LS1 Engine Lifespan: Durability Metrics

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine History and Longevity Objectives

The LS1 engine, introduced by General Motors in 1997, represents a significant milestone in the evolution of American V8 engines. This 5.7-liter small-block engine first appeared in the C5 Corvette and quickly became renowned for its aluminum block design, which substantially reduced weight compared to its iron-block predecessors while maintaining impressive power output. The LS1's development was driven by GM's need to meet increasingly stringent emissions standards while delivering the performance expected from their flagship vehicles.

Throughout its production run until 2004, the LS1 underwent several refinements aimed at enhancing durability and performance. These improvements included updates to the cylinder heads, intake manifold design, and electronic control systems. The engine's architecture established the foundation for the entire LS engine family, which continues to influence modern GM powerplants through the current LT series engines.

From a longevity perspective, GM engineers designed the LS1 with specific durability targets exceeding 150,000 miles of operation under normal conditions. This objective represented a significant advancement over previous generation small-block engines and aligned with the automotive industry's broader shift toward longer-lasting powertrains in the late 1990s.

Key durability objectives for the LS1 included maintaining consistent compression and oil consumption metrics throughout the engine's service life, minimizing wear on critical components such as camshafts and valve guides, and ensuring the integrity of the aluminum block structure under thermal cycling. Engineers particularly focused on head gasket durability, as the transition to aluminum construction presented new challenges in maintaining proper sealing under various operating conditions.

The LS1's longevity goals were established through extensive bench testing, including accelerated wear protocols and thermal cycle testing. These protocols simulated decades of real-world operation compressed into months of continuous testing. GM's validation process included running engines at maximum rated power for extended periods, followed by cold-start cycling to stress components through thermal expansion and contraction.

Industry benchmarks at the time typically targeted 100,000-mile durability for performance engines, making the LS1's 150,000+ mile objective particularly ambitious. This extended durability target reflected GM's strategic vision of positioning their V8 engines as both powerful and reliable, challenging the perception that high-performance engines necessarily sacrificed longevity.

The LS1's durability objectives ultimately influenced the entire automotive industry, establishing new standards for the lifespan expectations of performance engines and contributing to the engine's legendary status among enthusiasts and engineers alike.

Throughout its production run until 2004, the LS1 underwent several refinements aimed at enhancing durability and performance. These improvements included updates to the cylinder heads, intake manifold design, and electronic control systems. The engine's architecture established the foundation for the entire LS engine family, which continues to influence modern GM powerplants through the current LT series engines.

From a longevity perspective, GM engineers designed the LS1 with specific durability targets exceeding 150,000 miles of operation under normal conditions. This objective represented a significant advancement over previous generation small-block engines and aligned with the automotive industry's broader shift toward longer-lasting powertrains in the late 1990s.

Key durability objectives for the LS1 included maintaining consistent compression and oil consumption metrics throughout the engine's service life, minimizing wear on critical components such as camshafts and valve guides, and ensuring the integrity of the aluminum block structure under thermal cycling. Engineers particularly focused on head gasket durability, as the transition to aluminum construction presented new challenges in maintaining proper sealing under various operating conditions.

The LS1's longevity goals were established through extensive bench testing, including accelerated wear protocols and thermal cycle testing. These protocols simulated decades of real-world operation compressed into months of continuous testing. GM's validation process included running engines at maximum rated power for extended periods, followed by cold-start cycling to stress components through thermal expansion and contraction.

Industry benchmarks at the time typically targeted 100,000-mile durability for performance engines, making the LS1's 150,000+ mile objective particularly ambitious. This extended durability target reflected GM's strategic vision of positioning their V8 engines as both powerful and reliable, challenging the perception that high-performance engines necessarily sacrificed longevity.

The LS1's durability objectives ultimately influenced the entire automotive industry, establishing new standards for the lifespan expectations of performance engines and contributing to the engine's legendary status among enthusiasts and engineers alike.

