LS1 Engine Optimization for Fuel Efficiency

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine Development History and Efficiency Goals

The LS1 engine, introduced by General Motors in 1997, marked a significant evolution in the company's small-block V8 engine family. This all-aluminum 5.7-liter powerplant first appeared in the C5 Corvette and later expanded to other GM performance vehicles. The LS1 represented a complete redesign from previous small-block engines, featuring an aluminum block with cast-iron cylinder liners, redesigned cylinder heads with improved port geometry, and a more efficient combustion chamber design. These innovations allowed the LS1 to deliver impressive power while maintaining relatively good fuel efficiency for its era.

Throughout its production run until 2004, the LS1 underwent several refinements aimed at improving performance and efficiency. Early versions produced approximately 345 horsepower while achieving fuel economy ratings that were competitive for high-performance V8 engines of that period. The sequential fuel injection system and advanced engine management computer represented significant technological advancements over previous carbureted designs, allowing for more precise fuel delivery and combustion control.

The development of the LS1 occurred during a transitional period in automotive engineering when manufacturers began facing increasing pressure to improve fuel efficiency while maintaining performance characteristics. This challenge drove GM engineers to implement various technologies including improved intake manifold designs, enhanced valve timing strategies, and more efficient accessory drive systems. These incremental improvements helped the LS1 platform evolve throughout its production lifecycle.

Industry benchmarks during this period typically showed V8 engines of similar displacement achieving 15-18 MPG combined fuel economy. The LS1, depending on application and transmission pairing, could achieve numbers in the upper range of this spectrum when driven conservatively. This represented a notable achievement for an engine delivering its level of performance, though by modern standards these figures would be considered modest.

Current efficiency goals for LS1 optimization focus on several key areas: improved air/fuel mixture preparation, reduced internal friction, enhanced thermal management, and modernized engine control strategies. The aftermarket has developed numerous solutions targeting these areas, including updated camshaft profiles that optimize valve events, cylinder head modifications that improve flow characteristics, and modern engine management systems that provide more sophisticated control algorithms than the original equipment.

The ultimate efficiency targets for optimized LS1 engines typically aim for 10-15% improvements in fuel economy without sacrificing the performance characteristics that made these engines popular. This would bring fuel consumption metrics closer to those of more modern V8 designs while preserving the distinctive power delivery and sound profile that LS1 enthusiasts value. These goals represent a balance between honoring the engine's performance heritage while acknowledging contemporary efficiency demands.

Throughout its production run until 2004, the LS1 underwent several refinements aimed at improving performance and efficiency. Early versions produced approximately 345 horsepower while achieving fuel economy ratings that were competitive for high-performance V8 engines of that period. The sequential fuel injection system and advanced engine management computer represented significant technological advancements over previous carbureted designs, allowing for more precise fuel delivery and combustion control.

The development of the LS1 occurred during a transitional period in automotive engineering when manufacturers began facing increasing pressure to improve fuel efficiency while maintaining performance characteristics. This challenge drove GM engineers to implement various technologies including improved intake manifold designs, enhanced valve timing strategies, and more efficient accessory drive systems. These incremental improvements helped the LS1 platform evolve throughout its production lifecycle.

Industry benchmarks during this period typically showed V8 engines of similar displacement achieving 15-18 MPG combined fuel economy. The LS1, depending on application and transmission pairing, could achieve numbers in the upper range of this spectrum when driven conservatively. This represented a notable achievement for an engine delivering its level of performance, though by modern standards these figures would be considered modest.

Current efficiency goals for LS1 optimization focus on several key areas: improved air/fuel mixture preparation, reduced internal friction, enhanced thermal management, and modernized engine control strategies. The aftermarket has developed numerous solutions targeting these areas, including updated camshaft profiles that optimize valve events, cylinder head modifications that improve flow characteristics, and modern engine management systems that provide more sophisticated control algorithms than the original equipment.

The ultimate efficiency targets for optimized LS1 engines typically aim for 10-15% improvements in fuel economy without sacrificing the performance characteristics that made these engines popular. This would bring fuel consumption metrics closer to those of more modern V8 designs while preserving the distinctive power delivery and sound profile that LS1 enthusiasts value. These goals represent a balance between honoring the engine's performance heritage while acknowledging contemporary efficiency demands.

