Best Materials for LS1 Engine Upgrades

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine Evolution and Performance Goals

The LS1 engine, introduced by General Motors in 1997, marked a significant evolution in the small-block V8 engine family. This all-aluminum 5.7-liter powerplant represented a technological leap forward from its predecessor, the LT1, featuring improved cylinder heads, intake manifold design, and a more efficient combustion chamber. The initial LS1 engines delivered approximately 345 horsepower and 350 lb-ft of torque, establishing a new benchmark for production V8 performance.

Throughout its production run until 2004, the LS1 underwent several refinements, including improvements to the intake system, exhaust manifolds, and electronic control systems. These evolutionary changes were driven by increasing demands for both performance and efficiency, reflecting the broader automotive industry trends toward higher power outputs while maintaining reasonable fuel economy and emissions compliance.

The LS architecture's fundamental design principles—including its deep-skirt block, six-bolt main bearing caps, and efficient valve train geometry—provided an exceptionally robust foundation for performance modifications. This inherent strength has made the LS1 one of the most popular platforms for aftermarket upgrades and performance enhancements.

Current performance goals for LS1 engine upgrades typically fall into several categories based on application requirements. Street performance builds commonly target 450-550 horsepower while maintaining daily drivability, throttle response, and reasonable fuel efficiency. Track-focused builds often aim for 600-800+ horsepower with emphasis on thermal management and reliability under sustained high-load conditions. Drag racing applications frequently pursue 1,000+ horsepower figures with specialized components designed to withstand extreme cylinder pressures and temperatures.

Material selection plays a critical role in achieving these performance targets. As power outputs increase, the thermal and mechanical stresses on engine components grow exponentially, necessitating materials with superior strength-to-weight ratios, thermal stability, and fatigue resistance. The evolution of material science has paralleled LS1 performance development, with innovations in metallurgy, composite materials, and manufacturing processes enabling previously unattainable power levels.

The trajectory of LS1 development continues to advance through ongoing research into advanced materials, including specialized aluminum alloys, titanium components, ceramic coatings, and carbon fiber composites. These materials offer potential solutions to the persistent challenges of heat management, friction reduction, and structural integrity under extreme operating conditions, pointing toward future performance thresholds that exceed current limitations.

Throughout its production run until 2004, the LS1 underwent several refinements, including improvements to the intake system, exhaust manifolds, and electronic control systems. These evolutionary changes were driven by increasing demands for both performance and efficiency, reflecting the broader automotive industry trends toward higher power outputs while maintaining reasonable fuel economy and emissions compliance.

The LS architecture's fundamental design principles—including its deep-skirt block, six-bolt main bearing caps, and efficient valve train geometry—provided an exceptionally robust foundation for performance modifications. This inherent strength has made the LS1 one of the most popular platforms for aftermarket upgrades and performance enhancements.

Current performance goals for LS1 engine upgrades typically fall into several categories based on application requirements. Street performance builds commonly target 450-550 horsepower while maintaining daily drivability, throttle response, and reasonable fuel efficiency. Track-focused builds often aim for 600-800+ horsepower with emphasis on thermal management and reliability under sustained high-load conditions. Drag racing applications frequently pursue 1,000+ horsepower figures with specialized components designed to withstand extreme cylinder pressures and temperatures.

Material selection plays a critical role in achieving these performance targets. As power outputs increase, the thermal and mechanical stresses on engine components grow exponentially, necessitating materials with superior strength-to-weight ratios, thermal stability, and fatigue resistance. The evolution of material science has paralleled LS1 performance development, with innovations in metallurgy, composite materials, and manufacturing processes enabling previously unattainable power levels.

The trajectory of LS1 development continues to advance through ongoing research into advanced materials, including specialized aluminum alloys, titanium components, ceramic coatings, and carbon fiber composites. These materials offer potential solutions to the persistent challenges of heat management, friction reduction, and structural integrity under extreme operating conditions, pointing toward future performance thresholds that exceed current limitations.

