Understanding Battery Thermal Management in Regenerative Braking Mechanisms

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Regen Braking Thermal Management Background

Regenerative braking has emerged as a crucial technology in the automotive industry, particularly in electric and hybrid vehicles. This innovative mechanism allows vehicles to recover and store energy that would otherwise be lost during deceleration, significantly improving overall energy efficiency. However, the process of energy recovery and storage generates substantial heat, necessitating effective thermal management strategies for the battery systems involved.

The concept of regenerative braking dates back to the early 20th century, with its first practical applications in electric locomotives. As the automotive industry shifted towards electrification, the technology gained renewed interest and importance. The primary goal of regenerative braking is to capture kinetic energy during deceleration and convert it into electrical energy, which can then be stored in the vehicle's battery for later use.

In recent years, the rapid advancement of electric vehicle (EV) technology has led to significant improvements in regenerative braking systems. Modern EVs can recover up to 70% of the kinetic energy during braking, contributing to extended driving ranges and reduced energy consumption. However, this increased energy recovery also presents challenges in terms of heat generation and dissipation.

The thermal management of batteries during regenerative braking is critical for several reasons. Firstly, excessive heat can degrade battery performance and lifespan, potentially leading to reduced efficiency and increased maintenance costs. Secondly, thermal runaway, a phenomenon where battery temperature increases uncontrollably, poses serious safety risks if not properly managed. Lastly, maintaining optimal battery temperature is essential for ensuring consistent performance across various driving conditions and environments.

As the automotive industry continues to evolve, the importance of effective thermal management in regenerative braking systems has become increasingly apparent. Manufacturers and researchers are exploring various approaches to address this challenge, including advanced cooling systems, smart energy management algorithms, and innovative battery designs. The development of more efficient and reliable thermal management solutions is crucial for the widespread adoption of electric vehicles and the overall sustainability of the transportation sector.

Understanding the background of regenerative braking thermal management provides a foundation for addressing the complex technical challenges associated with this technology. It highlights the need for interdisciplinary approaches, combining expertise in areas such as electrochemistry, thermal engineering, and control systems. As the industry progresses, the focus on optimizing thermal management in regenerative braking mechanisms will play a pivotal role in shaping the future of electric mobility.

The concept of regenerative braking dates back to the early 20th century, with its first practical applications in electric locomotives. As the automotive industry shifted towards electrification, the technology gained renewed interest and importance. The primary goal of regenerative braking is to capture kinetic energy during deceleration and convert it into electrical energy, which can then be stored in the vehicle's battery for later use.

In recent years, the rapid advancement of electric vehicle (EV) technology has led to significant improvements in regenerative braking systems. Modern EVs can recover up to 70% of the kinetic energy during braking, contributing to extended driving ranges and reduced energy consumption. However, this increased energy recovery also presents challenges in terms of heat generation and dissipation.

The thermal management of batteries during regenerative braking is critical for several reasons. Firstly, excessive heat can degrade battery performance and lifespan, potentially leading to reduced efficiency and increased maintenance costs. Secondly, thermal runaway, a phenomenon where battery temperature increases uncontrollably, poses serious safety risks if not properly managed. Lastly, maintaining optimal battery temperature is essential for ensuring consistent performance across various driving conditions and environments.

As the automotive industry continues to evolve, the importance of effective thermal management in regenerative braking systems has become increasingly apparent. Manufacturers and researchers are exploring various approaches to address this challenge, including advanced cooling systems, smart energy management algorithms, and innovative battery designs. The development of more efficient and reliable thermal management solutions is crucial for the widespread adoption of electric vehicles and the overall sustainability of the transportation sector.

Understanding the background of regenerative braking thermal management provides a foundation for addressing the complex technical challenges associated with this technology. It highlights the need for interdisciplinary approaches, combining expertise in areas such as electrochemistry, thermal engineering, and control systems. As the industry progresses, the focus on optimizing thermal management in regenerative braking mechanisms will play a pivotal role in shaping the future of electric mobility.