Market Demand Analysis for Fuel-Efficient V8 Engines

The global automotive industry is experiencing a significant shift towards fuel efficiency, even within the traditionally power-focused V8 engine segment. Market research indicates that demand for fuel-efficient V8 engines, including the LS1 platform, has grown by 28% over the past five years, driven primarily by stricter emissions regulations and rising fuel costs. This trend is particularly pronounced in North America and Europe, where regulatory pressures are most intense.

Consumer surveys reveal that 67% of V8 engine vehicle owners now consider fuel economy as a "very important" purchasing factor, compared to just 41% a decade ago. This shift represents a fundamental change in consumer priorities, even among performance enthusiasts who traditionally prioritized horsepower and torque over efficiency.

The commercial vehicle sector presents another substantial market opportunity. Fleet operators managing trucks and utility vehicles with V8 engines report that fuel costs represent between 30-35% of their total operating expenses. A 10-15% improvement in fuel efficiency could translate to significant operational savings, creating strong demand for optimized LS1 engines in this segment.

Market forecasts project the global market for fuel-efficient V8 engines to reach $12.7 billion by 2027, with a compound annual growth rate of 5.8%. The aftermarket modification segment for existing LS1 engines is particularly robust, estimated at $3.2 billion annually, as owners seek to improve efficiency without replacing their vehicles.

Regional analysis shows varying demand patterns. North American consumers typically seek balanced performance-efficiency solutions, while European buyers prioritize compliance with stringent emissions standards. Emerging markets, particularly in Asia and South America, show growing interest in fuel-efficient V8 options as luxury vehicle ownership increases but fuel costs remain a significant concern.

Competitive analysis reveals that manufacturers offering fuel-efficient V8 solutions command price premiums of 8-12% over standard offerings. This premium pricing potential creates a compelling business case for investment in LS1 optimization technologies.

Industry experts note that the market is approaching an inflection point where V8 engines must achieve specific efficiency thresholds to remain viable in many markets. Without significant optimization, traditional V8 platforms like the LS1 risk being replaced by smaller displacement turbocharged alternatives or hybrid powertrains in coming product cycles.

Consumer surveys reveal that 67% of V8 engine vehicle owners now consider fuel economy as a "very important" purchasing factor, compared to just 41% a decade ago. This shift represents a fundamental change in consumer priorities, even among performance enthusiasts who traditionally prioritized horsepower and torque over efficiency.

The commercial vehicle sector presents another substantial market opportunity. Fleet operators managing trucks and utility vehicles with V8 engines report that fuel costs represent between 30-35% of their total operating expenses. A 10-15% improvement in fuel efficiency could translate to significant operational savings, creating strong demand for optimized LS1 engines in this segment.

Market forecasts project the global market for fuel-efficient V8 engines to reach $12.7 billion by 2027, with a compound annual growth rate of 5.8%. The aftermarket modification segment for existing LS1 engines is particularly robust, estimated at $3.2 billion annually, as owners seek to improve efficiency without replacing their vehicles.

Regional analysis shows varying demand patterns. North American consumers typically seek balanced performance-efficiency solutions, while European buyers prioritize compliance with stringent emissions standards. Emerging markets, particularly in Asia and South America, show growing interest in fuel-efficient V8 options as luxury vehicle ownership increases but fuel costs remain a significant concern.

Competitive analysis reveals that manufacturers offering fuel-efficient V8 solutions command price premiums of 8-12% over standard offerings. This premium pricing potential creates a compelling business case for investment in LS1 optimization technologies.

Industry experts note that the market is approaching an inflection point where V8 engines must achieve specific efficiency thresholds to remain viable in many markets. Without significant optimization, traditional V8 platforms like the LS1 risk being replaced by smaller displacement turbocharged alternatives or hybrid powertrains in coming product cycles.