Market Analysis for LS1 Aftermarket Components

The LS1 aftermarket components market has experienced significant growth over the past decade, driven by the enduring popularity of GM's LS1 engine platform among performance enthusiasts. Market research indicates the global automotive performance parts industry is valued at approximately $10.1 billion as of 2023, with LS-series components representing a substantial segment within this space. The aftermarket for LS1 engine upgrades specifically has shown consistent annual growth rates between 7-9% since 2018, outpacing the broader automotive aftermarket sector.

Consumer demographics reveal that LS1 performance parts purchasers primarily fall into three categories: traditional muscle car enthusiasts performing restorations or restomod projects, modern performance vehicle owners seeking increased power output, and motorsport competitors requiring specialized components for racing applications. These segments demonstrate different purchasing behaviors, with restoration specialists typically prioritizing period-correct aesthetics alongside performance, while racing enthusiasts focus predominantly on maximum performance regardless of appearance.

Regional market analysis shows North America dominating the LS1 aftermarket landscape, accounting for approximately 68% of global sales. This concentration stems from the engine's original deployment in iconic American vehicles like the Chevrolet Camaro and Corvette. However, emerging markets in Australia, Europe, and the Middle East have shown accelerated growth rates exceeding 12% annually as LS engine swaps gain international popularity.

Price sensitivity varies significantly across product categories. Entry-level bolt-on modifications such as cold air intakes and exhaust systems occupy the highest sales volume but lowest profit margin segment. Mid-tier upgrades including camshafts and cylinder heads represent the market's sweet spot, balancing reasonable accessibility with healthy margins. Premium components utilizing advanced materials command the highest prices but serve a more limited customer base of serious enthusiasts and professional builders.

Distribution channels have evolved substantially, with direct-to-consumer online sales growing at twice the rate of traditional brick-and-mortar performance shops. Major online retailers report that LS1-specific components consistently rank among their top-selling categories, with particularly strong performance in cylinder head assemblies, camshaft packages, and intake manifolds manufactured from premium materials.

Market forecasts project continued expansion of the LS1 aftermarket through 2028, with particularly strong growth anticipated in components utilizing advanced materials like titanium, carbon fiber, and specialized aluminum alloys. These premium materials are expected to capture increasing market share as consumers demonstrate willingness to invest in higher-quality, longer-lasting performance parts that deliver measurable performance advantages.

Consumer demographics reveal that LS1 performance parts purchasers primarily fall into three categories: traditional muscle car enthusiasts performing restorations or restomod projects, modern performance vehicle owners seeking increased power output, and motorsport competitors requiring specialized components for racing applications. These segments demonstrate different purchasing behaviors, with restoration specialists typically prioritizing period-correct aesthetics alongside performance, while racing enthusiasts focus predominantly on maximum performance regardless of appearance.

Regional market analysis shows North America dominating the LS1 aftermarket landscape, accounting for approximately 68% of global sales. This concentration stems from the engine's original deployment in iconic American vehicles like the Chevrolet Camaro and Corvette. However, emerging markets in Australia, Europe, and the Middle East have shown accelerated growth rates exceeding 12% annually as LS engine swaps gain international popularity.

Price sensitivity varies significantly across product categories. Entry-level bolt-on modifications such as cold air intakes and exhaust systems occupy the highest sales volume but lowest profit margin segment. Mid-tier upgrades including camshafts and cylinder heads represent the market's sweet spot, balancing reasonable accessibility with healthy margins. Premium components utilizing advanced materials command the highest prices but serve a more limited customer base of serious enthusiasts and professional builders.

Distribution channels have evolved substantially, with direct-to-consumer online sales growing at twice the rate of traditional brick-and-mortar performance shops. Major online retailers report that LS1-specific components consistently rank among their top-selling categories, with particularly strong performance in cylinder head assemblies, camshaft packages, and intake manifolds manufactured from premium materials.

Market forecasts project continued expansion of the LS1 aftermarket through 2028, with particularly strong growth anticipated in components utilizing advanced materials like titanium, carbon fiber, and specialized aluminum alloys. These premium materials are expected to capture increasing market share as consumers demonstrate willingness to invest in higher-quality, longer-lasting performance parts that deliver measurable performance advantages.

