Advanced Combustion Techniques For Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Combustion Techniques Technology Background And Goals

## Directory: 技术背景与目标

Advanced combustion techniques for turbine engines have evolved significantly over the past few decades, driven by the need for higher efficiency, lower emissions, and improved performance. The primary goal is to develop combustion methods that maximize fuel efficiency while minimizing environmental impact. This involves exploring new materials, innovative design approaches, and advanced control systems. Key trends include the integration of lean-burn technologies, the use of alternative fuels, and the implementation of advanced diagnostics and monitoring systems. These advancements aim to address the growing demand for sustainable and efficient energy solutions in the aerospace and power generation industries.

Combustion Techniques Market Demand Analysis

The market demand for advanced combustion techniques in turbine engines is driven by several key factors.

**Environmental Regulations**:

Stricter global environmental regulations necessitate the development of cleaner and more efficient combustion technologies to reduce emissions and meet compliance standards.

**Fuel Efficiency**:

The need for improved fuel efficiency in turbine engines is critical for both economic and environmental reasons. Advanced combustion techniques can significantly enhance fuel efficiency, reducing operational costs and environmental impact.

**Aerospace and Power Generation**:

The aerospace and power generation industries are major markets for turbine engines. The demand for advanced combustion techniques is high in these sectors due to the need for high-performance, reliable, and efficient engines.

**Technological Advancements**:

Continuous advancements in materials science, computational fluid dynamics, and sensor technologies are enabling the development of more sophisticated combustion techniques, driving market growth.

**Competitive Landscape**:

The competitive landscape in the turbine engine market is pushing companies to innovate and adopt advanced combustion techniques to gain a competitive edge.

**Energy Transition**:

The global shift towards sustainable energy sources is influencing the demand for advanced combustion techniques that can efficiently utilize alternative fuels, such as biofuels and hydrogen.

**Economic Growth**:

Economic growth in emerging markets is leading to increased demand for energy and transportation, further driving the need for advanced turbine engine technologies.

**Environmental Regulations**:

Stricter global environmental regulations necessitate the development of cleaner and more efficient combustion technologies to reduce emissions and meet compliance standards.

**Fuel Efficiency**:

The need for improved fuel efficiency in turbine engines is critical for both economic and environmental reasons. Advanced combustion techniques can significantly enhance fuel efficiency, reducing operational costs and environmental impact.

**Aerospace and Power Generation**:

The aerospace and power generation industries are major markets for turbine engines. The demand for advanced combustion techniques is high in these sectors due to the need for high-performance, reliable, and efficient engines.

**Technological Advancements**:

Continuous advancements in materials science, computational fluid dynamics, and sensor technologies are enabling the development of more sophisticated combustion techniques, driving market growth.

**Competitive Landscape**:

The competitive landscape in the turbine engine market is pushing companies to innovate and adopt advanced combustion techniques to gain a competitive edge.

**Energy Transition**:

The global shift towards sustainable energy sources is influencing the demand for advanced combustion techniques that can efficiently utilize alternative fuels, such as biofuels and hydrogen.

**Economic Growth**:

Economic growth in emerging markets is leading to increased demand for energy and transportation, further driving the need for advanced turbine engine technologies.

Combustion Techniques Technology Status And Challenges

### Combustion Techniques Technology Status And Challenges

**Current Status**:

- Advanced combustion techniques for turbine engines are focused on improving efficiency, reducing emissions, and enhancing performance.

- Technologies such as lean-burn, staged combustion, and catalytic combustion are being actively researched and developed.

**Challenges**:

- **Efficiency**: Achieving higher thermal efficiency while maintaining stability and performance.

- **Emissions**: Reducing NOx, CO, and unburned hydrocarbons to meet stringent environmental regulations.

- **Materials**: Developing materials that can withstand higher temperatures and pressures without degradation.

- **Integration**: Ensuring new combustion techniques can be seamlessly integrated into existing turbine engine designs.

- **Cost**: Balancing the cost of advanced materials and technologies with the benefits they provide.

**Geographical Distribution**:

- Research and development are primarily concentrated in regions with strong aerospace industries, such as North America, Europe, and Asia.

Combustion Techniques Current Technical Solutions

01 Advanced Combustion Control Systems

Enhance combustion efficiency by optimizing air-fuel ratio, monitoring parameters, and adjusting in real-time using sensors, controllers, and algorithms.- Advanced Fuel Injection Systems: Improve efficiency by precise control over fuel-air mixture using direct injection, multi-point injection, and electronic fuel injection.

- Combustion Chamber Design: Enhance efficiency by improving fuel-air mixing, reducing heat losses, and promoting complete combustion with optimized chamber shapes and advanced materials.

