The Future of Regenerative Braking in Flywheel Energy Storage Systems

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flywheel Braking Evolution

The evolution of flywheel braking systems in energy storage has been marked by significant technological advancements and innovative approaches. Initially, flywheels were primarily used in mechanical systems for energy storage and power smoothing. However, the concept of regenerative braking using flywheels gained traction in the late 20th century, particularly in automotive and transportation applications.

In the 1970s and 1980s, researchers began exploring the potential of flywheel energy storage systems (FESS) for regenerative braking in vehicles. Early prototypes demonstrated the ability to capture and store kinetic energy during deceleration, which could then be used to assist acceleration. These systems were bulky and had limited energy storage capacity, but they laid the foundation for future developments.

The 1990s saw a shift towards more advanced materials and designs. High-strength composite materials allowed for the construction of lighter and faster-spinning flywheels, significantly increasing energy density. Magnetic bearings were introduced to reduce friction and improve efficiency. These advancements made FESS more viable for practical applications in vehicles and stationary energy storage.

By the early 2000s, flywheel-based regenerative braking systems were being tested in various transportation sectors, including passenger vehicles, buses, and trains. The automotive industry, in particular, showed interest in integrating FESS with hybrid powertrains to enhance fuel efficiency and reduce emissions. Concurrently, research into high-speed electric motors and power electronics improved the energy conversion efficiency between mechanical and electrical forms.

The past decade has witnessed a surge in research focused on optimizing flywheel design for specific applications. Advanced control algorithms have been developed to maximize energy recovery and minimize losses during braking and acceleration cycles. Integration with other energy storage technologies, such as batteries and supercapacitors, has led to hybrid systems that leverage the strengths of each technology.

Recent developments have also addressed safety concerns associated with high-speed rotating masses. Containment systems and fail-safe mechanisms have been improved, making FESS more reliable and suitable for widespread adoption. Additionally, the use of vacuum-sealed housings and advanced bearing systems has further reduced energy losses, enhancing overall system efficiency.

Looking towards the future, the evolution of flywheel braking systems is likely to focus on increasing energy density, improving system integration, and reducing costs. Emerging technologies such as graphene-based composites and superconducting magnetic bearings hold promise for pushing the boundaries of flywheel performance. As the demand for efficient energy storage solutions grows, particularly in the context of renewable energy integration and electric mobility, flywheel-based regenerative braking systems are poised to play an increasingly important role in sustainable energy management.

In the 1970s and 1980s, researchers began exploring the potential of flywheel energy storage systems (FESS) for regenerative braking in vehicles. Early prototypes demonstrated the ability to capture and store kinetic energy during deceleration, which could then be used to assist acceleration. These systems were bulky and had limited energy storage capacity, but they laid the foundation for future developments.

The 1990s saw a shift towards more advanced materials and designs. High-strength composite materials allowed for the construction of lighter and faster-spinning flywheels, significantly increasing energy density. Magnetic bearings were introduced to reduce friction and improve efficiency. These advancements made FESS more viable for practical applications in vehicles and stationary energy storage.

By the early 2000s, flywheel-based regenerative braking systems were being tested in various transportation sectors, including passenger vehicles, buses, and trains. The automotive industry, in particular, showed interest in integrating FESS with hybrid powertrains to enhance fuel efficiency and reduce emissions. Concurrently, research into high-speed electric motors and power electronics improved the energy conversion efficiency between mechanical and electrical forms.

The past decade has witnessed a surge in research focused on optimizing flywheel design for specific applications. Advanced control algorithms have been developed to maximize energy recovery and minimize losses during braking and acceleration cycles. Integration with other energy storage technologies, such as batteries and supercapacitors, has led to hybrid systems that leverage the strengths of each technology.

Recent developments have also addressed safety concerns associated with high-speed rotating masses. Containment systems and fail-safe mechanisms have been improved, making FESS more reliable and suitable for widespread adoption. Additionally, the use of vacuum-sealed housings and advanced bearing systems has further reduced energy losses, enhancing overall system efficiency.

