How to Rebuild an LS1 Engine

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine History and Rebuild Objectives

The LS1 engine, introduced by General Motors in 1997, represents a significant milestone in automotive engineering history. This small-block V8 engine first appeared in the C5 Corvette and quickly became renowned for its lightweight aluminum construction, impressive power output, and remarkable efficiency. The LS1 belongs to the broader LS engine family, which has since evolved through multiple generations and continues to influence modern engine design principles across the automotive industry.

The development of the LS1 engine stemmed from GM's need to create a more fuel-efficient, powerful, and emissions-compliant V8 engine to replace the aging LT1 platform. Engineers implemented several revolutionary design elements, including a deep-skirt block design, high-flow cylinder heads, and a sophisticated electronic control system. These innovations allowed the LS1 to produce 345 horsepower and 350 lb-ft of torque in its initial configuration while maintaining reasonable fuel economy.

Over its production life from 1997 to 2004, the LS1 underwent various refinements and improvements. These evolutionary changes addressed initial design limitations and enhanced performance characteristics, making the engine increasingly popular among performance enthusiasts and custom builders. The LS1's adaptability and robust architecture have contributed to its enduring legacy in both factory applications and aftermarket modifications.

The primary objectives of an LS1 engine rebuild typically fall into several categories. Performance enhancement represents a common goal, with rebuilders seeking to increase horsepower, torque, and overall engine efficiency through upgraded components and optimized specifications. Reliability improvement constitutes another critical objective, particularly for engines with high mileage or those subjected to demanding conditions such as racing or towing.

Modernization serves as another rebuild objective, allowing owners to incorporate newer technologies and materials that weren't available during the original production run. This might include updated valvetrain components, modern sealing technologies, or enhanced lubrication systems. For classic vehicle restorations, period-correct rebuilds focus on maintaining originality while addressing wear issues and ensuring proper functionality.

Cost considerations invariably influence rebuild objectives, with budget constraints often determining the extent of modifications and quality of replacement parts. The technical complexity of the rebuild must align with the rebuilder's skill level, available tools, and workshop facilities. Finally, the intended application—whether daily driving, occasional weekend cruising, drag racing, or track days—significantly shapes the specific rebuild goals and component selection criteria.

The development of the LS1 engine stemmed from GM's need to create a more fuel-efficient, powerful, and emissions-compliant V8 engine to replace the aging LT1 platform. Engineers implemented several revolutionary design elements, including a deep-skirt block design, high-flow cylinder heads, and a sophisticated electronic control system. These innovations allowed the LS1 to produce 345 horsepower and 350 lb-ft of torque in its initial configuration while maintaining reasonable fuel economy.

Over its production life from 1997 to 2004, the LS1 underwent various refinements and improvements. These evolutionary changes addressed initial design limitations and enhanced performance characteristics, making the engine increasingly popular among performance enthusiasts and custom builders. The LS1's adaptability and robust architecture have contributed to its enduring legacy in both factory applications and aftermarket modifications.

The primary objectives of an LS1 engine rebuild typically fall into several categories. Performance enhancement represents a common goal, with rebuilders seeking to increase horsepower, torque, and overall engine efficiency through upgraded components and optimized specifications. Reliability improvement constitutes another critical objective, particularly for engines with high mileage or those subjected to demanding conditions such as racing or towing.

Modernization serves as another rebuild objective, allowing owners to incorporate newer technologies and materials that weren't available during the original production run. This might include updated valvetrain components, modern sealing technologies, or enhanced lubrication systems. For classic vehicle restorations, period-correct rebuilds focus on maintaining originality while addressing wear issues and ensuring proper functionality.

Cost considerations invariably influence rebuild objectives, with budget constraints often determining the extent of modifications and quality of replacement parts. The technical complexity of the rebuild must align with the rebuilder's skill level, available tools, and workshop facilities. Finally, the intended application—whether daily driving, occasional weekend cruising, drag racing, or track days—significantly shapes the specific rebuild goals and component selection criteria.