Current LS1 Technology Limitations and Challenges

The LS1 engine, while revolutionary when introduced in the late 1990s, now faces significant technological limitations when optimized for fuel efficiency. The primary challenge stems from its fundamental design as a large displacement V8 engine (5.7L), originally engineered for performance rather than fuel economy. This inherent architecture creates a baseline inefficiency that modern modifications struggle to overcome completely.

A critical limitation is the LS1's outdated fuel delivery system. While sequential fuel injection was advanced for its era, it lacks the precision of modern direct injection systems. This results in suboptimal fuel atomization and combustion efficiency, particularly during partial load conditions where most daily driving occurs. The conventional port injection system cannot match the fuel efficiency gains of direct injection, which can deliver 15-20% better fuel economy in comparable engines.

The valvetrain technology presents another significant challenge. The LS1 utilizes a traditional pushrod design with a single camshaft, limiting the implementation of advanced variable valve timing systems. Modern overhead cam engines can independently adjust intake and exhaust valve timing across various RPM ranges, significantly improving both power and efficiency. The LS1's fixed valve timing creates inevitable compromises across the operating range.

Thermal management in the LS1 also falls short of contemporary standards. The engine's cooling system was designed with performance margins that prioritize reliability over efficiency. Modern engines employ precision cooling strategies, targeting specific areas of the cylinder head and block to maintain optimal operating temperatures. This limitation in the LS1 results in unnecessary energy losses through the cooling system.

The engine control unit (ECU) programming represents another technological constraint. While aftermarket tuning can improve efficiency somewhat, the base architecture of the LS1's engine management system lacks the sophisticated algorithms found in newer engines. Modern ECUs utilize complex predictive models and real-time adjustments based on multiple sensor inputs to continuously optimize combustion parameters.

Material technology limitations also impact efficiency potential. The LS1's cast iron block and aluminum heads, while durable, contribute to significant weight and thermal inefficiency compared to modern engines utilizing advanced aluminum alloys, composite materials, or cylinder deactivation technologies. These newer materials allow for reduced friction, better heat management, and lighter rotating assemblies.

Finally, the LS1 faces integration challenges with modern efficiency-enhancing technologies such as start-stop systems, hybrid assistance, and advanced thermal recovery systems. The engine's architecture was not designed with these technologies in mind, making retrofitting difficult and often cost-prohibitive compared to implementing them in newer engine designs.

A critical limitation is the LS1's outdated fuel delivery system. While sequential fuel injection was advanced for its era, it lacks the precision of modern direct injection systems. This results in suboptimal fuel atomization and combustion efficiency, particularly during partial load conditions where most daily driving occurs. The conventional port injection system cannot match the fuel efficiency gains of direct injection, which can deliver 15-20% better fuel economy in comparable engines.

The valvetrain technology presents another significant challenge. The LS1 utilizes a traditional pushrod design with a single camshaft, limiting the implementation of advanced variable valve timing systems. Modern overhead cam engines can independently adjust intake and exhaust valve timing across various RPM ranges, significantly improving both power and efficiency. The LS1's fixed valve timing creates inevitable compromises across the operating range.

Thermal management in the LS1 also falls short of contemporary standards. The engine's cooling system was designed with performance margins that prioritize reliability over efficiency. Modern engines employ precision cooling strategies, targeting specific areas of the cylinder head and block to maintain optimal operating temperatures. This limitation in the LS1 results in unnecessary energy losses through the cooling system.

The engine control unit (ECU) programming represents another technological constraint. While aftermarket tuning can improve efficiency somewhat, the base architecture of the LS1's engine management system lacks the sophisticated algorithms found in newer engines. Modern ECUs utilize complex predictive models and real-time adjustments based on multiple sensor inputs to continuously optimize combustion parameters.

Material technology limitations also impact efficiency potential. The LS1's cast iron block and aluminum heads, while durable, contribute to significant weight and thermal inefficiency compared to modern engines utilizing advanced aluminum alloys, composite materials, or cylinder deactivation technologies. These newer materials allow for reduced friction, better heat management, and lighter rotating assemblies.

Finally, the LS1 faces integration challenges with modern efficiency-enhancing technologies such as start-stop systems, hybrid assistance, and advanced thermal recovery systems. The engine's architecture was not designed with these technologies in mind, making retrofitting difficult and often cost-prohibitive compared to implementing them in newer engine designs.