Looking towards the future, the evolution of flywheel braking systems is likely to focus on increasing energy density, improving system integration, and reducing costs. Emerging technologies such as graphene-based composites and superconducting magnetic bearings hold promise for pushing the boundaries of flywheel performance. As the demand for efficient energy storage solutions grows, particularly in the context of renewable energy integration and electric mobility, flywheel-based regenerative braking systems are poised to play an increasingly important role in sustainable energy management.

Market Demand Analysis

The market demand for regenerative braking in flywheel energy storage systems (FESS) is experiencing significant growth, driven by the increasing focus on energy efficiency and sustainability across various industries. The automotive sector, in particular, has shown a strong interest in this technology as it aligns with the global push towards electrification and reduced emissions.

In the automotive market, the demand for regenerative braking systems is primarily fueled by the rapid expansion of electric and hybrid vehicle production. As governments worldwide implement stricter emissions regulations, automakers are increasingly incorporating regenerative braking technologies to improve overall vehicle efficiency. This trend is expected to continue, with the global electric vehicle market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years.

The public transportation sector also presents a substantial market opportunity for FESS with regenerative braking. Bus and train operators are seeking ways to reduce energy consumption and operating costs, making regenerative braking systems an attractive solution. Several major cities have already begun implementing these systems in their public transit fleets, with positive results in terms of energy savings and reduced maintenance costs.

Industrial applications represent another growing market for FESS with regenerative braking. In manufacturing and material handling, where frequent start-stop operations are common, the energy recovery potential of these systems is significant. The ability to capture and reuse energy that would otherwise be lost as heat during braking processes is particularly appealing to industries looking to optimize their energy usage and reduce operational expenses.

The renewable energy sector is also showing increased interest in FESS for grid stabilization and energy storage. As the penetration of intermittent renewable energy sources like wind and solar increases, the need for efficient energy storage solutions becomes more critical. FESS with regenerative braking capabilities offer a promising solution for short-term energy storage and rapid response to grid fluctuations.

Despite the growing market demand, there are still challenges to widespread adoption. The initial cost of implementing FESS with regenerative braking can be high, which may deter some potential users. Additionally, there is a need for further education and awareness about the long-term benefits and return on investment of these systems.

Looking ahead, the market for FESS with regenerative braking is expected to expand as technological advancements lead to more efficient and cost-effective solutions. The increasing emphasis on circular economy principles and energy conservation across industries is likely to drive further demand for these systems in the coming years.

In the automotive market, the demand for regenerative braking systems is primarily fueled by the rapid expansion of electric and hybrid vehicle production. As governments worldwide implement stricter emissions regulations, automakers are increasingly incorporating regenerative braking technologies to improve overall vehicle efficiency. This trend is expected to continue, with the global electric vehicle market projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years.

The public transportation sector also presents a substantial market opportunity for FESS with regenerative braking. Bus and train operators are seeking ways to reduce energy consumption and operating costs, making regenerative braking systems an attractive solution. Several major cities have already begun implementing these systems in their public transit fleets, with positive results in terms of energy savings and reduced maintenance costs.

Industrial applications represent another growing market for FESS with regenerative braking. In manufacturing and material handling, where frequent start-stop operations are common, the energy recovery potential of these systems is significant. The ability to capture and reuse energy that would otherwise be lost as heat during braking processes is particularly appealing to industries looking to optimize their energy usage and reduce operational expenses.

The renewable energy sector is also showing increased interest in FESS for grid stabilization and energy storage. As the penetration of intermittent renewable energy sources like wind and solar increases, the need for efficient energy storage solutions becomes more critical. FESS with regenerative braking capabilities offer a promising solution for short-term energy storage and rapid response to grid fluctuations.

Despite the growing market demand, there are still challenges to widespread adoption. The initial cost of implementing FESS with regenerative braking can be high, which may deter some potential users. Additionally, there is a need for further education and awareness about the long-term benefits and return on investment of these systems.

Looking ahead, the market for FESS with regenerative braking is expected to expand as technological advancements lead to more efficient and cost-effective solutions. The increasing emphasis on circular economy principles and energy conservation across industries is likely to drive further demand for these systems in the coming years.