Market Analysis for LS1 Rebuilds and Performance Parts

The LS1 engine rebuild and performance parts market has experienced significant growth over the past decade, driven by the enduring popularity of GM's LS engine platform among automotive enthusiasts. Market research indicates that the global automotive aftermarket for performance parts was valued at approximately $340 billion in 2022, with the LS-specific segment representing a substantial portion of the V8 performance market.

Consumer demand analysis reveals three primary market segments: restoration specialists seeking factory-correct rebuilds, performance enthusiasts pursuing moderate power gains, and racing professionals requiring maximum performance modifications. The restoration segment has shown steady 5-7% annual growth, while the performance modification segment has expanded more rapidly at 8-10% annually, reflecting the growing popularity of LS swaps into various vehicle platforms.

Regional market distribution shows particular strength in North America, where the LS1 originated, with the Southern and Midwestern United States representing the highest concentration of customers. However, international markets including Australia, Europe, and the Middle East have shown increasing demand, particularly as global motorsport continues to embrace LS-based powerplants.

Price sensitivity varies significantly across market segments. Entry-level rebuild kits typically range from $600-1,500, while comprehensive performance builds can command $5,000-15,000 depending on component quality and performance targets. Premium racing-oriented builds frequently exceed $20,000, representing a smaller but highly profitable market segment.

Distribution channels have evolved considerably, with traditional brick-and-mortar speed shops now competing with specialized online retailers. E-commerce platforms have captured approximately 65% of the aftermarket parts sales for LS engines, offering consumers greater selection and competitive pricing. However, professional installation services remain predominantly local, creating partnership opportunities between online retailers and installation shops.

Market forecasts project continued growth in the LS rebuild sector despite the platform's age, with compound annual growth rates estimated at 4-6% through 2028. This resilience is attributed to the engine's modular design, abundant parts availability, and extensive knowledge base. The emergence of hybrid and electric vehicles has not significantly impacted this market segment, as enthusiasts continue to value the simplicity, reliability, and modification potential of the LS platform.

Competition analysis reveals a fragmented market with numerous specialized manufacturers focusing on specific component categories rather than comprehensive solutions. This creates opportunities for businesses that can offer integrated rebuild packages and technical support across the entire rebuild process.

Consumer demand analysis reveals three primary market segments: restoration specialists seeking factory-correct rebuilds, performance enthusiasts pursuing moderate power gains, and racing professionals requiring maximum performance modifications. The restoration segment has shown steady 5-7% annual growth, while the performance modification segment has expanded more rapidly at 8-10% annually, reflecting the growing popularity of LS swaps into various vehicle platforms.

Regional market distribution shows particular strength in North America, where the LS1 originated, with the Southern and Midwestern United States representing the highest concentration of customers. However, international markets including Australia, Europe, and the Middle East have shown increasing demand, particularly as global motorsport continues to embrace LS-based powerplants.

Price sensitivity varies significantly across market segments. Entry-level rebuild kits typically range from $600-1,500, while comprehensive performance builds can command $5,000-15,000 depending on component quality and performance targets. Premium racing-oriented builds frequently exceed $20,000, representing a smaller but highly profitable market segment.

Distribution channels have evolved considerably, with traditional brick-and-mortar speed shops now competing with specialized online retailers. E-commerce platforms have captured approximately 65% of the aftermarket parts sales for LS engines, offering consumers greater selection and competitive pricing. However, professional installation services remain predominantly local, creating partnership opportunities between online retailers and installation shops.

Market forecasts project continued growth in the LS rebuild sector despite the platform's age, with compound annual growth rates estimated at 4-6% through 2028. This resilience is attributed to the engine's modular design, abundant parts availability, and extensive knowledge base. The emergence of hybrid and electric vehicles has not significantly impacted this market segment, as enthusiasts continue to value the simplicity, reliability, and modification potential of the LS platform.

Competition analysis reveals a fragmented market with numerous specialized manufacturers focusing on specific component categories rather than comprehensive solutions. This creates opportunities for businesses that can offer integrated rebuild packages and technical support across the entire rebuild process.

