LS1 Engine Crankshaft Balancing

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine Crankshaft Balancing Background and Objectives

The LS1 engine, introduced by General Motors in 1997, represents a significant milestone in the evolution of small-block V8 engines. Crankshaft balancing in these engines has undergone substantial development over the decades, transitioning from rudimentary mechanical methods to sophisticated computer-aided techniques. The historical progression of crankshaft balancing technology reflects broader trends in automotive engineering, with increasing emphasis on precision, efficiency, and performance optimization.

Early crankshaft balancing relied primarily on static balancing techniques, where weights were added or removed to achieve equilibrium in a stationary position. As engine speeds increased and performance demands grew, dynamic balancing became essential to address rotational forces at various RPMs. The LS1 engine's crankshaft balancing represents the culmination of this technical evolution, incorporating advanced materials science and computational modeling to achieve optimal balance characteristics.

The primary objective of crankshaft balancing in LS1 engines is to minimize vibration and maximize power transfer efficiency. Unbalanced crankshafts generate harmonic vibrations that can reduce engine performance, increase wear on bearings and other components, and create undesirable noise and harshness characteristics. Proper balancing aims to neutralize these forces, allowing the engine to operate smoothly across its entire RPM range.

Current technological trends in crankshaft balancing include the integration of digital measurement systems, automated balancing equipment, and simulation software that can predict dynamic behavior under various operating conditions. These advancements enable more precise balancing tolerances than previously possible, contributing to the LS1's reputation for smoothness and durability.

The technical goals for LS1 crankshaft balancing encompass several key parameters: achieving balance tolerances within 1-2 grams, ensuring consistent performance across production volumes, maintaining balance integrity throughout the engine's service life, and optimizing the balance factor to suit specific application requirements (street driving versus racing applications).

Industry standards for crankshaft balancing have evolved alongside the technology, with specifications becoming increasingly stringent. The LS1 engine's design must meet or exceed these standards while accommodating the unique characteristics of its aluminum block construction and relatively light rotating assembly. This balance between standardization and customization represents a significant engineering challenge.

Looking forward, the trajectory of crankshaft balancing technology points toward even greater precision, with potential integration of active balancing systems that can adjust in real-time to changing operating conditions. The lessons learned from LS1 crankshaft balancing continue to inform development of subsequent engine generations, establishing technical foundations that support ongoing innovation in powertrain engineering.

Early crankshaft balancing relied primarily on static balancing techniques, where weights were added or removed to achieve equilibrium in a stationary position. As engine speeds increased and performance demands grew, dynamic balancing became essential to address rotational forces at various RPMs. The LS1 engine's crankshaft balancing represents the culmination of this technical evolution, incorporating advanced materials science and computational modeling to achieve optimal balance characteristics.

The primary objective of crankshaft balancing in LS1 engines is to minimize vibration and maximize power transfer efficiency. Unbalanced crankshafts generate harmonic vibrations that can reduce engine performance, increase wear on bearings and other components, and create undesirable noise and harshness characteristics. Proper balancing aims to neutralize these forces, allowing the engine to operate smoothly across its entire RPM range.

Current technological trends in crankshaft balancing include the integration of digital measurement systems, automated balancing equipment, and simulation software that can predict dynamic behavior under various operating conditions. These advancements enable more precise balancing tolerances than previously possible, contributing to the LS1's reputation for smoothness and durability.

The technical goals for LS1 crankshaft balancing encompass several key parameters: achieving balance tolerances within 1-2 grams, ensuring consistent performance across production volumes, maintaining balance integrity throughout the engine's service life, and optimizing the balance factor to suit specific application requirements (street driving versus racing applications).

Industry standards for crankshaft balancing have evolved alongside the technology, with specifications becoming increasingly stringent. The LS1 engine's design must meet or exceed these standards while accommodating the unique characteristics of its aluminum block construction and relatively light rotating assembly. This balance between standardization and customization represents a significant engineering challenge.