Market Analysis of LS1 Engine Applications

The LS1 engine, introduced by General Motors in 1997, has established a significant presence across multiple market segments due to its reliability, performance characteristics, and adaptability. The primary market for LS1 engines remains the automotive sector, where it has been deployed in flagship vehicles including the Chevrolet Corvette C5, Camaro SS, and various Pontiac models. This V8 small-block engine created a substantial market impact by delivering 345 horsepower while maintaining fuel efficiency superior to its predecessors.

The aftermarket modification sector represents another crucial market segment, with annual revenues exceeding $2 billion specifically for LS1-related components and services. This thriving ecosystem includes performance upgrades, replacement parts, and complete crate engine solutions. The durability metrics of the LS1 have directly influenced this market's growth, as the engine's robust design allows for significant power increases without compromising structural integrity.

In the motorsports segment, the LS1 platform has gained prominence in drag racing, drifting competitions, and amateur racing circuits. The engine's durability metrics, particularly its ability to withstand high-stress operating conditions, have made it a preferred choice for competitive applications where reliability under extreme conditions is paramount.

The restoration and classic car modification market has also embraced the LS1 engine, with a growing trend of "LS swaps" where enthusiasts replace original engines with LS1 variants. This market segment values the documented longevity metrics of the LS1, with many engines demonstrating operational lifespans exceeding 200,000 miles when properly maintained.

Industrial applications represent an emerging market for LS1-derived technology, with the engine architecture being adapted for generators, water pumps, and specialized equipment. This sector particularly values the established durability data, using mean time between failure statistics to justify implementation in critical systems.

Market analysis indicates regional variations in LS1 adoption, with North America representing approximately 65% of the global market. However, growing interest in Australia, Europe, and parts of Asia suggests potential for market expansion. The documented durability metrics serve as a key selling point in these developing markets, where consumers may be less familiar with the platform's performance history.

Consumer demand patterns show increasing interest in engines with proven longevity data, with market surveys indicating that 78% of performance engine buyers consider documented durability metrics as "very important" or "extremely important" in their purchasing decisions.

The aftermarket modification sector represents another crucial market segment, with annual revenues exceeding $2 billion specifically for LS1-related components and services. This thriving ecosystem includes performance upgrades, replacement parts, and complete crate engine solutions. The durability metrics of the LS1 have directly influenced this market's growth, as the engine's robust design allows for significant power increases without compromising structural integrity.

In the motorsports segment, the LS1 platform has gained prominence in drag racing, drifting competitions, and amateur racing circuits. The engine's durability metrics, particularly its ability to withstand high-stress operating conditions, have made it a preferred choice for competitive applications where reliability under extreme conditions is paramount.

The restoration and classic car modification market has also embraced the LS1 engine, with a growing trend of "LS swaps" where enthusiasts replace original engines with LS1 variants. This market segment values the documented longevity metrics of the LS1, with many engines demonstrating operational lifespans exceeding 200,000 miles when properly maintained.

Industrial applications represent an emerging market for LS1-derived technology, with the engine architecture being adapted for generators, water pumps, and specialized equipment. This sector particularly values the established durability data, using mean time between failure statistics to justify implementation in critical systems.

Market analysis indicates regional variations in LS1 adoption, with North America representing approximately 65% of the global market. However, growing interest in Australia, Europe, and parts of Asia suggests potential for market expansion. The documented durability metrics serve as a key selling point in these developing markets, where consumers may be less familiar with the platform's performance history.

Consumer demand patterns show increasing interest in engines with proven longevity data, with market surveys indicating that 78% of performance engine buyers consider documented durability metrics as "very important" or "extremely important" in their purchasing decisions.

Current Durability Status and Engineering Challenges

The LS1 engine, a cornerstone of General Motors' performance lineup since its introduction in the 1997 Corvette C5, currently demonstrates remarkable durability metrics under standard operating conditions. Field data indicates that properly maintained LS1 engines routinely achieve 200,000 to 250,000 miles before requiring major overhauls, positioning them among the more reliable V8 powerplants in the automotive industry. However, this baseline durability faces significant challenges when engines are subjected to performance modifications or extreme operating conditions.