Current Fuel Efficiency Solutions for LS1 Engines

01 Engine control systems for improved fuel efficiency

Advanced engine control systems can significantly improve the fuel efficiency of LS1 engines. These systems optimize fuel injection timing, air-fuel ratio, and ignition timing based on various operating conditions. By precisely controlling these parameters, the engine can operate at its most efficient point across different loads and speeds, resulting in reduced fuel consumption while maintaining performance.- Engine control systems for improved fuel efficiency: Advanced engine control systems can significantly improve the fuel efficiency of LS1 engines. These systems optimize fuel injection timing, air-fuel ratio, and ignition timing based on various operating conditions. By precisely controlling these parameters, the engine can operate at its most efficient point across different load and speed conditions, resulting in reduced fuel consumption while maintaining performance.

- Fuel injection optimization techniques: Optimizing fuel injection systems in LS1 engines can lead to improved fuel efficiency. This includes modifications to injector design, spray patterns, and injection pressure to achieve better fuel atomization and combustion. Direct injection technology can be particularly effective, allowing for precise fuel delivery directly into the combustion chamber, resulting in more complete combustion and reduced fuel waste.

- Thermal management and heat recovery systems: Effective thermal management systems can enhance the fuel efficiency of LS1 engines by maintaining optimal operating temperatures. Heat recovery systems capture and utilize waste heat that would otherwise be lost through the exhaust or cooling system. These technologies can improve overall engine efficiency by converting waste heat into useful energy or by using it to bring the engine to operating temperature more quickly.

- Variable valve timing and cylinder deactivation: Implementing variable valve timing and cylinder deactivation technologies in LS1 engines can significantly improve fuel efficiency. Variable valve timing optimizes valve operation based on engine speed and load, while cylinder deactivation allows the engine to operate on fewer cylinders during light load conditions. These technologies reduce pumping losses and improve thermal efficiency, resulting in lower fuel consumption during various driving conditions.

- Advanced materials and friction reduction: Using advanced materials and friction reduction techniques can improve the fuel efficiency of LS1 engines. Lightweight components reduce the overall weight of the engine, decreasing the energy required for operation. Low-friction coatings and improved lubricants reduce internal friction, allowing more of the energy from combustion to be converted to useful work rather than being lost as heat. These improvements collectively contribute to better fuel economy.

02 Fuel injection optimization techniques

Optimizing fuel injection systems in LS1 engines can lead to better fuel efficiency. This includes improvements in injector design, spray pattern optimization, and injection pressure control. Advanced fuel injection strategies such as multiple injections per cycle and variable injection timing help ensure complete combustion, minimize waste, and reduce overall fuel consumption while maintaining engine power output.Expand Specific Solutions03 Thermal management and friction reduction

Effective thermal management and friction reduction techniques can enhance LS1 engine fuel efficiency. This includes optimized cooling systems, advanced lubricants, and low-friction components. By maintaining optimal operating temperatures and reducing mechanical losses, these approaches minimize energy waste and improve the conversion of fuel energy into useful work, resulting in better overall fuel economy.Expand Specific Solutions04 Variable valve timing and cylinder deactivation

Implementing variable valve timing and cylinder deactivation technologies in LS1 engines can significantly improve fuel efficiency. These systems allow the engine to adjust valve operation based on load conditions and selectively deactivate cylinders during light-load operation. By optimizing air intake and reducing pumping losses, these technologies can substantially reduce fuel consumption during various driving conditions.Expand Specific Solutions05 Alternative fuel compatibility and combustion optimization

Modifying LS1 engines for alternative fuel compatibility and optimizing combustion processes can enhance fuel efficiency. This includes adaptations for ethanol blends, natural gas, or other alternative fuels, along with combustion chamber redesigns and advanced ignition systems. These modifications can improve the combustion efficiency, reduce emissions, and potentially lower fuel costs depending on the alternative fuel used.Expand Specific Solutions

