How Diffusion Bonding Controls Flatness And Distortion In Large Panels?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Diffusion Bonding Technology Background and Objectives

Diffusion bonding represents a solid-state joining process that has evolved significantly since its initial development in the mid-20th century. This metallurgical technique enables the creation of high-strength bonds between similar or dissimilar materials without the need for a liquid phase, making it particularly valuable for applications requiring precise dimensional control. The process fundamentally relies on atomic diffusion across the interface of clean material surfaces when subjected to elevated temperatures and pressure in controlled environments.

The historical trajectory of diffusion bonding technology shows a progression from basic applications in aerospace components to increasingly sophisticated implementations in large-scale industrial manufacturing. Initially limited by process control capabilities, modern advancements in temperature regulation, pressure application systems, and surface preparation techniques have dramatically expanded the practical applications of this joining method.

Current technological trends in diffusion bonding focus on overcoming the persistent challenges of maintaining flatness and minimizing distortion in large panel structures. This represents a critical frontier as industries increasingly demand larger, more complex components with tighter dimensional tolerances. The aerospace, automotive, and energy sectors are particularly driving innovation in this area, seeking solutions that can deliver consistent quality across expansive bonded surfaces.

The primary technical objective in diffusion bonding large panels is to achieve uniform atomic diffusion across the entire bonding interface while maintaining dimensional stability. This requires precise control of multiple process parameters including temperature gradients, pressure distribution, surface preparation consistency, and atmospheric conditions throughout the bonding cycle.

Secondary objectives include reducing cycle times, minimizing energy consumption, and developing more cost-effective tooling solutions that can accommodate larger workpieces without compromising bond quality or dimensional accuracy. The development of in-process monitoring capabilities represents another significant goal, as real-time feedback mechanisms could enable adaptive control strategies to prevent distortion before it occurs.

The ultimate technological aim is to establish reliable, repeatable processes for producing large-scale diffusion-bonded panels with predictable flatness characteristics, minimal post-bond machining requirements, and mechanical properties equivalent to the parent materials. This would enable broader industrial adoption of diffusion bonding for applications where traditional joining methods introduce unacceptable levels of distortion or compromise structural integrity.

The historical trajectory of diffusion bonding technology shows a progression from basic applications in aerospace components to increasingly sophisticated implementations in large-scale industrial manufacturing. Initially limited by process control capabilities, modern advancements in temperature regulation, pressure application systems, and surface preparation techniques have dramatically expanded the practical applications of this joining method.

Current technological trends in diffusion bonding focus on overcoming the persistent challenges of maintaining flatness and minimizing distortion in large panel structures. This represents a critical frontier as industries increasingly demand larger, more complex components with tighter dimensional tolerances. The aerospace, automotive, and energy sectors are particularly driving innovation in this area, seeking solutions that can deliver consistent quality across expansive bonded surfaces.

The primary technical objective in diffusion bonding large panels is to achieve uniform atomic diffusion across the entire bonding interface while maintaining dimensional stability. This requires precise control of multiple process parameters including temperature gradients, pressure distribution, surface preparation consistency, and atmospheric conditions throughout the bonding cycle.

Secondary objectives include reducing cycle times, minimizing energy consumption, and developing more cost-effective tooling solutions that can accommodate larger workpieces without compromising bond quality or dimensional accuracy. The development of in-process monitoring capabilities represents another significant goal, as real-time feedback mechanisms could enable adaptive control strategies to prevent distortion before it occurs.

The ultimate technological aim is to establish reliable, repeatable processes for producing large-scale diffusion-bonded panels with predictable flatness characteristics, minimal post-bond machining requirements, and mechanical properties equivalent to the parent materials. This would enable broader industrial adoption of diffusion bonding for applications where traditional joining methods introduce unacceptable levels of distortion or compromise structural integrity.

Market Analysis for Precision-Bonded Large Panel Applications

The precision-bonded large panel market is experiencing significant growth driven by increasing demand across multiple high-value industries. Aerospace and defense sectors represent the largest market segment, with an estimated market size of $3.2 billion in 2023, projected to grow at 7.8% CAGR through 2030. These industries require large structural panels with exceptional flatness tolerances for aircraft fuselages, spacecraft components, and radar systems where even minor distortion can compromise performance.