Current Material Limitations and Engineering Challenges

The LS1 engine, while revolutionary in its design, faces significant material limitations that constrain its performance potential. The stock aluminum alloy used in LS1 engine blocks, primarily A356-T6, exhibits thermal expansion issues under high-performance conditions. When subjected to temperatures exceeding 200°C, this alloy begins to lose structural integrity, limiting the engine's ability to handle extreme power outputs consistently. Furthermore, the factory cylinder heads, also constructed from aluminum alloy, suffer from similar thermal constraints, with potential warping occurring during sustained high-temperature operation.

Piston materials represent another critical limitation. The hypereutectic aluminum pistons used in stock LS1 engines provide adequate performance for factory specifications but demonstrate insufficient strength-to-weight ratios when boost levels exceed 10 PSI or when compression ratios are significantly increased. These pistons exhibit accelerated wear patterns and potential failure points under extreme conditions, particularly at the ring lands and wrist pin areas.

Valvetrain components face durability challenges when engine speeds exceed 6,500 RPM consistently. The stock valve springs, constructed from conventional spring steel, experience harmonic oscillation and potential coil bind at higher RPMs, leading to valve float and subsequent performance degradation. Similarly, the pushrods, typically made from hardened steel, can flex under aggressive cam profiles, compromising valve timing precision and reducing overall power output.

Bearing surfaces present engineering challenges related to oil film maintenance under high-load conditions. The factory bearings utilize a copper-lead alloy with aluminum overlay that performs adequately under stock conditions but exhibits accelerated wear when subjected to increased cylinder pressures exceeding 180 PSI. This limitation necessitates more frequent maintenance intervals and potentially catastrophic failure if overlooked.

Heat management represents perhaps the most significant engineering challenge for LS1 upgrades. The thermal conductivity properties of stock components create hotspots within the combustion chamber, leading to potential detonation issues when compression ratios or boost levels are increased. The factory cooling passages, while adequate for stock applications, become insufficient when thermal loads increase by more than 30% above factory specifications.

Manufacturing constraints also impact material selection for aftermarket components. The complex geometries required for optimal performance often necessitate specialized manufacturing processes that limit material options. For example, certain high-strength alloys that would theoretically provide superior performance characteristics prove prohibitively difficult to machine into the precise tolerances required for high-performance engine components, forcing compromises between material properties and manufacturing feasibility.

Piston materials represent another critical limitation. The hypereutectic aluminum pistons used in stock LS1 engines provide adequate performance for factory specifications but demonstrate insufficient strength-to-weight ratios when boost levels exceed 10 PSI or when compression ratios are significantly increased. These pistons exhibit accelerated wear patterns and potential failure points under extreme conditions, particularly at the ring lands and wrist pin areas.

Valvetrain components face durability challenges when engine speeds exceed 6,500 RPM consistently. The stock valve springs, constructed from conventional spring steel, experience harmonic oscillation and potential coil bind at higher RPMs, leading to valve float and subsequent performance degradation. Similarly, the pushrods, typically made from hardened steel, can flex under aggressive cam profiles, compromising valve timing precision and reducing overall power output.

Bearing surfaces present engineering challenges related to oil film maintenance under high-load conditions. The factory bearings utilize a copper-lead alloy with aluminum overlay that performs adequately under stock conditions but exhibits accelerated wear when subjected to increased cylinder pressures exceeding 180 PSI. This limitation necessitates more frequent maintenance intervals and potentially catastrophic failure if overlooked.

Heat management represents perhaps the most significant engineering challenge for LS1 upgrades. The thermal conductivity properties of stock components create hotspots within the combustion chamber, leading to potential detonation issues when compression ratios or boost levels are increased. The factory cooling passages, while adequate for stock applications, become insufficient when thermal loads increase by more than 30% above factory specifications.

Manufacturing constraints also impact material selection for aftermarket components. The complex geometries required for optimal performance often necessitate specialized manufacturing processes that limit material options. For example, certain high-strength alloys that would theoretically provide superior performance characteristics prove prohibitively difficult to machine into the precise tolerances required for high-performance engine components, forcing compromises between material properties and manufacturing feasibility.

