Improving Combustion Efficiency Of Turbine Engines

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Technology Background and Goals

Under the background of turbine engine combustion efficiency improvement, the primary objective is to enhance fuel utilization and reduce emissions. Historically, turbine engines have evolved from simple jet engines to advanced turbofans, with significant improvements in materials, aerodynamics, and combustion technology. The trend is towards higher efficiency and lower environmental impact, driven by stringent regulations and the need for cost-effective operations. The goal is to achieve breakthroughs in combustion technology that can lead to more efficient and cleaner turbine engines, aligning with global sustainability targets and industry demands for better performance and lower operational costs.

Turbine Engine Market Demand Analysis

### Turbine Engine Market Demand Analysis

**Market Overview**:

The turbine engine market is experiencing significant growth driven by increasing demand in aviation, power generation, and industrial applications. The need for efficient and reliable engines is paramount in these sectors.

**Aviation Sector**:

In aviation, the demand for turbine engines is propelled by the expansion of commercial and military aircraft fleets. Airlines are seeking engines that offer better fuel efficiency and lower emissions to meet stringent environmental regulations.

**Power Generation**:

For power generation, turbine engines are essential in both traditional and renewable energy setups. The shift towards cleaner energy sources has increased the demand for gas turbines, which are more efficient and produce fewer emissions compared to coal-fired plants.

**Industrial Applications**:

In industrial applications, turbine engines are used in various sectors such as oil and gas, manufacturing, and marine propulsion. The need for high-performance engines that can operate under extreme conditions is driving market growth.

**Regional Demand**:

Geographically, North America and Europe are leading markets due to advanced technological infrastructure and high investment in R&D. However, Asia-Pacific is emerging as a significant market due to rapid industrialization and increasing energy needs.

**Future Trends**:

Future trends indicate a growing emphasis on hybrid and electric propulsion systems, which could reshape the turbine engine market. Innovations aimed at improving combustion efficiency and reducing carbon footprint are expected to drive future demand.

Turbine Engine Technology Status and Challenges

### Turbine Engine Technology Status and Challenges

**Current State of Technology**:

- Turbine engines are widely used in aviation and power generation, with advancements focusing on efficiency and emissions reduction.

- Modern engines incorporate advanced materials, aerodynamics, and cooling technologies to enhance performance.

**Challenges**:

- **Combustion Efficiency**: Achieving higher combustion efficiency while minimizing pollutants remains a significant challenge.

- **Thermal Management**: Managing high temperatures without compromising engine integrity is critical.

- **Material Limitations**: Developing materials that can withstand extreme conditions without degradation is essential.

- **Environmental Regulations**: Stricter emissions standards require continuous innovation in combustion and after-treatment technologies.

**Geographical Distribution**:

- **North America and Europe**: Leading in research and development, with significant investments in advanced turbine technologies.

- **Asia**: Rapidly growing market with increasing focus on indigenous development and manufacturing capabilities.

**Conclusion**:

- The turbine engine sector faces substantial technical challenges, particularly in improving combustion efficiency and meeting environmental standards. Continued innovation and investment are crucial for overcoming these hurdles.

Turbine Engine Current Technical Solutions

01 Optimizing fuel-air mixture

Improving combustion efficiency by optimizing the fuel-air mixture through precise control of fuel injection and air intake, reducing unburned fuel and emissions. Techniques include variable geometry turbines and advanced fuel injectors.- Optimizing fuel-air mixture: Improving combustion efficiency by optimizing the fuel-air mixture through precise control of fuel injection and air intake, reducing unburned fuel and emissions. Advanced sensors and control systems monitor and adjust the mixture in real-time.

- Enhancing combustion chamber design: Innovations in combustion chamber geometry, materials, and cooling techniques improve combustion efficiency, achieving higher temperatures and pressures, resulting in better fuel efficiency and lower emissions.

- Utilizing advanced materials: Advanced materials withstand higher temperatures and pressures, enhancing engine performance and reducing weight, thus improving overall efficiency.

- Implementing staged combustion: Staged combustion improves efficiency by burning fuel in multiple stages, allowing better control of the combustion process, reducing pollutants, and increasing overall efficiency.

- Improving turbine blade cooling: Advanced cooling techniques, such as film cooling and internal cooling channels, keep turbine blades at optimal temperatures, preventing overheating and allowing higher operating temperatures, thus improving efficiency.