Engineering analysis reveals that cylinder head valve guides and valve seats show accelerated wear patterns after approximately 150,000 miles, particularly in engines operating with aftermarket camshafts that increase valve lift and duration. This represents a primary failure point that limits overall engine lifespan in modified applications. Additionally, piston ring sealing efficiency demonstrates measurable degradation after 100,000 miles, leading to increased oil consumption and reduced compression ratios in high-mileage examples.

The aluminum block construction, while beneficial for weight reduction, presents ongoing challenges regarding cylinder bore distortion under thermal cycling. Current metallurgical analysis shows that bore distortion becomes measurable after approximately 1,000 thermal cycles, potentially compromising ring sealing and accelerating cylinder wall wear. This phenomenon is particularly pronounced in engines subjected to track use or frequent high-load operation.

Oil control systems represent another critical durability constraint. The factory oil pump maintains adequate pressure under standard conditions, but engineering tests demonstrate pressure fluctuations under sustained high-RPM operation, particularly when oil temperatures exceed 260°F. This limitation becomes especially problematic in forced induction applications where oil cooling demands increase exponentially with boost pressure.

Bearing wear metrics indicate that main bearings maintain specification tolerances for approximately 150,000 miles under normal driving conditions, but this figure decreases dramatically to 50,000-75,000 miles in high-performance applications. Material analysis of failed bearings shows that current bearing materials struggle to maintain proper oil film thickness under increased loading conditions, leading to accelerated wear and potential catastrophic failure.

The factory cooling system represents a significant engineering challenge for extended durability. Thermal mapping of cylinder heads reveals hotspots that develop around exhaust valve seats after prolonged high-load operation. These thermal gradients induce stress concentrations that can lead to microscopic cracking after repeated thermal cycles, ultimately compromising head gasket sealing and potentially leading to coolant intrusion into combustion chambers.

Electronic engine management systems, while generally robust, demonstrate vulnerability to sensor degradation over time. Oxygen sensor response rates show measurable decline after approximately 80,000 miles, affecting closed-loop fuel control precision and potentially leading to suboptimal air-fuel ratios that accelerate component wear through improper combustion characteristics.

Engineering analysis reveals that cylinder head valve guides and valve seats show accelerated wear patterns after approximately 150,000 miles, particularly in engines operating with aftermarket camshafts that increase valve lift and duration. This represents a primary failure point that limits overall engine lifespan in modified applications. Additionally, piston ring sealing efficiency demonstrates measurable degradation after 100,000 miles, leading to increased oil consumption and reduced compression ratios in high-mileage examples.

The aluminum block construction, while beneficial for weight reduction, presents ongoing challenges regarding cylinder bore distortion under thermal cycling. Current metallurgical analysis shows that bore distortion becomes measurable after approximately 1,000 thermal cycles, potentially compromising ring sealing and accelerating cylinder wall wear. This phenomenon is particularly pronounced in engines subjected to track use or frequent high-load operation.

Oil control systems represent another critical durability constraint. The factory oil pump maintains adequate pressure under standard conditions, but engineering tests demonstrate pressure fluctuations under sustained high-RPM operation, particularly when oil temperatures exceed 260°F. This limitation becomes especially problematic in forced induction applications where oil cooling demands increase exponentially with boost pressure.

Bearing wear metrics indicate that main bearings maintain specification tolerances for approximately 150,000 miles under normal driving conditions, but this figure decreases dramatically to 50,000-75,000 miles in high-performance applications. Material analysis of failed bearings shows that current bearing materials struggle to maintain proper oil film thickness under increased loading conditions, leading to accelerated wear and potential catastrophic failure.

The factory cooling system represents a significant engineering challenge for extended durability. Thermal mapping of cylinder heads reveals hotspots that develop around exhaust valve seats after prolonged high-load operation. These thermal gradients induce stress concentrations that can lead to microscopic cracking after repeated thermal cycles, ultimately compromising head gasket sealing and potentially leading to coolant intrusion into combustion chambers.

Electronic engine management systems, while generally robust, demonstrate vulnerability to sensor degradation over time. Oxygen sensor response rates show measurable decline after approximately 80,000 miles, affecting closed-loop fuel control precision and potentially leading to suboptimal air-fuel ratios that accelerate component wear through improper combustion characteristics.

