Improving Performance Of Internal Combustion Engines With Advanced Fuel Injection Systems

Technology Background And Goals

The analysis should shed light on the driving forces behind these technological advancements, such as the need for improved fuel efficiency, reduced emissions, and enhanced engine performance. Additionally, it is crucial to outline the expected technological goals and targets that future fuel injection systems aim to achieve, aligning with industry standards and environmental regulations.

Market Demand Analysis

- Market Size and Growth

The market for advanced fuel injection systems in internal combustion engines is substantial and growing rapidly. Factors driving demand include stricter emissions regulations, the need for improved fuel efficiency, and the increasing adoption of advanced engine technologies. - Industry Trends

Key trends shaping the market include the development of gasoline direct injection (GDI) systems, the integration of fuel injection with other engine technologies like turbocharging and variable valve timing, and the adoption of alternative fuels like biofuels and hydrogen. - Regional Dynamics

The Asia-Pacific region, particularly China and India, is expected to witness the highest growth in demand due to rapid industrialization and urbanization. Europe and North America also represent significant markets, driven by stringent emissions standards and consumer demand for fuel-efficient vehicles. - Application Segments

The automotive industry is the largest consumer of advanced fuel injection systems, with demand stemming from both passenger cars and commercial vehicles. Other applications include marine engines, industrial machinery, and power generation equipment.

Technology Status And Challenges

- Technological Advancements

Internal combustion engines have undergone significant advancements, with improved fuel injection systems playing a crucial role in enhancing performance and efficiency. - Emission Regulations

Stringent emission regulations have driven the development of advanced fuel injection technologies to reduce harmful emissions and meet environmental standards. - Fuel Efficiency Demands

Rising fuel costs and environmental concerns have increased the demand for fuel-efficient engines, prompting research into optimized fuel injection strategies. - Computational Capabilities

Advancements in computational power and simulation tools have enabled more accurate modeling and optimization of fuel injection systems. - Material Science Innovations

Innovations in materials science have led to the development of high-performance fuel injectors and components capable of withstanding extreme operating conditions.

Current Technical Solutions

01 Improved Atomization Systems

These systems enhance fuel atomization through techniques like high-pressure injection, air-assisted injection, or specialized nozzle designs for better combustion and reduced emissions.- Improved Atomization Systems: These systems enhance fuel atomization for better combustion and reduced emissions through advanced injector designs, higher injection pressures, or specialized nozzles.

- Variable Injection Timing Systems: These systems allow adjustable injection timing for optimized fuel delivery based on engine conditions, improving combustion efficiency, power output, and emissions control.

- Multiple Injection Event Systems: These systems employ multiple fuel injections per combustion cycle, enabling better control over the combustion process for improved efficiency, reduced emissions, and better transient response.

- Advanced Control Strategy Systems: These systems incorporate advanced control algorithms and sensors to optimize fuel delivery based on various engine parameters and operating conditions, leading to improved performance and efficiency.

- Alternative Fuel Compatible Systems: These systems are designed to accommodate alternative fuels, such as biofuels or gaseous fuels, while maintaining efficient combustion and emissions control.

02 Variable Timing and Pressure Systems

These systems allow adjustments in fuel injection timing and pressure, enabling optimized combustion under different engine conditions for improved fuel efficiency and reduced emissions.Expand Specific Solutions03 Multiple Injector Systems

These systems incorporate multiple injectors per cylinder for precise control over the fuel injection process, leading to improved combustion, reduced emissions, and better engine performance.Expand Specific Solutions04 Advanced Control Strategy Systems

These systems employ advanced control algorithms and sensors to optimize fuel injection parameters in real-time based on various engine conditions, resulting in improved fuel efficiency, reduced emissions, and better overall engine performance.Expand Specific Solutions05 Alternative Fuel Compatible Systems

These systems are designed to accommodate alternative fuels like biofuels or gaseous fuels, in addition to conventional fuels, involving modifications to injection system components and control strategies.Expand Specific Solutions

Main Player Analysis

Robert Bosch GmbH

Toyota Motor Corp.

Key Technology Interpretation

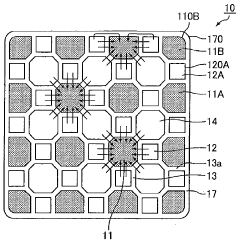

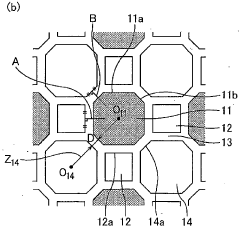

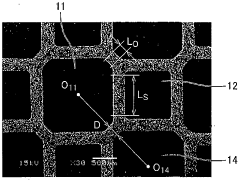

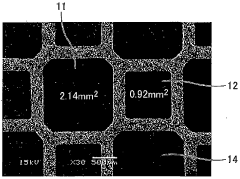

- The use of a honeycomb filter structure to improve fuel atomization and combustion efficiency.

- The honeycomb filter is integrated into the fuel injection system, allowing for better mixing of fuel and air.

- The honeycomb filter can be designed to be replaceable, allowing for easy maintenance and replacement when necessary.

Advanced Fuel Injection Systems Economic Analysis

By leveraging advanced fuel injection technology, engines can achieve higher fuel efficiency and reduced emissions. This leads to potential savings on fuel expenditure, making it an economically attractive option for fleet operators and consumers with high mileage. Furthermore, the reduction in emissions may help avoid penalties related to environmental regulations, thus mitigating additional costs for manufacturers and end-users.

Investments in research and development for these advanced systems could be high, yet the overall return on investment is promising. The initial cost can be offset by long-term savings and compliance benefits. Additionally, a well-implemented system may offer better engine longevity, further lowering the total cost of ownership. From a market perspective, the adoption of advanced fuel injection systems could boost competitive advantage for automotive manufacturers, enabling them to meet stricter environmental standards while appealing to an environmentally conscious consumer base.

Overall, the economic feasibility of advanced fuel injection systems is supported by the evident demand for more efficient and sustainable automotive solutions, providing a solid business case for continued development and adoption in the industry.

Advanced Fuel Injection Systems Environmental Impact

The integration of advanced fuel injection systems in internal combustion engines aims to enhance performance while addressing environmental concerns. By optimizing the fuel-air mixture and improving the precision of fuel delivery, these systems can significantly reduce the emission of harmful gases such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. Advanced fuel injection technologies, like direct injection and variable injection timing, contribute to more complete combustion processes, thereby minimizing the particulate matter and greenhouse gas emissions that are prevalent in traditional engine designs.

Moreover, these systems enhance fuel efficiency, resulting in lower fuel consumption and reduced carbon dioxide (CO2) emissions. This improvement directly supports global efforts to tackle climate change by reducing the carbon footprint of vehicles powered by internal combustion engines. Additionally, the implementation of these systems can facilitate compliance with stringent emission regulations currently being enforced internationally, driving the adoption of more environmentally friendly automotive technologies.

Overall, advanced fuel injection systems not only promise superior engine performance but also hold significant potential in mitigating the environmental impact of internal combustion engines, making them a crucial component in the transition towards sustainable transportation solutions.