The semiconductor and electronics manufacturing equipment sector constitutes another substantial market, valued at approximately $2.7 billion. This segment demands ultra-flat panels for wafer processing equipment, vacuum chambers, and precision optical tables. As semiconductor manufacturing moves toward more advanced nodes (3nm and below), flatness requirements have become increasingly stringent, with tolerances now measured in micrometers across meter-scale panels.

Automotive applications represent an emerging market for precision-bonded large panels, particularly in electric vehicle battery enclosures and structural components. This segment is growing at 12.3% annually as manufacturers seek lightweight yet rigid structures to improve vehicle efficiency while maintaining dimensional stability.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific (32%) and Europe (24%). China and South Korea are showing the fastest growth rates, driven by government investments in semiconductor manufacturing and aerospace capabilities.

Customer requirements across these markets consistently emphasize three key performance metrics: dimensional stability under thermal cycling, minimal post-bonding distortion, and long-term reliability. End users are willing to pay premium prices (typically 30-45% higher than conventional joining methods) for panels that maintain flatness specifications throughout their operational lifetime.

Market research indicates that customers increasingly value suppliers who can provide comprehensive solutions including design optimization, process simulation, and post-bonding verification. This trend has led to the emergence of specialized service providers who combine materials expertise with advanced process control capabilities.

The competitive landscape features both large materials conglomerates and specialized bonding technology firms. Recent market consolidation has occurred through strategic acquisitions, with major players seeking to integrate diffusion bonding expertise into their manufacturing capabilities. This consolidation trend is expected to continue as the technology becomes increasingly critical for next-generation products across multiple industries.

The semiconductor and electronics manufacturing equipment sector constitutes another substantial market, valued at approximately $2.7 billion. This segment demands ultra-flat panels for wafer processing equipment, vacuum chambers, and precision optical tables. As semiconductor manufacturing moves toward more advanced nodes (3nm and below), flatness requirements have become increasingly stringent, with tolerances now measured in micrometers across meter-scale panels.

Automotive applications represent an emerging market for precision-bonded large panels, particularly in electric vehicle battery enclosures and structural components. This segment is growing at 12.3% annually as manufacturers seek lightweight yet rigid structures to improve vehicle efficiency while maintaining dimensional stability.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific (32%) and Europe (24%). China and South Korea are showing the fastest growth rates, driven by government investments in semiconductor manufacturing and aerospace capabilities.

Customer requirements across these markets consistently emphasize three key performance metrics: dimensional stability under thermal cycling, minimal post-bonding distortion, and long-term reliability. End users are willing to pay premium prices (typically 30-45% higher than conventional joining methods) for panels that maintain flatness specifications throughout their operational lifetime.

Market research indicates that customers increasingly value suppliers who can provide comprehensive solutions including design optimization, process simulation, and post-bonding verification. This trend has led to the emergence of specialized service providers who combine materials expertise with advanced process control capabilities.

The competitive landscape features both large materials conglomerates and specialized bonding technology firms. Recent market consolidation has occurred through strategic acquisitions, with major players seeking to integrate diffusion bonding expertise into their manufacturing capabilities. This consolidation trend is expected to continue as the technology becomes increasingly critical for next-generation products across multiple industries.

Current Challenges in Flatness Control During Diffusion Bonding

Diffusion bonding of large panels presents significant challenges in maintaining flatness and controlling distortion. The primary difficulty stems from the inherent thermal expansion and contraction cycles that materials undergo during the bonding process. When large panels are subjected to high temperatures necessary for diffusion bonding, uneven heating and cooling can create internal stresses that manifest as warpage or distortion in the final product.

Material selection compounds this challenge, as different materials exhibit varying coefficients of thermal expansion. When bonding dissimilar materials, these differences create additional stress at the interface, further complicating flatness control. Even with identical materials, thickness variations across large panels can lead to differential expansion and subsequent distortion.

Surface preparation presents another critical challenge. For optimal diffusion bonding, surfaces must be extremely flat and clean at the microscopic level. Achieving and maintaining this flatness becomes exponentially more difficult as panel dimensions increase. Any surface irregularities or contaminants can create voids or weak spots in the bond, compromising both structural integrity and flatness.

