How to Refine Propionic Acid's Effective Application Techniques?

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propionic Acid Overview and Objectives

Propionic acid, a three-carbon short-chain fatty acid, has been a subject of increasing interest in various industries due to its versatile applications and potential benefits. This organic compound, naturally occurring in some foods and produced by gut bacteria, has gained attention for its antimicrobial, preservative, and flavor-enhancing properties. The evolution of propionic acid technology has been driven by the growing demand for natural food preservatives, animal feed additives, and pharmaceutical intermediates.

The primary objective of refining propionic acid's effective application techniques is to optimize its utilization across diverse sectors while addressing current limitations and exploring new possibilities. This involves enhancing production methods, improving purification processes, and developing novel formulations to expand its applicability. By focusing on these aspects, researchers and industry professionals aim to unlock the full potential of propionic acid and overcome existing challenges in its use.

One of the key trends in propionic acid technology is the shift towards more sustainable and cost-effective production methods. Traditional petrochemical-based production is gradually being complemented or replaced by bio-based processes, utilizing renewable resources and fermentation techniques. This aligns with the global push for greener technologies and circular economy principles, potentially opening up new markets and applications for propionic acid.

In the food industry, the refinement of propionic acid application techniques is centered on enhancing its preservative efficacy while maintaining product quality and safety. This includes developing improved delivery systems, optimizing concentration levels, and exploring synergistic effects with other preservatives. The goal is to extend shelf life, reduce food waste, and meet consumer demands for clean label products.

The animal feed sector presents another significant area for propionic acid technology advancement. Research is focused on improving its effectiveness as a mold inhibitor and feed preservative, particularly in challenging environmental conditions. Additionally, there is growing interest in exploring propionic acid's potential role in animal gut health and performance enhancement, which could lead to more targeted application techniques in livestock nutrition.

In the pharmaceutical and chemical industries, efforts are directed towards refining propionic acid's role as a precursor and intermediate in various synthesis processes. This involves developing more efficient catalytic systems, exploring new reaction pathways, and optimizing purification methods to enhance yield and purity. The aim is to broaden propionic acid's utility in producing high-value chemicals and pharmaceuticals.

As we delve deeper into refining propionic acid's effective application techniques, it is crucial to consider the regulatory landscape, environmental impact, and market dynamics. These factors will shape the direction of research and development efforts, ultimately determining the success of new applications and technologies in this field.

The primary objective of refining propionic acid's effective application techniques is to optimize its utilization across diverse sectors while addressing current limitations and exploring new possibilities. This involves enhancing production methods, improving purification processes, and developing novel formulations to expand its applicability. By focusing on these aspects, researchers and industry professionals aim to unlock the full potential of propionic acid and overcome existing challenges in its use.

One of the key trends in propionic acid technology is the shift towards more sustainable and cost-effective production methods. Traditional petrochemical-based production is gradually being complemented or replaced by bio-based processes, utilizing renewable resources and fermentation techniques. This aligns with the global push for greener technologies and circular economy principles, potentially opening up new markets and applications for propionic acid.

In the food industry, the refinement of propionic acid application techniques is centered on enhancing its preservative efficacy while maintaining product quality and safety. This includes developing improved delivery systems, optimizing concentration levels, and exploring synergistic effects with other preservatives. The goal is to extend shelf life, reduce food waste, and meet consumer demands for clean label products.

The animal feed sector presents another significant area for propionic acid technology advancement. Research is focused on improving its effectiveness as a mold inhibitor and feed preservative, particularly in challenging environmental conditions. Additionally, there is growing interest in exploring propionic acid's potential role in animal gut health and performance enhancement, which could lead to more targeted application techniques in livestock nutrition.

In the pharmaceutical and chemical industries, efforts are directed towards refining propionic acid's role as a precursor and intermediate in various synthesis processes. This involves developing more efficient catalytic systems, exploring new reaction pathways, and optimizing purification methods to enhance yield and purity. The aim is to broaden propionic acid's utility in producing high-value chemicals and pharmaceuticals.

As we delve deeper into refining propionic acid's effective application techniques, it is crucial to consider the regulatory landscape, environmental impact, and market dynamics. These factors will shape the direction of research and development efforts, ultimately determining the success of new applications and technologies in this field.

