How Diffusion Bonding Validates Hermeticity And Mechanical Acceptance?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Diffusion Bonding Technology Background and Objectives

Diffusion bonding represents a solid-state joining process that has evolved significantly since its initial development in the mid-20th century. This technique enables the creation of high-strength bonds between similar or dissimilar materials without the need for a liquid phase or filler material. The process relies on atomic diffusion across the interface between clean material surfaces while under pressure and elevated temperature, typically below the melting point of the materials being joined.

The historical trajectory of diffusion bonding technology shows a progression from rudimentary applications in aerospace industries during the 1950s to sophisticated implementations across multiple sectors today. Initially developed for joining titanium alloys in aircraft components, the technology has expanded to address critical joining needs in electronics, medical devices, nuclear applications, and microelectromechanical systems (MEMS).

Recent technological advancements have focused on optimizing process parameters to achieve hermetic seals with exceptional mechanical properties. The primary objective in modern diffusion bonding research centers on developing reliable validation methodologies for hermeticity and mechanical acceptance - critical factors for applications requiring absolute containment integrity and structural reliability.

Current technical goals in diffusion bonding validation include establishing standardized testing protocols that can accurately predict long-term hermetic performance, developing non-destructive evaluation techniques for bond quality assessment, and creating computational models that can simulate the diffusion process across various material combinations and geometries.

The industry is witnessing a shift toward more precise control of surface preparation techniques, as surface cleanliness and roughness have proven to be determinant factors in achieving consistent hermetic seals. Advanced surface characterization methods, including atomic force microscopy and X-ray photoelectron spectroscopy, are increasingly employed to quantify surface conditions prior to bonding.

Temperature and pressure control systems have also evolved significantly, with vacuum hot presses and hot isostatic pressing (HIP) equipment offering unprecedented precision in process parameter management. These technological improvements directly contribute to enhanced bond quality and reliability, particularly for hermetic applications.

Looking forward, the field is trending toward integration with other advanced manufacturing techniques, including additive manufacturing and precision machining, to create complex components with embedded hermetic seals. Additionally, there is growing interest in low-temperature diffusion bonding processes that can accommodate temperature-sensitive materials while maintaining hermeticity standards.

The historical trajectory of diffusion bonding technology shows a progression from rudimentary applications in aerospace industries during the 1950s to sophisticated implementations across multiple sectors today. Initially developed for joining titanium alloys in aircraft components, the technology has expanded to address critical joining needs in electronics, medical devices, nuclear applications, and microelectromechanical systems (MEMS).

Recent technological advancements have focused on optimizing process parameters to achieve hermetic seals with exceptional mechanical properties. The primary objective in modern diffusion bonding research centers on developing reliable validation methodologies for hermeticity and mechanical acceptance - critical factors for applications requiring absolute containment integrity and structural reliability.

Current technical goals in diffusion bonding validation include establishing standardized testing protocols that can accurately predict long-term hermetic performance, developing non-destructive evaluation techniques for bond quality assessment, and creating computational models that can simulate the diffusion process across various material combinations and geometries.

The industry is witnessing a shift toward more precise control of surface preparation techniques, as surface cleanliness and roughness have proven to be determinant factors in achieving consistent hermetic seals. Advanced surface characterization methods, including atomic force microscopy and X-ray photoelectron spectroscopy, are increasingly employed to quantify surface conditions prior to bonding.

Temperature and pressure control systems have also evolved significantly, with vacuum hot presses and hot isostatic pressing (HIP) equipment offering unprecedented precision in process parameter management. These technological improvements directly contribute to enhanced bond quality and reliability, particularly for hermetic applications.

Looking forward, the field is trending toward integration with other advanced manufacturing techniques, including additive manufacturing and precision machining, to create complex components with embedded hermetic seals. Additionally, there is growing interest in low-temperature diffusion bonding processes that can accommodate temperature-sensitive materials while maintaining hermeticity standards.