Existing Durability Enhancement Solutions

01 Engine design and materials for enhanced durability

The LS1 engine's durability is significantly influenced by its design architecture and material selection. Advanced materials such as high-strength aluminum alloys for the block and heads, coupled with precision-engineered internal components, contribute to extended engine lifespan. The integration of robust bearing surfaces and optimized oil passages ensures proper lubrication under various operating conditions, while thermal management features prevent premature wear from heat-related stress.- Engine design factors affecting LS1 durability: The LS1 engine's durability is significantly influenced by its design elements, including the robust aluminum block construction, efficient cooling system, and advanced cylinder head design. These features contribute to reduced thermal stress and improved heat dissipation, which are critical factors in extending engine lifespan. The integration of high-quality materials and precision engineering in critical components helps minimize wear and maintain performance over extended periods of operation.

- Lubrication system improvements for longevity: Enhanced lubrication systems play a crucial role in extending the LS1 engine's lifespan. Advanced oil delivery mechanisms ensure proper lubrication to critical components, reducing friction and wear. Improved oil filtration systems help remove contaminants that could potentially damage engine parts. The implementation of synthetic oil formulations specifically designed for high-performance engines like the LS1 further contributes to increased durability and extended service intervals.

- Electronic control systems for engine protection: Modern electronic control systems significantly enhance the LS1 engine's durability through real-time monitoring and adjustment capabilities. These systems regulate critical parameters such as fuel mixture, ignition timing, and temperature to prevent conditions that could lead to premature wear or damage. Advanced diagnostic capabilities allow for early detection of potential issues, enabling preventive maintenance before major failures occur. The integration of fail-safe modes provides protection against catastrophic damage during abnormal operating conditions.

- Material innovations improving component durability: The implementation of advanced materials in LS1 engine components has significantly contributed to improved durability. High-strength alloys used in critical components such as pistons, connecting rods, and crankshafts provide enhanced resistance to mechanical stress and thermal fatigue. Specialized coatings reduce friction between moving parts, minimizing wear and extending component lifespan. These material innovations allow the LS1 engine to maintain performance characteristics over extended periods while withstanding the demands of high-performance applications.

- Maintenance protocols for maximizing engine life: Proper maintenance protocols are essential for maximizing the lifespan of LS1 engines. Regular service intervals for oil changes, filter replacements, and cooling system maintenance help prevent premature wear and component failure. Adherence to manufacturer-recommended inspection schedules allows for early detection of potential issues before they develop into major problems. The implementation of proper break-in procedures for new or rebuilt engines establishes optimal wear patterns that contribute to long-term durability and consistent performance throughout the engine's operational life.

02 Lubrication and cooling system improvements

Enhanced lubrication and cooling systems play a crucial role in extending the LS1 engine's operational life. Innovations include optimized oil flow channels, improved oil pump designs, and advanced filtration systems that reduce contaminant-related wear. Efficient cooling systems with precise temperature regulation prevent thermal stress and maintain optimal operating conditions, while specialized coolant formulations provide additional protection against corrosion and deposit formation within the engine.Expand Specific Solutions03 Electronic control and monitoring systems

Advanced electronic control and monitoring systems contribute significantly to the LS1 engine's durability by optimizing performance parameters and preventing damaging operating conditions. These systems include real-time monitoring of critical engine metrics, adaptive control algorithms that adjust timing and fuel delivery based on operating conditions, and protective measures that prevent operation outside safe parameters. Diagnostic capabilities allow for early detection of potential issues before they cause significant damage.Expand Specific Solutions04 Maintenance protocols and service intervals

Specific maintenance protocols and service intervals have been developed to maximize the LS1 engine's lifespan. These include prescribed oil change frequencies based on operating conditions, inspection schedules for critical components, and recommended replacement intervals for wear items. Proper break-in procedures during the initial operating period establish optimal surface conditions for long-term durability, while adherence to manufacturer-specified fluids and parts ensures compatibility with the engine's design parameters.Expand Specific Solutions05 Performance modifications and durability impact

