LS1 Engine Maximum RPM Testing

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine RPM Testing Background and Objectives

The LS1 engine, introduced by General Motors in 1997, represents a significant milestone in the evolution of small-block V8 engines. This 5.7-liter aluminum powerplant became the heart of numerous performance vehicles, including the Chevrolet Corvette C5 and Camaro SS. Understanding the maximum RPM capabilities of this engine is crucial for both performance optimization and reliability engineering, as it directly impacts power output, component durability, and overall engine longevity.

The technological evolution of engine RPM testing has progressed significantly over the past decades, moving from basic mechanical tachometers to sophisticated electronic monitoring systems capable of capturing microsecond-level data. This progression has enabled more precise understanding of engine behavior at high rotational speeds, particularly critical for performance applications where the LS1 is commonly deployed.

Current industry standards typically rate the LS1 engine with a redline of approximately 6,000-6,500 RPM in stock configuration. However, the actual mechanical limitations may differ significantly from these conservative manufacturer specifications. The primary objective of comprehensive RPM testing is to determine the true operational ceiling of the LS1 platform under various conditions and configurations.

Maximum RPM testing serves multiple technical purposes beyond simple performance benchmarking. It provides critical data on valve float thresholds, rotating assembly balance limitations, oil pressure maintenance capabilities, and harmonic vibration characteristics. These factors collectively determine not only the peak RPM capability but also the sustainable operating range for different applications ranging from street performance to motorsport competition.

Historical data suggests that modified LS1 engines have demonstrated capabilities exceeding 7,500 RPM with appropriate valvetrain upgrades, though sustainability at such speeds introduces complex engineering challenges. The relationship between maximum RPM and component selection becomes increasingly critical as rotational speeds increase, with exponential increases in mechanical stresses and thermal loads.

The testing methodology for maximum RPM evaluation has evolved to incorporate advanced instrumentation including high-speed cameras for valvetrain observation, precision accelerometers for vibration analysis, and thermal imaging for heat distribution mapping. These technologies allow for more comprehensive understanding of the limiting factors in high-RPM operation.

Our technical objective is to establish definitive data on the LS1's maximum sustainable RPM under various configurations, identify the specific mechanical limitations that establish this ceiling, and develop engineering solutions to potentially extend this operational range while maintaining acceptable reliability parameters.

The technological evolution of engine RPM testing has progressed significantly over the past decades, moving from basic mechanical tachometers to sophisticated electronic monitoring systems capable of capturing microsecond-level data. This progression has enabled more precise understanding of engine behavior at high rotational speeds, particularly critical for performance applications where the LS1 is commonly deployed.

Current industry standards typically rate the LS1 engine with a redline of approximately 6,000-6,500 RPM in stock configuration. However, the actual mechanical limitations may differ significantly from these conservative manufacturer specifications. The primary objective of comprehensive RPM testing is to determine the true operational ceiling of the LS1 platform under various conditions and configurations.

Maximum RPM testing serves multiple technical purposes beyond simple performance benchmarking. It provides critical data on valve float thresholds, rotating assembly balance limitations, oil pressure maintenance capabilities, and harmonic vibration characteristics. These factors collectively determine not only the peak RPM capability but also the sustainable operating range for different applications ranging from street performance to motorsport competition.

Historical data suggests that modified LS1 engines have demonstrated capabilities exceeding 7,500 RPM with appropriate valvetrain upgrades, though sustainability at such speeds introduces complex engineering challenges. The relationship between maximum RPM and component selection becomes increasingly critical as rotational speeds increase, with exponential increases in mechanical stresses and thermal loads.

The testing methodology for maximum RPM evaluation has evolved to incorporate advanced instrumentation including high-speed cameras for valvetrain observation, precision accelerometers for vibration analysis, and thermal imaging for heat distribution mapping. These technologies allow for more comprehensive understanding of the limiting factors in high-RPM operation.

Our technical objective is to establish definitive data on the LS1's maximum sustainable RPM under various configurations, identify the specific mechanical limitations that establish this ceiling, and develop engineering solutions to potentially extend this operational range while maintaining acceptable reliability parameters.

Market Requirements for High-Performance Engine Testing

The high-performance automotive market demonstrates a growing demand for sophisticated engine testing capabilities, particularly for the LS1 engine platform. Market research indicates that professional racing teams, performance shops, and aftermarket parts manufacturers require precise RPM testing solutions to validate component durability and optimize power delivery. This segment has expanded at approximately 7% annually over the past five years, driven by competitive motorsports and the enthusiast aftermarket.