Technical Challenges

Regenerative braking in flywheel energy storage systems faces several significant technical challenges that need to be addressed for widespread adoption and optimal performance. One of the primary issues is the high-speed rotation of flywheels, which can reach up to 100,000 RPM. At these speeds, material strength becomes a critical factor, as the centrifugal forces exerted on the flywheel can lead to structural failure if not properly managed.

The development of advanced materials capable of withstanding these extreme forces while maintaining low weight is crucial. Carbon fiber composites have shown promise, but further research is needed to optimize their performance and reduce costs. Additionally, the integration of these materials into complex flywheel designs presents manufacturing challenges that must be overcome.

Another significant hurdle is the minimization of energy losses due to friction. While magnetic bearings have been employed to reduce mechanical friction, they introduce their own set of challenges, including the need for precise control systems and potential instability at high speeds. The development of more efficient and reliable bearing systems remains an active area of research.

Heat generation and management also pose substantial technical difficulties. The high-speed rotation and frequent energy conversions in regenerative braking systems can lead to significant heat buildup. Effective cooling mechanisms must be designed to prevent overheating and maintain system efficiency. This is particularly challenging in compact automotive applications where space is limited.

The control and power electronics required for efficient energy conversion and storage present another set of technical challenges. Rapid and precise control of the flywheel's speed during braking and acceleration events is essential for maximizing energy recovery. This requires sophisticated control algorithms and high-performance power electronics capable of handling large power flows in both directions.

Safety concerns also need to be addressed, particularly in mobile applications. The high rotational energy of flywheels poses risks in the event of a crash or system failure. Developing fail-safe mechanisms and containment systems that can effectively manage these risks without significantly increasing weight or cost is a critical area of ongoing research.

Lastly, the integration of flywheel energy storage systems with existing vehicle architectures presents significant engineering challenges. This includes optimizing the placement of the flywheel within the vehicle, managing the gyroscopic effects on vehicle dynamics, and developing efficient interfaces with conventional braking and propulsion systems.

The development of advanced materials capable of withstanding these extreme forces while maintaining low weight is crucial. Carbon fiber composites have shown promise, but further research is needed to optimize their performance and reduce costs. Additionally, the integration of these materials into complex flywheel designs presents manufacturing challenges that must be overcome.

Another significant hurdle is the minimization of energy losses due to friction. While magnetic bearings have been employed to reduce mechanical friction, they introduce their own set of challenges, including the need for precise control systems and potential instability at high speeds. The development of more efficient and reliable bearing systems remains an active area of research.

Heat generation and management also pose substantial technical difficulties. The high-speed rotation and frequent energy conversions in regenerative braking systems can lead to significant heat buildup. Effective cooling mechanisms must be designed to prevent overheating and maintain system efficiency. This is particularly challenging in compact automotive applications where space is limited.

The control and power electronics required for efficient energy conversion and storage present another set of technical challenges. Rapid and precise control of the flywheel's speed during braking and acceleration events is essential for maximizing energy recovery. This requires sophisticated control algorithms and high-performance power electronics capable of handling large power flows in both directions.

Safety concerns also need to be addressed, particularly in mobile applications. The high rotational energy of flywheels poses risks in the event of a crash or system failure. Developing fail-safe mechanisms and containment systems that can effectively manage these risks without significantly increasing weight or cost is a critical area of ongoing research.

Lastly, the integration of flywheel energy storage systems with existing vehicle architectures presents significant engineering challenges. This includes optimizing the placement of the flywheel within the vehicle, managing the gyroscopic effects on vehicle dynamics, and developing efficient interfaces with conventional braking and propulsion systems.

