Capturing Benefits of Propionic Acid in Polymer Industries

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid in Polymers: Background and Objectives

Propionic acid has emerged as a significant player in the polymer industry, offering a range of benefits that have captured the attention of researchers and manufacturers alike. This organic compound, with its unique chemical properties, has been increasingly explored for its potential to enhance various aspects of polymer production and performance.

The journey of propionic acid in the polymer industry began in the mid-20th century when scientists first recognized its potential as a preservative and mold inhibitor. However, it wasn't until recent decades that its applications in polymer science gained substantial traction. The growing interest in sustainable and bio-based materials has further propelled the exploration of propionic acid as a key component in polymer formulations.

From a chemical perspective, propionic acid (C3H6O2) is a carboxylic acid with a three-carbon backbone. Its molecular structure allows for versatile interactions with polymer chains, offering opportunities for modification and enhancement of polymer properties. This structural compatibility has opened doors for its use in various polymer types, including polyesters, polyamides, and polyolefins.

The primary objectives of incorporating propionic acid into polymer industries are multifaceted. Firstly, there is a strong focus on improving the physical and chemical properties of polymers. Researchers aim to enhance characteristics such as thermal stability, mechanical strength, and resistance to degradation through the strategic integration of propionic acid into polymer matrices.

Secondly, the industry is keen on leveraging propionic acid's potential as a bio-based additive. With the growing emphasis on sustainability and environmental consciousness, propionic acid derived from renewable sources presents an attractive option for reducing the carbon footprint of polymer production.

Another critical objective is the exploration of propionic acid's role in polymer synthesis. Its ability to participate in polymerization reactions and act as a chain transfer agent has sparked interest in developing novel polymer architectures and controlling molecular weight distributions.

Furthermore, the polymer industry aims to harness propionic acid's antimicrobial properties. By incorporating it into polymer formulations, manufacturers seek to create materials with inherent resistance to microbial growth, potentially expanding applications in packaging, healthcare, and other sectors where hygiene is paramount.

As research in this field progresses, the overarching goal is to fully understand and exploit the synergies between propionic acid and various polymer systems. This includes investigating its impact on processing parameters, long-term stability, and overall performance of polymer products across different applications.

The journey of propionic acid in the polymer industry began in the mid-20th century when scientists first recognized its potential as a preservative and mold inhibitor. However, it wasn't until recent decades that its applications in polymer science gained substantial traction. The growing interest in sustainable and bio-based materials has further propelled the exploration of propionic acid as a key component in polymer formulations.

From a chemical perspective, propionic acid (C3H6O2) is a carboxylic acid with a three-carbon backbone. Its molecular structure allows for versatile interactions with polymer chains, offering opportunities for modification and enhancement of polymer properties. This structural compatibility has opened doors for its use in various polymer types, including polyesters, polyamides, and polyolefins.

The primary objectives of incorporating propionic acid into polymer industries are multifaceted. Firstly, there is a strong focus on improving the physical and chemical properties of polymers. Researchers aim to enhance characteristics such as thermal stability, mechanical strength, and resistance to degradation through the strategic integration of propionic acid into polymer matrices.

Secondly, the industry is keen on leveraging propionic acid's potential as a bio-based additive. With the growing emphasis on sustainability and environmental consciousness, propionic acid derived from renewable sources presents an attractive option for reducing the carbon footprint of polymer production.

Another critical objective is the exploration of propionic acid's role in polymer synthesis. Its ability to participate in polymerization reactions and act as a chain transfer agent has sparked interest in developing novel polymer architectures and controlling molecular weight distributions.

Furthermore, the polymer industry aims to harness propionic acid's antimicrobial properties. By incorporating it into polymer formulations, manufacturers seek to create materials with inherent resistance to microbial growth, potentially expanding applications in packaging, healthcare, and other sectors where hygiene is paramount.

As research in this field progresses, the overarching goal is to fully understand and exploit the synergies between propionic acid and various polymer systems. This includes investigating its impact on processing parameters, long-term stability, and overall performance of polymer products across different applications.

Market Analysis for Propionic Acid-Enhanced Polymers

The market for propionic acid-enhanced polymers has shown significant growth potential in recent years, driven by increasing demand for high-performance materials across various industries. The global market size for these specialized polymers is expected to reach several billion dollars by 2025, with a compound annual growth rate (CAGR) exceeding 5% during the forecast period.