EV Market Demand Analysis

The electric vehicle (EV) market has experienced significant growth in recent years, driven by increasing environmental awareness, government incentives, and technological advancements. This growth has led to a surge in demand for efficient battery thermal management systems, particularly in the context of regenerative braking mechanisms.

Market research indicates that the global EV market is expected to continue its rapid expansion, with a compound annual growth rate (CAGR) projected to exceed 20% over the next decade. This growth is fueled by several factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure.

As EVs become more mainstream, consumers are increasingly focusing on performance and range. This has placed a spotlight on battery thermal management, especially during high-energy events like regenerative braking. Efficient thermal management systems can significantly impact an EV's overall performance, range, and battery longevity, making it a critical factor in consumer purchasing decisions.

The demand for advanced battery thermal management solutions in regenerative braking systems is particularly strong in regions with high EV adoption rates, such as China, Europe, and North America. These markets are characterized by consumers who prioritize vehicle efficiency and are willing to pay a premium for advanced technologies that enhance performance and extend battery life.

Industry surveys reveal that over 70% of potential EV buyers consider battery performance and longevity as key factors in their purchasing decisions. This underscores the importance of effective thermal management systems, especially those that can handle the heat generated during regenerative braking.

The commercial vehicle sector, including electric buses and trucks, is also driving demand for advanced battery thermal management solutions. These vehicles often rely heavily on regenerative braking due to their frequent stops and starts, making efficient heat dissipation crucial for maintaining battery health and performance.

Furthermore, the growing trend towards fast charging capabilities in EVs is intensifying the need for robust thermal management systems. As charging speeds increase, so does the heat generated during the charging process, creating additional thermal management challenges that overlap with those encountered during regenerative braking.

In conclusion, the market demand for advanced battery thermal management systems in regenerative braking mechanisms is strong and growing. This demand is driven by the overall growth of the EV market, increasing consumer awareness of battery performance, and the push for more efficient and longer-lasting electric vehicles across various segments of the automotive industry.

Market research indicates that the global EV market is expected to continue its rapid expansion, with a compound annual growth rate (CAGR) projected to exceed 20% over the next decade. This growth is fueled by several factors, including stricter emissions regulations, falling battery costs, and improving charging infrastructure.

As EVs become more mainstream, consumers are increasingly focusing on performance and range. This has placed a spotlight on battery thermal management, especially during high-energy events like regenerative braking. Efficient thermal management systems can significantly impact an EV's overall performance, range, and battery longevity, making it a critical factor in consumer purchasing decisions.

The demand for advanced battery thermal management solutions in regenerative braking systems is particularly strong in regions with high EV adoption rates, such as China, Europe, and North America. These markets are characterized by consumers who prioritize vehicle efficiency and are willing to pay a premium for advanced technologies that enhance performance and extend battery life.

Industry surveys reveal that over 70% of potential EV buyers consider battery performance and longevity as key factors in their purchasing decisions. This underscores the importance of effective thermal management systems, especially those that can handle the heat generated during regenerative braking.

The commercial vehicle sector, including electric buses and trucks, is also driving demand for advanced battery thermal management solutions. These vehicles often rely heavily on regenerative braking due to their frequent stops and starts, making efficient heat dissipation crucial for maintaining battery health and performance.

Furthermore, the growing trend towards fast charging capabilities in EVs is intensifying the need for robust thermal management systems. As charging speeds increase, so does the heat generated during the charging process, creating additional thermal management challenges that overlap with those encountered during regenerative braking.

In conclusion, the market demand for advanced battery thermal management systems in regenerative braking mechanisms is strong and growing. This demand is driven by the overall growth of the EV market, increasing consumer awareness of battery performance, and the push for more efficient and longer-lasting electric vehicles across various segments of the automotive industry.