Current Flywheel Solutions

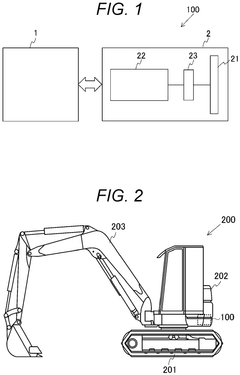

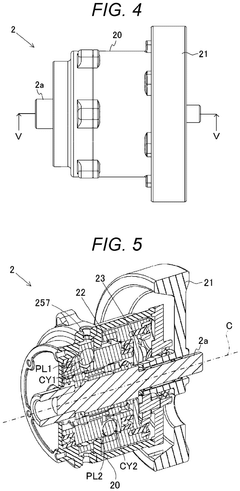

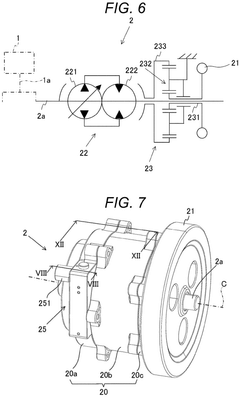

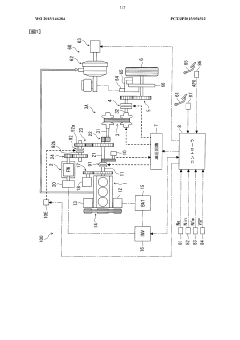

01 Flywheel energy storage system design

Flywheel energy storage systems are designed to capture and store kinetic energy during braking. These systems typically consist of a rotating mass connected to an electric motor/generator. When the vehicle brakes, the kinetic energy is converted into electrical energy, which is then used to spin up the flywheel. This stored energy can be later released to assist in acceleration, improving overall energy efficiency.- Flywheel energy storage system design: Flywheel energy storage systems are designed to capture and store kinetic energy during braking. These systems typically consist of a rotating mass connected to an electric motor/generator. When the vehicle brakes, the kinetic energy is converted to electrical energy, which is then used to spin up the flywheel. This stored energy can be later released to assist in acceleration, improving overall energy efficiency.

- Integration with regenerative braking systems: Flywheel energy storage systems are often integrated with regenerative braking systems in vehicles. During deceleration, the regenerative braking system converts kinetic energy into electrical energy, which is then used to accelerate the flywheel. This integration allows for efficient energy recovery and storage, reducing energy waste and improving overall vehicle efficiency.

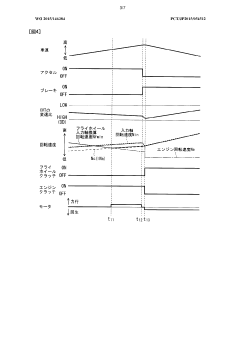

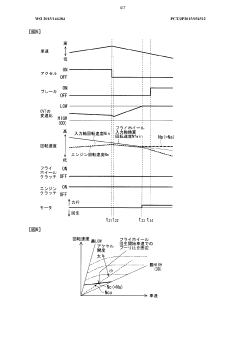

- Control strategies for energy management: Advanced control strategies are employed to manage the energy flow between the flywheel, regenerative braking system, and vehicle powertrain. These strategies optimize energy recovery during braking, energy storage in the flywheel, and energy release during acceleration. The control systems also ensure smooth operation and seamless integration with other vehicle systems.

- Application in hybrid and electric vehicles: Flywheel energy storage systems with regenerative braking are particularly beneficial in hybrid and electric vehicles. They complement battery systems by providing rapid energy storage and release capabilities, which can extend battery life and improve overall vehicle performance. These systems are especially effective in scenarios involving frequent starts and stops, such as urban driving.

- Mechanical and safety considerations: The design of flywheel energy storage systems must address mechanical and safety considerations. This includes managing the high rotational speeds of the flywheel, ensuring proper containment in case of failure, and minimizing gyroscopic effects on vehicle handling. Advanced materials and containment designs are used to enhance safety and reliability while maximizing energy storage capacity.

02 Integration with regenerative braking systems

Flywheel energy storage systems are often integrated with regenerative braking systems in vehicles. During deceleration, the regenerative braking system converts kinetic energy into electrical energy, which is then used to accelerate the flywheel. This integration allows for efficient energy recovery and storage, reducing energy waste and improving overall vehicle efficiency.Expand Specific Solutions03 Control strategies for energy management

Advanced control strategies are employed to optimize the energy management between the flywheel storage system and the vehicle's powertrain. These strategies determine when to store energy in the flywheel, when to release it, and how to distribute power between the flywheel and the main power source. Such control systems aim to maximize energy efficiency and vehicle performance.Expand Specific Solutions04 Application in hybrid and electric vehicles