Current LS1 Rebuild Challenges and Technical Limitations

Despite significant advancements in automotive engineering, LS1 engine rebuilding continues to present several technical challenges that limit both professional mechanics and enthusiasts. The primary limitation remains the specialized tooling requirements, which include custom cylinder hone fixtures, torque angle meters, and proprietary GM diagnostic equipment. These tools represent substantial investments that many independent shops cannot justify for occasional LS1 rebuilds, creating a technical barrier to entry.

Material degradation presents another significant challenge, particularly with aluminum components that experience thermal cycling. The LS1's aluminum block and heads are susceptible to warping under extreme conditions, while valve seats may recede after extended high-temperature operation. Current metallurgical solutions only partially address these issues, requiring careful measurement and potential replacement of affected components during rebuilds.

Precision tolerances represent a formidable technical limitation in LS1 rebuilding. The engine's performance characteristics depend on maintaining clearances within micron-level specifications, particularly for main bearings and piston-to-wall clearances. Traditional measurement tools often lack the precision required for optimal rebuilding, while modern digital measurement systems remain prohibitively expensive for many rebuilders.

The integration of electronic systems with mechanical components creates additional complexity. The LS1's engine management system requires specific calibration parameters that must be maintained or recalibrated during rebuilding. Current aftermarket solutions for ECU reprogramming often lack the sophistication of factory tools, resulting in suboptimal performance or reliability issues after rebuilds.

Heat management during the rebuilding process itself presents technical challenges. Proper thermal expansion techniques for press-fitting components like valve guides and cylinder sleeves require precise temperature control that many rebuilding environments cannot maintain consistently. This limitation often leads to premature component failure or improper seating.

Supply chain constraints have emerged as a contemporary limitation, with certain OEM components becoming increasingly scarce. This scarcity has driven rebuilders toward aftermarket alternatives of varying quality, creating inconsistency in rebuild outcomes. The lack of standardization in aftermarket parts specifications further complicates quality control during rebuilds.

Knowledge transfer represents a final but critical limitation. The specialized techniques for LS1 rebuilding developed by experienced mechanics often remain undocumented, creating a widening knowledge gap as veteran rebuilders retire. Current technical documentation fails to capture many of the nuanced approaches required for addressing LS1-specific issues, limiting the development of new rebuilding expertise.

Material degradation presents another significant challenge, particularly with aluminum components that experience thermal cycling. The LS1's aluminum block and heads are susceptible to warping under extreme conditions, while valve seats may recede after extended high-temperature operation. Current metallurgical solutions only partially address these issues, requiring careful measurement and potential replacement of affected components during rebuilds.

Precision tolerances represent a formidable technical limitation in LS1 rebuilding. The engine's performance characteristics depend on maintaining clearances within micron-level specifications, particularly for main bearings and piston-to-wall clearances. Traditional measurement tools often lack the precision required for optimal rebuilding, while modern digital measurement systems remain prohibitively expensive for many rebuilders.

The integration of electronic systems with mechanical components creates additional complexity. The LS1's engine management system requires specific calibration parameters that must be maintained or recalibrated during rebuilding. Current aftermarket solutions for ECU reprogramming often lack the sophistication of factory tools, resulting in suboptimal performance or reliability issues after rebuilds.

Heat management during the rebuilding process itself presents technical challenges. Proper thermal expansion techniques for press-fitting components like valve guides and cylinder sleeves require precise temperature control that many rebuilding environments cannot maintain consistently. This limitation often leads to premature component failure or improper seating.

Supply chain constraints have emerged as a contemporary limitation, with certain OEM components becoming increasingly scarce. This scarcity has driven rebuilders toward aftermarket alternatives of varying quality, creating inconsistency in rebuild outcomes. The lack of standardization in aftermarket parts specifications further complicates quality control during rebuilds.

Knowledge transfer represents a final but critical limitation. The specialized techniques for LS1 rebuilding developed by experienced mechanics often remain undocumented, creating a widening knowledge gap as veteran rebuilders retire. Current technical documentation fails to capture many of the nuanced approaches required for addressing LS1-specific issues, limiting the development of new rebuilding expertise.