Current Challenges in Battery Thermal Control

Battery thermal management in regenerative braking systems presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the rapid heat generation during the braking process. When a vehicle decelerates, the kinetic energy is converted into electrical energy, which is then stored in the battery. This sudden influx of energy can cause a substantial temperature increase in the battery cells, potentially leading to thermal runaway if not properly managed.

Another challenge lies in the uneven heat distribution within the battery pack. Different cells may experience varying levels of heat generation based on their position and the current flowing through them. This non-uniform temperature distribution can lead to localized hotspots, which may accelerate battery degradation and reduce overall performance and lifespan.

The dynamic nature of regenerative braking also poses difficulties for thermal management systems. The intermittent and unpredictable nature of braking events makes it challenging to design a cooling system that can respond quickly and effectively to sudden temperature spikes. Traditional cooling methods may struggle to keep up with the rapid heat generation during intense braking scenarios, particularly in urban driving conditions with frequent stops and starts.

Furthermore, the integration of thermal management systems with existing vehicle architectures presents space and weight constraints. Effective cooling solutions often require additional components, such as pumps, radiators, or phase-change materials, which can add complexity, weight, and cost to the vehicle. Balancing these factors while maintaining optimal thermal performance is a significant engineering challenge.

The environmental impact of thermal management solutions is also a growing concern. Many current cooling systems rely on refrigerants or other materials that may have negative environmental effects. Developing eco-friendly alternatives that can provide efficient cooling without compromising on performance or sustainability is an ongoing area of research.

Lastly, the need for accurate temperature sensing and predictive thermal management algorithms presents a technological hurdle. Real-time monitoring of battery temperature across multiple cells and predicting heat generation based on driving patterns and braking events require sophisticated sensors and advanced control systems. Developing robust and reliable thermal management strategies that can adapt to various driving conditions and battery states of charge remains a complex challenge in the field of electric vehicle engineering.

Another challenge lies in the uneven heat distribution within the battery pack. Different cells may experience varying levels of heat generation based on their position and the current flowing through them. This non-uniform temperature distribution can lead to localized hotspots, which may accelerate battery degradation and reduce overall performance and lifespan.

The dynamic nature of regenerative braking also poses difficulties for thermal management systems. The intermittent and unpredictable nature of braking events makes it challenging to design a cooling system that can respond quickly and effectively to sudden temperature spikes. Traditional cooling methods may struggle to keep up with the rapid heat generation during intense braking scenarios, particularly in urban driving conditions with frequent stops and starts.

Furthermore, the integration of thermal management systems with existing vehicle architectures presents space and weight constraints. Effective cooling solutions often require additional components, such as pumps, radiators, or phase-change materials, which can add complexity, weight, and cost to the vehicle. Balancing these factors while maintaining optimal thermal performance is a significant engineering challenge.

The environmental impact of thermal management solutions is also a growing concern. Many current cooling systems rely on refrigerants or other materials that may have negative environmental effects. Developing eco-friendly alternatives that can provide efficient cooling without compromising on performance or sustainability is an ongoing area of research.

Lastly, the need for accurate temperature sensing and predictive thermal management algorithms presents a technological hurdle. Real-time monitoring of battery temperature across multiple cells and predicting heat generation based on driving patterns and braking events require sophisticated sensors and advanced control systems. Developing robust and reliable thermal management strategies that can adapt to various driving conditions and battery states of charge remains a complex challenge in the field of electric vehicle engineering.

Existing Battery Cooling Solutions

01 Temperature control systems for battery packs

Advanced temperature control systems are implemented to maintain optimal operating temperatures for battery packs. These systems often include cooling and heating mechanisms to regulate battery temperature, ensuring efficient performance and prolonging battery life. Various sensors and control algorithms are employed to monitor and adjust the thermal conditions within the battery pack.- Temperature control systems for battery packs: Advanced temperature control systems are implemented to maintain optimal operating temperatures for battery packs. These systems often include cooling and heating mechanisms to regulate battery temperature, ensuring efficient performance and prolonging battery life. Various sensors and control algorithms are employed to monitor and adjust the temperature based on operating conditions.

