Diffusion Bonding Vs Brazing: Temperature–Pressure Windows, Joint Strength And Hermeticity

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Diffusion Bonding and Brazing Technology Evolution

The evolution of joining technologies has been marked by significant advancements in both diffusion bonding and brazing processes over the past century. Diffusion bonding emerged in the early 1900s as a theoretical concept, but practical applications only materialized in the 1940s with aerospace applications. The technology saw substantial refinement during the Cold War era when materials scientists developed improved understanding of atomic diffusion mechanisms across interfaces.

Brazing, with its ancient origins dating back to over 4000 years ago, underwent revolutionary changes in the mid-20th century with the introduction of vacuum brazing techniques. This innovation dramatically improved joint quality by eliminating oxide formation during the joining process. The 1960s and 1970s witnessed the development of specialized filler metals and fluxes that expanded brazing capabilities across diverse material combinations.

The 1980s marked a pivotal shift in both technologies with the introduction of computer-controlled process parameters. Temperature and pressure profiles could be precisely managed in diffusion bonding, while brazing benefited from automated heating cycles that optimized filler metal flow. This period also saw the first comprehensive studies comparing the hermetic sealing capabilities of both joining methods.

By the 1990s, diffusion bonding technology advanced with the development of transient liquid phase bonding (TLP), which combined aspects of both diffusion bonding and brazing. This hybrid approach offered improved joint strength while operating at lower temperatures than traditional diffusion bonding. Simultaneously, active metal brazing techniques emerged, enabling direct ceramic-to-metal joints without metallization pre-treatments.

The early 2000s brought significant improvements in process modeling capabilities. Finite element analysis allowed engineers to predict joint performance and optimize temperature-pressure windows for diffusion bonding. For brazing, computational fluid dynamics models helped visualize and control filler metal flow behavior, reducing void formation and improving joint reliability.

Most recently, the integration of in-situ monitoring systems has revolutionized both technologies. Real-time assessment of bond formation in diffusion bonding and filler metal wetting in brazing has enabled adaptive process control, significantly improving joint quality consistency. Additionally, the development of nano-enhanced filler metals for brazing and surface activation techniques for diffusion bonding has pushed the boundaries of what materials can be successfully joined.

Current research focuses on expanding the temperature-pressure processing windows for both technologies, with particular emphasis on reducing energy requirements while maintaining or improving joint strength and hermeticity performance.

Brazing, with its ancient origins dating back to over 4000 years ago, underwent revolutionary changes in the mid-20th century with the introduction of vacuum brazing techniques. This innovation dramatically improved joint quality by eliminating oxide formation during the joining process. The 1960s and 1970s witnessed the development of specialized filler metals and fluxes that expanded brazing capabilities across diverse material combinations.

The 1980s marked a pivotal shift in both technologies with the introduction of computer-controlled process parameters. Temperature and pressure profiles could be precisely managed in diffusion bonding, while brazing benefited from automated heating cycles that optimized filler metal flow. This period also saw the first comprehensive studies comparing the hermetic sealing capabilities of both joining methods.

By the 1990s, diffusion bonding technology advanced with the development of transient liquid phase bonding (TLP), which combined aspects of both diffusion bonding and brazing. This hybrid approach offered improved joint strength while operating at lower temperatures than traditional diffusion bonding. Simultaneously, active metal brazing techniques emerged, enabling direct ceramic-to-metal joints without metallization pre-treatments.

The early 2000s brought significant improvements in process modeling capabilities. Finite element analysis allowed engineers to predict joint performance and optimize temperature-pressure windows for diffusion bonding. For brazing, computational fluid dynamics models helped visualize and control filler metal flow behavior, reducing void formation and improving joint reliability.

Most recently, the integration of in-situ monitoring systems has revolutionized both technologies. Real-time assessment of bond formation in diffusion bonding and filler metal wetting in brazing has enabled adaptive process control, significantly improving joint quality consistency. Additionally, the development of nano-enhanced filler metals for brazing and surface activation techniques for diffusion bonding has pushed the boundaries of what materials can be successfully joined.

Current research focuses on expanding the temperature-pressure processing windows for both technologies, with particular emphasis on reducing energy requirements while maintaining or improving joint strength and hermeticity performance.