Standard LS1 Rebuild Methodologies and Procedures

01 LS1 Engine Design and Components

The LS1 engine is characterized by its specific design features and components that contribute to its performance and efficiency. These include the engine block, cylinder heads, valvetrain, and other critical components that are engineered for optimal power output and durability. The design incorporates advanced materials and manufacturing techniques to reduce weight while maintaining strength.- LS1 Engine Design and Components: The LS1 engine is a V8 engine design with specific components and configurations. It features a unique block design, cylinder head configuration, and intake/exhaust system. The engine's architecture includes specialized valvetrain components, cooling systems, and lubrication systems that contribute to its performance characteristics. These design elements are critical to the engine's power output, efficiency, and reliability.

- LS1 Engine Performance Enhancements: Various modifications and enhancements can be applied to the LS1 engine to improve its performance. These include upgraded camshafts, high-flow cylinder heads, performance intake manifolds, and exhaust systems. Electronic control unit (ECU) tuning and fuel system upgrades are also common methods to increase horsepower and torque. These performance enhancements can be implemented individually or in combination to achieve desired power outputs.

- LS1 Engine Integration Systems: The integration of LS1 engines into various vehicles requires specific mounting systems, wiring harnesses, and control interfaces. Adaptation systems for different transmission types, cooling systems, and exhaust configurations are essential for successful engine swaps. These integration systems often include specialized brackets, electronic interfaces, and custom components to ensure proper fitment and functionality in different vehicle platforms.

- LS1 Engine Cooling and Thermal Management: Effective cooling and thermal management are crucial for LS1 engine performance and longevity. This includes specialized cooling jackets, water pump designs, thermostat configurations, and radiator systems. Advanced thermal management techniques may incorporate oil coolers, heat exchangers, and electronic temperature control systems. These systems work together to maintain optimal operating temperatures under various driving conditions and power outputs.

- LS1 Engine Aesthetic and External Design: The external appearance and aesthetic design of LS1 engines and their components include distinctive valve covers, intake manifolds, and accessory mounting systems. Custom finishes, colors, and decorative elements can be applied to enhance the visual appeal of the engine. These design aspects often include branded elements, specialized textures, and unique shapes that distinguish the LS1 engine in engine bay presentations and showcase applications.

02 LS1 Engine Performance Enhancements

Various modifications and enhancements can be applied to the LS1 engine to improve its performance characteristics. These include upgrades to the fuel delivery system, ignition system, exhaust system, and intake manifold. Performance tuning of the engine control module (ECM) can also optimize power output, torque, and fuel efficiency across different operating conditions.Expand Specific Solutions03 LS1 Engine Integration Systems

The integration of the LS1 engine with vehicle systems involves specialized mounting, cooling, electrical, and control interfaces. These integration systems ensure proper function of the engine within the vehicle's overall architecture, including compatibility with transmission systems, cooling systems, and electronic control units. Proper integration is essential for optimal engine performance and vehicle drivability.Expand Specific Solutions04 LS1 Engine Cooling and Thermal Management

Thermal management systems for the LS1 engine include specialized cooling components and strategies to maintain optimal operating temperatures. These systems may include advanced radiator designs, oil coolers, thermostat controls, and cooling fans. Effective thermal management is crucial for engine longevity, performance consistency, and prevention of heat-related failures.Expand Specific Solutions05 LS1 Engine Aesthetic and External Design

The external appearance and aesthetic design elements of the LS1 engine include distinctive covers, badges, and visual components that contribute to its recognizable identity. These design elements may serve both functional and aesthetic purposes, such as engine covers that provide thermal insulation while also enhancing the visual appeal of the engine compartment.Expand Specific Solutions

Major Manufacturers in LS1 Aftermarket Industry

The LS1 engine rebuild market is currently in a mature growth phase, characterized by a stable demand from automotive enthusiasts and performance vehicle owners. The market size is estimated at approximately $500-700 million annually, driven by aftermarket parts and specialized rebuild services. From a technical maturity perspective, the landscape is well-established with major automotive manufacturers like Ford Global Technologies, GM Global Technology Operations, and Toyota Motor Corp leading innovation in engine rebuilding technologies and performance enhancement. Specialized companies such as Henan Diesel Engine Industry and Anhui Quanchai Engine Co. have developed comprehensive rebuild solutions, while performance-focused entities like Guangxi Yuchai Machinery offer advanced component upgrades. The competitive environment balances between OEM-quality rebuilds and aftermarket performance enhancements, with increasing integration of digital diagnostics and precision machining technologies.