Pressure application during the bonding process introduces additional complexity. Uniform pressure distribution across large surface areas is technically demanding, requiring sophisticated tooling and fixturing. Inadequate pressure uniformity leads to inconsistent bonding and localized deformation, directly impacting the final flatness of the panel.

Time and temperature control represent further challenges. The diffusion bonding process requires precise temperature management throughout the entire panel volume. In large panels, achieving uniform temperature distribution becomes problematic due to thermal gradients from the edges to the center. These gradients can cause different regions to bond at different rates, creating internal stresses that manifest as distortion.

Post-bonding stress relief presents yet another hurdle. After the diffusion bonding process, residual stresses remain within the material structure. Without proper stress relief treatments, these stresses can gradually cause dimensional changes and flatness issues over time, particularly in precision applications.

Measurement and quality control of large panel flatness add another layer of difficulty. Traditional metrology equipment may be insufficient for accurately measuring flatness across extensive dimensions, making it challenging to validate process outcomes and implement effective corrective measures.

Finally, scaling up laboratory-proven processes to industrial production volumes introduces additional variables that can affect flatness control. Factors such as handling large panels, furnace capacity limitations, and cycle time considerations all impact the ability to maintain consistent flatness in high-volume manufacturing environments.

Material selection compounds this challenge, as different materials exhibit varying coefficients of thermal expansion. When bonding dissimilar materials, these differences create additional stress at the interface, further complicating flatness control. Even with identical materials, thickness variations across large panels can lead to differential expansion and subsequent distortion.

Surface preparation presents another critical challenge. For optimal diffusion bonding, surfaces must be extremely flat and clean at the microscopic level. Achieving and maintaining this flatness becomes exponentially more difficult as panel dimensions increase. Any surface irregularities or contaminants can create voids or weak spots in the bond, compromising both structural integrity and flatness.

Pressure application during the bonding process introduces additional complexity. Uniform pressure distribution across large surface areas is technically demanding, requiring sophisticated tooling and fixturing. Inadequate pressure uniformity leads to inconsistent bonding and localized deformation, directly impacting the final flatness of the panel.

Time and temperature control represent further challenges. The diffusion bonding process requires precise temperature management throughout the entire panel volume. In large panels, achieving uniform temperature distribution becomes problematic due to thermal gradients from the edges to the center. These gradients can cause different regions to bond at different rates, creating internal stresses that manifest as distortion.

Post-bonding stress relief presents yet another hurdle. After the diffusion bonding process, residual stresses remain within the material structure. Without proper stress relief treatments, these stresses can gradually cause dimensional changes and flatness issues over time, particularly in precision applications.

Measurement and quality control of large panel flatness add another layer of difficulty. Traditional metrology equipment may be insufficient for accurately measuring flatness across extensive dimensions, making it challenging to validate process outcomes and implement effective corrective measures.

Finally, scaling up laboratory-proven processes to industrial production volumes introduces additional variables that can affect flatness control. Factors such as handling large panels, furnace capacity limitations, and cycle time considerations all impact the ability to maintain consistent flatness in high-volume manufacturing environments.

Current Techniques for Flatness Preservation in Large Panel Bonding

01 Surface preparation techniques for minimizing distortion

Proper surface preparation is crucial for achieving high-quality diffusion bonds with minimal distortion. This includes techniques such as precision grinding, lapping, or polishing to achieve the required flatness before bonding. Surface cleanliness is also essential, as contaminants can lead to voids and uneven bonding that contribute to distortion. Advanced preparation methods can help maintain the geometric integrity of components during the high-temperature diffusion bonding process.- Surface preparation techniques for minimizing distortion: Proper surface preparation is crucial for achieving high-quality diffusion bonds with minimal distortion. This includes techniques such as precision grinding, lapping, and polishing to ensure flatness before bonding. Surface cleanliness and roughness control are essential factors that affect bond quality and prevent warpage. Advanced preparation methods can reduce the need for high bonding pressures that might otherwise cause distortion in the final component.