Market Applications and Industry Demand Analysis

The global market for advanced joining technologies continues to expand, driven by increasing demands for high-performance materials and components across multiple industries. Diffusion bonding and brazing represent critical technologies within this sector, with the global metal joining market valued at approximately $20 billion and growing at a compound annual rate of 4.8% through 2025.

Aerospace and defense industries remain the primary consumers of diffusion bonding technology, accounting for roughly 35% of market applications. These sectors require hermetically sealed joints capable of withstanding extreme thermal cycling and mechanical stress while maintaining structural integrity. The increasing adoption of titanium alloys, superalloys, and metal matrix composites in next-generation aircraft has further accelerated demand for diffusion bonding solutions.

Electronics and semiconductor manufacturing represent the fastest-growing application segment for both technologies, with particular emphasis on brazing for hermetic packaging. This sector demands joining solutions that can deliver excellent thermal conductivity while maintaining hermeticity at the microscale. Market analysis indicates that approximately 28% of precision brazing applications now serve semiconductor and electronics manufacturing.

The automotive industry, particularly in electric vehicle production, has emerged as a significant market driver. The need for efficient thermal management systems and lightweight structural components has increased demand for aluminum and copper brazing solutions. Industry reports suggest that automotive applications now constitute approximately 22% of the total brazing market.

Medical device manufacturing represents another high-value application segment, where the biocompatibility and hermeticity requirements make both diffusion bonding and brazing essential technologies. The market for medical-grade joining solutions is growing at approximately 6.2% annually, outpacing the overall market.

Energy sector applications, including nuclear, oil and gas, and renewable energy systems, collectively represent approximately 15% of the market. These applications typically demand the highest levels of joint strength and hermeticity under extreme operating conditions.

Regional analysis indicates that North America and Europe currently lead in diffusion bonding technology adoption, while Asia-Pacific dominates in brazing applications, particularly in electronics manufacturing. However, the fastest market growth is occurring in emerging economies where manufacturing capabilities are rapidly advancing to meet global supply chain demands.

Customer requirements across all sectors increasingly emphasize process reliability, joint quality verification, and cost-effectiveness. This has driven significant innovation in process control systems and non-destructive testing methodologies specific to these joining technologies.

Aerospace and defense industries remain the primary consumers of diffusion bonding technology, accounting for roughly 35% of market applications. These sectors require hermetically sealed joints capable of withstanding extreme thermal cycling and mechanical stress while maintaining structural integrity. The increasing adoption of titanium alloys, superalloys, and metal matrix composites in next-generation aircraft has further accelerated demand for diffusion bonding solutions.

Electronics and semiconductor manufacturing represent the fastest-growing application segment for both technologies, with particular emphasis on brazing for hermetic packaging. This sector demands joining solutions that can deliver excellent thermal conductivity while maintaining hermeticity at the microscale. Market analysis indicates that approximately 28% of precision brazing applications now serve semiconductor and electronics manufacturing.

The automotive industry, particularly in electric vehicle production, has emerged as a significant market driver. The need for efficient thermal management systems and lightweight structural components has increased demand for aluminum and copper brazing solutions. Industry reports suggest that automotive applications now constitute approximately 22% of the total brazing market.

Medical device manufacturing represents another high-value application segment, where the biocompatibility and hermeticity requirements make both diffusion bonding and brazing essential technologies. The market for medical-grade joining solutions is growing at approximately 6.2% annually, outpacing the overall market.

Energy sector applications, including nuclear, oil and gas, and renewable energy systems, collectively represent approximately 15% of the market. These applications typically demand the highest levels of joint strength and hermeticity under extreme operating conditions.

Regional analysis indicates that North America and Europe currently lead in diffusion bonding technology adoption, while Asia-Pacific dominates in brazing applications, particularly in electronics manufacturing. However, the fastest market growth is occurring in emerging economies where manufacturing capabilities are rapidly advancing to meet global supply chain demands.

Customer requirements across all sectors increasingly emphasize process reliability, joint quality verification, and cost-effectiveness. This has driven significant innovation in process control systems and non-destructive testing methodologies specific to these joining technologies.

Technical Challenges in Temperature-Pressure Parameters

The implementation of both diffusion bonding and brazing processes faces significant technical challenges related to temperature-pressure parameters. These parameters critically influence the quality, reliability, and performance of the resulting joints. One of the primary challenges is establishing precise temperature control throughout the bonding process. Temperature gradients across the workpiece can lead to uneven bonding, residual stresses, and potential joint failure. This is particularly problematic for large or geometrically complex components where maintaining uniform temperature distribution becomes increasingly difficult.