Market Analysis for Propionic Acid Applications

The global market for propionic acid applications has been experiencing steady growth, driven by increasing demand across various industries. The food and feed preservation sector remains the largest application area, accounting for a significant portion of the market share. Propionic acid's effectiveness as a mold inhibitor and preservative in animal feed and bakery products has solidified its position in this segment.

In the food industry, there is a growing trend towards natural preservatives, which has led to increased adoption of propionic acid as a safer alternative to synthetic preservatives. This shift is particularly evident in developed markets where consumers are more health-conscious and demand clean-label products. The dairy industry also presents a promising market for propionic acid, especially in cheese production where it serves as an effective anti-mold agent.

The pharmaceutical sector is emerging as a key growth area for propionic acid applications. Its use as a precursor in the synthesis of various drugs and as a solvent in pharmaceutical formulations is expanding. The increasing focus on healthcare and the pharmaceutical industry's continuous innovation are expected to drive demand in this segment.

In the agriculture sector, propionic acid's application as a grain preservative is gaining traction, particularly in regions with high humidity where grain spoilage is a significant concern. The push for sustainable agriculture practices and the need to reduce post-harvest losses are contributing factors to this growth.

The chemical industry represents another substantial market for propionic acid, where it is used as an intermediate in the production of cellulose acetate propionate, pesticides, and other chemicals. The expanding chemical manufacturing sector in emerging economies is likely to boost demand in this application area.

Geographically, North America and Europe currently dominate the propionic acid market, owing to their well-established food and feed industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing population, and rising disposable incomes leading to higher demand for processed foods and animal products.

Market challenges include volatility in raw material prices, particularly propylene, which can impact profit margins. Additionally, stringent regulations regarding food additives and preservatives in some regions may pose hurdles to market expansion. However, ongoing research into new applications and more efficient production methods presents opportunities for market players to innovate and capture larger market shares.

In the food industry, there is a growing trend towards natural preservatives, which has led to increased adoption of propionic acid as a safer alternative to synthetic preservatives. This shift is particularly evident in developed markets where consumers are more health-conscious and demand clean-label products. The dairy industry also presents a promising market for propionic acid, especially in cheese production where it serves as an effective anti-mold agent.

The pharmaceutical sector is emerging as a key growth area for propionic acid applications. Its use as a precursor in the synthesis of various drugs and as a solvent in pharmaceutical formulations is expanding. The increasing focus on healthcare and the pharmaceutical industry's continuous innovation are expected to drive demand in this segment.

In the agriculture sector, propionic acid's application as a grain preservative is gaining traction, particularly in regions with high humidity where grain spoilage is a significant concern. The push for sustainable agriculture practices and the need to reduce post-harvest losses are contributing factors to this growth.

The chemical industry represents another substantial market for propionic acid, where it is used as an intermediate in the production of cellulose acetate propionate, pesticides, and other chemicals. The expanding chemical manufacturing sector in emerging economies is likely to boost demand in this application area.

Geographically, North America and Europe currently dominate the propionic acid market, owing to their well-established food and feed industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing population, and rising disposable incomes leading to higher demand for processed foods and animal products.

Market challenges include volatility in raw material prices, particularly propylene, which can impact profit margins. Additionally, stringent regulations regarding food additives and preservatives in some regions may pose hurdles to market expansion. However, ongoing research into new applications and more efficient production methods presents opportunities for market players to innovate and capture larger market shares.

Technical Challenges in Propionic Acid Refinement

The refinement of propionic acid presents several significant technical challenges that researchers and industry professionals must address to enhance its effective application techniques. One of the primary obstacles lies in the purification process, particularly in separating propionic acid from other organic compounds and water. Traditional distillation methods often struggle with the formation of azeotropes, making it difficult to achieve high purity levels without substantial energy input.

Another critical challenge is the corrosive nature of propionic acid, which necessitates the use of specialized materials in processing equipment. This requirement not only increases production costs but also complicates the design and maintenance of refinement facilities. The selection of appropriate corrosion-resistant materials that can withstand prolonged exposure to propionic acid while maintaining process efficiency remains an ongoing area of research.