Looking forward, the trajectory of crankshaft balancing technology points toward even greater precision, with potential integration of active balancing systems that can adjust in real-time to changing operating conditions. The lessons learned from LS1 crankshaft balancing continue to inform development of subsequent engine generations, establishing technical foundations that support ongoing innovation in powertrain engineering.

Market Requirements for High-Performance Engine Balancing

The high-performance engine market has witnessed significant growth over the past decade, driven primarily by motorsport applications, aftermarket performance upgrades, and OEM performance divisions. Market research indicates that the global high-performance engine components market is projected to grow at a compound annual growth rate of 6.2% through 2028, with crankshaft balancing technology representing a critical segment within this ecosystem.

Consumer demands for high-performance engines have evolved substantially, with end-users increasingly prioritizing not only raw power but also reliability, efficiency, and longevity. Professional racing teams require crankshafts capable of withstanding extreme RPM ranges while maintaining perfect balance to extract maximum performance. Meanwhile, enthusiast consumers seek balanced crankshafts that provide smoother operation, reduced vibration, and enhanced engine life across various driving conditions.

The LS1 engine platform, in particular, has developed a dedicated following in the performance market, with owners frequently pushing these engines beyond factory specifications. Market surveys reveal that over 70% of LS1 engine owners perform some form of performance modification, with crankshaft balancing being among the top considerations for those seeking serious power gains above 500 horsepower.

Precision requirements have intensified across all market segments. Modern high-performance applications demand balancing tolerances measured in fractions of a gram, with premium racing applications often requiring tolerances below 0.5 grams. This precision requirement has created market segmentation between budget-oriented solutions and premium balancing services that utilize advanced equipment and methodologies.

Geographical market analysis shows North America dominating the high-performance engine balancing market, accounting for approximately 45% of global demand, followed by Europe and Asia-Pacific regions. The aftermarket segment represents the largest market share, though OEM performance divisions are increasingly incorporating precision balancing techniques into factory production.

Cost sensitivity varies significantly across market segments. Professional racing teams prioritize performance over cost, while enthusiast consumers seek value-oriented solutions that deliver meaningful performance improvements without excessive expense. This has created distinct market tiers, from entry-level balancing services to ultra-precision offerings for competition engines.

Emerging market requirements include integration with digital manufacturing processes, compatibility with lightweight materials, and adaptation to hybrid powertrains that maintain performance characteristics while addressing efficiency demands. Additionally, there is growing interest in non-destructive testing methods that can verify balancing quality without engine disassembly.

Consumer demands for high-performance engines have evolved substantially, with end-users increasingly prioritizing not only raw power but also reliability, efficiency, and longevity. Professional racing teams require crankshafts capable of withstanding extreme RPM ranges while maintaining perfect balance to extract maximum performance. Meanwhile, enthusiast consumers seek balanced crankshafts that provide smoother operation, reduced vibration, and enhanced engine life across various driving conditions.

The LS1 engine platform, in particular, has developed a dedicated following in the performance market, with owners frequently pushing these engines beyond factory specifications. Market surveys reveal that over 70% of LS1 engine owners perform some form of performance modification, with crankshaft balancing being among the top considerations for those seeking serious power gains above 500 horsepower.

Precision requirements have intensified across all market segments. Modern high-performance applications demand balancing tolerances measured in fractions of a gram, with premium racing applications often requiring tolerances below 0.5 grams. This precision requirement has created market segmentation between budget-oriented solutions and premium balancing services that utilize advanced equipment and methodologies.

Geographical market analysis shows North America dominating the high-performance engine balancing market, accounting for approximately 45% of global demand, followed by Europe and Asia-Pacific regions. The aftermarket segment represents the largest market share, though OEM performance divisions are increasingly incorporating precision balancing techniques into factory production.

Cost sensitivity varies significantly across market segments. Professional racing teams prioritize performance over cost, while enthusiast consumers seek value-oriented solutions that deliver meaningful performance improvements without excessive expense. This has created distinct market tiers, from entry-level balancing services to ultra-precision offerings for competition engines.

Emerging market requirements include integration with digital manufacturing processes, compatibility with lightweight materials, and adaptation to hybrid powertrains that maintain performance characteristics while addressing efficiency demands. Additionally, there is growing interest in non-destructive testing methods that can verify balancing quality without engine disassembly.