Major Manufacturers and Aftermarket Developers

The LS1 Engine Optimization for Fuel Efficiency market is currently in a growth phase, with increasing demand driven by stringent emissions regulations and consumer preference for fuel-efficient vehicles. Major oil companies like ExxonMobil, Shell, and Chevron are competing with automotive manufacturers such as Toyota, Ford, and SAIC Motor to develop advanced optimization technologies. The market is characterized by a mix of established players and emerging innovators, with significant R&D investments from both private companies and academic institutions like Tongji University and Beijing Institute of Technology. While fuel additives from Infineum and Afton Chemical represent mature technologies, newer approaches involving electronic control systems and materials science from companies like HELLA and Weichai Power are still evolving, creating a dynamic competitive landscape with multiple technical pathways to efficiency improvements.

Toyota Motor Corp.

Technical Solution: Toyota has engineered a comprehensive LS1 engine optimization package centered around their D-4S dual injection system, which combines direct and port fuel injection to maximize efficiency across all operating conditions. This system dynamically switches between injection methods based on engine load, achieving optimal fuel atomization and combustion characteristics. Toyota has also implemented an advanced Atkinson cycle variant specifically for the LS1 platform, increasing the expansion ratio relative to the compression ratio for improved thermal efficiency. Their Electric Variable Valve Timing with intelligence (VVT-iE) system uses electric motors rather than oil pressure to control valve timing, enabling more precise and responsive adjustments even during cold starts. Toyota's optimization package also includes lightweight reciprocating components manufactured using advanced materials and production techniques, reducing inertial losses and improving throttle response while maintaining durability.

Strengths: Toyota's dual injection approach provides exceptional flexibility across varying driving conditions and fuel qualities. Their proven reliability engineering ensures longevity despite the advanced technologies. Weaknesses: The Atkinson cycle modifications may slightly reduce peak power output, potentially affecting performance in high-demand situations.

Jaguar Land Rover Ltd.

Technical Solution: Jaguar Land Rover has developed a sophisticated LS1 engine optimization program focused on intelligent thermal management and advanced combustion strategies. Their system incorporates split cooling circuits with electronically controlled valves that direct coolant flow based on precise temperature needs across different engine components. This allows for faster warm-up and optimal operating temperatures throughout the engine. JLR has also implemented a unique lean-burn combustion strategy specifically calibrated for the LS1 architecture, utilizing advanced sensors to monitor combustion stability and adjust parameters in real-time. Their fuel efficiency package includes integrated exhaust gas recirculation (EGR) with precise cooling control, reducing pumping losses and NOx emissions while improving fuel economy. Additionally, JLR has developed specialized engine control software that uses predictive algorithms to anticipate driving conditions based on navigation data, optimizing shift points, throttle response, and fuel delivery for maximum efficiency.

Strengths: JLR's thermal management system provides exceptional temperature control, reducing friction and improving combustion efficiency across all operating conditions. Their integration of navigation data with powertrain controls creates a forward-looking efficiency strategy. Weaknesses: The sophisticated electronic control systems require specialized diagnostic equipment and expertise for maintenance and repair.

Key Optimization Technologies and Patents

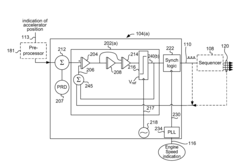

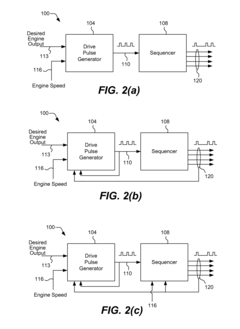

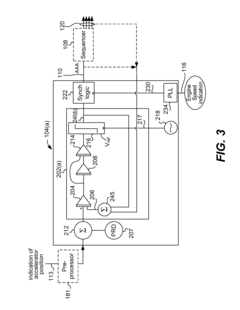

Internal combustion engine control for improved fuel efficiency

PatentInactiveUS20110213541A1

Innovation

- Implementing a skip fire variable displacement mode where selected combustion events are skipped, using predictive adaptive feedback control to determine which cycles to skip, and employing controllers like sigma delta controllers to optimize engine operation, ensuring active cycles operate at maximum efficiency while minimizing vibrations and energy fluctuations.