The environmental impact of propionic acid refinement processes poses additional challenges. Current methods often involve the use of solvents or catalysts that may have adverse effects on the environment. Developing greener, more sustainable refinement techniques that minimize waste generation and reduce the carbon footprint of production is a pressing concern for the industry.

Energy efficiency in the refinement process is another significant hurdle. The high boiling point of propionic acid (141°C) necessitates substantial energy input for distillation and other separation techniques. Innovative approaches to reduce energy consumption while maintaining or improving product quality are essential for enhancing the economic viability of propionic acid production.

Scale-up challenges present further complications in the refinement of propionic acid. Laboratory-scale processes often do not translate directly to industrial-scale production, requiring significant engineering efforts to maintain efficiency and product quality at larger volumes. This scaling issue affects various aspects of the refinement process, from reaction kinetics to heat transfer and separation efficiencies.

The optimization of catalytic processes for propionic acid production and refinement remains an active area of research. Current catalysts may suffer from deactivation, selectivity issues, or require harsh reaction conditions. Developing more robust, selective, and efficient catalysts could significantly improve the overall refinement process, potentially leading to higher yields and purer products.

Lastly, the variability in feedstock quality, particularly when using bio-based sources for propionic acid production, introduces additional refinement challenges. Fluctuations in impurity profiles and concentrations can impact downstream processing steps, necessitating the development of flexible and adaptive refinement technologies capable of handling diverse input streams while consistently producing high-quality propionic acid.

Another critical challenge is the corrosive nature of propionic acid, which necessitates the use of specialized materials in processing equipment. This requirement not only increases production costs but also complicates the design and maintenance of refinement facilities. The selection of appropriate corrosion-resistant materials that can withstand prolonged exposure to propionic acid while maintaining process efficiency remains an ongoing area of research.

The environmental impact of propionic acid refinement processes poses additional challenges. Current methods often involve the use of solvents or catalysts that may have adverse effects on the environment. Developing greener, more sustainable refinement techniques that minimize waste generation and reduce the carbon footprint of production is a pressing concern for the industry.

Energy efficiency in the refinement process is another significant hurdle. The high boiling point of propionic acid (141°C) necessitates substantial energy input for distillation and other separation techniques. Innovative approaches to reduce energy consumption while maintaining or improving product quality are essential for enhancing the economic viability of propionic acid production.

Scale-up challenges present further complications in the refinement of propionic acid. Laboratory-scale processes often do not translate directly to industrial-scale production, requiring significant engineering efforts to maintain efficiency and product quality at larger volumes. This scaling issue affects various aspects of the refinement process, from reaction kinetics to heat transfer and separation efficiencies.

The optimization of catalytic processes for propionic acid production and refinement remains an active area of research. Current catalysts may suffer from deactivation, selectivity issues, or require harsh reaction conditions. Developing more robust, selective, and efficient catalysts could significantly improve the overall refinement process, potentially leading to higher yields and purer products.

Lastly, the variability in feedstock quality, particularly when using bio-based sources for propionic acid production, introduces additional refinement challenges. Fluctuations in impurity profiles and concentrations can impact downstream processing steps, necessitating the development of flexible and adaptive refinement technologies capable of handling diverse input streams while consistently producing high-quality propionic acid.

Current Refinement Techniques

01 Use of propionic acid in food preservation

Propionic acid is widely used as a food preservative due to its antimicrobial properties. It is effective in inhibiting the growth of mold and bacteria in various food products, extending their shelf life. This application is particularly important in bakery goods, dairy products, and animal feed.- Use of propionic acid in food preservation: Propionic acid is widely used as a food preservative due to its antimicrobial properties. It is effective in inhibiting the growth of mold and bacteria, extending the shelf life of various food products. This application is particularly important in bakery goods, dairy products, and animal feed.

- Production methods for propionic acid: Various methods have been developed for the production of propionic acid, including fermentation processes and chemical synthesis. These methods aim to improve yield, reduce costs, and enhance the purity of the final product. Innovations in production techniques contribute to the wider application of propionic acid in different industries.

- Application in pharmaceuticals and personal care products: Propionic acid and its derivatives find applications in the pharmaceutical and personal care industries. They are used in the formulation of various medications, topical treatments, and cosmetic products. The acid's properties make it useful in creating stable and effective formulations for these applications.