Ford Global Technologies LLC

Technical Solution: While Ford is a major automotive manufacturer, they don't have specific technical solutions for rebuilding LS1 engines as these are General Motors products. Ford's engine rebuilding technologies focus on their own engine families like the Modular V8, EcoBoost, and Coyote platforms. Their approach to engine rebuilding generally involves similar fundamental processes including disassembly, cleaning, inspection, machining, and reassembly with precision measurements and quality control, but these are not directly applicable to the GM LS1 architecture which has different design characteristics, dimensions, and specifications. Ford's engine rebuilding protocols are optimized for their own engine designs and would require significant adaptation to be applied to an LS1 rebuild project.

Not applicable as Ford does not have specific LS1 rebuilding technology. Their strengths lie in rebuilding Ford-designed engines with proprietary knowledge of their own platforms.

GM Global Technology Operations LLC

Technical Solution: GM's LS1 engine rebuilding technology focuses on a comprehensive approach that includes advanced machining processes and precision assembly techniques. Their method involves complete disassembly, thorough inspection, and precision machining of the block and cylinder heads. GM employs specialized honing techniques for cylinder walls to achieve optimal cross-hatching patterns that enhance oil retention and ring sealing. Their rebuilding process incorporates proprietary camshaft profiles designed specifically for the LS1 architecture, optimizing valve timing for improved performance across various RPM ranges. GM's approach also includes advanced balancing procedures for rotating assemblies, utilizing computer-aided equipment to achieve tolerances within 1-2 grams. The company has developed specific torque sequences and specifications for critical fasteners, ensuring proper loading and preventing distortion of components. Additionally, GM implements a break-in procedure that gradually increases load on the engine to properly seat piston rings and establish oil film on bearing surfaces.

Strengths: Access to original engineering specifications and proprietary knowledge of the LS1 design; extensive testing facilities to validate rebuilding procedures; comprehensive quality control processes. Weaknesses: Higher cost compared to aftermarket solutions; less flexibility for performance modifications beyond factory specifications; longer lead times due to rigorous quality control processes.

Critical Technologies in Modern LS1 Engine Rebuilding

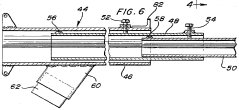

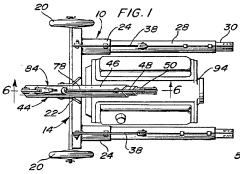

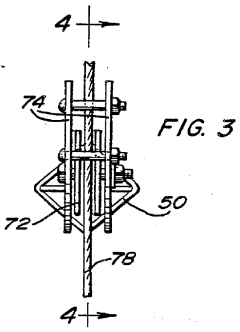

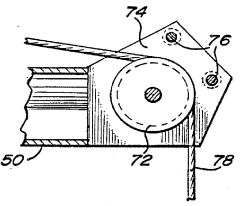

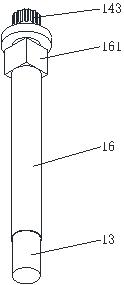

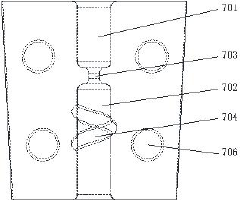

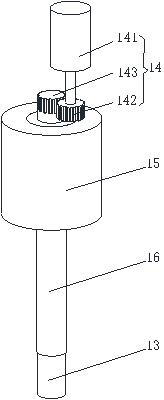

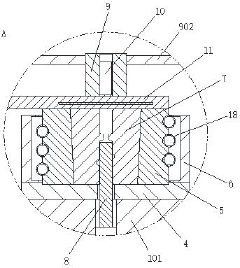

Mobile engine hoist and rebuild stand assembly

PatentInactiveUS4770304A

Innovation

- A mobile engine hoist and rebuild stand assembly with a removable boom and adjustable angular displacement, featuring telescoping components and a come-along system for lifting and securing engines, allowing for easy access and compact storage.