Pressure application presents another set of challenges. In diffusion bonding, insufficient pressure may result in inadequate atomic diffusion across the interface, while excessive pressure can cause unwanted deformation of the base materials. The pressure must be carefully calibrated to ensure intimate contact between surfaces without compromising the dimensional integrity of the components. For brazing, the pressure parameters are less critical but still require precise control to ensure proper capillary flow of the filler metal.

The time-temperature-pressure relationship introduces additional complexity. Extended exposure to high temperatures can trigger undesirable microstructural changes in the base materials, including grain growth, phase transformations, or precipitation of secondary phases. These microstructural alterations may compromise the mechanical properties of the joint and the adjacent heat-affected zones. Conversely, insufficient time at temperature may result in incomplete bonding or inadequate filler metal flow.

Material compatibility with the selected temperature-pressure parameters represents another significant challenge. Different materials exhibit varying thermal expansion coefficients, which can generate substantial internal stresses during heating and cooling cycles. These stresses may lead to distortion, cracking, or joint failure. Additionally, some materials may undergo phase transformations or oxidation at the required bonding temperatures, further complicating the process.

The equipment limitations also pose technical hurdles. High-temperature, high-pressure environments demand specialized equipment with precise control capabilities. The cost and complexity of such equipment increase substantially with the required temperature and pressure ranges. Furthermore, the integration of accurate sensing and feedback systems for real-time monitoring and adjustment of process parameters remains technically challenging, particularly in production environments where consistency and repeatability are essential.

Environmental considerations add another layer of complexity. Many high-temperature processes require protective atmospheres or vacuum conditions to prevent oxidation or contamination of the bonding surfaces. Maintaining these controlled environments while simultaneously applying pressure introduces significant engineering challenges, particularly for large-scale industrial applications.

Pressure application presents another set of challenges. In diffusion bonding, insufficient pressure may result in inadequate atomic diffusion across the interface, while excessive pressure can cause unwanted deformation of the base materials. The pressure must be carefully calibrated to ensure intimate contact between surfaces without compromising the dimensional integrity of the components. For brazing, the pressure parameters are less critical but still require precise control to ensure proper capillary flow of the filler metal.

The time-temperature-pressure relationship introduces additional complexity. Extended exposure to high temperatures can trigger undesirable microstructural changes in the base materials, including grain growth, phase transformations, or precipitation of secondary phases. These microstructural alterations may compromise the mechanical properties of the joint and the adjacent heat-affected zones. Conversely, insufficient time at temperature may result in incomplete bonding or inadequate filler metal flow.

Material compatibility with the selected temperature-pressure parameters represents another significant challenge. Different materials exhibit varying thermal expansion coefficients, which can generate substantial internal stresses during heating and cooling cycles. These stresses may lead to distortion, cracking, or joint failure. Additionally, some materials may undergo phase transformations or oxidation at the required bonding temperatures, further complicating the process.

The equipment limitations also pose technical hurdles. High-temperature, high-pressure environments demand specialized equipment with precise control capabilities. The cost and complexity of such equipment increase substantially with the required temperature and pressure ranges. Furthermore, the integration of accurate sensing and feedback systems for real-time monitoring and adjustment of process parameters remains technically challenging, particularly in production environments where consistency and repeatability are essential.

Environmental considerations add another layer of complexity. Many high-temperature processes require protective atmospheres or vacuum conditions to prevent oxidation or contamination of the bonding surfaces. Maintaining these controlled environments while simultaneously applying pressure introduces significant engineering challenges, particularly for large-scale industrial applications.

Current Temperature-Pressure Window Solutions

01 Diffusion bonding techniques for enhanced joint strength

Diffusion bonding creates strong metallurgical bonds by applying heat and pressure to join materials at the atomic level. This technique produces high-strength joints with excellent hermeticity by eliminating interfaces and creating a continuous microstructure. The process parameters including temperature, pressure, and time significantly influence the final joint strength. Advanced diffusion bonding methods can join dissimilar materials while maintaining structural integrity and hermetic sealing properties.- Diffusion bonding techniques for enhanced joint strength: Diffusion bonding creates strong metallurgical bonds by applying heat and pressure to join materials at the atomic level. This technique produces high-strength joints with excellent hermeticity by eliminating interfaces and creating a continuous microstructure. The process parameters including temperature, pressure, and time significantly influence the final joint strength. Proper surface preparation and cleanliness are essential to achieve optimal bonding and prevent contamination that could compromise joint integrity.