- Use in industrial processes and chemical synthesis: Propionic acid serves as an important intermediate in various industrial processes and chemical syntheses. It is used in the production of cellulose acetate propionate, herbicides, and other chemical compounds. Its versatility in chemical reactions makes it a valuable component in many manufacturing processes.

- Environmental and agricultural applications: Propionic acid has found applications in environmental protection and agriculture. It is used in the treatment of wastewater, as a soil fumigant, and in the preservation of grain and silage. Its biodegradable nature and effectiveness against harmful microorganisms make it an environmentally friendly option for these applications.

02 Propionic acid in pharmaceutical applications

Propionic acid and its derivatives have various pharmaceutical applications. They are used in the formulation of certain medications, particularly those related to skin treatments. The acid's properties make it useful in topical preparations and as a precursor in drug synthesis.Expand Specific Solutions03 Industrial production of propionic acid

Various methods for the industrial production of propionic acid have been developed. These include fermentation processes using specific microorganisms, as well as chemical synthesis routes. Improvements in production efficiency and yield are ongoing areas of research and development.Expand Specific Solutions04 Propionic acid in agriculture

Propionic acid finds applications in agriculture, particularly in the preservation of grain and silage. It helps prevent spoilage and mold growth in stored crops, reducing post-harvest losses. Additionally, it can be used as a herbicide or in the formulation of certain pesticides.Expand Specific Solutions05 Environmental and industrial applications

Propionic acid has various environmental and industrial applications. It is used in the production of plastics, as a chemical intermediate in the synthesis of other compounds, and in certain cleaning products. Its biodegradable nature makes it an attractive option for environmentally friendly applications.Expand Specific Solutions

Key Industry Players and Competitors

The competitive landscape for refining propionic acid's effective application techniques is evolving rapidly, reflecting the growing importance of this chemical in various industries. The market is in a growth phase, with increasing demand driving innovation and research. Key players like Dow Chemical, Evonik, and BASF are investing heavily in R&D to improve production efficiency and expand applications. The technology maturity varies across different application areas, with some sectors like food preservation being well-established, while others like biofuels and pharmaceuticals are still developing. Universities such as Jiangnan University and Nanjing Tech University are contributing significantly to advancing the fundamental understanding of propionic acid applications, potentially leading to breakthroughs in the near future.

Rohm & Haas Co.

Technical Solution: Rohm & Haas has refined propionic acid's application techniques through the development of advanced surface treatment technologies. Their research has focused on utilizing propionic acid derivatives in corrosion-resistant coatings for metal surfaces. The company has patented a process that incorporates propionic acid-based compounds into polymer matrices, creating thin-film coatings with exceptional adhesion and durability[9]. Additionally, Rohm & Haas has explored the use of propionic acid in water treatment applications, developing novel flocculants that improve water clarity and reduce chemical consumption in industrial processes[10].

Strengths: Diversified applications beyond traditional markets, high-performance specialty products. Weaknesses: Potentially higher production costs, reliance on specialized application techniques.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced catalytic processes for propionic acid production, focusing on improving yield and selectivity. Their approach involves using heterogeneous catalysts in a fixed-bed reactor system, which allows for continuous production with reduced energy consumption. The company has also implemented a novel purification technique that utilizes membrane technology, resulting in higher purity propionic acid (>99.5%) with fewer impurities[1]. Additionally, Evonik has explored the use of bio-based feedstocks for propionic acid production, aligning with sustainability trends in the chemical industry[2].

Strengths: High-purity product, energy-efficient process, and potential for bio-based production. Weaknesses: Potentially higher capital costs for specialized equipment and catalyst development.

Innovative Patents in Propionic Acid Processing

Chromatographic separation of propionic acid using strong base anion exchange resin

PatentWO2017095685A1

Innovation

- Chromatographic separation using a strong base anion exchange resin, specifically a gel-type, Type I resin, to separate propionic acid from liquid feed mixtures containing various organic acids, alcohols, and carbohydrates, effectively addressing the limitations of existing methods.