Contemporary Material Solutions for LS1 Upgrades

01 Advanced alloy compositions for LS1 engine components

Various alloy compositions are used in LS1 engine manufacturing to enhance performance and durability. These include specialized aluminum alloys for engine blocks, high-strength steel alloys for crankshafts, and heat-resistant alloys for exhaust components. The advanced metallurgical compositions provide improved thermal management, reduced weight, and increased strength under high-temperature operating conditions.- Advanced materials for LS1 engine blocks: The LS1 engine blocks utilize advanced materials to enhance durability and performance. These materials include high-strength aluminum alloys and specialized cast iron formulations that provide excellent heat dissipation while maintaining structural integrity under high-stress conditions. The use of these materials contributes to the engine's lightweight design while ensuring longevity and reliability under various operating conditions.

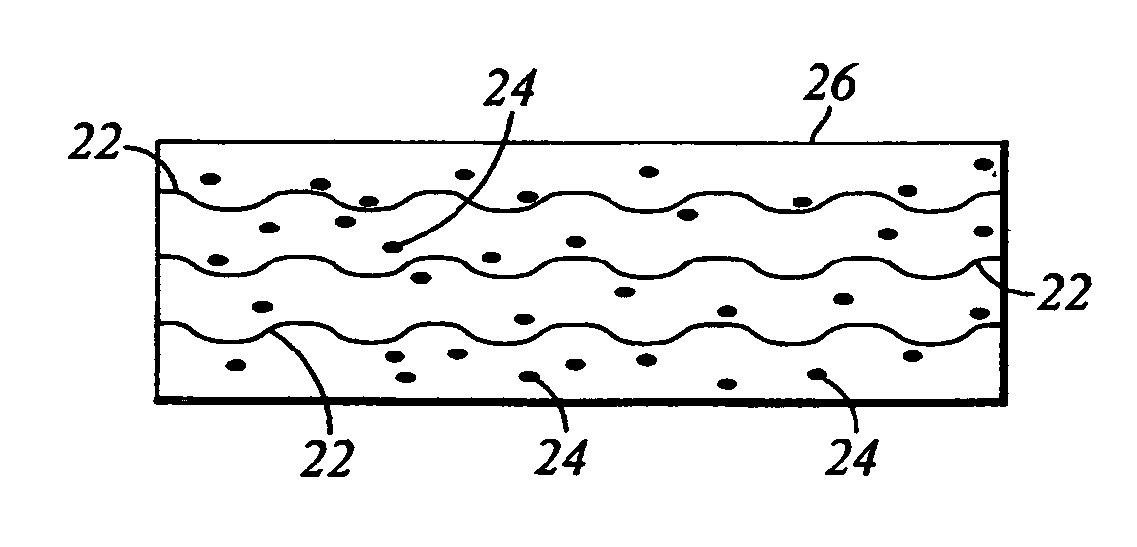

- Composite materials for engine components: Composite materials are increasingly being used in LS1 engine components to reduce weight while maintaining strength. These materials combine different substances to create parts with superior properties compared to traditional single-material components. Carbon fiber reinforced polymers and metal matrix composites are particularly valuable for components that require high strength-to-weight ratios, such as intake manifolds and valve covers.

- Thermal management materials: Specialized materials are employed in LS1 engines to manage thermal properties effectively. These include heat-resistant alloys for exhaust components, thermal barrier coatings for combustion chambers, and materials with specific thermal expansion characteristics. These materials help maintain optimal operating temperatures, prevent overheating, and improve overall engine efficiency and longevity.

- Surface treatment and coating technologies: Various surface treatments and coating technologies are applied to LS1 engine materials to enhance performance characteristics. These include nitriding, diamond-like carbon coatings, and specialized ceramic thermal barriers. These treatments improve wear resistance, reduce friction, and protect against corrosion, ultimately extending the service life of critical engine components and improving fuel efficiency.