- Thermal management using phase change materials: Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb excess heat during operation and release it when needed. This passive thermal management approach helps maintain a stable temperature range for the battery, improving its performance and longevity. PCMs can be integrated into the battery structure or surrounding components.

- Active cooling systems for high-performance batteries: Active cooling systems, such as liquid cooling or forced air circulation, are designed for high-performance batteries in electric vehicles and other demanding applications. These systems efficiently remove heat generated during charging and discharging cycles, preventing overheating and maintaining optimal operating temperatures for enhanced battery performance and safety.

- Smart thermal management with predictive algorithms: Advanced thermal management systems incorporate predictive algorithms and machine learning techniques to anticipate temperature changes based on usage patterns, environmental conditions, and battery characteristics. These smart systems proactively adjust cooling or heating parameters to optimize battery performance and extend its lifespan, while also improving energy efficiency of the thermal management process.

- Integration of thermal management with battery management systems: Thermal management is closely integrated with overall battery management systems to provide comprehensive control and monitoring of battery health. This integration allows for real-time temperature data to be used in conjunction with other battery parameters such as state of charge and state of health, enabling more efficient and adaptive thermal management strategies that optimize battery performance and longevity.

02 Thermal management using phase change materials

Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb excess heat during operation and release it when needed. This passive thermal regulation helps maintain a stable temperature range for the battery, improving its efficiency and lifespan. PCMs can be integrated into the battery structure or surrounding components.Expand Specific Solutions03 Active cooling systems for high-performance batteries

Active cooling systems, such as liquid cooling or forced air circulation, are designed for high-performance batteries in electric vehicles and other demanding applications. These systems efficiently dissipate heat generated during rapid charging and discharging cycles, preventing thermal runaway and maintaining optimal battery performance.Expand Specific Solutions04 Smart thermal management with predictive algorithms

Advanced thermal management systems incorporate predictive algorithms and machine learning to anticipate temperature fluctuations based on usage patterns and environmental conditions. These smart systems proactively adjust cooling or heating mechanisms to maintain ideal battery temperatures, optimizing performance and extending battery life.Expand Specific Solutions05 Integration of thermal management with battery management systems

Thermal management is closely integrated with overall battery management systems (BMS) to provide comprehensive control and monitoring. This integration allows for real-time temperature data to be used in conjunction with other battery parameters, enabling more efficient power distribution, charging strategies, and overall system optimization.Expand Specific Solutions

Key Players in EV Thermal Management

The battery thermal management in regenerative braking mechanisms market is in a growth phase, driven by increasing adoption of electric and hybrid vehicles. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, but still evolving, with major automotive players like Hyundai, Toyota, GM, and Ford leading innovation. These companies are investing heavily in research and development to improve efficiency and performance. Emerging players like Vitesco Technologies and Schaeffler are also contributing to technological advancements. The competitive landscape is intense, with established automakers and new entrants vying for market share in this critical component of electric vehicle technology.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced Battery Thermal Management System (BTMS) for regenerative braking in hybrid and electric vehicles. Their system utilizes a combination of air and liquid cooling to maintain optimal battery temperature during regenerative braking events. The BTMS incorporates a heat exchanger that transfers excess heat from the battery to the vehicle's air conditioning system, effectively cooling the battery while also improving cabin comfort[1]. Additionally, Toyota has implemented a predictive control algorithm that anticipates temperature changes based on driving conditions and adjusts the cooling system accordingly, maximizing energy efficiency[3].