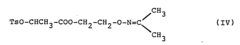

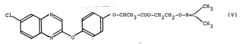

Process for the preparation of propionic-acid derivatives

PatentInactiveEP0276741A2

Innovation

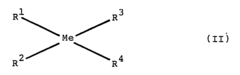

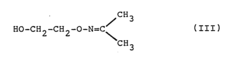

- A process involving the reaction of alkyl 2-[(p-tolylsulfonyl) oxy] propionate with isopropylideneaminooxyethanol using titanium or zirconium catalysts, followed by conversion to 2-[(isopropylideneamino) oxy] ethyl 2- [p- [(6-chloro-2-quinoxalinyl) oxy] phenoxy] propionate, utilizing specific catalysts and solvents, and optimizing reaction conditions to achieve high yields and enantiomeric purity.

Environmental Impact Assessment

The environmental impact assessment of refining propionic acid's effective application techniques is crucial for ensuring sustainable practices in its production and use. Propionic acid, a widely used chemical in various industries, has potential environmental implications that must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with propionic acid production is the emission of volatile organic compounds (VOCs). These emissions can contribute to air pollution and the formation of ground-level ozone, which can have adverse effects on human health and ecosystems. Implementing advanced air pollution control technologies, such as thermal oxidizers or scrubbers, can significantly reduce VOC emissions during the production process.

Water pollution is another critical aspect to consider. The production and application of propionic acid may generate wastewater containing organic compounds and other contaminants. Proper treatment of this wastewater is essential to prevent the release of harmful substances into aquatic ecosystems. Advanced wastewater treatment technologies, including biological treatment systems and membrane filtration, can effectively remove pollutants and ensure compliance with environmental regulations.

Energy consumption and greenhouse gas emissions are also important factors in the environmental impact assessment. Refining propionic acid typically requires significant energy inputs, which can contribute to carbon dioxide emissions if fossil fuels are the primary energy source. Implementing energy-efficient processes and exploring renewable energy options can help reduce the carbon footprint associated with propionic acid production and application.

The potential for soil contamination should be addressed, particularly in agricultural applications where propionic acid is used as a preservative. Proper handling, storage, and application techniques are crucial to prevent soil pollution and maintain soil health. Developing guidelines for safe and efficient application methods can minimize the risk of environmental contamination.

Biodegradability and persistence in the environment are important considerations when assessing the long-term impact of propionic acid. While propionic acid is generally considered biodegradable, its behavior in different environmental compartments should be thoroughly studied to ensure it does not accumulate or cause unforeseen ecological effects.

Life cycle assessment (LCA) is a valuable tool for comprehensively evaluating the environmental impact of propionic acid production and application. An LCA can identify hotspots in the production chain where environmental improvements can be made, from raw material extraction to end-of-life disposal or recycling.

Developing eco-friendly alternatives and green chemistry approaches for propionic acid production can significantly reduce its environmental footprint. This may include exploring bio-based feedstocks, optimizing reaction conditions to minimize waste generation, and investigating catalytic processes that operate under milder conditions with reduced energy requirements.

One of the primary environmental concerns associated with propionic acid production is the emission of volatile organic compounds (VOCs). These emissions can contribute to air pollution and the formation of ground-level ozone, which can have adverse effects on human health and ecosystems. Implementing advanced air pollution control technologies, such as thermal oxidizers or scrubbers, can significantly reduce VOC emissions during the production process.

Water pollution is another critical aspect to consider. The production and application of propionic acid may generate wastewater containing organic compounds and other contaminants. Proper treatment of this wastewater is essential to prevent the release of harmful substances into aquatic ecosystems. Advanced wastewater treatment technologies, including biological treatment systems and membrane filtration, can effectively remove pollutants and ensure compliance with environmental regulations.

Energy consumption and greenhouse gas emissions are also important factors in the environmental impact assessment. Refining propionic acid typically requires significant energy inputs, which can contribute to carbon dioxide emissions if fossil fuels are the primary energy source. Implementing energy-efficient processes and exploring renewable energy options can help reduce the carbon footprint associated with propionic acid production and application.

The potential for soil contamination should be addressed, particularly in agricultural applications where propionic acid is used as a preservative. Proper handling, storage, and application techniques are crucial to prevent soil pollution and maintain soil health. Developing guidelines for safe and efficient application methods can minimize the risk of environmental contamination.

