these standards to ensure the safe and effective use of ultralight Kevlar composites in aerospace applications.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies responsible for setting and enforcing safety standards in the aerospace industry. These organizations have established comprehensive guidelines for the certification of composite materials, including ultralight Kevlar composites.

One of the key certification standards for aerospace composites is the FAA's Advisory Circular AC 20-107B, which provides guidance on the certification of composite aircraft structures. This document outlines the requirements for material qualification, design allowables, structural substantiation, and manufacturing processes. For ultralight Kevlar composites, manufacturers must demonstrate compliance with these guidelines to obtain certification.

Safety standards for aerospace composites also address fire resistance and toxicity. The FAA's regulations, such as 14 CFR 25.853, specify the flammability requirements for materials used in aircraft interiors. Ultralight Kevlar composites must meet or exceed these standards to be considered for use in aerospace applications.

Mechanical property testing is another crucial aspect of certification. Standards such as ASTM D3039 for tensile properties and ASTM D7264 for flexural properties are commonly used to evaluate the performance of composite materials. For ultralight Kevlar composites, these tests help determine their strength-to-weight ratio and overall structural integrity.

Environmental testing is also a significant component of the certification process. Standards like RTCA DO-160 outline the environmental conditions that aerospace materials must withstand, including temperature extremes, humidity, and vibration. Ultralight Kevlar composites must demonstrate their ability to maintain their properties under these challenging conditions.

Quality control and manufacturing process validation are essential elements of safety standards for aerospace composites. The AS9100 quality management system, specific to the aerospace industry, provides a framework for ensuring consistent production of high-quality composite materials. Manufacturers of ultralight Kevlar composites must implement robust quality control measures to meet these standards.

As the development of ultralight Kevlar composites progresses, it is likely that new certification and safety standards will emerge to address the unique properties and applications of these materials. Ongoing collaboration between regulatory bodies, industry stakeholders, and research institutions will be crucial in developing and refining these standards to ensure the safe and effective use of ultralight Kevlar composites in aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!