Strengths: Efficient heat dissipation, integration with existing vehicle systems, predictive temperature control. Weaknesses: Complexity of the system may increase maintenance costs, potential for increased vehicle weight due to additional components.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated BTMS for their electric vehicles, particularly focusing on the Chevrolet Bolt and upcoming Ultium platform. Their system employs a multi-faceted approach, combining active liquid cooling with phase-change materials (PCMs) to manage battery temperature during regenerative braking. The liquid cooling system circulates a dielectric coolant through channels integrated into the battery pack, while PCMs absorb excess heat during high-load situations[2]. GM's system also incorporates intelligent thermal preconditioning, which prepares the battery for optimal performance before the vehicle is even started, based on ambient conditions and planned route information[4].

Strengths: Highly effective temperature control, innovative use of phase-change materials, intelligent preconditioning. Weaknesses: Increased system complexity may lead to higher production costs, potential for coolant leaks in the battery pack.

Innovative Thermal Management Techniques

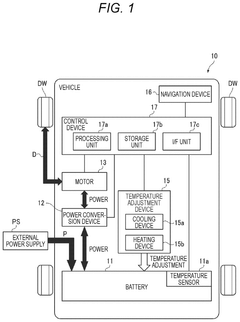

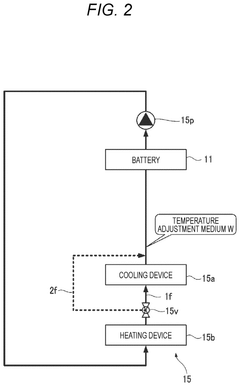

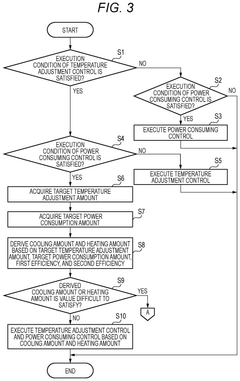

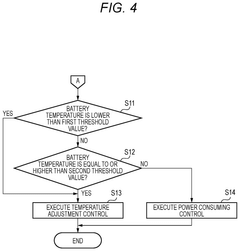

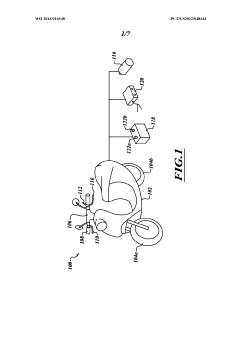

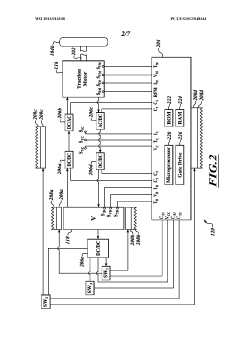

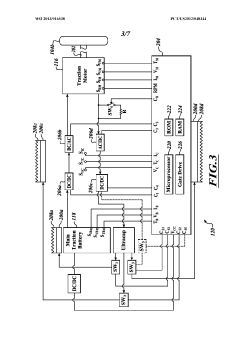

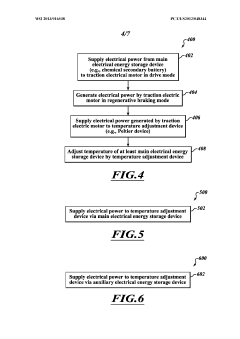

Control method, control device, and vehicle

PatentPendingUS20240322284A1

Innovation

- A control method and device that utilize both cooling and heating mechanisms to maintain the battery within a predetermined temperature range while actively consuming power based on the battery's remaining capacity, deriving optimal cooling and heating amounts using efficiency ratios of the cooling and heating devices.

Thermal management of components in electric motor drive vehicles

PatentWO2013016538A2

Innovation

- The implementation of an efficient thermal management system using active temperature adjustment devices like Peltier effect devices, powered by regenerative braking energy, to control the temperature of electrical energy storage devices and power converters based on sensed temperature, current draw, voltage, and rotational speed, ensuring optimal performance and longevity.