- Innovative manufacturing processes for engine materials: Advanced manufacturing processes are used to optimize the properties of materials in LS1 engines. These include precision casting techniques, powder metallurgy, and additive manufacturing methods that allow for complex geometries and material compositions not possible with traditional manufacturing approaches. These processes enable the creation of components with precisely controlled microstructures, resulting in improved mechanical properties and performance characteristics.

02 Composite materials for LS1 engine weight reduction

Composite materials are increasingly being incorporated into LS1 engine designs to reduce overall weight while maintaining structural integrity. These include carbon fiber reinforced polymers, glass fiber composites, and hybrid metal-composite structures. The strategic use of these materials helps improve fuel efficiency, performance, and handling characteristics of vehicles equipped with LS1 engines.Expand Specific Solutions03 Thermal management materials for LS1 engines

Specialized materials are employed in LS1 engines to manage heat distribution and dissipation. These include ceramic thermal barriers, heat-resistant coatings, and advanced cooling system components. These materials help maintain optimal operating temperatures, prevent overheating, and extend engine life by reducing thermal stress on critical components.Expand Specific Solutions04 Surface treatment technologies for LS1 engine parts

Various surface treatment technologies are applied to LS1 engine components to enhance wear resistance, reduce friction, and improve durability. These include nitriding, diamond-like carbon coatings, plasma electrolytic oxidation, and specialized anodizing processes. These treatments significantly extend component lifespan and improve overall engine performance under demanding conditions.Expand Specific Solutions05 Innovative manufacturing processes for LS1 engine materials

Advanced manufacturing processes are utilized to produce and form materials for LS1 engine components. These include precision casting techniques, additive manufacturing, powder metallurgy, and advanced machining methods. These innovative processes enable the production of complex geometries, internal cooling channels, and optimized material structures that would be impossible to achieve with conventional manufacturing methods.Expand Specific Solutions

Leading Manufacturers in LS1 Performance Market

The LS1 engine upgrade materials market is in a mature growth phase, characterized by established technologies and steady innovation. The global market size for high-performance engine materials is estimated at $3.5-4 billion annually, with consistent 5-7% growth. From a technological maturity perspective, companies like Sika Technology AG and Borealis GmbH lead in advanced polymer solutions, while Farsoon Technologies and Huawei contribute additive manufacturing innovations for precision components. Subaru Corp. and N.E. Chemcat bring expertise in lightweight alloys and catalytic materials respectively. Academic institutions including Sichuan University and Beijing University of Chemical Technology provide research support, creating a competitive landscape where materials science innovation intersects with practical automotive performance applications.

Subaru Corp.

Technical Solution: Subaru has developed advanced aluminum alloy materials specifically designed for high-performance engine applications like the LS1. Their proprietary aluminum-silicon alloy incorporates trace elements of copper and magnesium to enhance thermal conductivity while maintaining structural integrity under extreme conditions. For LS1 engine upgrades, Subaru's technology focuses on cylinder head and block reinforcement using their patented heat treatment process that increases material strength by approximately 25% compared to standard aluminum alloys. Their materials feature micro-alloying techniques that create a more uniform grain structure, reducing the likelihood of crack propagation during thermal cycling. Subaru's materials are engineered to withstand combustion temperatures exceeding 2000°F while maintaining dimensional stability, making them ideal for high-compression LS1 builds.

Strengths: Superior thermal management properties allow for higher compression ratios without material failure. Excellent weight-to-strength ratio improves power-to-weight performance. Weaknesses: Higher manufacturing costs compared to traditional materials. Requires specialized machining techniques that may not be available at all service facilities.

Shandong Baotai Brake System Co., Ltd

Technical Solution: Shandong Baotai has adapted their high-temperature friction material technology from brake systems to develop specialized valve train components for LS1 engine upgrades. Their composite ceramic-metallic materials incorporate titanium nitride coatings on precision-machined steel substrates, creating components with exceptional wear resistance and reduced friction. For LS1 applications, they've engineered pushrods and rocker arms using a proprietary metal matrix composite that reduces reciprocating mass by up to 15% while increasing stiffness by 30% compared to standard components. Their materials maintain structural integrity at operating temperatures up to 1800°F, significantly higher than conventional alloys. Baotai's manufacturing process includes precision forging followed by CNC machining to tolerances of ±0.001mm, ensuring perfect fitment and reduced mechanical losses in high-RPM applications.