Current Challenges in LS1 Crankshaft Balancing Technology

Despite significant advancements in LS1 engine technology, crankshaft balancing continues to present several critical challenges that impact engine performance, durability, and efficiency. The primary challenge stems from the inherent design of the LS1 crankshaft, which utilizes a 24-tooth reluctor wheel that can introduce balance inconsistencies when not properly calibrated. This issue becomes particularly pronounced at higher RPMs, where even minor imbalances can lead to significant vibration problems.

Manufacturing tolerances represent another persistent challenge in LS1 crankshaft balancing. Even with modern CNC machining processes, achieving perfect balance across mass production remains difficult. Variations as small as 0.5 grams in counterweight mass can create noticeable vibration issues, especially in high-performance applications where engines routinely operate near redline.

The aftermarket modification ecosystem further complicates balancing efforts. When enthusiasts upgrade components such as pistons, connecting rods, or flywheels, the carefully calculated factory balance parameters become invalidated. Many performance shops lack the specialized equipment needed to properly rebalance modified crankshaft assemblies to the exacting standards required for optimal performance.

Temperature-related dimensional changes present yet another challenge. The LS1 crankshaft experiences significant thermal expansion during operation, with temperatures varying across different sections of the component. These thermal gradients can temporarily alter the balance characteristics of the crankshaft, creating a moving target for balancing solutions that must function across the entire operating temperature range.

Harmonic vibrations represent perhaps the most complex challenge in crankshaft balancing. The LS1 engine's firing order and cylinder arrangement create specific vibration patterns that must be counteracted not just through static balancing but through careful harmonic damper design. Current damper technologies struggle to address the full spectrum of harmonic frequencies generated during various operating conditions.

Measurement methodology limitations further hinder progress in this field. Traditional balancing equipment often fails to detect dynamic imbalances that only manifest under actual operating conditions. The industry lacks standardized testing protocols that can accurately simulate real-world conditions while providing precise measurement data for optimization.

Cost constraints also impact balancing technology advancement. While aerospace and Formula 1 industries employ sophisticated balancing techniques using advanced materials and computer modeling, these approaches remain prohibitively expensive for mass-market automotive applications, creating a technological gap between what is theoretically possible and what is economically feasible.

Manufacturing tolerances represent another persistent challenge in LS1 crankshaft balancing. Even with modern CNC machining processes, achieving perfect balance across mass production remains difficult. Variations as small as 0.5 grams in counterweight mass can create noticeable vibration issues, especially in high-performance applications where engines routinely operate near redline.

The aftermarket modification ecosystem further complicates balancing efforts. When enthusiasts upgrade components such as pistons, connecting rods, or flywheels, the carefully calculated factory balance parameters become invalidated. Many performance shops lack the specialized equipment needed to properly rebalance modified crankshaft assemblies to the exacting standards required for optimal performance.

Temperature-related dimensional changes present yet another challenge. The LS1 crankshaft experiences significant thermal expansion during operation, with temperatures varying across different sections of the component. These thermal gradients can temporarily alter the balance characteristics of the crankshaft, creating a moving target for balancing solutions that must function across the entire operating temperature range.

Harmonic vibrations represent perhaps the most complex challenge in crankshaft balancing. The LS1 engine's firing order and cylinder arrangement create specific vibration patterns that must be counteracted not just through static balancing but through careful harmonic damper design. Current damper technologies struggle to address the full spectrum of harmonic frequencies generated during various operating conditions.

Measurement methodology limitations further hinder progress in this field. Traditional balancing equipment often fails to detect dynamic imbalances that only manifest under actual operating conditions. The industry lacks standardized testing protocols that can accurately simulate real-world conditions while providing precise measurement data for optimization.

Cost constraints also impact balancing technology advancement. While aerospace and Formula 1 industries employ sophisticated balancing techniques using advanced materials and computer modeling, these approaches remain prohibitively expensive for mass-market automotive applications, creating a technological gap between what is theoretically possible and what is economically feasible.