- Pressure control systems to maintain flatness: Specialized pressure control systems are employed during diffusion bonding to maintain component flatness. These systems include uniform pressure distribution mechanisms, adaptive pressure application based on material properties, and precision tooling that compensates for thermal expansion. By carefully controlling the applied pressure across the entire bonding interface, distortion can be minimized even when joining dissimilar materials or complex geometries.

- Temperature management for distortion prevention: Effective temperature management during diffusion bonding is essential for preventing distortion. This includes precise heating rate control, uniform temperature distribution across the workpiece, and optimized cooling cycles. Gradient heating techniques can be employed to accommodate different thermal expansion rates in various parts of the component. Some advanced processes utilize localized heating to minimize overall thermal stress and maintain flatness in critical areas.

- Fixture and tooling design for flatness retention: Specialized fixtures and tooling are designed to maintain component flatness throughout the diffusion bonding process. These include precision alignment systems, anti-distortion supports, and materials with matched thermal expansion coefficients. Some fixtures incorporate compensation features that account for predicted distortion patterns. Advanced tooling may include ceramic or refractory metal components that maintain dimensional stability at high bonding temperatures.

- Post-bonding treatments to correct distortion: Various post-bonding treatments can be applied to correct distortion that occurs during the diffusion bonding process. These include controlled heat treatments to relieve residual stresses, precision machining to restore flatness, and specialized flattening operations. Some processes incorporate hot isostatic pressing to eliminate voids while simultaneously improving flatness. Advanced techniques may combine mechanical and thermal treatments to achieve optimal dimensional accuracy in the final component.

02 Pressure control systems to maintain flatness

Specialized pressure control systems are employed during diffusion bonding to maintain component flatness. These systems apply uniform pressure across the bonding interface, preventing localized deformation. Adaptive pressure distribution mechanisms can compensate for thermal expansion differences between materials. Some advanced systems incorporate real-time monitoring and adjustment capabilities to optimize pressure throughout the bonding cycle, significantly reducing distortion in the final bonded assembly.Expand Specific Solutions03 Temperature management for distortion prevention

Precise temperature control during diffusion bonding is essential for minimizing distortion. Gradual heating and cooling rates help prevent thermal shock and uneven expansion. Temperature gradients across the workpiece must be carefully managed to ensure uniform bonding conditions. Some advanced processes employ zone-controlled heating systems that can create optimized temperature profiles across complex geometries, allowing for diffusion bonding while maintaining critical dimensional tolerances.Expand Specific Solutions04 Fixture and tooling designs for maintaining geometry

Specialized fixtures and tooling are critical for maintaining component geometry during diffusion bonding. These fixtures provide support to prevent sagging or warping while allowing for thermal expansion. Some designs incorporate materials with matched thermal expansion coefficients to the workpieces. Advanced fixtures may include adjustable elements that accommodate dimensional changes during the bonding process, helping to preserve flatness and prevent distortion in the final bonded assembly.Expand Specific Solutions05 Post-bonding treatments to correct distortion

Various post-bonding treatments can be employed to address distortion that occurs during the diffusion bonding process. These include controlled heat treatments to relieve residual stresses, precision machining to restore flatness, and specialized flattening operations. Some advanced processes incorporate predictive modeling to anticipate distortion and implement preventive measures. For critical applications, combination approaches using both preventive techniques during bonding and corrective treatments afterward may be necessary to achieve the required flatness specifications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Diffusion Bonding

Diffusion bonding technology for large panel flatness control is currently in a growth phase, with the market expanding due to increasing demand in aerospace, semiconductor, and defense industries. The global market size is estimated to reach significant value by 2030, driven by applications requiring high-precision, distortion-free bonding of large metal panels. Technologically, the field shows varying maturity levels across players. Industry leaders like Boeing and Rolls-Royce have developed advanced proprietary techniques for aerospace applications, while Applied Materials and Agilent Technologies have adapted the technology for semiconductor manufacturing. Research institutions including Harbin Institute of Technology and Northwestern Polytechnical University are advancing fundamental understanding of the process physics. HRL Laboratories and AVIC Shenyang Liming are focusing on specialized applications for critical components requiring exceptional dimensional stability.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced diffusion bonding technology specifically designed to control flatness and minimize distortion in large panels for semiconductor and display manufacturing. Their proprietary Surface Transformation Diffusion Bonding (STDB) process utilizes precisely controlled temperature gradients and pressure distribution systems to achieve uniform bonding across large surface areas. The company employs multi-zone heating elements that create tailored thermal profiles across the entire panel surface, compensating for edge effects that typically cause warping. Additionally, their vacuum-assisted bonding chambers incorporate specialized fixturing systems with adaptive pressure control that maintains consistent contact force distribution during the entire bonding cycle, preventing localized stress concentrations that lead to distortion. Applied Materials' process also features real-time monitoring with integrated sensors that track dimensional changes during bonding, allowing for dynamic adjustments to process parameters.