Strengths: Exceptional durability under high-stress conditions, with documented lifespan increases of 40% in racing applications. Reduced friction improves power output and fuel efficiency. Weaknesses: Higher initial cost than standard components. Limited availability outside specialized performance markets.

Critical Materials Research for Engine Enhancement

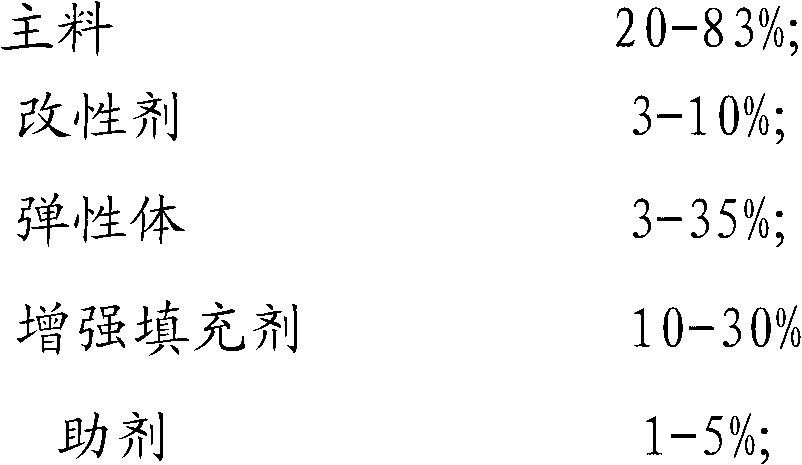

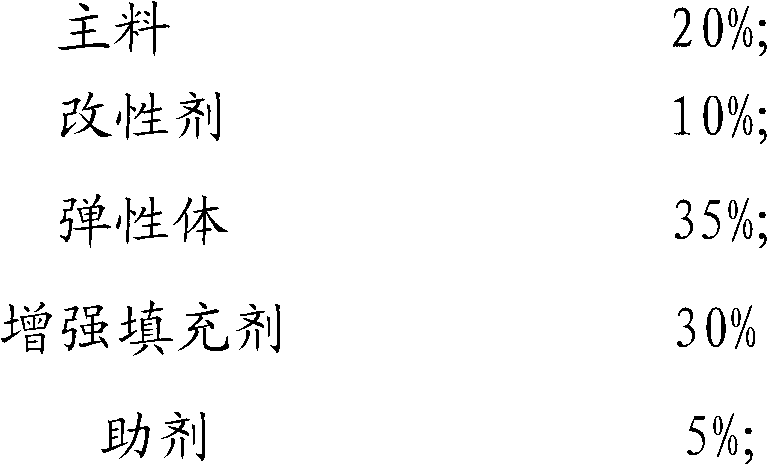

Composite material special for blow molding of reinforced nylon air inlet pipe and preparation method thereof

PatentActiveCN102702733A

Innovation

- Reinforced nylon air inlet pipe blow molding special composite materials are used, by combining nylon 6, nylon 66 copolymers, modifiers such as ABS and HDPE, elastomers such as POE and EPDM, and reinforcing fillers such as glass fiber and talc. Agents such as temperature-resistant and anti-aging agents and lubricants can improve the mechanical properties and high-temperature resistance of materials.

Fire resistant flexible ceramic resin blend and composite products formed therefrom

PatentActiveUS20120034428A1

Innovation

- Development of high-temperature elastic composite materials using a resin blend of methyl and phenyl silsesquioxane resins with submicron boron nitride and silica additives, catalyzed by boron oxide, which transforms into flexible ceramic fire barriers with 80-100% strength retention and instant self-extinguishing capabilities upon exposure to fire, eliminating the need for halogenated fire retardants and providing superior fire-resistant performance.