Integrated preparation process of B4C reinforced 6082Al composite material

PatentActiveCN117733143A

Innovation

- An integrated B4C-reinforced 6082Al composite material preparation device is used. Through the combined use of a press, a hydraulic cylinder and a deformation die, the composite powder can be directly loaded and subjected to large plastic deformation, avoiding sintering and utilizing upsetting deformation and extrusion deformation. Achieve low-temperature consolidation and reduce the unevenness of material diameter reduction and extrusion deformation.

Environmental Considerations in Engine Rebuilding

Engine rebuilding processes have significant environmental implications that must be addressed in modern automotive maintenance practices. The LS1 engine rebuilding process generates various waste materials including used oil, coolant, cleaning solvents, metal shavings, and worn components that require proper disposal according to environmental regulations. EPA guidelines mandate specific handling procedures for these automotive fluids and parts, with severe penalties for non-compliance that can reach tens of thousands of dollars for commercial operations.

Sustainable rebuilding practices have emerged as industry standards, focusing on responsible fluid disposal through certified recycling centers. Used engine oil, which can contaminate up to one million gallons of freshwater if improperly discarded, must be collected in approved containers and transported to designated collection facilities. Similarly, coolant containing ethylene glycol requires specialized handling due to its toxicity to wildlife and water systems.

Parts cleaning represents another environmental challenge, as traditional solvent-based cleaners contain volatile organic compounds (VOCs) that contribute to air pollution. The industry has responded with water-based and biodegradable cleaning solutions that maintain effectiveness while reducing environmental impact. Ultrasonic cleaning systems have also gained popularity as they minimize chemical usage while achieving superior results for intricate LS1 components.

Remanufacturing and reconditioning of LS1 parts significantly reduces the environmental footprint of engine rebuilding. Processes such as cylinder head reconditioning, crankshaft polishing, and block resurfacing extend component lifespan, reducing raw material demand and energy consumption associated with manufacturing new parts. Studies indicate that rebuilding an engine requires approximately 85% less energy than producing a new one.

Workshop air quality management has become increasingly important, with proper ventilation systems and filtration equipment now considered essential for capturing airborne particulates generated during machining operations. These systems protect both technician health and prevent environmental contamination through air emissions.

The emergence of environmentally certified rebuilding facilities demonstrates the industry's commitment to sustainability. These operations implement comprehensive waste management programs, energy efficiency measures, and often utilize renewable energy sources. For DIY rebuilders, many communities now offer specific guidance and collection programs to ensure home mechanics can complete LS1 rebuilds while maintaining environmental compliance.

Sustainable rebuilding practices have emerged as industry standards, focusing on responsible fluid disposal through certified recycling centers. Used engine oil, which can contaminate up to one million gallons of freshwater if improperly discarded, must be collected in approved containers and transported to designated collection facilities. Similarly, coolant containing ethylene glycol requires specialized handling due to its toxicity to wildlife and water systems.

Parts cleaning represents another environmental challenge, as traditional solvent-based cleaners contain volatile organic compounds (VOCs) that contribute to air pollution. The industry has responded with water-based and biodegradable cleaning solutions that maintain effectiveness while reducing environmental impact. Ultrasonic cleaning systems have also gained popularity as they minimize chemical usage while achieving superior results for intricate LS1 components.

Remanufacturing and reconditioning of LS1 parts significantly reduces the environmental footprint of engine rebuilding. Processes such as cylinder head reconditioning, crankshaft polishing, and block resurfacing extend component lifespan, reducing raw material demand and energy consumption associated with manufacturing new parts. Studies indicate that rebuilding an engine requires approximately 85% less energy than producing a new one.

Workshop air quality management has become increasingly important, with proper ventilation systems and filtration equipment now considered essential for capturing airborne particulates generated during machining operations. These systems protect both technician health and prevent environmental contamination through air emissions.