Strengths: Superior flatness control through proprietary multi-zone heating technology; advanced in-situ monitoring capabilities; scalable to very large panel sizes for display manufacturing. Weaknesses: Higher equipment costs compared to conventional bonding methods; requires significant technical expertise to operate and maintain; process cycle times can be longer than alternative joining methods.

The Boeing Co.

Technical Solution: Boeing has pioneered advanced diffusion bonding techniques for aerospace applications, specifically addressing flatness and distortion challenges in large structural panels. Their Superplastic Forming/Diffusion Bonding (SPF/DB) process combines controlled deformation with precise bonding to create complex, lightweight structures with minimal distortion. Boeing's approach utilizes specialized tooling with embedded thermal management systems that create uniform temperature distribution across titanium and aluminum alloy panels up to 2.5 meters in length. The company's proprietary stop-off patterns and materials prevent unwanted bonding in specific areas while maintaining structural integrity. Boeing's process incorporates pre-bonding surface preparation techniques including chemical etching and plasma treatment that enhance bond quality while minimizing thermal stresses. Their multi-stage bonding cycle includes carefully controlled cooling rates that prevent residual stress accumulation, a primary cause of post-bond distortion in large panels. Boeing has also developed computer modeling techniques that predict and compensate for potential distortion before manufacturing begins.

Strengths: Exceptional strength-to-weight ratio in final components; ability to create complex internal structures without fasteners; proven reliability in critical aerospace applications with decades of flight heritage. Weaknesses: Process requires significant capital investment; limited material compatibility compared to mechanical joining methods; longer processing times impact production throughput for high-volume applications.

Key Patents and Research on Diffusion Bonding Distortion Control

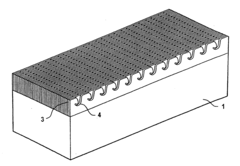

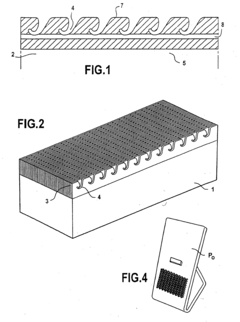

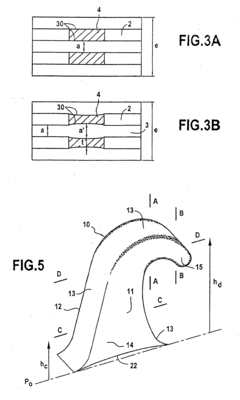

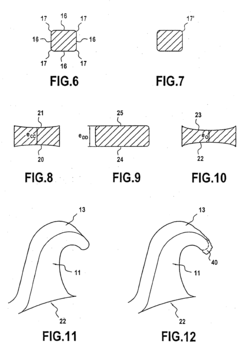

Insertion block for the formation of a hook field on an injection-moulded object, and a moulded object comprising a hook field of this type

PatentActiveUS20090106955A1

Innovation

- The use of diffusion bonding to securely join plates without liquid interfaces, incorporating aeration channels with stepped or flared cross-sections to prevent thermoplastic infiltration and burr formation, allowing for thin, efficient hook field production with reduced surface area usage.

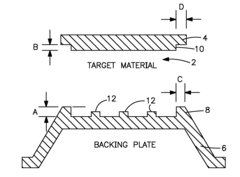

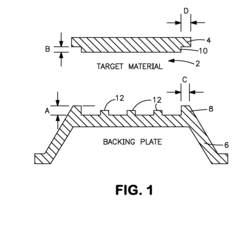

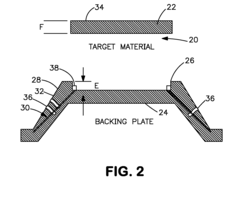

Sputter target and backing plate assembly

PatentInactiveUS20100187098A1

Innovation

- A method involving a backing plate with spaced-apart peripheral flange segments and corresponding notched segments on the sputter target, allowing for a uniform solder bonded interface that centers the target and maintains microstructural integrity, using solder material to bond the components with a consistent thickness.