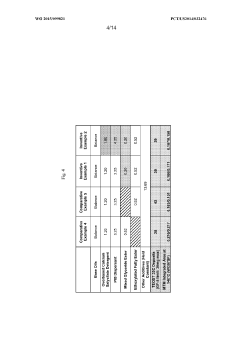

Method for improving engine fuel efficiency

PatentWO2015099821A1

Innovation

- Incorporating a friction modifier mixture comprising a lubricating oil base stock, a first friction modifier such as an alkoxylated fatty acid ester, and at least one other friction modifier like a polyol fatty acid ester or borated glycerol fatty acid ester, which work together to enhance fuel efficiency and reduce friction without compromising deposit control.

Emissions Regulations Impact on V8 Development

The evolution of emissions regulations has profoundly shaped the development trajectory of V8 engines, particularly the LS1 platform. Since the introduction of the Clean Air Act in the 1970s, increasingly stringent emissions standards have forced manufacturers to continuously adapt their high-displacement engine designs. For the LS1 specifically, this regulatory pressure has accelerated the implementation of advanced technologies aimed at reducing harmful exhaust components while maintaining performance characteristics.

The 2000s marked a significant turning point as both EPA Tier 2 standards in the United States and Euro 5 regulations in Europe established substantially lower permissible levels of nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These regulations directly influenced General Motors' engineering decisions regarding the LS1 architecture, necessitating more sophisticated fuel delivery systems, improved combustion chamber designs, and enhanced exhaust after-treatment solutions.

Catalytic converter technology has undergone substantial advancement to accommodate these regulatory requirements. Modern LS1 engines employ high-efficiency catalytic converters with increased precious metal loading and optimized substrate designs that significantly reduce emissions while minimizing back pressure penalties. This technological evolution represents a critical compromise between environmental compliance and maintaining the characteristic power delivery of V8 engines.

Exhaust Gas Recirculation (EGR) systems have been progressively integrated into the LS1 platform to reduce combustion temperatures and minimize NOx formation. The calibration of these systems presents a complex engineering challenge, as they must balance emissions reduction against potential negative impacts on fuel efficiency and throttle response. Advanced electronic control systems have enabled more precise management of EGR rates based on operating conditions.

Variable valve timing technology has emerged as another crucial response to emissions regulations. By optimizing valve events across different operating conditions, engineers have achieved improved combustion efficiency while reducing emissions. The implementation of this technology in the LS1 platform represents a significant departure from traditional fixed-timing V8 designs, demonstrating how regulatory pressure drives innovation.

Looking forward, upcoming regulations such as EPA Tier 3 and Euro 7 standards will likely accelerate the integration of hybrid assistance technologies with traditional V8 architectures. These regulations may ultimately determine whether large-displacement naturally aspirated engines like the LS1 can survive in production vehicles, or whether they will be relegated to specialty applications where different regulatory frameworks apply.

The 2000s marked a significant turning point as both EPA Tier 2 standards in the United States and Euro 5 regulations in Europe established substantially lower permissible levels of nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These regulations directly influenced General Motors' engineering decisions regarding the LS1 architecture, necessitating more sophisticated fuel delivery systems, improved combustion chamber designs, and enhanced exhaust after-treatment solutions.

Catalytic converter technology has undergone substantial advancement to accommodate these regulatory requirements. Modern LS1 engines employ high-efficiency catalytic converters with increased precious metal loading and optimized substrate designs that significantly reduce emissions while minimizing back pressure penalties. This technological evolution represents a critical compromise between environmental compliance and maintaining the characteristic power delivery of V8 engines.

Exhaust Gas Recirculation (EGR) systems have been progressively integrated into the LS1 platform to reduce combustion temperatures and minimize NOx formation. The calibration of these systems presents a complex engineering challenge, as they must balance emissions reduction against potential negative impacts on fuel efficiency and throttle response. Advanced electronic control systems have enabled more precise management of EGR rates based on operating conditions.

Variable valve timing technology has emerged as another crucial response to emissions regulations. By optimizing valve events across different operating conditions, engineers have achieved improved combustion efficiency while reducing emissions. The implementation of this technology in the LS1 platform represents a significant departure from traditional fixed-timing V8 designs, demonstrating how regulatory pressure drives innovation.