- Brazing methods for hermetic sealing: Brazing techniques utilize filler metals that melt and flow between the components to be joined, creating strong hermetic seals upon solidification. The selection of appropriate brazing alloys with compatible melting points and wetting characteristics is crucial for achieving high-quality joints. Controlled atmosphere or vacuum brazing environments prevent oxidation and ensure proper flow of the brazing material. These methods are particularly effective for joining dissimilar materials while maintaining excellent hermeticity in applications requiring gas-tight seals.

- Hybrid joining processes combining diffusion bonding and brazing: Hybrid joining processes that combine diffusion bonding and brazing techniques leverage the advantages of both methods to create superior joints. The initial brazing phase facilitates material flow and gap filling, while the subsequent diffusion phase strengthens the bond through atomic migration. This approach is particularly effective for complex geometries and dissimilar material combinations where conventional single-method joining might be insufficient. The resulting joints exhibit excellent mechanical strength, thermal stability, and hermeticity suitable for demanding applications.

- Testing and evaluation methods for joint strength and hermeticity: Various testing methodologies are employed to evaluate the strength and hermeticity of diffusion bonded and brazed joints. Mechanical testing includes tensile, shear, and fatigue tests to determine joint strength under different loading conditions. Hermeticity testing involves pressure differential, helium leak detection, and bubble testing to verify gas-tight seals. Non-destructive evaluation techniques such as ultrasonic inspection, X-ray analysis, and acoustic emission are used to detect internal defects without compromising the joint. These comprehensive testing approaches ensure the reliability and performance of the bonded components in their intended applications.

- Material selection and surface preparation for optimal bonding: The selection of compatible materials and proper surface preparation are critical factors affecting joint strength and hermeticity in both diffusion bonding and brazing processes. Surface treatments including cleaning, etching, and activation remove oxides and contaminants that could impede bonding. Interlayer materials can be introduced to facilitate joining of otherwise incompatible materials or to enhance specific joint properties. The microstructure and composition of the base materials significantly influence the diffusion mechanisms and resulting bond quality. Optimized surface roughness promotes mechanical interlocking while maintaining sufficient contact area for atomic diffusion.

02 Brazing methods for hermetic sealing

Brazing techniques utilize filler metals that melt and flow between components to create hermetic seals. The selection of appropriate brazing alloys and fluxes is critical for achieving high-quality hermetic joints. Vacuum brazing and controlled atmosphere brazing methods prevent oxidation during the joining process, resulting in superior hermeticity. Proper surface preparation and joint design significantly impact the quality of brazed hermetic seals, particularly in applications requiring long-term reliability.Expand Specific Solutions03 Hybrid joining processes combining diffusion bonding and brazing

Hybrid joining processes that combine diffusion bonding and brazing techniques leverage the advantages of both methods. These combined approaches often result in superior joint strength and hermeticity compared to either method alone. The initial brazing phase creates a preliminary bond, while subsequent diffusion bonding promotes atomic migration across the interface, eliminating voids and enhancing mechanical properties. This hybrid methodology is particularly effective for joining complex geometries and dissimilar materials where traditional single-method approaches may be inadequate.Expand Specific Solutions04 Testing and evaluation methods for joint strength and hermeticity

Various testing methodologies are employed to evaluate the strength and hermeticity of diffusion bonded and brazed joints. Mechanical testing techniques including tensile, shear, and fatigue testing provide quantitative measurements of joint strength. Hermeticity testing methods such as helium leak detection, pressure decay testing, and bubble testing assess the seal integrity. Non-destructive evaluation techniques including ultrasonic inspection, X-ray analysis, and acoustic emission testing enable quality assessment without compromising the joint. These testing protocols are essential for validating joint performance in critical applications.Expand Specific Solutions05 Material selection and surface preparation for optimal bonding