Market Demand Analysis for Hermetic Sealing Solutions

The global market for hermetic sealing solutions has experienced significant growth in recent years, driven primarily by increasing demands in aerospace, defense, medical devices, and semiconductor industries. The hermetic sealing market was valued at approximately $3.8 billion in 2022 and is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory underscores the critical importance of reliable hermetic sealing technologies across multiple high-value industries.

Diffusion bonding as a hermetic sealing method has gained particular attention due to its ability to create joints with mechanical properties approaching those of the base materials. Market research indicates that industries requiring high-reliability components are increasingly adopting diffusion bonding techniques, with the aerospace and defense sectors accounting for nearly 40% of the current market share.

The medical device industry represents another significant growth area, with hermetically sealed implantable devices market expanding at 9.3% annually. These devices require absolute hermeticity to protect sensitive electronics from bodily fluids while maintaining biocompatibility. Traditional sealing methods often fall short in meeting these stringent requirements, creating substantial market opportunities for advanced diffusion bonding solutions.

In the semiconductor and microelectronics sectors, the miniaturization trend continues to drive demand for hermetic packaging solutions that can provide reliable protection while accommodating increasingly complex designs. The market for MEMS (Micro-Electro-Mechanical Systems) devices alone is expected to reach $18.2 billion by 2025, with hermetic sealing being a critical component in ensuring long-term reliability.

Industry surveys reveal that end-users are primarily concerned with three factors when selecting hermetic sealing technologies: long-term reliability, validation methodologies, and cost-effectiveness. Diffusion bonding addresses these concerns by providing joints that can be thoroughly validated for both hermeticity and mechanical integrity through established testing protocols.

The automotive electronics market, particularly with the rise of electric vehicles and autonomous driving systems, represents an emerging opportunity for hermetic sealing solutions. These applications require components that can withstand harsh environmental conditions while maintaining perfect seals for safety-critical systems. Market analysts predict this segment will grow at 12.5% annually through 2030.

Geographically, North America and Europe currently dominate the market for advanced hermetic sealing technologies, though Asia-Pacific regions are showing the fastest growth rates as manufacturing capabilities expand and quality requirements increase across industries.

Diffusion bonding as a hermetic sealing method has gained particular attention due to its ability to create joints with mechanical properties approaching those of the base materials. Market research indicates that industries requiring high-reliability components are increasingly adopting diffusion bonding techniques, with the aerospace and defense sectors accounting for nearly 40% of the current market share.

The medical device industry represents another significant growth area, with hermetically sealed implantable devices market expanding at 9.3% annually. These devices require absolute hermeticity to protect sensitive electronics from bodily fluids while maintaining biocompatibility. Traditional sealing methods often fall short in meeting these stringent requirements, creating substantial market opportunities for advanced diffusion bonding solutions.

In the semiconductor and microelectronics sectors, the miniaturization trend continues to drive demand for hermetic packaging solutions that can provide reliable protection while accommodating increasingly complex designs. The market for MEMS (Micro-Electro-Mechanical Systems) devices alone is expected to reach $18.2 billion by 2025, with hermetic sealing being a critical component in ensuring long-term reliability.

Industry surveys reveal that end-users are primarily concerned with three factors when selecting hermetic sealing technologies: long-term reliability, validation methodologies, and cost-effectiveness. Diffusion bonding addresses these concerns by providing joints that can be thoroughly validated for both hermeticity and mechanical integrity through established testing protocols.

The automotive electronics market, particularly with the rise of electric vehicles and autonomous driving systems, represents an emerging opportunity for hermetic sealing solutions. These applications require components that can withstand harsh environmental conditions while maintaining perfect seals for safety-critical systems. Market analysts predict this segment will grow at 12.5% annually through 2030.

Geographically, North America and Europe currently dominate the market for advanced hermetic sealing technologies, though Asia-Pacific regions are showing the fastest growth rates as manufacturing capabilities expand and quality requirements increase across industries.

Current State and Challenges in Diffusion Bonding Validation

Diffusion bonding has emerged as a critical joining technology in industries requiring high-integrity hermetic seals and superior mechanical properties. Currently, the global state of diffusion bonding validation presents a complex landscape with significant regional variations. In North America and Europe, standardized testing protocols have been established, while Asia-Pacific regions are rapidly advancing their validation methodologies, particularly in Japan and South Korea where precision manufacturing is paramount.