Key factors contributing to this market growth include the rising adoption of propionic acid-enhanced polymers in packaging, automotive, construction, and electronics industries. In the packaging sector, these polymers offer improved barrier properties, extending the shelf life of food products and reducing waste. The automotive industry benefits from their lightweight and durable characteristics, which help improve fuel efficiency and vehicle performance.

The construction sector has also embraced propionic acid-enhanced polymers for their weather resistance and thermal insulation properties. In electronics, these materials provide enhanced protection against moisture and corrosion, ensuring longer product lifespans.

Geographically, North America and Europe currently dominate the market, owing to their advanced manufacturing capabilities and stringent regulations promoting sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable income, and growing awareness of eco-friendly products.

Market segmentation reveals that biodegradable propionic acid-enhanced polymers are gaining traction, particularly in regions with strict environmental regulations. This segment is projected to grow at a higher rate than conventional polymers, as consumers and businesses increasingly prioritize sustainability.

The competitive landscape of the propionic acid-enhanced polymer market is characterized by a mix of established chemical companies and innovative startups. Major players are investing heavily in research and development to create novel formulations and expand their product portfolios. Strategic partnerships and collaborations between polymer manufacturers and end-user industries are becoming more common, fostering innovation and market expansion.

Challenges facing the market include fluctuating raw material prices and the need for substantial initial investments in production facilities. However, these are offset by the long-term benefits of improved product performance and potential cost savings in various applications.

Key factors contributing to this market growth include the rising adoption of propionic acid-enhanced polymers in packaging, automotive, construction, and electronics industries. In the packaging sector, these polymers offer improved barrier properties, extending the shelf life of food products and reducing waste. The automotive industry benefits from their lightweight and durable characteristics, which help improve fuel efficiency and vehicle performance.

The construction sector has also embraced propionic acid-enhanced polymers for their weather resistance and thermal insulation properties. In electronics, these materials provide enhanced protection against moisture and corrosion, ensuring longer product lifespans.

Geographically, North America and Europe currently dominate the market, owing to their advanced manufacturing capabilities and stringent regulations promoting sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing disposable income, and growing awareness of eco-friendly products.

Market segmentation reveals that biodegradable propionic acid-enhanced polymers are gaining traction, particularly in regions with strict environmental regulations. This segment is projected to grow at a higher rate than conventional polymers, as consumers and businesses increasingly prioritize sustainability.

The competitive landscape of the propionic acid-enhanced polymer market is characterized by a mix of established chemical companies and innovative startups. Major players are investing heavily in research and development to create novel formulations and expand their product portfolios. Strategic partnerships and collaborations between polymer manufacturers and end-user industries are becoming more common, fostering innovation and market expansion.

Challenges facing the market include fluctuating raw material prices and the need for substantial initial investments in production facilities. However, these are offset by the long-term benefits of improved product performance and potential cost savings in various applications.

Current Challenges in Propionic Acid Polymer Integration

The integration of propionic acid into polymer industries presents several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the corrosive nature of propionic acid, which can degrade equipment and infrastructure used in polymer production processes. This necessitates the use of specialized, corrosion-resistant materials, significantly increasing production costs and limiting scalability.

Another major challenge lies in the volatility of propionic acid, which can lead to issues in handling, storage, and processing. The acid's low boiling point and high vapor pressure make it prone to evaporation, potentially resulting in loss of material and environmental concerns. This volatility also complicates its incorporation into polymer matrices, as it may escape during high-temperature processing steps, affecting the final product's properties and consistency.

The reactivity of propionic acid with certain polymer components poses additional difficulties. While this reactivity can be beneficial in some applications, it can also lead to undesired side reactions, potentially altering the polymer's structure and properties. Controlling these reactions and achieving consistent results across different polymer formulations remains a significant technical hurdle.

Furthermore, the odor associated with propionic acid presents challenges in terms of worker safety and product acceptability. Even small amounts of residual acid can impart an unpleasant smell to the final polymer product, potentially limiting its use in consumer goods and requiring additional processing steps for odor removal.