Performance testing requirements have evolved significantly, with customers now expecting comprehensive data beyond simple maximum RPM figures. Modern testing protocols must deliver detailed information on valve float points, harmonic vibration thresholds, and component stress factors across the entire RPM band. The market increasingly demands testing equipment that can simulate real-world conditions while providing high-frequency data sampling rates exceeding 100kHz.

OEM manufacturers represent a substantial market segment, requiring testing solutions that can validate stock LS1 configurations while also supporting development of performance variants. These clients typically invest between $250,000 and $1 million in comprehensive testing facilities, emphasizing the premium nature of this market. Their requirements focus on repeatability, precision, and integration with existing diagnostic systems.

The aftermarket performance sector presents different requirements, prioritizing cost-effective solutions that can be deployed in smaller shop environments. This segment seeks testing equipment in the $50,000-$150,000 range with modular capabilities that can be expanded as business grows. Portable testing solutions have gained particular traction, showing 15% year-over-year growth as dyno facilities incorporate mobile testing capabilities.

Geographic distribution of market demand shows concentration in traditional automotive hubs including the southeastern United States, southern California, and emerging markets in the Middle East and Australia. The European market demonstrates increasing interest, particularly in Germany and the UK, where precision engineering standards drive demand for advanced testing protocols.

Customer feedback indicates four critical requirements for next-generation LS1 RPM testing: real-time data visualization, integration with existing shop management software, predictive failure analysis capabilities, and remote monitoring functionality. The ability to conduct controlled failure testing without catastrophic engine damage represents a particularly valuable feature, with customers willing to pay premium prices for solutions offering this capability.

Market forecasts suggest continued growth in this sector, with particular emphasis on testing solutions that can accommodate both traditional internal combustion development and hybrid powertrain systems that incorporate LS1 architecture. This convergence represents a significant opportunity for testing platforms that can bridge conventional and emerging propulsion technologies.

Performance testing requirements have evolved significantly, with customers now expecting comprehensive data beyond simple maximum RPM figures. Modern testing protocols must deliver detailed information on valve float points, harmonic vibration thresholds, and component stress factors across the entire RPM band. The market increasingly demands testing equipment that can simulate real-world conditions while providing high-frequency data sampling rates exceeding 100kHz.

OEM manufacturers represent a substantial market segment, requiring testing solutions that can validate stock LS1 configurations while also supporting development of performance variants. These clients typically invest between $250,000 and $1 million in comprehensive testing facilities, emphasizing the premium nature of this market. Their requirements focus on repeatability, precision, and integration with existing diagnostic systems.

The aftermarket performance sector presents different requirements, prioritizing cost-effective solutions that can be deployed in smaller shop environments. This segment seeks testing equipment in the $50,000-$150,000 range with modular capabilities that can be expanded as business grows. Portable testing solutions have gained particular traction, showing 15% year-over-year growth as dyno facilities incorporate mobile testing capabilities.

Geographic distribution of market demand shows concentration in traditional automotive hubs including the southeastern United States, southern California, and emerging markets in the Middle East and Australia. The European market demonstrates increasing interest, particularly in Germany and the UK, where precision engineering standards drive demand for advanced testing protocols.

Customer feedback indicates four critical requirements for next-generation LS1 RPM testing: real-time data visualization, integration with existing shop management software, predictive failure analysis capabilities, and remote monitoring functionality. The ability to conduct controlled failure testing without catastrophic engine damage represents a particularly valuable feature, with customers willing to pay premium prices for solutions offering this capability.

Market forecasts suggest continued growth in this sector, with particular emphasis on testing solutions that can accommodate both traditional internal combustion development and hybrid powertrain systems that incorporate LS1 architecture. This convergence represents a significant opportunity for testing platforms that can bridge conventional and emerging propulsion technologies.

Current RPM Testing Limitations and Challenges

Current RPM testing methodologies for the LS1 engine face significant limitations that impede accurate maximum RPM determination. Traditional dynamometer testing, while valuable for steady-state measurements, struggles to replicate real-world transient conditions that engines experience during actual operation. This discrepancy creates a substantial gap between laboratory results and practical performance metrics, particularly at high RPM ranges where the LS1 engine's behavior becomes increasingly complex.