The primary technical challenge facing diffusion bonding validation lies in the non-destructive assessment of bond integrity. Traditional methods often require sacrificial samples, which cannot guarantee the quality of actual production components. This creates a fundamental disconnect between validation testing and real-world performance assurance. Furthermore, the microscopic nature of diffusion interfaces makes visual inspection nearly impossible without destructive sectioning.

Helium leak testing remains the gold standard for hermeticity validation, but it presents limitations when applied to complex geometries or multi-material bonds. The detection threshold of conventional leak testing equipment (typically 10^-9 atm·cc/sec) may be insufficient for next-generation microelectronic and aerospace applications requiring ultra-high vacuum integrity.

Mechanical acceptance validation faces its own set of challenges. Current shear and tensile testing methodologies often produce inconsistent results due to variations in fixture design and loading conditions. The industry lacks standardized approaches for correlating mechanical test data with actual in-service performance, particularly for components experiencing thermal cycling or vibration environments.

Advanced non-destructive evaluation techniques such as acoustic microscopy, X-ray tomography, and neutron diffraction are being explored, but each presents limitations in resolution, penetration depth, or accessibility. The correlation between these non-destructive measurements and actual bond quality remains difficult to establish with high confidence.

Material compatibility issues further complicate validation efforts. Diffusion bonding between dissimilar materials creates intermetallic compounds and transitional zones that exhibit complex mechanical behaviors not easily characterized by conventional testing. The industry currently lacks standardized acceptance criteria for these heterogeneous interfaces.

Time and cost constraints represent significant practical challenges. High-quality diffusion bonding often requires extended processing times at elevated temperatures, making rapid validation and quality control difficult to implement in production environments. This creates tension between manufacturing efficiency and thorough validation protocols.

Regulatory frameworks have not kept pace with technological advancements, resulting in validation requirements that may be either insufficient or unnecessarily burdensome depending on the application. This regulatory uncertainty hampers industry-wide adoption of consistent validation methodologies.

The primary technical challenge facing diffusion bonding validation lies in the non-destructive assessment of bond integrity. Traditional methods often require sacrificial samples, which cannot guarantee the quality of actual production components. This creates a fundamental disconnect between validation testing and real-world performance assurance. Furthermore, the microscopic nature of diffusion interfaces makes visual inspection nearly impossible without destructive sectioning.

Helium leak testing remains the gold standard for hermeticity validation, but it presents limitations when applied to complex geometries or multi-material bonds. The detection threshold of conventional leak testing equipment (typically 10^-9 atm·cc/sec) may be insufficient for next-generation microelectronic and aerospace applications requiring ultra-high vacuum integrity.

Mechanical acceptance validation faces its own set of challenges. Current shear and tensile testing methodologies often produce inconsistent results due to variations in fixture design and loading conditions. The industry lacks standardized approaches for correlating mechanical test data with actual in-service performance, particularly for components experiencing thermal cycling or vibration environments.

Advanced non-destructive evaluation techniques such as acoustic microscopy, X-ray tomography, and neutron diffraction are being explored, but each presents limitations in resolution, penetration depth, or accessibility. The correlation between these non-destructive measurements and actual bond quality remains difficult to establish with high confidence.

Material compatibility issues further complicate validation efforts. Diffusion bonding between dissimilar materials creates intermetallic compounds and transitional zones that exhibit complex mechanical behaviors not easily characterized by conventional testing. The industry currently lacks standardized acceptance criteria for these heterogeneous interfaces.

Time and cost constraints represent significant practical challenges. High-quality diffusion bonding often requires extended processing times at elevated temperatures, making rapid validation and quality control difficult to implement in production environments. This creates tension between manufacturing efficiency and thorough validation protocols.

Regulatory frameworks have not kept pace with technological advancements, resulting in validation requirements that may be either insufficient or unnecessarily burdensome depending on the application. This regulatory uncertainty hampers industry-wide adoption of consistent validation methodologies.