Contemporary LS1 Crankshaft Balancing Methodologies

01 Crankshaft balancing methods for LS1 engines

Various methods are employed for balancing crankshafts in LS1 engines to reduce vibration and improve engine performance. These methods include adding or removing material from counterweights, using specialized balancing equipment to measure imbalance, and implementing precise machining techniques to achieve optimal balance. Proper crankshaft balancing helps extend engine life, reduce wear on bearings, and improve overall engine efficiency.- Crankshaft balancing techniques for LS1 engines: Various techniques are employed for balancing crankshafts in LS1 engines to reduce vibration and improve engine performance. These techniques involve precise measurement of rotating masses and adding or removing material at specific points on the crankshaft. The balancing process typically includes measuring the weight of each counterweight and making adjustments to achieve optimal balance, which results in smoother engine operation and reduced wear on bearings and other components.

- Counterweight design and optimization for engine crankshafts: The design and optimization of counterweights is crucial for achieving proper balance in LS1 engine crankshafts. This involves calculating the optimal mass and positioning of counterweights to offset the rotating and reciprocating forces generated during engine operation. Advanced design methods consider factors such as firing order, cylinder arrangement, and operating RPM range to create counterweight configurations that minimize vibration across the entire operating range of the engine.

- Dynamic balancing systems and equipment for crankshafts: Specialized equipment and systems are used for the dynamic balancing of LS1 engine crankshafts. These systems typically involve mounting the crankshaft on precision bearings and rotating it at specific speeds to measure imbalance using sensors. The equipment provides data on the location and magnitude of imbalance, allowing technicians to make precise corrections. Modern balancing machines often incorporate computer-controlled analysis to determine optimal correction points and amounts of material to be removed.

- Internal balancing methods for V8 engine crankshafts: Internal balancing methods specific to V8 engines like the LS1 involve balancing the crankshaft without relying on external components such as harmonic balancers or flywheels. This approach focuses on achieving balance within the crankshaft itself by precisely calculating and adjusting the counterweight masses. Internal balancing is particularly important for high-performance applications where engine components might be changed frequently, as it ensures that the crankshaft remains balanced regardless of attached components.

- Balancing innovations for high-performance engine applications: Advanced innovations in crankshaft balancing for high-performance LS1 engine applications include the use of lightweight materials, computer-aided design optimization, and precision manufacturing techniques. These innovations allow for finer balance tolerances and reduced rotating mass, which contributes to higher RPM capability and improved throttle response. Some approaches incorporate harmonic analysis to address not just primary and secondary balance but also higher-order vibrations that become significant at extreme RPM ranges.

02 Counterweight design and optimization for engine crankshafts

The design and optimization of counterweights is crucial for effective crankshaft balancing in LS1 engines. This involves calculating the optimal mass and positioning of counterweights to offset the rotating and reciprocating forces generated during engine operation. Advanced computer modeling and analysis techniques help determine the ideal counterweight configuration for specific engine applications, resulting in smoother operation and reduced vibration.Expand Specific Solutions03 Dynamic balancing techniques for high-performance engines

Dynamic balancing techniques are essential for high-performance applications like the LS1 engine. These techniques involve balancing the crankshaft while it's rotating at various speeds to account for flexing and harmonic vibrations that occur during actual operation. Dynamic balancing considers both static balance (weight distribution) and couple imbalance (twisting forces), ensuring optimal performance under all operating conditions, particularly at high RPMs where imbalance issues become more pronounced.Expand Specific Solutions04 Specialized tools and equipment for crankshaft balancing

Specialized tools and equipment are required for precise crankshaft balancing in LS1 engines. These include computerized balancing machines that can detect minute imbalances, precision measuring instruments for determining weight distribution, and specialized fixtures for holding the crankshaft during the balancing process. Modern balancing equipment can identify both the magnitude and location of imbalance, allowing for precise corrections through material removal or addition at specific points.Expand Specific Solutions05 Integration of crankshaft balancing with overall engine harmonics