The integration of propionic acid into polymer systems also faces challenges related to dispersion and compatibility. Achieving uniform distribution of the acid within the polymer matrix is crucial for optimal performance but can be difficult due to differences in polarity and molecular structure between the acid and various polymer types.

Regulatory compliance and environmental concerns add another layer of complexity to the integration process. Stringent regulations regarding the use of volatile organic compounds (VOCs) and emissions control necessitate careful management of propionic acid throughout the polymer production lifecycle, from raw material handling to final product disposal.

Lastly, the economic viability of incorporating propionic acid into polymer industries remains a significant challenge. While the acid offers potential benefits in terms of antimicrobial properties and performance enhancement, the additional costs associated with its integration, including specialized equipment, safety measures, and potential process modifications, must be carefully balanced against the value added to the final product.

Another major challenge lies in the volatility of propionic acid, which can lead to issues in handling, storage, and processing. The acid's low boiling point and high vapor pressure make it prone to evaporation, potentially resulting in loss of material and environmental concerns. This volatility also complicates its incorporation into polymer matrices, as it may escape during high-temperature processing steps, affecting the final product's properties and consistency.

The reactivity of propionic acid with certain polymer components poses additional difficulties. While this reactivity can be beneficial in some applications, it can also lead to undesired side reactions, potentially altering the polymer's structure and properties. Controlling these reactions and achieving consistent results across different polymer formulations remains a significant technical hurdle.

Furthermore, the odor associated with propionic acid presents challenges in terms of worker safety and product acceptability. Even small amounts of residual acid can impart an unpleasant smell to the final polymer product, potentially limiting its use in consumer goods and requiring additional processing steps for odor removal.

The integration of propionic acid into polymer systems also faces challenges related to dispersion and compatibility. Achieving uniform distribution of the acid within the polymer matrix is crucial for optimal performance but can be difficult due to differences in polarity and molecular structure between the acid and various polymer types.

Regulatory compliance and environmental concerns add another layer of complexity to the integration process. Stringent regulations regarding the use of volatile organic compounds (VOCs) and emissions control necessitate careful management of propionic acid throughout the polymer production lifecycle, from raw material handling to final product disposal.

Lastly, the economic viability of incorporating propionic acid into polymer industries remains a significant challenge. While the acid offers potential benefits in terms of antimicrobial properties and performance enhancement, the additional costs associated with its integration, including specialized equipment, safety measures, and potential process modifications, must be carefully balanced against the value added to the final product.

Existing Applications of Propionic Acid in Polymers

01 Antimicrobial properties

Propionic acid exhibits strong antimicrobial properties, making it effective in inhibiting the growth of various microorganisms, including bacteria and fungi. This characteristic makes it valuable in food preservation, animal feed, and pharmaceutical applications.- Antimicrobial properties: Propionic acid exhibits strong antimicrobial properties, making it effective in preventing the growth of mold, bacteria, and other microorganisms. This benefit is particularly useful in food preservation, animal feed, and various industrial applications.

- Food preservation: Propionic acid is widely used as a food preservative due to its ability to extend shelf life and maintain food quality. It is particularly effective in bakery products, dairy items, and processed foods, helping to prevent spoilage and maintain freshness.

- Animal feed additive: Propionic acid is beneficial as an animal feed additive, improving feed efficiency and promoting animal growth. It helps maintain the nutritional value of feed by preventing mold growth and reducing bacterial contamination, leading to better animal health and performance.

- Industrial applications: Propionic acid has various industrial applications, including its use as a chemical intermediate in the production of plastics, herbicides, and pharmaceuticals. It is also utilized in the manufacturing of cellulose acetate propionate and other specialty chemicals.

- Environmental benefits: Propionic acid offers environmental benefits as a biodegradable and eco-friendly alternative to some synthetic chemicals. It can be produced through sustainable fermentation processes, making it a more environmentally conscious choice for various applications in agriculture and industry.