The emergence of environmentally certified rebuilding facilities demonstrates the industry's commitment to sustainability. These operations implement comprehensive waste management programs, energy efficiency measures, and often utilize renewable energy sources. For DIY rebuilders, many communities now offer specific guidance and collection programs to ensure home mechanics can complete LS1 rebuilds while maintaining environmental compliance.

Cost-Benefit Analysis of LS1 Rebuild Options

When evaluating whether to rebuild an LS1 engine, a comprehensive cost-benefit analysis is essential for making an informed decision. The financial investment for a complete LS1 rebuild typically ranges from $2,000 to $7,000, depending on the extent of work required, parts quality, and labor costs. This variance stems from factors such as machine shop services, component replacement needs, and whether specialized modifications are incorporated.

A DIY rebuild approach can significantly reduce labor costs, potentially saving $1,500-$3,000 compared to professional services. However, this option requires substantial technical knowledge, specialized tools, and dedicated workspace. The time investment for DIY rebuilders typically spans 40-80 hours, representing an opportunity cost that must be factored into the overall equation.

Performance benefits from a properly executed rebuild can be substantial. A standard rebuild often yields 10-15% power increases, while performance-oriented rebuilds may deliver 20-30% gains or more. These improvements translate to enhanced vehicle responsiveness, acceleration, and potentially improved fuel efficiency when combined with modern engine management systems.

Longevity considerations present another significant benefit. A professionally rebuilt LS1 can reliably deliver another 100,000-150,000 miles of service when properly maintained. This extended service life must be weighed against the alternative of engine replacement, which typically costs $4,000-$8,000 for a quality remanufactured unit plus installation expenses.

The rebuild versus replace decision hinges on several factors beyond direct costs. Vehicle value, intended use period, and performance goals all influence the optimal choice. For collectible or modified vehicles where originality or specific performance characteristics are valued, rebuilding often represents the superior option despite potentially higher initial costs.

Environmental considerations also favor rebuilding, as it reduces manufacturing resource demands and keeps serviceable components from entering waste streams. This aspect, while difficult to quantify financially, represents an increasingly important factor for environmentally conscious owners and organizations.

Return on investment timelines vary significantly based on usage patterns. For high-mileage applications like commercial vehicles, the cost-per-mile advantage of a rebuild can create positive returns within 1-2 years. For enthusiast vehicles with limited annual mileage, the value proposition typically centers more on performance improvements and preservation of vehicle character rather than strict financial metrics.

A DIY rebuild approach can significantly reduce labor costs, potentially saving $1,500-$3,000 compared to professional services. However, this option requires substantial technical knowledge, specialized tools, and dedicated workspace. The time investment for DIY rebuilders typically spans 40-80 hours, representing an opportunity cost that must be factored into the overall equation.

Performance benefits from a properly executed rebuild can be substantial. A standard rebuild often yields 10-15% power increases, while performance-oriented rebuilds may deliver 20-30% gains or more. These improvements translate to enhanced vehicle responsiveness, acceleration, and potentially improved fuel efficiency when combined with modern engine management systems.

Longevity considerations present another significant benefit. A professionally rebuilt LS1 can reliably deliver another 100,000-150,000 miles of service when properly maintained. This extended service life must be weighed against the alternative of engine replacement, which typically costs $4,000-$8,000 for a quality remanufactured unit plus installation expenses.

The rebuild versus replace decision hinges on several factors beyond direct costs. Vehicle value, intended use period, and performance goals all influence the optimal choice. For collectible or modified vehicles where originality or specific performance characteristics are valued, rebuilding often represents the superior option despite potentially higher initial costs.

Environmental considerations also favor rebuilding, as it reduces manufacturing resource demands and keeps serviceable components from entering waste streams. This aspect, while difficult to quantify financially, represents an increasingly important factor for environmentally conscious owners and organizations.

Return on investment timelines vary significantly based on usage patterns. For high-mileage applications like commercial vehicles, the cost-per-mile advantage of a rebuild can create positive returns within 1-2 years. For enthusiast vehicles with limited annual mileage, the value proposition typically centers more on performance improvements and preservation of vehicle character rather than strict financial metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!