Flywheel energy storage systems with regenerative braking are particularly beneficial in hybrid and electric vehicles. They complement battery systems by handling rapid charge and discharge cycles, reducing battery stress and extending its life. These systems can provide additional power for acceleration and help in maintaining consistent battery charge levels.Expand Specific Solutions05 Mechanical and safety considerations

The design of flywheel energy storage systems involves careful consideration of mechanical aspects and safety features. This includes the use of high-strength materials for the flywheel, advanced bearing systems to reduce friction, and containment systems to ensure safety in case of failure. Vacuum or low-pressure environments are often used to minimize air resistance and energy losses.Expand Specific Solutions

Industry Leaders

The regenerative braking market in flywheel energy storage systems is in a growth phase, with increasing adoption across automotive and industrial sectors. The market size is expanding, driven by the push for energy efficiency and sustainability. Technologically, the field is advancing rapidly, with companies like Torus, Inc. and Ford Global Technologies LLC leading innovation. State Power Investment Corporation and AUDI AG are also making significant strides. While the technology is maturing, there's still room for improvement in efficiency, cost-effectiveness, and integration with other systems. The competitive landscape is diverse, featuring both established automotive giants and specialized energy storage startups, indicating a dynamic and evolving market with potential for further growth and technological breakthroughs.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a hybrid flywheel-battery system for regenerative braking. This innovative approach combines a compact flywheel with a small battery pack to optimize energy recovery and storage. The flywheel, made of advanced composite materials, operates at speeds up to 50,000 rpm and is coupled with a high-efficiency electric motor-generator[3]. Ford's system uses a continuously variable transmission (CVT) to manage power flow between the flywheel and the vehicle's drivetrain. The integrated control system dynamically allocates energy between the flywheel and battery based on driving conditions and energy demands[4]. Ford has also developed predictive algorithms that use GPS and traffic data to anticipate braking events and maximize energy recovery efficiency.

Strengths: Balanced approach combining the rapid response of flywheels with the energy density of batteries, potentially lower cost than pure flywheel systems. Weaknesses: Added complexity from managing two energy storage systems, potential reliability concerns with the CVT.

AUDI AG

Technical Solution: Audi has developed a cutting-edge Flywheel Energy Storage System (FESS) for regenerative braking, particularly focused on high-performance vehicles. Their system utilizes a carbon-fiber reinforced polymer flywheel that can reach speeds of up to 65,000 rpm, storing kinetic energy efficiently[5]. Audi's FESS is integrated with an electric motor-generator and a specialized transmission system that allows for rapid energy transfer between the flywheel and the vehicle's powertrain. The company has implemented advanced control algorithms that optimize energy recovery based on driving style and road conditions. Audi's system also incorporates active magnetic bearings to minimize friction losses and enhance overall efficiency[6]. The FESS is designed to be compact and lightweight, making it suitable for integration into various vehicle platforms without significantly impacting weight distribution or handling characteristics.

Strengths: High power density, rapid energy transfer capabilities, and integration with high-performance vehicle dynamics. Weaknesses: Potentially higher cost due to advanced materials and complex integration, limited energy storage capacity compared to battery systems.

Key Flywheel Innovations

Energy storage device and work machine

PatentPendingEP4431326A1

Innovation

- Incorporating a hydraulic element between the motor and the flywheel to change rotation speed, reducing the need for a clutch and minimizing frictional losses, while using a reducer to optimize energy storage and release.

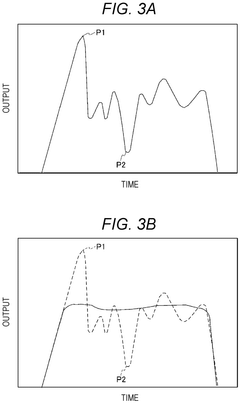

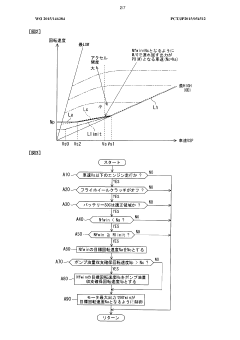

Flywheel regeneration system

PatentWO2015146384A1

Innovation

- A flywheel regenerative system that employs rotational speed difference control using a motor to reduce the rotational speed difference between the frictional engagement elements before engagement, allowing for efficient energy transfer and minimizing heat-generated energy loss by setting a target rotation speed based on vehicle speed and engaging the clutch while it slips.