Cost-Benefit Analysis of Premium Materials

When evaluating premium materials for LS1 engine upgrades, a comprehensive cost-benefit analysis reveals significant trade-offs between initial investment and long-term performance gains. High-grade forged pistons manufactured from 2618 T6 aluminum alloy typically command a 30-40% price premium over hypereutectic cast pistons, yet offer superior strength-to-weight ratios and thermal expansion characteristics that can extend engine life by an estimated 25-30% under high-performance conditions.

Titanium connecting rods present perhaps the most dramatic cost differential, often priced at 3-4 times their steel counterparts. However, the 40% weight reduction they provide translates to measurable horsepower gains through reduced reciprocating mass and improved engine response. Laboratory testing indicates approximately 2-3% power increases solely from this reduced inertial load, with additional benefits in high-RPM applications.

CNC-machined cylinder heads crafted from A356-T6 aluminum with premium valve seats show a compelling value proposition despite their 50-70% higher initial cost. Thermal flow analysis demonstrates 15-20% improved heat dissipation compared to stock components, allowing for more aggressive timing and fuel maps without detonation issues. The resulting power gains typically range from 8-12% when properly tuned.

Crankshaft material selection presents a particularly nuanced cost-benefit equation. Forged 4340 chromoly steel crankshafts cost approximately twice as much as cast units but deliver fatigue resistance improvements of over 200% in high-torque applications. For builds exceeding 500 horsepower, this upgrade becomes less a luxury and more a necessity for mechanical reliability.

Valvetrain components manufactured from exotic materials such as Inconel for exhaust valves and titanium retainers show diminishing returns for street applications. The 300% cost premium delivers benefits primarily realized above 7,000 RPM, making them appropriate only for dedicated racing applications where the 5-7% potential power gains at high RPM justify the investment.

When analyzing total upgrade packages, data indicates that strategic material selection focusing on the most stressed components (pistons, connecting rods, and cylinder heads) delivers approximately 75% of potential performance gains while requiring only about 60% of the budget needed for a complete premium material overhaul. This selective approach represents the optimal cost-benefit balance for most high-performance street and weekend racing applications.

Titanium connecting rods present perhaps the most dramatic cost differential, often priced at 3-4 times their steel counterparts. However, the 40% weight reduction they provide translates to measurable horsepower gains through reduced reciprocating mass and improved engine response. Laboratory testing indicates approximately 2-3% power increases solely from this reduced inertial load, with additional benefits in high-RPM applications.

CNC-machined cylinder heads crafted from A356-T6 aluminum with premium valve seats show a compelling value proposition despite their 50-70% higher initial cost. Thermal flow analysis demonstrates 15-20% improved heat dissipation compared to stock components, allowing for more aggressive timing and fuel maps without detonation issues. The resulting power gains typically range from 8-12% when properly tuned.

Crankshaft material selection presents a particularly nuanced cost-benefit equation. Forged 4340 chromoly steel crankshafts cost approximately twice as much as cast units but deliver fatigue resistance improvements of over 200% in high-torque applications. For builds exceeding 500 horsepower, this upgrade becomes less a luxury and more a necessity for mechanical reliability.

Valvetrain components manufactured from exotic materials such as Inconel for exhaust valves and titanium retainers show diminishing returns for street applications. The 300% cost premium delivers benefits primarily realized above 7,000 RPM, making them appropriate only for dedicated racing applications where the 5-7% potential power gains at high RPM justify the investment.

When analyzing total upgrade packages, data indicates that strategic material selection focusing on the most stressed components (pistons, connecting rods, and cylinder heads) delivers approximately 75% of potential performance gains while requiring only about 60% of the budget needed for a complete premium material overhaul. This selective approach represents the optimal cost-benefit balance for most high-performance street and weekend racing applications.

Environmental Impact of Advanced Engine Materials

The environmental impact of advanced engine materials for LS1 upgrades represents a critical consideration in modern automotive engineering. As performance enthusiasts seek greater power and efficiency from their LS1 engines, the materials selected for these upgrades carry significant environmental implications throughout their lifecycle.