Biodegradability and persistence in the environment are important considerations when assessing the long-term impact of propionic acid. While propionic acid is generally considered biodegradable, its behavior in different environmental compartments should be thoroughly studied to ensure it does not accumulate or cause unforeseen ecological effects.

Life cycle assessment (LCA) is a valuable tool for comprehensively evaluating the environmental impact of propionic acid production and application. An LCA can identify hotspots in the production chain where environmental improvements can be made, from raw material extraction to end-of-life disposal or recycling.

Developing eco-friendly alternatives and green chemistry approaches for propionic acid production can significantly reduce its environmental footprint. This may include exploring bio-based feedstocks, optimizing reaction conditions to minimize waste generation, and investigating catalytic processes that operate under milder conditions with reduced energy requirements.

Regulatory Compliance in Chemical Processing

Regulatory compliance in chemical processing is a critical aspect of propionic acid production and application. The manufacturing, handling, storage, and use of propionic acid are subject to various regulations and standards set by governmental bodies and industry organizations. These regulations aim to ensure safety, environmental protection, and product quality throughout the entire lifecycle of propionic acid.

In the United States, the Environmental Protection Agency (EPA) regulates propionic acid under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including exposure limits and handling procedures for propionic acid.

The European Union regulates propionic acid under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Companies must register their use of propionic acid and provide safety data to the European Chemicals Agency (ECHA). The Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper hazard communication on product labels and safety data sheets.

Food-grade propionic acid used as a preservative must comply with food safety regulations. In the US, it is regulated by the Food and Drug Administration (FDA) as a Generally Recognized as Safe (GRAS) substance. The European Food Safety Authority (EFSA) has established acceptable daily intake levels for propionic acid and its salts when used as food additives.

Transportation of propionic acid is subject to regulations such as the US Department of Transportation's Hazardous Materials Regulations and the International Maritime Dangerous Goods (IMDG) Code. These regulations specify requirements for packaging, labeling, and documentation during transport.

Environmental regulations also play a crucial role in propionic acid processing. Facilities must comply with air emission standards, wastewater discharge limits, and waste management regulations. Many countries require environmental impact assessments and permits for chemical processing facilities.

To ensure regulatory compliance, companies involved in propionic acid processing must implement robust management systems. This includes maintaining up-to-date documentation, conducting regular audits, providing employee training, and staying informed about regulatory changes. Many organizations adopt international standards such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety to demonstrate their commitment to compliance and continuous improvement.

As regulations evolve, companies must adapt their processes and practices accordingly. This may involve investing in new technologies, modifying production methods, or reformulating products to meet stricter standards. Staying compliant not only ensures legal operation but also enhances product quality, worker safety, and environmental stewardship in the propionic acid industry.

In the United States, the Environmental Protection Agency (EPA) regulates propionic acid under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including exposure limits and handling procedures for propionic acid.

The European Union regulates propionic acid under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Companies must register their use of propionic acid and provide safety data to the European Chemicals Agency (ECHA). The Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper hazard communication on product labels and safety data sheets.

Food-grade propionic acid used as a preservative must comply with food safety regulations. In the US, it is regulated by the Food and Drug Administration (FDA) as a Generally Recognized as Safe (GRAS) substance. The European Food Safety Authority (EFSA) has established acceptable daily intake levels for propionic acid and its salts when used as food additives.

Transportation of propionic acid is subject to regulations such as the US Department of Transportation's Hazardous Materials Regulations and the International Maritime Dangerous Goods (IMDG) Code. These regulations specify requirements for packaging, labeling, and documentation during transport.

Environmental regulations also play a crucial role in propionic acid processing. Facilities must comply with air emission standards, wastewater discharge limits, and waste management regulations. Many countries require environmental impact assessments and permits for chemical processing facilities.

To ensure regulatory compliance, companies involved in propionic acid processing must implement robust management systems. This includes maintaining up-to-date documentation, conducting regular audits, providing employee training, and staying informed about regulatory changes. Many organizations adopt international standards such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety to demonstrate their commitment to compliance and continuous improvement.

As regulations evolve, companies must adapt their processes and practices accordingly. This may involve investing in new technologies, modifying production methods, or reformulating products to meet stricter standards. Staying compliant not only ensures legal operation but also enhances product quality, worker safety, and environmental stewardship in the propionic acid industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!