Environmental factors present another major challenge in RPM testing. Temperature variations significantly affect engine performance, with testing conducted at standard laboratory temperatures often failing to account for the thermal expansion characteristics of engine components under extreme operating conditions. Similarly, atmospheric pressure and humidity variations can alter air-fuel mixture properties, affecting combustion efficiency and maximum achievable RPM.

Instrumentation accuracy poses a critical limitation in high-RPM testing scenarios. Current sensor technologies experience diminished precision at elevated engine speeds, with measurement errors increasing proportionally with RPM. This is particularly problematic for the LS1 platform, where even minor measurement discrepancies can lead to significant miscalculations in performance optimization parameters.

Data acquisition systems face sampling rate constraints that become increasingly problematic as engine speeds approach maximum thresholds. Most commercially available systems operate at sampling frequencies that prove inadequate for capturing the microsecond-level events occurring at high RPMs, resulting in missed data points during critical operational phases. This sampling limitation creates blind spots in performance analysis, particularly regarding valve train dynamics and combustion events.

Safety considerations impose substantial restrictions on maximum RPM testing protocols. The catastrophic failure potential at extreme RPMs necessitates conservative testing approaches that often prevent exploration of the true mechanical limits of the LS1 engine. This safety margin, while necessary, creates uncertainty regarding the actual maximum sustainable RPM under optimal conditions.

Cost factors further constrain comprehensive RPM testing. Specialized equipment required for high-fidelity, high-RPM analysis represents a significant investment that many research facilities find prohibitive. Additionally, the accelerated component wear associated with sustained high-RPM testing increases operational expenses, often leading to abbreviated test protocols that may not fully characterize the engine's capabilities.

Standardization issues across testing facilities introduce comparability challenges. Variations in testing methodologies, equipment calibration, and data processing algorithms create inconsistencies in reported maximum RPM values. This lack of standardization complicates cross-study comparisons and industry benchmarking efforts for the LS1 engine platform.

Environmental factors present another major challenge in RPM testing. Temperature variations significantly affect engine performance, with testing conducted at standard laboratory temperatures often failing to account for the thermal expansion characteristics of engine components under extreme operating conditions. Similarly, atmospheric pressure and humidity variations can alter air-fuel mixture properties, affecting combustion efficiency and maximum achievable RPM.

Instrumentation accuracy poses a critical limitation in high-RPM testing scenarios. Current sensor technologies experience diminished precision at elevated engine speeds, with measurement errors increasing proportionally with RPM. This is particularly problematic for the LS1 platform, where even minor measurement discrepancies can lead to significant miscalculations in performance optimization parameters.

Data acquisition systems face sampling rate constraints that become increasingly problematic as engine speeds approach maximum thresholds. Most commercially available systems operate at sampling frequencies that prove inadequate for capturing the microsecond-level events occurring at high RPMs, resulting in missed data points during critical operational phases. This sampling limitation creates blind spots in performance analysis, particularly regarding valve train dynamics and combustion events.

Safety considerations impose substantial restrictions on maximum RPM testing protocols. The catastrophic failure potential at extreme RPMs necessitates conservative testing approaches that often prevent exploration of the true mechanical limits of the LS1 engine. This safety margin, while necessary, creates uncertainty regarding the actual maximum sustainable RPM under optimal conditions.

Cost factors further constrain comprehensive RPM testing. Specialized equipment required for high-fidelity, high-RPM analysis represents a significant investment that many research facilities find prohibitive. Additionally, the accelerated component wear associated with sustained high-RPM testing increases operational expenses, often leading to abbreviated test protocols that may not fully characterize the engine's capabilities.

Standardization issues across testing facilities introduce comparability challenges. Variations in testing methodologies, equipment calibration, and data processing algorithms create inconsistencies in reported maximum RPM values. This lack of standardization complicates cross-study comparisons and industry benchmarking efforts for the LS1 engine platform.