Advanced lightweight alloys, particularly aluminum and titanium components, offer substantial environmental benefits through weight reduction. These materials contribute to improved fuel efficiency and reduced emissions during vehicle operation. Studies indicate that for every 10% reduction in vehicle weight, fuel consumption decreases by approximately 6-8%. However, the extraction and processing of these metals, especially titanium, requires considerable energy input and generates significant carbon emissions during production phases.

Ceramic-coated components present an interesting environmental profile. While their production involves energy-intensive processes, their superior thermal properties extend engine life and improve combustion efficiency. This results in lower lifetime emissions and reduced resource consumption through decreased replacement frequency. Ceramic thermal barriers in exhaust components can improve catalytic converter efficiency by maintaining optimal operating temperatures more consistently.

Composite materials, particularly carbon fiber reinforced polymers (CFRP), offer exceptional strength-to-weight ratios but raise end-of-life concerns. Current recycling technologies for these materials remain limited and energy-intensive, creating potential waste management challenges as these components reach end-of-life. The automotive industry has begun investing in improved CFRP recycling processes, though commercial viability remains several years away.

Manufacturing processes for advanced engine materials also merit environmental consideration. Precision CNC machining of high-performance alloys generates metallic waste streams, though these are highly recyclable. Newer additive manufacturing techniques reduce material waste but may consume more energy per component produced. Life cycle assessments indicate that the environmental benefits of advanced materials typically outweigh their production impacts when considering full vehicle lifetime.

Durability factors significantly into environmental impact calculations. Premium materials that extend service intervals and overall engine lifespan reduce the environmental burden of manufacturing replacement parts. High-performance nickel alloys in valvetrain components, for instance, can double service life compared to standard materials, effectively halving the environmental impact of these components over time.

Emerging bio-based composites and recycled metal alloys represent promising directions for environmentally conscious LS1 upgrades, potentially offering comparable performance with reduced environmental footprints. Several aftermarket manufacturers have begun incorporating recycled aluminum in non-critical components, reducing primary resource demands while maintaining performance specifications.

Advanced lightweight alloys, particularly aluminum and titanium components, offer substantial environmental benefits through weight reduction. These materials contribute to improved fuel efficiency and reduced emissions during vehicle operation. Studies indicate that for every 10% reduction in vehicle weight, fuel consumption decreases by approximately 6-8%. However, the extraction and processing of these metals, especially titanium, requires considerable energy input and generates significant carbon emissions during production phases.

Ceramic-coated components present an interesting environmental profile. While their production involves energy-intensive processes, their superior thermal properties extend engine life and improve combustion efficiency. This results in lower lifetime emissions and reduced resource consumption through decreased replacement frequency. Ceramic thermal barriers in exhaust components can improve catalytic converter efficiency by maintaining optimal operating temperatures more consistently.

Composite materials, particularly carbon fiber reinforced polymers (CFRP), offer exceptional strength-to-weight ratios but raise end-of-life concerns. Current recycling technologies for these materials remain limited and energy-intensive, creating potential waste management challenges as these components reach end-of-life. The automotive industry has begun investing in improved CFRP recycling processes, though commercial viability remains several years away.

Manufacturing processes for advanced engine materials also merit environmental consideration. Precision CNC machining of high-performance alloys generates metallic waste streams, though these are highly recyclable. Newer additive manufacturing techniques reduce material waste but may consume more energy per component produced. Life cycle assessments indicate that the environmental benefits of advanced materials typically outweigh their production impacts when considering full vehicle lifetime.

Durability factors significantly into environmental impact calculations. Premium materials that extend service intervals and overall engine lifespan reduce the environmental burden of manufacturing replacement parts. High-performance nickel alloys in valvetrain components, for instance, can double service life compared to standard materials, effectively halving the environmental impact of these components over time.

Emerging bio-based composites and recycled metal alloys represent promising directions for environmentally conscious LS1 upgrades, potentially offering comparable performance with reduced environmental footprints. Several aftermarket manufacturers have begun incorporating recycled aluminum in non-critical components, reducing primary resource demands while maintaining performance specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!