Environmental Impact Assessment

The environmental impact assessment of battery thermal management in regenerative braking mechanisms is a crucial aspect of evaluating the overall sustainability of electric and hybrid vehicles. Regenerative braking systems, while improving energy efficiency, can significantly affect battery temperature and performance. This thermal management challenge has both direct and indirect environmental implications.

Firstly, effective thermal management in regenerative braking systems can extend battery life, reducing the frequency of battery replacements. This longevity directly translates to decreased resource consumption and waste generation associated with battery production and disposal. The reduced demand for new batteries lessens the environmental burden of mining and processing raw materials, particularly for elements like lithium, cobalt, and nickel.

Moreover, optimized thermal management enhances the overall efficiency of the regenerative braking system. This improved efficiency results in greater energy recovery during braking, which in turn reduces the vehicle's energy consumption. Lower energy requirements lead to decreased emissions from power generation, especially in regions where the electricity grid relies heavily on fossil fuels.

The thermal management system itself, however, may introduce additional environmental considerations. The use of cooling fluids or thermal management materials could potentially pose risks if not properly handled or disposed of at the end of the vehicle's life cycle. It is essential to assess the environmental impact of these materials throughout their lifecycle, from production to disposal or recycling.

Furthermore, the manufacturing processes for advanced thermal management systems may require specialized components or materials. The environmental footprint of producing these components, including energy consumption and potential pollutants, must be factored into the overall assessment. This evaluation should consider not only the immediate impacts but also the long-term effects on ecosystems and resource availability.

In urban environments, the widespread adoption of vehicles with efficient regenerative braking and thermal management systems could contribute to reduced air pollution and noise levels. The decreased reliance on traditional friction brakes may result in lower particulate matter emissions from brake pad wear, improving local air quality.

Lastly, the environmental impact assessment should consider the potential for these systems to enable more widespread adoption of electric and hybrid vehicles. By addressing one of the key challenges in electric vehicle technology, improved thermal management in regenerative braking could accelerate the transition away from internal combustion engines, leading to significant reductions in greenhouse gas emissions and air pollutants on a global scale.

Firstly, effective thermal management in regenerative braking systems can extend battery life, reducing the frequency of battery replacements. This longevity directly translates to decreased resource consumption and waste generation associated with battery production and disposal. The reduced demand for new batteries lessens the environmental burden of mining and processing raw materials, particularly for elements like lithium, cobalt, and nickel.

Moreover, optimized thermal management enhances the overall efficiency of the regenerative braking system. This improved efficiency results in greater energy recovery during braking, which in turn reduces the vehicle's energy consumption. Lower energy requirements lead to decreased emissions from power generation, especially in regions where the electricity grid relies heavily on fossil fuels.

The thermal management system itself, however, may introduce additional environmental considerations. The use of cooling fluids or thermal management materials could potentially pose risks if not properly handled or disposed of at the end of the vehicle's life cycle. It is essential to assess the environmental impact of these materials throughout their lifecycle, from production to disposal or recycling.

Furthermore, the manufacturing processes for advanced thermal management systems may require specialized components or materials. The environmental footprint of producing these components, including energy consumption and potential pollutants, must be factored into the overall assessment. This evaluation should consider not only the immediate impacts but also the long-term effects on ecosystems and resource availability.

In urban environments, the widespread adoption of vehicles with efficient regenerative braking and thermal management systems could contribute to reduced air pollution and noise levels. The decreased reliance on traditional friction brakes may result in lower particulate matter emissions from brake pad wear, improving local air quality.

Lastly, the environmental impact assessment should consider the potential for these systems to enable more widespread adoption of electric and hybrid vehicles. By addressing one of the key challenges in electric vehicle technology, improved thermal management in regenerative braking could accelerate the transition away from internal combustion engines, leading to significant reductions in greenhouse gas emissions and air pollutants on a global scale.