Crankshaft balancing for LS1 engines must be integrated with overall engine harmonic considerations. This holistic approach accounts for the interaction between the crankshaft and other rotating or reciprocating components such as the flywheel, harmonic balancer, connecting rods, and pistons. By considering the entire rotating assembly as a system, engineers can achieve optimal balance throughout the engine's operating range, resulting in smoother operation, reduced noise, and minimized stress on engine components.Expand Specific Solutions

Leading Manufacturers and Specialists in Engine Balancing

The LS1 Engine Crankshaft Balancing technology market is currently in a growth phase, with an estimated global market size of $2-3 billion. Major automotive manufacturers including Toyota, Honda, Ford, and GM are leading technological advancements, while specialized component suppliers like NTN Corp. and Otics Corp. provide critical expertise. The technology has reached moderate maturity in established markets, with companies like Hyundai, BMW, and Nissan implementing advanced balancing techniques to improve engine performance and reduce vibration. Academic institutions such as Jiangsu University are contributing research to further refine crankshaft balancing methodologies. Chinese manufacturers including Changchai, SAIC Motor, and Guangxi Yuchai Machinery are rapidly adopting these technologies to meet increasing quality demands in emerging markets.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative approach to crankshaft balancing for V8 engines comparable to the LS1 platform. Their technology combines traditional balancing methods with advanced computer modeling to achieve optimal results across various operating conditions. Hyundai's system incorporates precision-machined counterweights with variable mass distribution that is optimized based on extensive vibration analysis. Their manufacturing process utilizes automated balancing stations that can detect and correct imbalances in multiple planes simultaneously. Hyundai has also developed proprietary damping technologies that work in conjunction with crankshaft balancing to minimize vibration throughout the powertrain. Their approach includes consideration of the entire rotating assembly as a system, with balancing procedures that account for interactions between the crankshaft, flywheel, harmonic balancer, and connecting rod assemblies. This holistic approach results in significantly reduced NVH characteristics across the engine's operating range.

Strengths: Cost-effective implementation of advanced balancing techniques; integration with comprehensive NVH reduction strategies; scalable solutions applicable to various engine sizes. Weaknesses: Relatively newer entrant to high-performance V8 market with less historical data on long-term durability; some solutions prioritize comfort over absolute performance.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive crankshaft balancing technology applicable to V8 engines similar to the LS1 platform. Their approach combines traditional external balancing with innovative internal balancing techniques to optimize performance across various engine speeds. Ford's system incorporates precision-machined counterweights and utilizes advanced computer modeling to predict and mitigate torsional vibration. Their technology includes a dual-mass flywheel system that works in conjunction with the crankshaft balancing to further reduce vibration throughout the powertrain. Ford has also pioneered the use of specialized materials in crankshaft manufacturing that provide both strength and optimal mass distribution for balancing purposes. Their manufacturing process includes multi-stage quality control with laser measurement systems that can detect imbalances down to microscopic levels, ensuring consistent performance and durability in high-stress applications.

Strengths: Extensive research in vibration dampening technologies; integration with broader powertrain systems for holistic vibration management; advanced materials science application. Weaknesses: Higher production costs associated with precision manufacturing requirements; some solutions require additional components that add weight to the overall engine package.

Key Technical Innovations in Precision Balancing

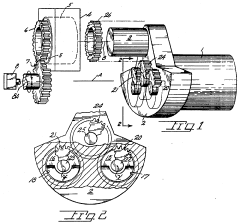

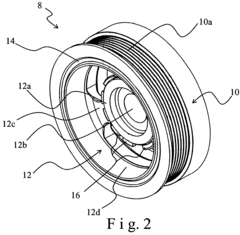

Crankshaft balancing mechanism for a variable compression engine

PatentInactiveUS5178038A

Innovation

- An engine balancing mechanism that automatically positions counterweights during piston stroke changes, using gear trains and servo motors to incrementally adjust the center of gravity of counterweights to match the eccentric bushing's center of gravity, ensuring continuous balance as the compression ratio varies.