Energy Efficiency Impact

The implementation of regenerative braking in flywheel energy storage systems (FESS) has the potential to significantly impact energy efficiency across various applications. By capturing and storing kinetic energy that would otherwise be lost as heat during braking, FESS can substantially reduce overall energy consumption and improve system performance.

In automotive applications, regenerative braking with FESS can increase the energy efficiency of vehicles by up to 30%. This improvement is particularly notable in urban driving scenarios with frequent stops and starts. The stored energy can be used to assist acceleration, reducing the load on the primary power source and decreasing fuel consumption in conventional vehicles or extending the range of electric vehicles.

For rail transportation, the impact of FESS-based regenerative braking is even more pronounced. Studies have shown that energy savings of up to 40% can be achieved in metro systems, where trains make frequent stops. The recaptured energy can be used to power auxiliary systems or be fed back into the grid, reducing the overall energy demand of the rail network.

In industrial applications, such as large machinery and manufacturing equipment, FESS regenerative braking can lead to energy savings of 20-35%. This efficiency gain is particularly valuable in high-cycle operations where frequent starts and stops are common, such as in material handling equipment or production line machinery.

The integration of FESS with renewable energy sources, such as wind and solar power, can further enhance energy efficiency. By using flywheels to store excess energy during peak production periods and releasing it during low production times, the overall efficiency and reliability of renewable energy systems can be improved by up to 25%.

Moreover, the fast response time of FESS makes it ideal for grid stabilization and power quality improvement. When used in conjunction with traditional power generation methods, FESS can help smooth out power fluctuations, reducing energy losses associated with grid instability by up to 15%.

As FESS technology continues to advance, the energy efficiency impact is expected to grow. Improvements in materials science, such as the development of high-strength, low-density composites for flywheel construction, promise to increase energy storage capacity and reduce losses. Additionally, advancements in magnetic bearings and vacuum technologies are likely to further minimize friction losses, pushing the overall system efficiency even higher.

In automotive applications, regenerative braking with FESS can increase the energy efficiency of vehicles by up to 30%. This improvement is particularly notable in urban driving scenarios with frequent stops and starts. The stored energy can be used to assist acceleration, reducing the load on the primary power source and decreasing fuel consumption in conventional vehicles or extending the range of electric vehicles.

For rail transportation, the impact of FESS-based regenerative braking is even more pronounced. Studies have shown that energy savings of up to 40% can be achieved in metro systems, where trains make frequent stops. The recaptured energy can be used to power auxiliary systems or be fed back into the grid, reducing the overall energy demand of the rail network.

In industrial applications, such as large machinery and manufacturing equipment, FESS regenerative braking can lead to energy savings of 20-35%. This efficiency gain is particularly valuable in high-cycle operations where frequent starts and stops are common, such as in material handling equipment or production line machinery.

The integration of FESS with renewable energy sources, such as wind and solar power, can further enhance energy efficiency. By using flywheels to store excess energy during peak production periods and releasing it during low production times, the overall efficiency and reliability of renewable energy systems can be improved by up to 25%.

Moreover, the fast response time of FESS makes it ideal for grid stabilization and power quality improvement. When used in conjunction with traditional power generation methods, FESS can help smooth out power fluctuations, reducing energy losses associated with grid instability by up to 15%.

As FESS technology continues to advance, the energy efficiency impact is expected to grow. Improvements in materials science, such as the development of high-strength, low-density composites for flywheel construction, promise to increase energy storage capacity and reduce losses. Additionally, advancements in magnetic bearings and vacuum technologies are likely to further minimize friction losses, pushing the overall system efficiency even higher.

Safety Considerations

Safety considerations are paramount in the development and implementation of flywheel energy storage systems (FESS) with regenerative braking capabilities. As these systems operate at high rotational speeds, potential risks must be thoroughly addressed to ensure safe and reliable operation.