Material Science Considerations for Optimal Bonding Results

The material science aspects of diffusion bonding play a crucial role in controlling flatness and minimizing distortion in large panels. At the atomic level, diffusion bonding relies on the migration of atoms across the interface between two materials, forming a cohesive bond without the need for a liquid phase. This process is highly dependent on the crystallographic structure and composition of the materials being joined.

Surface preparation represents one of the most critical factors affecting bond quality. Materials must exhibit specific surface roughness parameters—typically in the range of 0.4-1.6 μm Ra—to achieve optimal contact area while preventing excessive void formation. Chemical cleaning protocols must remove all organic contaminants, oxides, and other surface impurities that could impede atomic diffusion or create inclusions in the final bond.

Material compatibility is essential for successful diffusion bonding. The coefficient of thermal expansion (CTE) mismatch between joined materials must be minimized to prevent residual stresses that lead to warping or distortion during cooling. For large panels, CTE differences exceeding 2×10^-6/°C often result in unacceptable distortion unless specialized intermediate layers are employed.

Grain structure and size significantly influence diffusion rates and mechanical properties of the bonded interface. Fine-grained materials generally facilitate faster diffusion but may experience more pronounced grain growth during the bonding cycle. This grain growth must be carefully controlled, particularly in large panels where non-uniform grain structures can lead to localized stress concentrations and subsequent distortion.

The presence of alloying elements and their distribution across the interface affects diffusion kinetics and bond strength. Elements like boron, phosphorus, and silicon can enhance diffusion rates but may form brittle intermetallic compounds if their concentrations are not precisely controlled. Conversely, elements such as chromium and molybdenum can improve high-temperature stability but may slow the diffusion process, requiring longer bonding cycles.

Microstructural evolution during the bonding process must be carefully managed through precise temperature control. The formation of secondary phases, precipitation of carbides, or recrystallization phenomena can all contribute to dimensional changes in large panels. Advanced material science approaches, such as tailored heat treatment cycles and controlled cooling rates, help maintain dimensional stability throughout the bonding process.

For large panels specifically, the homogeneity of material properties across the entire bonding surface is paramount. Variations in composition, grain structure, or surface condition can lead to differential diffusion rates, creating internal stresses that manifest as warping or localized distortion in the final component.

Surface preparation represents one of the most critical factors affecting bond quality. Materials must exhibit specific surface roughness parameters—typically in the range of 0.4-1.6 μm Ra—to achieve optimal contact area while preventing excessive void formation. Chemical cleaning protocols must remove all organic contaminants, oxides, and other surface impurities that could impede atomic diffusion or create inclusions in the final bond.

Material compatibility is essential for successful diffusion bonding. The coefficient of thermal expansion (CTE) mismatch between joined materials must be minimized to prevent residual stresses that lead to warping or distortion during cooling. For large panels, CTE differences exceeding 2×10^-6/°C often result in unacceptable distortion unless specialized intermediate layers are employed.

Grain structure and size significantly influence diffusion rates and mechanical properties of the bonded interface. Fine-grained materials generally facilitate faster diffusion but may experience more pronounced grain growth during the bonding cycle. This grain growth must be carefully controlled, particularly in large panels where non-uniform grain structures can lead to localized stress concentrations and subsequent distortion.

The presence of alloying elements and their distribution across the interface affects diffusion kinetics and bond strength. Elements like boron, phosphorus, and silicon can enhance diffusion rates but may form brittle intermetallic compounds if their concentrations are not precisely controlled. Conversely, elements such as chromium and molybdenum can improve high-temperature stability but may slow the diffusion process, requiring longer bonding cycles.

Microstructural evolution during the bonding process must be carefully managed through precise temperature control. The formation of secondary phases, precipitation of carbides, or recrystallization phenomena can all contribute to dimensional changes in large panels. Advanced material science approaches, such as tailored heat treatment cycles and controlled cooling rates, help maintain dimensional stability throughout the bonding process.