02 Feed additive for livestock

Propionic acid is widely used as a feed additive in livestock nutrition. It helps improve feed efficiency, promotes animal growth, and enhances overall health by maintaining a balanced gut microbiome and preventing mold growth in animal feed.Expand Specific Solutions03 Food preservation

Propionic acid serves as an effective food preservative, extending the shelf life of various food products by inhibiting mold growth and bacterial contamination. It is particularly useful in bakery products, dairy items, and processed foods.Expand Specific Solutions04 Industrial applications

Propionic acid finds use in various industrial applications, including the production of plastics, herbicides, and pharmaceuticals. It serves as a precursor for the synthesis of other chemicals and is utilized in the manufacturing of cellulose acetate propionate.Expand Specific Solutions05 Skin care and cosmetic applications

Propionic acid and its derivatives have benefits in skin care and cosmetic formulations. They can help regulate skin pH, act as exfoliants, and provide antimicrobial properties in personal care products.Expand Specific Solutions

Key Players in Propionic Acid and Polymer Manufacturing

The market for capturing benefits of propionic acid in polymer industries is in a growth phase, driven by increasing demand for sustainable and bio-based materials. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like Novomer, Braskem, and Dow Global Technologies leading innovation. These firms are developing novel catalysts and processes to efficiently incorporate propionic acid into polymer production. While the technology is not yet fully mature, it is progressing towards commercial viability, with several key players investing in research and development to overcome existing challenges and improve cost-effectiveness.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel process for the production of propionic acid through the oxidation of propane. This method utilizes a multi-component catalyst system containing vanadium and phosphorus, achieving high selectivity and yield[1]. The process operates at moderate temperatures (200-300°C) and pressures (10-30 bar), resulting in improved energy efficiency compared to traditional methods[2]. Additionally, Sinopec has implemented advanced purification techniques, including extractive distillation, to obtain high-purity propionic acid suitable for polymer applications[3].

Strengths: Cost-effective production from readily available propane feedstock; improved energy efficiency; high-purity product. Weaknesses: Potential catalyst deactivation over time; requires careful process control to maintain optimal performance.

Novomer, Inc.

Technical Solution: Novomer has pioneered the development of a proprietary catalyst system for the copolymerization of propylene oxide and carbon dioxide to produce polypropylene carbonate (PPC). This innovative process incorporates propionic acid as a chain transfer agent, allowing for precise control of molecular weight and end-group functionality[4]. The resulting PPC exhibits enhanced biodegradability and improved mechanical properties compared to conventional polymers[5]. Novomer's technology also enables the production of polyols with tailored hydroxyl values, which are valuable intermediates for polyurethane manufacturing[6].

Strengths: Utilizes CO2 as a renewable feedstock; produces biodegradable polymers; offers precise control over polymer properties. Weaknesses: May require specialized equipment for large-scale production; market acceptance of novel materials can be challenging.

Innovative Technologies for Propionic Acid Polymer Synthesis

Method for Improving Acid tolerance of Propionibacterium acdipropionici

PatentInactiveUS20140178952A1

Innovation

- Adding arginine and/or aspartic acid to the culture medium during the cultivation of Propionibacterium acdipropionici to enhance acid tolerance and propionic acid productivity.

Improved propionibacterium strains for the production of propionic acid

PatentInactiveUS20190071697A1

Innovation

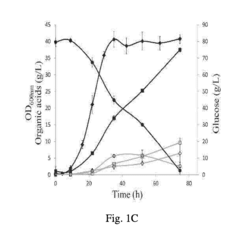

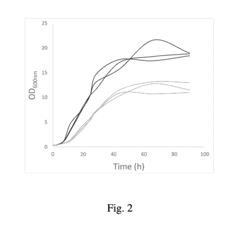

- Selecting and combining Propionibacterium strains with high potential for propionic acid production, such as P. acidipropionici ATCC 4875 and P. acidipropionici ATCC 55737, through genome shuffling to create novel strains with improved growth rates and reduced byproduct production, such as P. acidipropionici F3E8, which achieves enhanced propionic acid yields and growth rates.

Environmental Impact of Propionic Acid in Polymer Production

The environmental impact of propionic acid in polymer production is a critical consideration for sustainable manufacturing practices. Propionic acid, while offering numerous benefits in polymer industries, also presents potential environmental challenges that must be carefully managed.

One of the primary environmental concerns associated with propionic acid use in polymer production is its volatile organic compound (VOC) emissions. During manufacturing processes, propionic acid can evaporate and contribute to air pollution. These emissions may lead to the formation of ground-level ozone and smog, which can have adverse effects on human health and ecosystems. To mitigate this impact, many polymer manufacturers have implemented advanced emission control technologies, such as regenerative thermal oxidizers and carbon adsorption systems.