The selection of compatible base materials and appropriate surface preparation techniques significantly impacts joint quality. Surface cleaning methods to remove oxides, contaminants, and adsorbed gases are crucial for achieving strong, hermetic bonds. Specialized surface treatments including chemical etching, mechanical abrasion, and plasma activation enhance bonding by increasing surface energy and promoting atomic diffusion. Interlayer materials can be strategically employed to accommodate differences in thermal expansion coefficients and improve bonding between dissimilar materials, resulting in stronger joints with superior hermeticity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The diffusion bonding versus brazing technology landscape is currently in a growth phase, with an expanding market driven by aerospace, automotive, and electronics applications. The technology maturity varies significantly among key players, with aerospace giants like Boeing, Rolls-Royce, and SNECMA leading advanced diffusion bonding implementations. Research institutions including Harbin Institute of Technology, Shandong University, and Southwest Jiaotong University are advancing fundamental research, while industrial players such as SCHOTT AG, NGK Insulators, and Honeywell are developing specialized applications. Material specialists like Nippon Steel and Konfoong Materials are focusing on compatible substrate development. The competitive landscape shows regional clusters of expertise in North America, Europe, and Asia, with increasing cross-sector collaboration accelerating technology adoption.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed advanced diffusion bonding techniques specifically for titanium alloys and dissimilar metal joints. Their research focuses on optimizing temperature-pressure parameters to achieve superior joint strength while minimizing microstructural changes. They've established that diffusion bonding of Ti-6Al-4V alloys achieves optimal results at 850-900°C with pressures of 5-10 MPa and holding times of 60-120 minutes, resulting in joints with up to 95% of base material strength. Their proprietary surface preparation method enhances diffusion by removing oxide layers and increasing contact area. For hermetic sealing applications, they've developed a two-stage bonding process that first establishes diffusion at interfaces before applying lower pressure to maintain hermeticity without deformation. This approach has been successfully applied to aerospace components requiring both high mechanical integrity and perfect gas-tightness.

Strengths: Exceptional expertise in titanium alloy bonding with near-parent material strength properties; specialized surface preparation techniques that enhance diffusion without additional interlayers. Weaknesses: Their processes typically require longer cycle times compared to conventional brazing, and the high-temperature requirements may cause unwanted microstructural changes in heat-sensitive materials.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered a hybrid bonding approach that combines elements of both diffusion bonding and brazing for critical aerospace applications. Their proprietary "DiffBraze" technology utilizes a thin-film braze alloy interlayer (typically 10-25μm) that facilitates initial joining at lower temperatures (around 950°C versus 1100°C for pure diffusion bonding), followed by a controlled diffusion cycle. This process creates a gradient interface rather than a distinct joint line, achieving hermetic seals with helium leak rates below 10^-9 mbar·l/s. For high-temperature applications in gas turbines, Honeywell has developed specialized nickel-based braze alloys with additions of boron and silicon that lower melting points while maintaining oxidation resistance up to 850°C. Their temperature-pressure optimization studies have established precise processing windows: diffusion bonding of superalloys occurs at 1050-1150°C with 15-20 MPa pressure, while their advanced brazing operates at 900-1050°C with minimal fixture pressure, reducing distortion in thin-walled components.

Strengths: Their hybrid approach offers superior hermetic sealing capabilities while requiring lower bonding pressures than pure diffusion bonding, making it suitable for complex geometries and thin-walled structures. Weaknesses: The specialized braze alloys contain elements that can form brittle intermetallic phases if process parameters aren't precisely controlled, potentially compromising joint strength in certain applications.

Critical Patents in Joint Strength Enhancement

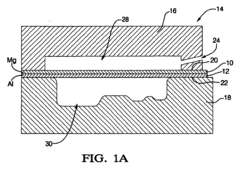

Method of diffusion bonding and brazing of materials

PatentInactiveUS4029254A

Innovation

- A novel method involving the deposition of a diffusion bridge laminate on the core and facing sheets, followed by the use of a mandrel with a thermal expansion coefficient greater than the materials, and filling a chamber with pellets to apply pressure, allowing for kinetic and static pressure distribution without a confining top surface to prevent undue stress, facilitating bonding at a controlled temperature below the metals' melting point.