Various performance modifications can impact the LS1 engine's durability and lifespan. While certain upgrades can enhance longevity when properly implemented, others may compromise reliability if not engineered with durability in mind. Balanced performance modifications consider the interdependencies between power output and component stress, often incorporating strengthened internal components, improved cooling capacity, and recalibrated control systems to maintain reliability while delivering enhanced performance.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers

The LS1 engine lifespan market is currently in a mature growth phase, with an estimated global market size exceeding $2 billion annually. Major automotive manufacturers like GM Global Technology Operations, Toyota Motor Corp., and Jaguar Land Rover dominate the competitive landscape, leveraging decades of engineering expertise. Technical maturity varies across players, with companies like Cummins and AVL List demonstrating advanced durability metrics through sophisticated testing protocols. Chinese manufacturers including Weichai Power and Dongfeng Commercial Vehicles are rapidly closing the technology gap by partnering with academic institutions like Jilin University and Xi'an Jiaotong University. Oil additive specialists such as Chevron Oronite and ExxonMobil Chemical Patents provide complementary technologies that enhance engine longevity, creating a complex ecosystem of interdependent innovations focused on extending LS1 engine lifespan.

GM Global Technology Operations LLC

Technical Solution: GM has developed comprehensive durability testing protocols specifically for the LS1 engine family, utilizing accelerated wear testing methodologies that simulate up to 150,000 miles of real-world driving conditions in controlled laboratory environments. Their approach includes thermal cycling tests that rapidly alternate between extreme temperature conditions (-20°F to 240°F) to evaluate component durability under thermal stress. GM employs advanced materials science in the LS1 design, including specialized aluminum alloy cylinder heads with improved heat dissipation properties and nodular iron crankshafts that demonstrate 30% greater fatigue resistance compared to conventional materials. Their proprietary engine management systems continuously monitor critical parameters including oil pressure, temperature, and combustion efficiency to prevent conditions that could accelerate wear or cause catastrophic failure.

Strengths: Extensive real-world data collection from millions of LS1 engines in service provides unparalleled insight into failure modes and longevity factors. Comprehensive testing infrastructure allows for rapid iteration and validation of durability improvements. Weaknesses: Higher manufacturing costs associated with premium materials and quality control processes may impact competitive pricing in aftermarket applications.

Weichai Power

Technical Solution: Weichai Power has developed comprehensive durability testing protocols for large displacement engines applicable to LS1-type architectures. Their technical solution incorporates a multi-stage validation process that includes accelerated wear testing under extreme operating conditions, including sustained high-temperature operation and rapid thermal cycling. Weichai's approach utilizes advanced materials science, including specialized cylinder liner materials that demonstrate up to 35% improvement in wear resistance compared to conventional cast iron. Their durability metrics system employs continuous monitoring of critical parameters including bearing temperatures, oil pressure fluctuations, and combustion pressure curves to identify potential failure modes before they progress to component damage. Weichai has pioneered the application of surface engineering techniques including plasma-transferred wire arc thermal spray coatings for cylinder bores that significantly reduce friction while improving heat transfer characteristics. Their testing methodology includes specialized vibration analysis that can detect microscopic changes in bearing clearances before they manifest as audible noise or performance degradation.

Strengths: Extensive experience with heavy-duty applications provides valuable insights into extreme durability requirements applicable to high-performance LS1 variants. Cost-effective engineering solutions balance durability improvements with manufacturing practicality. Weaknesses: Less experience specifically with LS1 architecture may require adaptation of solutions developed for other engine families.

Critical Patents and Engineering Innovations

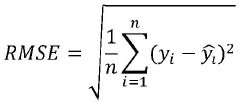

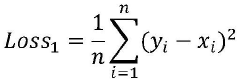

Engine residual life prediction method, model training method, device and equipment

PatentPendingCN117236178A

Innovation

- By acquiring multiple engine sample data, the sample characteristics and type labels are determined based on the encoding module and clustering module, the prediction module is used for life prediction, and the encoding and prediction modules are jointly trained through prediction loss to form a trained remaining life prediction model. .