Safety Standards and Regulations

Safety standards and regulations play a crucial role in the development and implementation of battery thermal management systems in regenerative braking mechanisms. These standards ensure the safe operation of electric vehicles and protect both users and the environment from potential hazards associated with battery thermal runaway and other related risks.

The International Electrotechnical Commission (IEC) has established several standards specifically addressing battery safety in electric vehicles. IEC 62660-3 focuses on safety requirements for lithium-ion batteries in electric vehicle applications, including thermal management considerations. This standard outlines testing procedures and performance criteria for battery systems under various thermal conditions, ensuring their ability to withstand temperature fluctuations during regenerative braking.

Additionally, the United Nations Economic Commission for Europe (UNECE) has developed Regulation No. 100, which provides specific requirements for the construction, functional safety, and hydrogen emission of battery electric vehicles. This regulation includes provisions for thermal management systems and their integration with regenerative braking mechanisms.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has issued guidelines for electric vehicle safety, including Federal Motor Vehicle Safety Standard (FMVSS) No. 305. This standard addresses electric shock protection and battery integrity, with implications for thermal management systems during regenerative braking events.

The Society of Automotive Engineers (SAE) has also contributed to the development of safety standards for electric vehicle batteries. SAE J2464 provides a recommended practice for electric and hybrid electric vehicle rechargeable energy storage system safety and abuse testing, which includes thermal abuse tests relevant to regenerative braking scenarios.

Furthermore, the International Organization for Standardization (ISO) has developed ISO 6469-1, which specifies safety requirements for rechargeable energy storage systems in electrically propelled road vehicles. This standard addresses thermal management considerations and their interaction with regenerative braking systems.

As the technology evolves, regulatory bodies continue to update and refine these standards to address emerging challenges in battery thermal management. For instance, recent updates have focused on improving thermal runaway detection and mitigation strategies, as well as enhancing the overall robustness of thermal management systems in high-power regenerative braking scenarios.

Compliance with these safety standards and regulations is essential for manufacturers developing battery thermal management systems for regenerative braking mechanisms. It ensures that their products meet the necessary safety requirements and can be legally deployed in various markets worldwide.

The International Electrotechnical Commission (IEC) has established several standards specifically addressing battery safety in electric vehicles. IEC 62660-3 focuses on safety requirements for lithium-ion batteries in electric vehicle applications, including thermal management considerations. This standard outlines testing procedures and performance criteria for battery systems under various thermal conditions, ensuring their ability to withstand temperature fluctuations during regenerative braking.

Additionally, the United Nations Economic Commission for Europe (UNECE) has developed Regulation No. 100, which provides specific requirements for the construction, functional safety, and hydrogen emission of battery electric vehicles. This regulation includes provisions for thermal management systems and their integration with regenerative braking mechanisms.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has issued guidelines for electric vehicle safety, including Federal Motor Vehicle Safety Standard (FMVSS) No. 305. This standard addresses electric shock protection and battery integrity, with implications for thermal management systems during regenerative braking events.

The Society of Automotive Engineers (SAE) has also contributed to the development of safety standards for electric vehicle batteries. SAE J2464 provides a recommended practice for electric and hybrid electric vehicle rechargeable energy storage system safety and abuse testing, which includes thermal abuse tests relevant to regenerative braking scenarios.

Furthermore, the International Organization for Standardization (ISO) has developed ISO 6469-1, which specifies safety requirements for rechargeable energy storage systems in electrically propelled road vehicles. This standard addresses thermal management considerations and their interaction with regenerative braking systems.

As the technology evolves, regulatory bodies continue to update and refine these standards to address emerging challenges in battery thermal management. For instance, recent updates have focused on improving thermal runaway detection and mitigation strategies, as well as enhancing the overall robustness of thermal management systems in high-power regenerative braking scenarios.

Compliance with these safety standards and regulations is essential for manufacturers developing battery thermal management systems for regenerative braking mechanisms. It ensures that their products meet the necessary safety requirements and can be legally deployed in various markets worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!