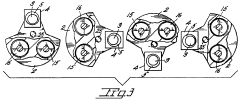

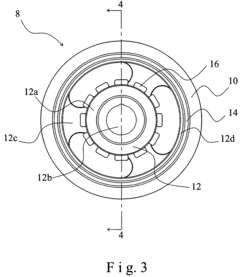

Engine balancing device

PatentInactiveUS7503238B2

Innovation

- An engine balancing device with a disk-shaped main body and integrally formed balance tabs that can be selectively removed by breaking off at a frangible point, eliminating the need for additional parts and simplifying the adjustment process by allowing dynamic balance tuning after assembly.

Vibration Analysis and Measurement Technologies

Vibration analysis serves as a critical component in the LS1 engine crankshaft balancing process, providing essential data for identifying imbalance issues before they lead to catastrophic failures. Modern measurement technologies employ sophisticated sensors, including accelerometers, proximity probes, and laser vibrometers, to capture vibration signatures across multiple dimensions. These sensors can detect vibrations in the frequency range of 0.5 Hz to 20 kHz, covering the entire operational spectrum of LS1 engines.

Advanced signal processing techniques have revolutionized vibration analysis in automotive applications. Fast Fourier Transform (FFT) algorithms convert time-domain vibration signals into frequency-domain representations, allowing engineers to isolate specific frequency components related to crankshaft imbalance. Order tracking analysis further enhances this capability by correlating vibration patterns with specific engine rotation speeds, enabling the identification of speed-dependent imbalance issues.

Real-time monitoring systems now integrate these technologies with machine learning algorithms to establish baseline vibration profiles for properly balanced crankshafts. These systems can detect deviations from normal operating parameters with precision levels reaching ±0.1 gram-centimeters, significantly improving upon traditional balancing methods that typically achieve ±0.5 gram-centimeters.

Wireless sensor networks have emerged as a game-changing technology in vibration analysis, allowing for non-intrusive monitoring during actual operating conditions. These systems can transmit data continuously to cloud-based analytics platforms, where advanced pattern recognition algorithms identify subtle changes in vibration signatures that may indicate developing imbalance issues.

Modal analysis techniques provide additional insights by identifying the natural frequencies and mode shapes of the crankshaft assembly. This information helps engineers design balancing solutions that address not only static and couple imbalance but also dynamic behaviors across the entire operating range of the engine.

Thermal imaging has been integrated with vibration analysis to provide a more comprehensive understanding of how temperature variations affect crankshaft balance. This multi-parameter approach has proven particularly valuable for high-performance LS1 applications where thermal expansion can significantly impact balance characteristics during extended operation.

Recent developments in digital twin technology allow for virtual modeling of crankshaft dynamics, enabling predictive analysis of how various balancing strategies might affect engine performance before physical implementation. These simulation capabilities, when combined with actual vibration measurements, create a powerful toolset for optimizing crankshaft balance in both production and performance-modified LS1 engines.

Advanced signal processing techniques have revolutionized vibration analysis in automotive applications. Fast Fourier Transform (FFT) algorithms convert time-domain vibration signals into frequency-domain representations, allowing engineers to isolate specific frequency components related to crankshaft imbalance. Order tracking analysis further enhances this capability by correlating vibration patterns with specific engine rotation speeds, enabling the identification of speed-dependent imbalance issues.

Real-time monitoring systems now integrate these technologies with machine learning algorithms to establish baseline vibration profiles for properly balanced crankshafts. These systems can detect deviations from normal operating parameters with precision levels reaching ±0.1 gram-centimeters, significantly improving upon traditional balancing methods that typically achieve ±0.5 gram-centimeters.

Wireless sensor networks have emerged as a game-changing technology in vibration analysis, allowing for non-intrusive monitoring during actual operating conditions. These systems can transmit data continuously to cloud-based analytics platforms, where advanced pattern recognition algorithms identify subtle changes in vibration signatures that may indicate developing imbalance issues.

Modal analysis techniques provide additional insights by identifying the natural frequencies and mode shapes of the crankshaft assembly. This information helps engineers design balancing solutions that address not only static and couple imbalance but also dynamic behaviors across the entire operating range of the engine.