Water pollution is another potential environmental issue related to propionic acid in polymer production. Improper handling or disposal of propionic acid-containing waste streams can contaminate water bodies, affecting aquatic life and potentially entering the food chain. To address this concern, companies are increasingly adopting closed-loop systems and advanced wastewater treatment technologies to minimize the release of propionic acid into the environment.

The production of propionic acid itself also has environmental implications. Traditional methods of propionic acid synthesis often rely on petrochemical feedstocks, contributing to carbon emissions and resource depletion. However, recent advancements in biotechnology have led to the development of more sustainable production methods, such as fermentation processes using renewable biomass feedstocks. These bio-based production routes can significantly reduce the carbon footprint associated with propionic acid manufacturing.

In terms of polymer lifecycle, the use of propionic acid as an additive or monomer can influence the biodegradability and recyclability of the final product. While propionic acid itself is biodegradable, its incorporation into polymer structures may alter the overall environmental persistence of the material. Researchers are actively exploring ways to optimize polymer formulations containing propionic acid to enhance end-of-life options, including improved recyclability and compostability.

The environmental impact of propionic acid in polymer production also extends to energy consumption. The integration of propionic acid into polymer manufacturing processes may require additional energy inputs for handling, storage, and processing. However, the potential benefits of propionic acid, such as improved polymer properties and processing efficiencies, may offset some of these energy-related environmental costs through reduced material waste and enhanced product performance.

As the polymer industry continues to evolve towards more sustainable practices, the environmental impact of propionic acid is being closely scrutinized. Life cycle assessments (LCAs) are increasingly being employed to quantify the overall environmental footprint of propionic acid use in polymer production, considering factors such as resource consumption, emissions, and waste generation across the entire value chain. These comprehensive analyses are guiding industry efforts to optimize the use of propionic acid while minimizing its environmental impact.

One of the primary environmental concerns associated with propionic acid use in polymer production is its volatile organic compound (VOC) emissions. During manufacturing processes, propionic acid can evaporate and contribute to air pollution. These emissions may lead to the formation of ground-level ozone and smog, which can have adverse effects on human health and ecosystems. To mitigate this impact, many polymer manufacturers have implemented advanced emission control technologies, such as regenerative thermal oxidizers and carbon adsorption systems.

Water pollution is another potential environmental issue related to propionic acid in polymer production. Improper handling or disposal of propionic acid-containing waste streams can contaminate water bodies, affecting aquatic life and potentially entering the food chain. To address this concern, companies are increasingly adopting closed-loop systems and advanced wastewater treatment technologies to minimize the release of propionic acid into the environment.

The production of propionic acid itself also has environmental implications. Traditional methods of propionic acid synthesis often rely on petrochemical feedstocks, contributing to carbon emissions and resource depletion. However, recent advancements in biotechnology have led to the development of more sustainable production methods, such as fermentation processes using renewable biomass feedstocks. These bio-based production routes can significantly reduce the carbon footprint associated with propionic acid manufacturing.

In terms of polymer lifecycle, the use of propionic acid as an additive or monomer can influence the biodegradability and recyclability of the final product. While propionic acid itself is biodegradable, its incorporation into polymer structures may alter the overall environmental persistence of the material. Researchers are actively exploring ways to optimize polymer formulations containing propionic acid to enhance end-of-life options, including improved recyclability and compostability.

The environmental impact of propionic acid in polymer production also extends to energy consumption. The integration of propionic acid into polymer manufacturing processes may require additional energy inputs for handling, storage, and processing. However, the potential benefits of propionic acid, such as improved polymer properties and processing efficiencies, may offset some of these energy-related environmental costs through reduced material waste and enhanced product performance.

As the polymer industry continues to evolve towards more sustainable practices, the environmental impact of propionic acid is being closely scrutinized. Life cycle assessments (LCAs) are increasingly being employed to quantify the overall environmental footprint of propionic acid use in polymer production, considering factors such as resource consumption, emissions, and waste generation across the entire value chain. These comprehensive analyses are guiding industry efforts to optimize the use of propionic acid while minimizing its environmental impact.