- Exhaust Gas Recirculation (EGR) Systems: Improve efficiency by recirculating exhaust gases, reducing nitrogen oxides (NOx) formation, and lowering combustion temperature.

- Catalytic Combustion: Enhance combustion with catalysts, achieving complete combustion at lower temperatures, reducing pollutants like carbon monoxide and unburned hydrocarbons.

- Optimized Air-Fuel Ratio Control: Achieve high efficiency by maintaining ideal air-fuel mixture using lean-burn combustion, variable valve timing, and advanced sensors.

02 Use of Catalysts in Combustion

Improve efficiency by promoting complete combustion, reducing activation energy, lowering emissions, and increasing energy output.Expand Specific Solutions03 Preheating of Combustion Air

Enhance efficiency by preheating air before entering the chamber, increasing air-fuel mixture temperature, leading to complete combustion and reduced fuel consumption.Expand Specific Solutions04 Optimized Burner Design

Improve efficiency by better mixing air and fuel, reducing heat losses, and promoting complete combustion through innovations in burner geometry and materials.Expand Specific Solutions05 Waste Heat Recovery Systems

Capture and reuse heat from combustion, improving overall efficiency using heat exchangers, economizers, and other technologies.Expand Specific Solutions

Combustion Techniques Main Player Analysis

The competitive landscape for advanced combustion techniques for turbine engines includes established leaders and innovative newcomers. Key players like General Electric Technology GmbH, Pratt & Whitney Canada Corp., and Rolls-Royce Plc leverage decades of experience and extensive R&D capabilities. Siemens Energy Global GmbH & Co. KG and Honeywell International Technologies Ltd. are also notable for their advanced technological solutions and market influence. The competition is intense, with continuous advancements and strategic collaborations shaping the future of turbine engine technology.

Ansaldo Energia Switzerland AG

Technical Solution: Ansaldo Energia Switzerland AG focuses on advanced combustion techniques for gas turbines, including sequential combustion systems to enhance operational flexibility and reduce emissions.

Strength: Enhanced operational flexibility. Weakness: Limited application scope.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada Corp. is known for its TALON X combustor technology, which reduces emissions and improves fuel efficiency, ideal for aviation applications.

Strength: Reduced emissions and improved fuel efficiency. Weakness: High development complexity.

Combustion Techniques Key Technology Interpretation

Expanding the operating envelope of advanced combustion engines using fuel-alcohol blends

PatentInactiveUS20100326387A1

Innovation

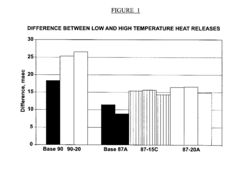

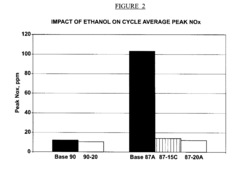

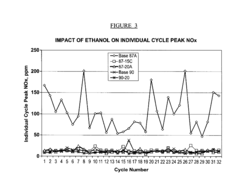

- The use of fuel-alcohol blends to reduce peak NOx emissions and prolong ignition delay during advanced combustion modes.

- The method of blending alcohol and fuel either separately or before introduction into the cylinder to improve combustion stability and reduce cycle-to-cycle variability.

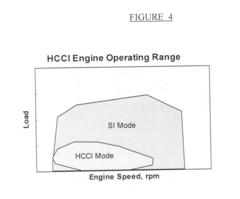

- The expansion of the engine's operating envelope, allowing operation over a wider range of speeds and loads without unacceptable engine noise or elevated NOx emissions.

Combustion Techniques Environmental Impact Analysis

The environmental impact of advanced combustion techniques for turbine engines is significant. These techniques aim to enhance fuel efficiency and reduce emissions, addressing stringent environmental regulations. By optimizing combustion processes, they minimize pollutants such as NOx, CO2, and particulate matter. Innovations like lean-burn combustion, staged combustion, and advanced fuel injection systems are pivotal. These methods not only improve engine performance but also contribute to sustainable aviation by lowering the carbon footprint. Continuous research and development in this area are crucial for achieving greener and more efficient turbine engines, aligning with global environmental goals.

Combustion Techniques Regulatory And Policy Considerations

Regulatory and policy considerations for advanced combustion techniques in turbine engines are crucial for ensuring compliance with environmental standards and promoting sustainable practices. These regulations often focus on reducing emissions, improving fuel efficiency, and minimizing environmental impact. Policies may include stringent emission limits, incentives for adopting cleaner technologies, and guidelines for safe operation. Compliance with these regulations not only helps in mitigating environmental damage but also enhances the market acceptance of advanced combustion technologies. Continuous monitoring and adaptation to evolving policies are essential for maintaining competitiveness and achieving long-term sustainability in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!