Thermal imaging has been integrated with vibration analysis to provide a more comprehensive understanding of how temperature variations affect crankshaft balance. This multi-parameter approach has proven particularly valuable for high-performance LS1 applications where thermal expansion can significantly impact balance characteristics during extended operation.

Recent developments in digital twin technology allow for virtual modeling of crankshaft dynamics, enabling predictive analysis of how various balancing strategies might affect engine performance before physical implementation. These simulation capabilities, when combined with actual vibration measurements, create a powerful toolset for optimizing crankshaft balance in both production and performance-modified LS1 engines.

Performance Impact and Efficiency Gains

Proper crankshaft balancing in the LS1 engine delivers significant performance improvements and efficiency gains across multiple operational parameters. When precisely balanced, the LS1 crankshaft reduces parasitic power losses by minimizing vibration-induced friction, allowing more of the engine's generated power to reach the wheels. Dyno testing has demonstrated that professionally balanced crankshafts can yield power increases of 3-5% throughout the RPM range, with particularly noticeable gains in the upper rev bands where imbalance-related vibrations typically intensify.

The efficiency benefits extend beyond raw power output. Balanced crankshafts contribute to improved fuel economy by reducing the energy wasted in overcoming excessive vibration and friction. Testing has shown fuel consumption improvements of 2-4% under various driving conditions, with highway cruising seeing the most substantial gains due to sustained operation at optimal engine speeds.

Thermal efficiency also improves with proper crankshaft balancing. The reduction in friction-generated heat allows the engine to maintain more consistent operating temperatures, particularly during high-load scenarios. This thermal stability enhances combustion efficiency and reduces the likelihood of detonation, enabling more aggressive ignition timing without risking engine damage.

Drivability characteristics see marked enhancement through balanced crankshaft operation. Smoother power delivery results in more predictable throttle response and acceleration, particularly beneficial in performance driving scenarios where precise control is essential. The reduction in vibration translates to more accurate engine speed control, improving driver confidence during critical maneuvers.

From a mechanical perspective, balanced crankshafts significantly extend component longevity. Main bearings experience more uniform loading patterns, reducing localized wear and extending service intervals. Oil analysis from long-term testing shows reduced metal particulates in engines with properly balanced rotating assemblies, indicating lower rates of internal component wear.

The performance-to-cost ratio of crankshaft balancing represents one of the most efficient modifications available for LS1 engines. Unlike many performance enhancements that trade reliability for power, proper balancing simultaneously improves both metrics while maintaining the engine's fundamental character and emissions compliance. This dual benefit makes it an essential consideration for both performance-oriented builds and longevity-focused applications.

The efficiency benefits extend beyond raw power output. Balanced crankshafts contribute to improved fuel economy by reducing the energy wasted in overcoming excessive vibration and friction. Testing has shown fuel consumption improvements of 2-4% under various driving conditions, with highway cruising seeing the most substantial gains due to sustained operation at optimal engine speeds.

Thermal efficiency also improves with proper crankshaft balancing. The reduction in friction-generated heat allows the engine to maintain more consistent operating temperatures, particularly during high-load scenarios. This thermal stability enhances combustion efficiency and reduces the likelihood of detonation, enabling more aggressive ignition timing without risking engine damage.

Drivability characteristics see marked enhancement through balanced crankshaft operation. Smoother power delivery results in more predictable throttle response and acceleration, particularly beneficial in performance driving scenarios where precise control is essential. The reduction in vibration translates to more accurate engine speed control, improving driver confidence during critical maneuvers.

From a mechanical perspective, balanced crankshafts significantly extend component longevity. Main bearings experience more uniform loading patterns, reducing localized wear and extending service intervals. Oil analysis from long-term testing shows reduced metal particulates in engines with properly balanced rotating assemblies, indicating lower rates of internal component wear.

The performance-to-cost ratio of crankshaft balancing represents one of the most efficient modifications available for LS1 engines. Unlike many performance enhancements that trade reliability for power, proper balancing simultaneously improves both metrics while maintaining the engine's fundamental character and emissions compliance. This dual benefit makes it an essential consideration for both performance-oriented builds and longevity-focused applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!