02 Advanced combustion chamber design

Innovations in combustion chamber geometry, materials, and cooling techniques improve combustion efficiency by enhancing fuel-air mixing, reducing hotspots, and improving thermal efficiency.Expand Specific Solutions03 Utilization of alternative fuels

Using alternative fuels like biofuels or synthetic fuels can improve combustion efficiency by achieving more complete combustion and lower emissions. Research focuses on optimizing engine performance with these fuels.Expand Specific Solutions04 Enhanced turbine blade cooling

Advanced cooling techniques, such as film cooling, transpiration cooling, and thermal barrier coatings, improve turbine blade efficiency and lifespan by managing high combustion temperatures.Expand Specific Solutions05 Improved exhaust gas recirculation

Exhaust gas recirculation (EGR) reduces nitrogen oxide emissions and improves combustion efficiency by recirculating exhaust gases back into the combustion chamber, lowering peak combustion temperatures and reducing pollutants.Expand Specific Solutions

Turbine Engine Main Player Analysis

The competitive landscape for improving combustion efficiency of turbine engines includes established leaders and innovative newcomers. Key players like General Electric Technology GmbH, General Electric Company, United Technologies Corp., and Rolls-Royce Corp. lead with advanced R&D and technologies. Pratt & Whitney Canada Corp., Honeywell International Technologies Ltd., and Mitsubishi Power Ltd. also drive technological advancements. Emerging players like Advanced Green Technologies LLC and Tula Technology, Inc. bring novel approaches, indicating a dynamic market.

General Electric Company

Technical Solution: General Electric Company has developed advanced turbine engine technologies using ceramic matrix composites and innovative cooling techniques to enhance performance and fuel efficiency.

Strength: Advanced materials and cooling techniques. Weakness: High development and implementation costs.

United Technologies Corp.

Technical Solution: United Technologies Corp. enhances combustion efficiency with high-efficiency combustors and advanced fuel injection systems to reduce emissions and improve fuel economy.

Strength: High-efficiency combustors. Weakness: Complex integration with existing systems.

Turbine Engine Key Technology Interpretation

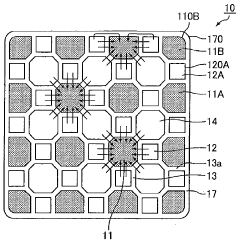

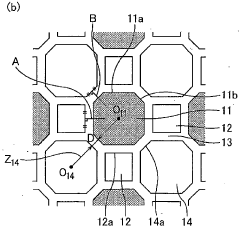

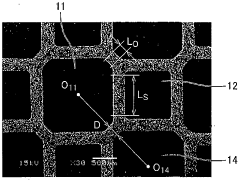

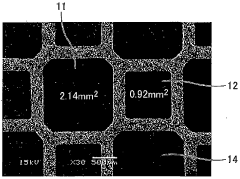

Honeycomb filter

PatentActiveIN1198CHENP2015A

Innovation

- The honeycomb filter structure increases the surface area for better filtration and combustion efficiency.

- The design of the honeycomb filter allows for more efficient trapping of particulates, reducing emissions.

- The lightweight construction of the honeycomb filter contributes to overall engine efficiency by reducing weight.

Turbine Engine Combustion Efficiency Economic Analysis

The economic analysis of improving turbine engine combustion efficiency involves evaluating the cost-benefit ratio of implementing advanced technologies. Enhanced combustion efficiency can lead to significant fuel savings, reduced emissions, and lower operational costs. However, the initial investment in research, development, and deployment of these technologies can be substantial. The analysis should consider the long-term financial benefits, including fuel cost reductions and potential regulatory compliance savings, against the upfront costs. Additionally, market demand for more efficient engines and the competitive advantage gained by adopting such technologies should be factored into the economic assessment.

Turbine Engine Combustion Efficiency Environmental Impact

Improving the combustion efficiency of turbine engines can significantly reduce environmental impact by lowering fuel consumption and emissions. Enhanced combustion efficiency leads to more complete fuel burning, reducing pollutants like NOx, CO, and unburned hydrocarbons. Advanced technologies such as lean-burn combustion, optimized fuel injection systems, and high-efficiency combustor designs are crucial. Additionally, integrating alternative fuels like biofuels or hydrogen can further minimize environmental footprints. Continuous research and development in these areas are essential to achieve sustainable and eco-friendly turbine engine operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!