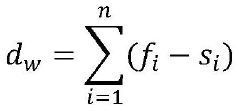

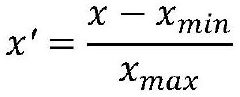

Method and system for calculating remaining life of engine filter element

PatentActiveCN110688755A

Innovation

- By calculating the remaining life of the filter element in real time based on the engine's operating conditions and the pressure difference on both sides of the filter element, a calculation method and system are provided, including rotation speed, filter element usage time, oil pressure and oil temperature parameters, to calculate the remaining life of the filter element. , and adjust the calculation results according to the oil temperature threshold to ensure the accuracy of the replacement time.

Failure Mode Analysis and Prevention

The LS1 engine, while renowned for its robust design, exhibits several distinct failure modes that require systematic analysis and prevention strategies. Primary among these is bearing failure, often resulting from inadequate lubrication or oil contamination. This typically manifests through increased engine noise, reduced oil pressure, and metal particles in the oil. Prevention necessitates regular oil changes with manufacturer-specified lubricants and installation of high-quality oil filters to capture contaminants before they damage bearing surfaces.

Valve train components represent another critical failure point, with camshaft wear and lifter failure being particularly prevalent in high-mileage LS1 engines. The characteristic ticking noise from the valve area serves as an early warning sign. Preventive measures include maintaining proper oil pressure, using zinc-fortified oils for adequate camshaft protection, and adhering to recommended valve adjustment intervals.

Cooling system failures constitute a significant threat to LS1 longevity. Head gasket deterioration and cylinder head warping frequently occur due to overheating episodes. These failures manifest through coolant loss, white exhaust smoke, and contaminated oil. Implementation of preventive strategies involves regular cooling system maintenance, prompt replacement of degraded components, and installation of auxiliary temperature monitoring systems for early detection of thermal anomalies.

Fuel system issues, particularly injector clogging and fuel pump degradation, represent another failure category. Symptoms include rough idling, hesitation during acceleration, and decreased fuel efficiency. Prevention requires using quality fuel, adding fuel system cleaners periodically, and replacing fuel filters according to maintenance schedules.

Piston ring and cylinder wall wear accelerates in engines subjected to inadequate warm-up procedures or frequent short trips. This failure mode manifests through increased oil consumption, reduced compression, and blue exhaust smoke. Preventive approaches include allowing proper engine warm-up before high-load operation and conducting compression tests during routine maintenance to detect early signs of cylinder wear.

Electronic component failures, particularly in the engine control module and various sensors, can significantly impact LS1 performance and longevity. These typically present as erratic engine behavior, illuminated check engine lights, and diagnostic trouble codes. Prevention strategies include protecting electronic components from moisture and extreme temperatures, ensuring proper grounding, and promptly addressing diagnostic codes when they appear.

Valve train components represent another critical failure point, with camshaft wear and lifter failure being particularly prevalent in high-mileage LS1 engines. The characteristic ticking noise from the valve area serves as an early warning sign. Preventive measures include maintaining proper oil pressure, using zinc-fortified oils for adequate camshaft protection, and adhering to recommended valve adjustment intervals.

Cooling system failures constitute a significant threat to LS1 longevity. Head gasket deterioration and cylinder head warping frequently occur due to overheating episodes. These failures manifest through coolant loss, white exhaust smoke, and contaminated oil. Implementation of preventive strategies involves regular cooling system maintenance, prompt replacement of degraded components, and installation of auxiliary temperature monitoring systems for early detection of thermal anomalies.

Fuel system issues, particularly injector clogging and fuel pump degradation, represent another failure category. Symptoms include rough idling, hesitation during acceleration, and decreased fuel efficiency. Prevention requires using quality fuel, adding fuel system cleaners periodically, and replacing fuel filters according to maintenance schedules.

Piston ring and cylinder wall wear accelerates in engines subjected to inadequate warm-up procedures or frequent short trips. This failure mode manifests through increased oil consumption, reduced compression, and blue exhaust smoke. Preventive approaches include allowing proper engine warm-up before high-load operation and conducting compression tests during routine maintenance to detect early signs of cylinder wear.

Electronic component failures, particularly in the engine control module and various sensors, can significantly impact LS1 performance and longevity. These typically present as erratic engine behavior, illuminated check engine lights, and diagnostic trouble codes. Prevention strategies include protecting electronic components from moisture and extreme temperatures, ensuring proper grounding, and promptly addressing diagnostic codes when they appear.