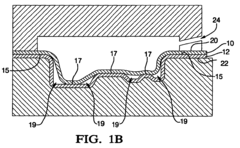

Method for diffusion bonding magnesium/aluminum components

PatentInactiveEP1273385A3

Innovation

- A method involving contacting aluminum and magnesium substrates with at least 50% aluminum and 50% magnesium, respectively, at elevated temperatures above 440°C, with pressure applied to bond them together, utilizing the diffusion of magnesium and aluminum to form a lower melting point intermetallic phase for bonding, which can occur without special surface preparation or fluxing agents.

Material Compatibility and Interface Characterization

Material compatibility is a critical factor in determining the success of both diffusion bonding and brazing processes. When selecting materials for joining, it is essential to consider their thermal expansion coefficients, melting points, and chemical reactivity. Diffusion bonding typically requires materials with similar thermal expansion properties to prevent residual stresses during cooling, while brazing can accommodate greater differences due to the ductile filler metal that can absorb some thermal mismatch.

The interface characteristics between joined materials significantly influence the mechanical properties and hermeticity of the final joint. In diffusion bonding, the interface ideally disappears as atoms diffuse across the boundary, creating a homogeneous microstructure. This results in excellent hermeticity and strength approaching that of the base materials. However, this ideal outcome requires precise control of surface preparation, including roughness, cleanliness, and oxide removal.

For brazing processes, the interface consists of a distinct layer of filler material between the joined components. The wetting behavior of the molten filler on the base materials determines the quality of the joint. Poor wetting can lead to void formation, compromising both strength and hermeticity. The interaction between the filler metal and base materials often results in the formation of intermetallic compounds at the interface, which can be either beneficial or detrimental depending on their nature and distribution.

Advanced characterization techniques are essential for evaluating the quality of bonded interfaces. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides valuable information about elemental distribution across the interface. Transmission electron microscopy (TEM) offers atomic-level insights into diffusion zones and intermetallic formation. Mechanical testing, including tensile, shear, and fatigue tests, complements these microstructural analyses by correlating interface characteristics with joint performance.

The formation of oxides at the interface presents a significant challenge for both joining methods. In diffusion bonding, surface oxides act as barriers to atomic diffusion, necessitating either their complete removal or the application of sufficient pressure and temperature to break them up. Brazing fluxes or vacuum/inert atmospheres are employed to prevent oxide formation during the brazing process, as oxides can prevent proper wetting of the filler metal.

Recent research has focused on developing predictive models for interface evolution during these joining processes. These models incorporate factors such as diffusion coefficients, activation energies, and phase transformation kinetics to optimize process parameters for specific material combinations. Such advancements are particularly valuable for joining dissimilar materials, where the complexity of interfacial reactions makes empirical optimization challenging and time-consuming.

The interface characteristics between joined materials significantly influence the mechanical properties and hermeticity of the final joint. In diffusion bonding, the interface ideally disappears as atoms diffuse across the boundary, creating a homogeneous microstructure. This results in excellent hermeticity and strength approaching that of the base materials. However, this ideal outcome requires precise control of surface preparation, including roughness, cleanliness, and oxide removal.

For brazing processes, the interface consists of a distinct layer of filler material between the joined components. The wetting behavior of the molten filler on the base materials determines the quality of the joint. Poor wetting can lead to void formation, compromising both strength and hermeticity. The interaction between the filler metal and base materials often results in the formation of intermetallic compounds at the interface, which can be either beneficial or detrimental depending on their nature and distribution.

Advanced characterization techniques are essential for evaluating the quality of bonded interfaces. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides valuable information about elemental distribution across the interface. Transmission electron microscopy (TEM) offers atomic-level insights into diffusion zones and intermetallic formation. Mechanical testing, including tensile, shear, and fatigue tests, complements these microstructural analyses by correlating interface characteristics with joint performance.

The formation of oxides at the interface presents a significant challenge for both joining methods. In diffusion bonding, surface oxides act as barriers to atomic diffusion, necessitating either their complete removal or the application of sufficient pressure and temperature to break them up. Brazing fluxes or vacuum/inert atmospheres are employed to prevent oxide formation during the brazing process, as oxides can prevent proper wetting of the filler metal.

Recent research has focused on developing predictive models for interface evolution during these joining processes. These models incorporate factors such as diffusion coefficients, activation energies, and phase transformation kinetics to optimize process parameters for specific material combinations. Such advancements are particularly valuable for joining dissimilar materials, where the complexity of interfacial reactions makes empirical optimization challenging and time-consuming.