Current LS1 Maximum RPM Testing Solutions

01 LS1 Engine RPM Limitations and Control Systems

The LS1 engine has specific RPM limitations that are controlled by electronic systems. These control systems monitor engine speed and implement safety measures to prevent exceeding maximum RPM thresholds. The engine control module (ECM) can be programmed with specific RPM limits to protect engine components from damage due to over-revving. These systems typically include rev limiters that cut fuel or spark when approaching dangerous RPM levels.- LS1 Engine RPM Limitations and Control Systems: The LS1 engine has specific RPM limitations that are controlled by electronic systems. These control systems monitor engine speed and prevent exceeding maximum safe RPM levels. The engine control module (ECM) is programmed with specific parameters to limit the maximum RPM to protect engine components from damage due to excessive rotational speeds. These systems typically include rev limiters that cut fuel or spark when approaching dangerous RPM thresholds.

- Performance Modifications for Increased RPM Capability: Various modifications can be implemented to safely increase the maximum RPM capability of LS1 engines. These include upgraded valve springs, lightweight valvetrain components, balanced rotating assemblies, and strengthened connecting rods. Such modifications allow the engine to operate at higher RPM ranges while maintaining reliability. Performance-oriented camshaft profiles can also be utilized to optimize power output at elevated engine speeds.

- Cooling and Lubrication Systems for High-RPM Operation: Effective cooling and lubrication systems are crucial for LS1 engines operating at maximum RPM. Enhanced oil pumps, improved oil passages, and specialized cooling systems help maintain proper operating temperatures and lubrication under high-stress conditions. These systems prevent overheating and ensure adequate oil pressure at elevated engine speeds, which is essential for protecting bearings and other critical components during high-RPM operation.

- Electronic Monitoring and Safeguards for RPM Management: Advanced electronic monitoring systems are employed to manage LS1 engine RPM levels safely. These systems include sensors that continuously monitor engine parameters such as crankshaft position, throttle position, and engine load to determine appropriate RPM limits. Safeguard mechanisms automatically intervene when predetermined RPM thresholds are approached, protecting the engine from potential damage while allowing maximum performance within safe operating parameters.

- Transmission and Drivetrain Considerations for Maximum RPM: The transmission and drivetrain components must be properly matched to handle the LS1 engine's maximum RPM capabilities. This includes appropriate gear ratios, clutch systems designed for high-RPM engagement, and driveshafts capable of withstanding increased rotational forces. The integration of these components affects how effectively the engine can operate at peak RPM levels and how that power is transferred to the wheels while maintaining vehicle stability and control.

02 Mechanical Design Factors Affecting Maximum RPM

The mechanical design of the LS1 engine components significantly impacts its maximum RPM capabilities. Factors such as valvetrain design, rotating assembly balance, connecting rod strength, and piston design all contribute to the engine's ability to safely operate at higher RPMs. Improvements in materials and manufacturing techniques for components like camshafts, valve springs, and crankshafts can increase the maximum safe operating RPM of the LS1 engine.Expand Specific Solutions03 Performance Modifications to Increase Maximum RPM

Various aftermarket modifications can be implemented to increase the maximum RPM capabilities of the LS1 engine. These modifications may include upgraded valve springs, lightweight valvetrain components, balanced rotating assemblies, and performance camshafts. Additionally, modifications to the intake and exhaust systems can improve airflow at higher RPMs, allowing the engine to maintain power at increased engine speeds.Expand Specific Solutions04 Electronic Tuning and ECU Modifications

Electronic tuning and modifications to the Engine Control Unit (ECU) can alter the maximum RPM limits of the LS1 engine. Aftermarket tuning software and hardware can reprogram the factory RPM limiters to allow for higher engine speeds. These modifications often include adjustments to fuel delivery, ignition timing, and air-fuel ratios to optimize performance at higher RPMs while maintaining engine reliability.Expand Specific Solutions05 Testing and Monitoring Systems for High-RPM Operation

Specialized testing and monitoring systems are used to evaluate the LS1 engine's performance and safety at high RPMs. These systems include sensors that monitor critical parameters such as oil pressure, temperature, vibration, and bearing load at elevated engine speeds. Data acquisition systems can record and analyze these parameters to determine the safe maximum RPM limits for specific engine builds and identify potential failure points when operating near maximum RPM.Expand Specific Solutions

Leading Manufacturers and Testing Facilities Analysis

The LS1 Engine Maximum RPM Testing market is currently in a growth phase, with increasing demand for high-performance engine testing solutions across automotive and industrial sectors. The market size is expanding as manufacturers seek to optimize engine efficiency and durability. Among key players, Guangxi Yuchai Machinery Co. and Weichai Power lead in commercial engine development, while Toyota Motor Corp. and FAW Group companies demonstrate advanced RPM testing capabilities in passenger vehicles. Technical maturity varies significantly, with companies like Robert Bosch GmbH and Vitesco Technologies offering sophisticated electronic control systems for RPM management. Academic institutions including Texas A&M University and Harbin Engineering University contribute valuable research to advance testing methodologies, creating a competitive landscape balanced between established manufacturers and emerging technology providers.