For large panels specifically, the homogeneity of material properties across the entire bonding surface is paramount. Variations in composition, grain structure, or surface condition can lead to differential diffusion rates, creating internal stresses that manifest as warping or localized distortion in the final component.

Quality Assurance and Testing Methods for Bonded Panels

Quality assurance and testing methods for diffusion bonded panels are critical to ensure the integrity, reliability, and performance of these components in demanding applications. Non-destructive testing (NDT) techniques form the cornerstone of quality control processes, with ultrasonic testing being particularly effective for detecting internal defects, delaminations, and bond quality variations without compromising the panel structure.

X-ray radiography and computed tomography provide complementary capabilities, allowing inspectors to visualize internal features and identify potential voids or inclusions that might affect flatness and distortion characteristics. These methods are especially valuable for thick or complex panel geometries where ultrasonic penetration may be limited.

Dimensional metrology plays a crucial role in flatness verification, with coordinate measuring machines (CMMs) and laser scanning technologies enabling precise measurement of surface profiles with micron-level accuracy. Advanced optical measurement systems utilizing structured light or laser interferometry can rapidly map entire panel surfaces, generating detailed topographical data to identify warpage or distortion patterns resulting from the bonding process.

Mechanical testing protocols have been established to validate bond strength and integrity. Lap shear tests, tensile tests, and bend tests provide quantitative data on bond performance under various loading conditions. For critical applications, accelerated aging tests simulate environmental exposure to predict long-term stability and resistance to distortion under operational conditions.

Statistical process control methodologies have been implemented across the diffusion bonding industry to monitor key process parameters that influence flatness outcomes. By tracking temperature profiles, pressure distribution, vacuum levels, and cooling rates, manufacturers can establish process-property relationships and develop predictive models for flatness control.

In-situ monitoring technologies represent the cutting edge of quality assurance for diffusion bonding. Acoustic emission sensors can detect microscopic bond formation events in real-time, while thermal imaging systems monitor temperature uniformity across large panels. These technologies enable process adjustments before distortion occurs, rather than relying solely on post-process inspection.

Standardization efforts by organizations such as ASTM International and AWS have established acceptance criteria and testing protocols specifically for diffusion bonded structures. These standards provide consistent frameworks for evaluating flatness and distortion, facilitating communication between suppliers and end-users regarding quality expectations and verification methods.

X-ray radiography and computed tomography provide complementary capabilities, allowing inspectors to visualize internal features and identify potential voids or inclusions that might affect flatness and distortion characteristics. These methods are especially valuable for thick or complex panel geometries where ultrasonic penetration may be limited.

Dimensional metrology plays a crucial role in flatness verification, with coordinate measuring machines (CMMs) and laser scanning technologies enabling precise measurement of surface profiles with micron-level accuracy. Advanced optical measurement systems utilizing structured light or laser interferometry can rapidly map entire panel surfaces, generating detailed topographical data to identify warpage or distortion patterns resulting from the bonding process.

Mechanical testing protocols have been established to validate bond strength and integrity. Lap shear tests, tensile tests, and bend tests provide quantitative data on bond performance under various loading conditions. For critical applications, accelerated aging tests simulate environmental exposure to predict long-term stability and resistance to distortion under operational conditions.

Statistical process control methodologies have been implemented across the diffusion bonding industry to monitor key process parameters that influence flatness outcomes. By tracking temperature profiles, pressure distribution, vacuum levels, and cooling rates, manufacturers can establish process-property relationships and develop predictive models for flatness control.

In-situ monitoring technologies represent the cutting edge of quality assurance for diffusion bonding. Acoustic emission sensors can detect microscopic bond formation events in real-time, while thermal imaging systems monitor temperature uniformity across large panels. These technologies enable process adjustments before distortion occurs, rather than relying solely on post-process inspection.

Standardization efforts by organizations such as ASTM International and AWS have established acceptance criteria and testing protocols specifically for diffusion bonded structures. These standards provide consistent frameworks for evaluating flatness and distortion, facilitating communication between suppliers and end-users regarding quality expectations and verification methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!