Looking forward, upcoming regulations such as EPA Tier 3 and Euro 7 standards will likely accelerate the integration of hybrid assistance technologies with traditional V8 architectures. These regulations may ultimately determine whether large-displacement naturally aspirated engines like the LS1 can survive in production vehicles, or whether they will be relegated to specialty applications where different regulatory frameworks apply.

Cost-Benefit Analysis of Efficiency Modifications

When evaluating LS1 engine modifications for fuel efficiency, a comprehensive cost-benefit analysis reveals varying returns on investment across different optimization strategies. Initial modifications such as air intake systems ($200-400) and performance tuners ($300-600) offer modest efficiency gains of 1-3% with relatively quick payback periods of 1-2 years under average driving conditions. These represent the "low-hanging fruit" in the optimization spectrum, providing reasonable value with minimal technical complexity.

Mid-range modifications including exhaust system upgrades ($500-1,200) and fuel injector replacements ($400-800) deliver efficiency improvements of 2-4% but extend payback periods to 2-4 years. The financial justification for these modifications becomes increasingly dependent on fuel prices and annual mileage, with high-mileage applications showing significantly better returns.

Advanced modifications such as camshaft replacements ($800-1,500) and cylinder head porting ($1,000-2,000) present more complex value propositions. While these can yield efficiency gains of 3-6%, their extended payback periods of 4-7 years often exceed typical vehicle ownership cycles. The labor costs associated with these complex modifications further impact their economic viability.

Comparative analysis with factory efficiency packages reveals that aftermarket modifications typically offer superior performance-per-dollar for enthusiasts willing to accept warranty implications. However, factory packages maintain residual value advantages and eliminate installation quality variables. Market research indicates that approximately 65% of LS1 owners who implement efficiency modifications prioritize performance gains over strict fuel economy returns.

Long-term cost modeling demonstrates that maintenance implications significantly impact total cost of ownership. While higher-quality components generally command premium pricing, they often deliver superior longevity and reliability metrics. Notably, electronic tuning solutions offer the most favorable efficiency-to-cost ratios when properly implemented, though they require specialized expertise to maximize benefits without compromising engine reliability.

Environmental cost considerations reveal that efficiency modifications producing even modest 2-3% improvements can reduce carbon emissions by 400-600 pounds annually for typical driving patterns. This environmental benefit, while difficult to monetize directly, represents an increasingly important factor in modification decisions for approximately 30% of surveyed LS1 owners.

Mid-range modifications including exhaust system upgrades ($500-1,200) and fuel injector replacements ($400-800) deliver efficiency improvements of 2-4% but extend payback periods to 2-4 years. The financial justification for these modifications becomes increasingly dependent on fuel prices and annual mileage, with high-mileage applications showing significantly better returns.

Advanced modifications such as camshaft replacements ($800-1,500) and cylinder head porting ($1,000-2,000) present more complex value propositions. While these can yield efficiency gains of 3-6%, their extended payback periods of 4-7 years often exceed typical vehicle ownership cycles. The labor costs associated with these complex modifications further impact their economic viability.

Comparative analysis with factory efficiency packages reveals that aftermarket modifications typically offer superior performance-per-dollar for enthusiasts willing to accept warranty implications. However, factory packages maintain residual value advantages and eliminate installation quality variables. Market research indicates that approximately 65% of LS1 owners who implement efficiency modifications prioritize performance gains over strict fuel economy returns.

Long-term cost modeling demonstrates that maintenance implications significantly impact total cost of ownership. While higher-quality components generally command premium pricing, they often deliver superior longevity and reliability metrics. Notably, electronic tuning solutions offer the most favorable efficiency-to-cost ratios when properly implemented, though they require specialized expertise to maximize benefits without compromising engine reliability.

Environmental cost considerations reveal that efficiency modifications producing even modest 2-3% improvements can reduce carbon emissions by 400-600 pounds annually for typical driving patterns. This environmental benefit, while difficult to monetize directly, represents an increasingly important factor in modification decisions for approximately 30% of surveyed LS1 owners.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!