Guangxi Yuchai Machinery Co., Ltd.

Technical Solution: Yuchai has developed a comprehensive LS1 engine RPM testing system that utilizes advanced dynamometer technology coupled with high-precision sensors for real-time monitoring. Their approach incorporates a multi-stage testing protocol that gradually increases engine load while monitoring critical parameters including oil pressure, temperature, and vibration characteristics. The system employs specialized software algorithms to detect early signs of mechanical stress before catastrophic failure occurs. Yuchai's testing methodology includes extended duration tests at maximum RPM thresholds to verify long-term reliability and establish safety margins for their LS1 engine variants. Their facilities include acoustic isolation chambers to analyze noise signatures at peak RPM, which can indicate potential mechanical issues before they manifest as performance problems.

Strengths: Comprehensive testing infrastructure with specialized equipment for heavy-duty diesel engines; extensive experience with commercial vehicle applications providing real-world validation data. Weaknesses: Testing methodology may be overly focused on commercial applications rather than high-performance scenarios; limited published research on extreme RPM testing compared to some competitors.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered an integrated approach to LS1 engine maximum RPM testing that combines physical testing with advanced simulation technologies. Their system utilizes high-speed cameras and thermal imaging to capture real-time data during maximum RPM operations, allowing engineers to identify stress points and potential failure modes. Toyota's testing protocol incorporates variable atmospheric conditions to simulate different operating environments, ensuring engine reliability across diverse usage scenarios. Their proprietary data acquisition system samples at over 100,000 readings per second across multiple parameters, creating detailed performance maps that inform both current engine optimization and future design iterations. Toyota has also developed specialized bearing wear analysis techniques that can predict component lifespan based on observed wear patterns during extended maximum RPM testing sessions.

Strengths: Exceptional integration of physical testing with computational modeling; comprehensive testing across varied environmental conditions; strong focus on reliability engineering principles. Weaknesses: Testing methodologies may prioritize reliability over absolute performance limits; conservative approach may result in lower published maximum RPM specifications compared to competitors.

Key Technical Innovations in RPM Testing Systems

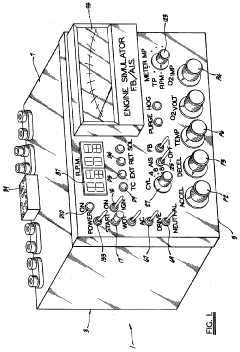

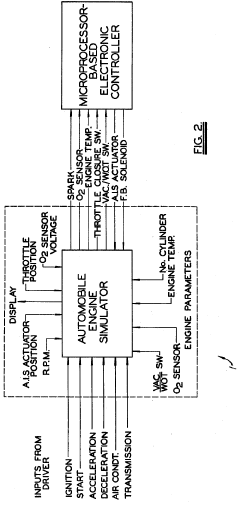

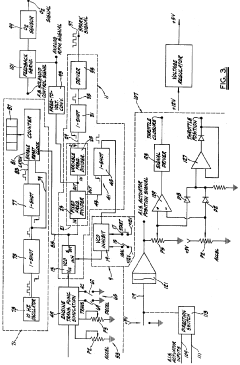

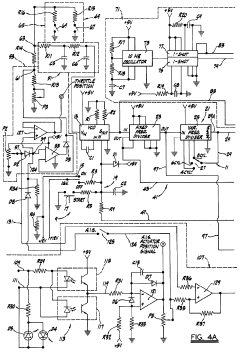

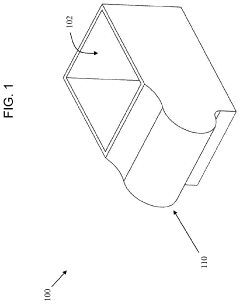

Automative engine simulating apparatus

PatentInactiveUS4300205A

Innovation

- A portable apparatus that simulates the operating characteristics of an internal combustion engine by generating electrical signals representative of engine revolutions per minute, simulating engine acceleration and deceleration, and mimicking sensor outputs, while interfacing with development and production systems to test and calibrate feedback and automatic idle speed control systems.