Cost-Benefit Analysis of Propionic Acid in Polymer Applications

The cost-benefit analysis of propionic acid in polymer applications reveals significant advantages that justify its incorporation into various polymer industries. Propionic acid, a versatile chemical compound, offers multiple benefits that can enhance the performance and properties of polymers while potentially reducing overall production costs.

One of the primary advantages of using propionic acid in polymer applications is its ability to act as an effective preservative and antimicrobial agent. When incorporated into polymer formulations, propionic acid can inhibit the growth of mold, bacteria, and other microorganisms, thereby extending the shelf life of polymer products and improving their resistance to degradation. This property is particularly valuable in packaging materials, where it can help maintain the quality and safety of food products for extended periods.

From a cost perspective, the use of propionic acid can lead to substantial savings in the long term. While the initial investment in propionic acid may be higher compared to some traditional additives, its multifunctional nature allows for the reduction or elimination of other additives in polymer formulations. This consolidation of ingredients can streamline production processes, reduce inventory management complexities, and potentially lower overall material costs.

Furthermore, propionic acid's role as a plasticizer in certain polymer applications can improve the flexibility and workability of materials without compromising their structural integrity. This property can lead to enhanced processing efficiency, reduced energy consumption during manufacturing, and improved end-product quality. The resulting cost savings in production and potential increase in product value can offset the initial investment in propionic acid.

In terms of environmental benefits, the use of propionic acid in polymer applications can contribute to the development of more sustainable products. Its biodegradability and low toxicity profile make it an attractive option for environmentally conscious manufacturers and consumers. The potential for creating bio-based propionic acid from renewable resources further enhances its appeal from a sustainability standpoint, potentially leading to long-term cost advantages as regulations around environmental impact become more stringent.

However, it is important to consider potential challenges in implementing propionic acid in polymer applications. These may include initial equipment modifications, formulation adjustments, and regulatory compliance requirements. While these factors may incur short-term costs, the long-term benefits in terms of product performance, efficiency gains, and market differentiation often outweigh the initial investments.

In conclusion, the cost-benefit analysis of propionic acid in polymer applications demonstrates a compelling case for its adoption across various sectors of the polymer industry. The combination of antimicrobial properties, potential cost savings through multifunctionality, improved processing characteristics, and environmental benefits presents a strong value proposition for manufacturers looking to enhance their product offerings and operational efficiency.

One of the primary advantages of using propionic acid in polymer applications is its ability to act as an effective preservative and antimicrobial agent. When incorporated into polymer formulations, propionic acid can inhibit the growth of mold, bacteria, and other microorganisms, thereby extending the shelf life of polymer products and improving their resistance to degradation. This property is particularly valuable in packaging materials, where it can help maintain the quality and safety of food products for extended periods.

From a cost perspective, the use of propionic acid can lead to substantial savings in the long term. While the initial investment in propionic acid may be higher compared to some traditional additives, its multifunctional nature allows for the reduction or elimination of other additives in polymer formulations. This consolidation of ingredients can streamline production processes, reduce inventory management complexities, and potentially lower overall material costs.

Furthermore, propionic acid's role as a plasticizer in certain polymer applications can improve the flexibility and workability of materials without compromising their structural integrity. This property can lead to enhanced processing efficiency, reduced energy consumption during manufacturing, and improved end-product quality. The resulting cost savings in production and potential increase in product value can offset the initial investment in propionic acid.

In terms of environmental benefits, the use of propionic acid in polymer applications can contribute to the development of more sustainable products. Its biodegradability and low toxicity profile make it an attractive option for environmentally conscious manufacturers and consumers. The potential for creating bio-based propionic acid from renewable resources further enhances its appeal from a sustainability standpoint, potentially leading to long-term cost advantages as regulations around environmental impact become more stringent.

However, it is important to consider potential challenges in implementing propionic acid in polymer applications. These may include initial equipment modifications, formulation adjustments, and regulatory compliance requirements. While these factors may incur short-term costs, the long-term benefits in terms of product performance, efficiency gains, and market differentiation often outweigh the initial investments.

In conclusion, the cost-benefit analysis of propionic acid in polymer applications demonstrates a compelling case for its adoption across various sectors of the polymer industry. The combination of antimicrobial properties, potential cost savings through multifunctionality, improved processing characteristics, and environmental benefits presents a strong value proposition for manufacturers looking to enhance their product offerings and operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!