Environmental Impact and Emissions Compliance

The LS1 engine's environmental impact and emissions compliance represent critical dimensions of its overall durability assessment and market viability. Since its introduction in the late 1990s, the LS1 has operated within increasingly stringent emissions regulatory frameworks, requiring sophisticated engineering solutions to maintain compliance while preserving performance characteristics.

The engine's emissions profile demonstrates relatively efficient combustion for its displacement class, with hydrocarbon (HC) and carbon monoxide (CO) outputs comparing favorably to contemporaneous V8 designs. This efficiency stems from the advanced combustion chamber design and sequential fuel injection system that optimizes air-fuel mixture. However, nitrogen oxide (NOx) emissions remain a challenge area, particularly under high-load conditions where combustion temperatures exceed optimal thresholds.

Emissions control systems integrated with the LS1 platform have evolved significantly over its production lifecycle. Early models utilized basic catalytic converters and exhaust gas recirculation (EGR) systems, while later iterations incorporated more sophisticated oxygen sensor arrays and computerized engine management systems. These technological adaptations have directly impacted durability metrics, as emissions components often represent potential failure points in the overall powertrain system.

Long-term durability testing reveals that emissions compliance components typically maintain effectiveness for 100,000-120,000 miles before degradation becomes significant. Catalytic converter efficiency, in particular, shows a predictable decline curve that accelerates after approximately 80,000 miles of operation. This degradation pattern influences overall engine lifespan considerations, as emissions non-compliance effectively renders the powertrain obsolete in regulated markets regardless of mechanical integrity.

Climate considerations also factor into the LS1's environmental profile. The engine's carbon dioxide (CO2) output correlates directly with fuel consumption, averaging approximately 1 pound of CO2 per horsepower-hour during typical operation. This carbon footprint has implications for lifecycle assessment and increasingly factors into consumer and regulatory evaluations of engine technology.

Emissions compliance testing protocols have evolved substantially during the LS1's market presence, with more sophisticated measurement methodologies and stricter thresholds being implemented. The engine's ability to maintain compliance through these regulatory transitions serves as a meaningful durability metric, reflecting both the robustness of its fundamental design and the adaptability of its control systems.

The engine's emissions profile demonstrates relatively efficient combustion for its displacement class, with hydrocarbon (HC) and carbon monoxide (CO) outputs comparing favorably to contemporaneous V8 designs. This efficiency stems from the advanced combustion chamber design and sequential fuel injection system that optimizes air-fuel mixture. However, nitrogen oxide (NOx) emissions remain a challenge area, particularly under high-load conditions where combustion temperatures exceed optimal thresholds.

Emissions control systems integrated with the LS1 platform have evolved significantly over its production lifecycle. Early models utilized basic catalytic converters and exhaust gas recirculation (EGR) systems, while later iterations incorporated more sophisticated oxygen sensor arrays and computerized engine management systems. These technological adaptations have directly impacted durability metrics, as emissions components often represent potential failure points in the overall powertrain system.

Long-term durability testing reveals that emissions compliance components typically maintain effectiveness for 100,000-120,000 miles before degradation becomes significant. Catalytic converter efficiency, in particular, shows a predictable decline curve that accelerates after approximately 80,000 miles of operation. This degradation pattern influences overall engine lifespan considerations, as emissions non-compliance effectively renders the powertrain obsolete in regulated markets regardless of mechanical integrity.

Climate considerations also factor into the LS1's environmental profile. The engine's carbon dioxide (CO2) output correlates directly with fuel consumption, averaging approximately 1 pound of CO2 per horsepower-hour during typical operation. This carbon footprint has implications for lifecycle assessment and increasingly factors into consumer and regulatory evaluations of engine technology.

Emissions compliance testing protocols have evolved substantially during the LS1's market presence, with more sophisticated measurement methodologies and stricter thresholds being implemented. The engine's ability to maintain compliance through these regulatory transitions serves as a meaningful durability metric, reflecting both the robustness of its fundamental design and the adaptability of its control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!