Quality Control and Non-Destructive Testing Methods

Quality control and non-destructive testing methods are critical for ensuring the reliability and performance of joints created through diffusion bonding and brazing processes. These methods must be tailored to the specific requirements of each joining technique, considering their unique temperature-pressure windows, joint strength characteristics, and hermeticity requirements.

For diffusion bonded joints, ultrasonic testing represents a primary inspection method, capable of detecting subsurface defects and incomplete bonding areas without compromising the joint integrity. Advanced techniques such as phased array ultrasonic testing (PAUT) offer enhanced resolution and detection capabilities for the typically homogeneous microstructure of diffusion bonds.

X-ray radiography and computed tomography (CT) scanning provide valuable insights into both diffusion bonded and brazed joints, revealing internal voids, inclusions, and crack formations. CT scanning is particularly effective for complex geometries where traditional inspection methods may be limited, offering three-dimensional visualization of the entire joint structure.

Helium leak testing stands as the gold standard for hermeticity verification, especially critical for applications in aerospace, semiconductor manufacturing, and vacuum systems. This method can detect leak rates as low as 10^-10 std-cc/sec, making it indispensable for high-reliability applications where absolute hermeticity is required.

Metallographic examination, while destructive in nature, provides crucial information about the microstructural characteristics of both joining methods. For brazed joints, this examination can reveal filler metal distribution, wetting behavior, and intermetallic compound formation. In diffusion bonds, it helps evaluate grain growth across the interface and the presence of any residual oxide layers.

Mechanical testing protocols differ significantly between the two joining methods. Tensile, shear, and fatigue testing for diffusion bonded joints typically focus on the parent material properties, as properly executed diffusion bonds often achieve strength comparable to the base materials. For brazed joints, testing must account for the distinct mechanical properties of the filler metal and the potential formation of brittle intermetallic phases.

Emerging technologies such as acoustic emission testing and digital image correlation are gaining prominence for in-situ monitoring of joint quality during thermal cycling and mechanical loading. These methods provide real-time data on joint behavior under operational conditions, offering predictive capabilities for long-term performance assessment.

Quality assurance standards and certification requirements vary by industry, with aerospace and medical device manufacturing typically imposing the most stringent criteria. Compliance with standards such as AWS C3.7 for brazing and ASME Section IX for diffusion bonding ensures consistent quality and reliability across production batches.

For diffusion bonded joints, ultrasonic testing represents a primary inspection method, capable of detecting subsurface defects and incomplete bonding areas without compromising the joint integrity. Advanced techniques such as phased array ultrasonic testing (PAUT) offer enhanced resolution and detection capabilities for the typically homogeneous microstructure of diffusion bonds.

X-ray radiography and computed tomography (CT) scanning provide valuable insights into both diffusion bonded and brazed joints, revealing internal voids, inclusions, and crack formations. CT scanning is particularly effective for complex geometries where traditional inspection methods may be limited, offering three-dimensional visualization of the entire joint structure.

Helium leak testing stands as the gold standard for hermeticity verification, especially critical for applications in aerospace, semiconductor manufacturing, and vacuum systems. This method can detect leak rates as low as 10^-10 std-cc/sec, making it indispensable for high-reliability applications where absolute hermeticity is required.

Metallographic examination, while destructive in nature, provides crucial information about the microstructural characteristics of both joining methods. For brazed joints, this examination can reveal filler metal distribution, wetting behavior, and intermetallic compound formation. In diffusion bonds, it helps evaluate grain growth across the interface and the presence of any residual oxide layers.

Mechanical testing protocols differ significantly between the two joining methods. Tensile, shear, and fatigue testing for diffusion bonded joints typically focus on the parent material properties, as properly executed diffusion bonds often achieve strength comparable to the base materials. For brazed joints, testing must account for the distinct mechanical properties of the filler metal and the potential formation of brittle intermetallic phases.

Emerging technologies such as acoustic emission testing and digital image correlation are gaining prominence for in-situ monitoring of joint quality during thermal cycling and mechanical loading. These methods provide real-time data on joint behavior under operational conditions, offering predictive capabilities for long-term performance assessment.

Quality assurance standards and certification requirements vary by industry, with aerospace and medical device manufacturing typically imposing the most stringent criteria. Compliance with standards such as AWS C3.7 for brazing and ASME Section IX for diffusion bonding ensures consistent quality and reliability across production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!