One of the primary safety concerns is the risk of catastrophic failure due to mechanical stress. Flywheels rotating at high speeds are subject to significant centrifugal forces, which can lead to material fatigue or sudden disintegration if not properly managed. To mitigate this risk, advanced materials such as carbon fiber composites are being explored for flywheel construction, offering superior strength-to-weight ratios and reduced risk of fragmentation in case of failure.

Containment is another critical safety aspect. In the event of a flywheel failure, robust containment systems must be in place to prevent the release of high-energy debris. Research is ongoing to develop advanced containment technologies that can effectively absorb and dissipate the energy of a failing flywheel while minimizing the overall system footprint and weight.

Bearing systems play a crucial role in FESS safety. Traditional mechanical bearings can introduce friction and wear, potentially leading to system instability or failure. Magnetic bearings are increasingly being adopted as a safer alternative, offering reduced friction, lower maintenance requirements, and enhanced system longevity. However, the integration of magnetic bearings introduces new challenges, such as the need for reliable power systems and backup mechanical bearings in case of power failure.

Thermal management is another important safety consideration. The high-speed rotation of flywheels can generate significant heat, which must be effectively dissipated to prevent overheating and potential system failure. Advanced cooling systems and thermal management strategies are being developed to address this challenge, including the use of innovative materials with superior heat dissipation properties.

Safety systems and protocols are essential for monitoring and controlling FESS operation. This includes the development of sophisticated sensors and control algorithms to detect anomalies, predict potential failures, and initiate safe shutdown procedures when necessary. Additionally, fail-safe mechanisms must be incorporated to ensure that the system can be safely decelerated and stopped in case of power loss or other emergency situations.

As FESS technology advances, regulatory frameworks and safety standards must evolve to keep pace. Collaboration between industry, research institutions, and regulatory bodies is crucial to establish comprehensive safety guidelines that address the unique challenges posed by high-speed flywheel systems. This includes developing standardized testing procedures, certification processes, and operational protocols to ensure consistent safety standards across different applications and environments.

One of the primary safety concerns is the risk of catastrophic failure due to mechanical stress. Flywheels rotating at high speeds are subject to significant centrifugal forces, which can lead to material fatigue or sudden disintegration if not properly managed. To mitigate this risk, advanced materials such as carbon fiber composites are being explored for flywheel construction, offering superior strength-to-weight ratios and reduced risk of fragmentation in case of failure.

Containment is another critical safety aspect. In the event of a flywheel failure, robust containment systems must be in place to prevent the release of high-energy debris. Research is ongoing to develop advanced containment technologies that can effectively absorb and dissipate the energy of a failing flywheel while minimizing the overall system footprint and weight.

Bearing systems play a crucial role in FESS safety. Traditional mechanical bearings can introduce friction and wear, potentially leading to system instability or failure. Magnetic bearings are increasingly being adopted as a safer alternative, offering reduced friction, lower maintenance requirements, and enhanced system longevity. However, the integration of magnetic bearings introduces new challenges, such as the need for reliable power systems and backup mechanical bearings in case of power failure.

Thermal management is another important safety consideration. The high-speed rotation of flywheels can generate significant heat, which must be effectively dissipated to prevent overheating and potential system failure. Advanced cooling systems and thermal management strategies are being developed to address this challenge, including the use of innovative materials with superior heat dissipation properties.

Safety systems and protocols are essential for monitoring and controlling FESS operation. This includes the development of sophisticated sensors and control algorithms to detect anomalies, predict potential failures, and initiate safe shutdown procedures when necessary. Additionally, fail-safe mechanisms must be incorporated to ensure that the system can be safely decelerated and stopped in case of power loss or other emergency situations.

As FESS technology advances, regulatory frameworks and safety standards must evolve to keep pace. Collaboration between industry, research institutions, and regulatory bodies is crucial to establish comprehensive safety guidelines that address the unique challenges posed by high-speed flywheel systems. This includes developing standardized testing procedures, certification processes, and operational protocols to ensure consistent safety standards across different applications and environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!