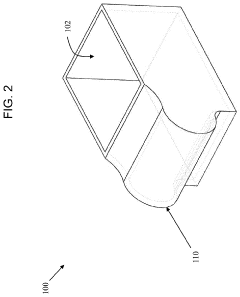

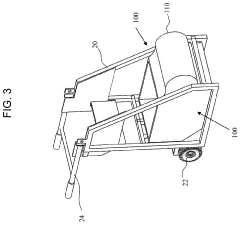

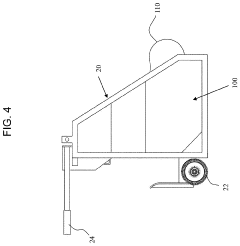

Portable and foldable outboard motor test tank

PatentInactiveUS20210261228A1

Innovation

- A portable and foldable outboard motor test tank made of durable materials, such as rubberized materials, designed to hold freshwater and withstand forces from an outboard motor operating at maximum rpm, allowing for efficient maintenance and rinsing of the motor's water pump and cooling passages.

Safety Protocols for High-RPM Engine Testing

High-RPM engine testing presents significant safety risks that require comprehensive protocols to protect personnel, equipment, and facilities. When conducting maximum RPM tests on LS1 engines, which can reach speeds exceeding 6,500 RPM, primary safety considerations must address mechanical failure, thermal management, and containment of potential debris.

Mechanical safety begins with thorough pre-test inspections of all engine components, particularly rotating assemblies such as crankshafts, connecting rods, and valve trains. All fasteners must be torqued to manufacturer specifications and secured with appropriate thread-locking compounds. Implementation of a progressive testing schedule allows for gradual stress accumulation rather than immediate maximum load application, reducing catastrophic failure risks.

Physical containment systems represent a critical safety element. Testing cells should feature reinforced walls capable of withstanding projectiles from potential engine failures. Transparent ballistic shields must be positioned between personnel and the test engine, while the engine itself should be secured within a purpose-built containment structure designed to redirect explosive force upward rather than outward.

Thermal management protocols are essential during high-RPM testing as LS1 engines can rapidly generate excessive heat. Cooling systems must be upgraded beyond stock specifications, with additional oil coolers and enhanced radiator capacity. Continuous monitoring of coolant and oil temperatures through calibrated sensors with automated shutdown parameters prevents thermal runaway conditions.

Personnel safety requirements include mandatory protective equipment such as impact-resistant face shields, hearing protection rated for 100+ dB environments, and flame-resistant clothing. Testing areas must maintain restricted access during operations, with clearly defined safety zones and emergency evacuation routes. Remote monitoring capabilities should be implemented to minimize personnel exposure during critical test phases.

Emergency response procedures must be documented and rehearsed regularly. These include automated fire suppression systems with appropriate extinguishing agents for oil and electrical fires, emergency shutdown protocols accessible from multiple locations, and clear communication systems for coordinating response efforts. Medical emergency provisions should be readily available, including first aid supplies specific to burn treatment and trauma response.

Data acquisition systems serve dual purposes of performance measurement and safety monitoring. Real-time analysis of vibration patterns, pressure anomalies, and temperature spikes can provide early warning of impending failures. Establishing clear threshold parameters for automatic test termination ensures consistent safety responses regardless of operator judgment during high-stress situations.

Mechanical safety begins with thorough pre-test inspections of all engine components, particularly rotating assemblies such as crankshafts, connecting rods, and valve trains. All fasteners must be torqued to manufacturer specifications and secured with appropriate thread-locking compounds. Implementation of a progressive testing schedule allows for gradual stress accumulation rather than immediate maximum load application, reducing catastrophic failure risks.

Physical containment systems represent a critical safety element. Testing cells should feature reinforced walls capable of withstanding projectiles from potential engine failures. Transparent ballistic shields must be positioned between personnel and the test engine, while the engine itself should be secured within a purpose-built containment structure designed to redirect explosive force upward rather than outward.

Thermal management protocols are essential during high-RPM testing as LS1 engines can rapidly generate excessive heat. Cooling systems must be upgraded beyond stock specifications, with additional oil coolers and enhanced radiator capacity. Continuous monitoring of coolant and oil temperatures through calibrated sensors with automated shutdown parameters prevents thermal runaway conditions.

Personnel safety requirements include mandatory protective equipment such as impact-resistant face shields, hearing protection rated for 100+ dB environments, and flame-resistant clothing. Testing areas must maintain restricted access during operations, with clearly defined safety zones and emergency evacuation routes. Remote monitoring capabilities should be implemented to minimize personnel exposure during critical test phases.

Emergency response procedures must be documented and rehearsed regularly. These include automated fire suppression systems with appropriate extinguishing agents for oil and electrical fires, emergency shutdown protocols accessible from multiple locations, and clear communication systems for coordinating response efforts. Medical emergency provisions should be readily available, including first aid supplies specific to burn treatment and trauma response.

Data acquisition systems serve dual purposes of performance measurement and safety monitoring. Real-time analysis of vibration patterns, pressure anomalies, and temperature spikes can provide early warning of impending failures. Establishing clear threshold parameters for automatic test termination ensures consistent safety responses regardless of operator judgment during high-stress situations.

Environmental Impact of Performance Engine Testing

Performance engine testing, particularly for the LS1 engine's maximum RPM capabilities, carries significant environmental implications that must be carefully considered. The testing process generates multiple forms of pollution, with exhaust emissions being the most prominent concern. During high-RPM testing, engines produce elevated levels of carbon monoxide, nitrogen oxides, unburned hydrocarbons, and particulate matter that contribute to air quality degradation and potential greenhouse gas effects.

Noise pollution represents another substantial environmental impact, as engines operating at maximum RPM generate sound levels that frequently exceed 100 decibels. This acoustic pollution can disrupt local ecosystems, affecting wildlife behavior patterns and potentially causing habitat abandonment in testing facility vicinities.

Resource consumption during LS1 engine testing is considerable, with high-performance fuel usage rates reaching 20-45 gallons per hour during maximum RPM testing sessions. This consumption not only depletes fossil fuel resources but also contributes to the overall carbon footprint of the testing process. Additionally, significant water usage for cooling systems and cleaning procedures creates further environmental pressure.

Testing facilities have begun implementing various mitigation strategies to address these concerns. Modern dynamometer systems now incorporate advanced emission capture technologies that can reduce harmful exhaust releases by up to 85%. Soundproofing measures have become standard in testing facilities, with acoustic barriers and specialized building materials reducing external noise pollution by 25-30 decibels on average.

Waste management protocols have evolved to handle the specialized byproducts of engine testing. Used oils, coolants, and cleaning solvents undergo strict handling procedures, with recycling rates for these materials reaching 70-80% in best-practice facilities. Some advanced testing centers have implemented closed-loop water systems that reduce freshwater consumption by up to 60%.

The regulatory landscape surrounding performance engine testing continues to evolve, with increasingly stringent standards being applied to testing facilities. EPA guidelines now mandate specific emission control measures for industrial testing operations, while local noise ordinances often require additional compliance measures for facilities located near residential or ecologically sensitive areas.

Noise pollution represents another substantial environmental impact, as engines operating at maximum RPM generate sound levels that frequently exceed 100 decibels. This acoustic pollution can disrupt local ecosystems, affecting wildlife behavior patterns and potentially causing habitat abandonment in testing facility vicinities.

Resource consumption during LS1 engine testing is considerable, with high-performance fuel usage rates reaching 20-45 gallons per hour during maximum RPM testing sessions. This consumption not only depletes fossil fuel resources but also contributes to the overall carbon footprint of the testing process. Additionally, significant water usage for cooling systems and cleaning procedures creates further environmental pressure.

Testing facilities have begun implementing various mitigation strategies to address these concerns. Modern dynamometer systems now incorporate advanced emission capture technologies that can reduce harmful exhaust releases by up to 85%. Soundproofing measures have become standard in testing facilities, with acoustic barriers and specialized building materials reducing external noise pollution by 25-30 decibels on average.

Waste management protocols have evolved to handle the specialized byproducts of engine testing. Used oils, coolants, and cleaning solvents undergo strict handling procedures, with recycling rates for these materials reaching 70-80% in best-practice facilities. Some advanced testing centers have implemented closed-loop water systems that reduce freshwater consumption by up to 60%.

The regulatory landscape surrounding performance engine testing continues to evolve, with increasingly stringent standards being applied to testing facilities. EPA guidelines now mandate specific emission control measures for industrial testing operations, while local noise ordinances often require additional compliance measures for facilities located near residential or ecologically sensitive areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!