Current Validation Methods for Diffusion Bonded Joints

01 Process parameters for hermetic diffusion bonding

Specific process parameters such as temperature, pressure, and time are critical for achieving hermetic seals in diffusion bonding. Proper control of these parameters ensures complete atomic diffusion across the interface, eliminating voids that could compromise hermeticity. Surface preparation, including cleaning and activation treatments, also plays a significant role in achieving reliable hermetic bonds that can pass leak testing requirements.- Process parameters for hermetic diffusion bonding: Specific process parameters such as temperature, pressure, and time are critical for achieving hermetic seals in diffusion bonding. Proper control of these parameters ensures complete atomic diffusion across the interface, eliminating voids and creating gas-tight seals. The bonding environment, including vacuum or inert gas atmosphere, plays a significant role in preventing oxidation and contamination that could compromise hermeticity. Surface preparation techniques prior to bonding also contribute to the quality of the hermetic seal.

- Material selection for hermetic diffusion bonds: The choice of materials significantly impacts the hermeticity and mechanical strength of diffusion bonds. Compatible materials with similar thermal expansion coefficients reduce stress at the bond interface. Certain metal combinations form intermetallic compounds that enhance bond strength and hermeticity. Materials with high diffusion rates create stronger bonds at lower temperatures. Surface coatings or interlayers can be used to promote diffusion between otherwise incompatible materials, improving both hermeticity and mechanical properties.

- Testing methods for diffusion bond hermeticity: Various testing methods are employed to evaluate the hermeticity of diffusion bonds. These include helium leak detection, which can identify extremely small leaks in sealed components. Pressure decay testing measures the rate of pressure loss in a sealed cavity over time. Bubble testing in liquid can visually identify leak paths. Advanced methods like acoustic microscopy can detect subsurface voids or unbonded areas that might compromise hermeticity. Mechanical testing such as tensile and shear tests correlate with bond integrity and can predict hermetic performance.

- Surface preparation techniques for improved bonding: Surface preparation is crucial for achieving high-quality diffusion bonds with excellent hermeticity and mechanical properties. Techniques include chemical cleaning to remove organic contaminants, mechanical polishing to reduce surface roughness, and plasma treatment to activate surfaces. Ion beam cleaning can remove oxide layers that inhibit diffusion. Surface flatness and parallelism are critical parameters that affect bond quality. Some processes incorporate specialized etching patterns to increase surface area and improve mechanical interlocking between bonded components.

- Specialized diffusion bonding for electronic packaging: Electronic packaging applications require specialized diffusion bonding techniques to ensure both hermeticity and reliable electrical connections. Low-temperature diffusion bonding methods preserve the functionality of sensitive electronic components while maintaining hermetic seals. Transient liquid phase bonding combines diffusion bonding with brazing to create void-free interfaces. Solid-state bonding techniques for semiconductor materials enable hermetic packaging of microelectronic devices. These methods often incorporate unique material combinations and geometries specifically designed for electronic applications.

02 Material selection for hermetic diffusion bonds

The choice of materials significantly impacts the hermeticity and mechanical strength of diffusion bonds. Compatible materials with similar thermal expansion coefficients reduce stress at the bond interface. Certain metal combinations form intermetallic compounds that enhance bond strength and hermeticity. Materials that resist oxidation or include elements that can dissolve surface oxides during bonding are particularly effective for hermetic sealing applications.Expand Specific Solutions03 Testing methods for diffusion bond quality

Various testing methods are employed to verify the hermeticity and mechanical integrity of diffusion bonds. These include helium leak detection, pressure decay testing, and dye penetrant inspection for hermeticity evaluation. Mechanical acceptance is verified through tensile testing, shear testing, and microstructural analysis. Non-destructive testing methods such as ultrasonic inspection and X-ray analysis can detect internal defects without compromising the bonded structure.Expand Specific Solutions04 Surface preparation techniques for enhanced bonding

Proper surface preparation is essential for achieving high-quality diffusion bonds with excellent hermeticity. Techniques include mechanical polishing, chemical etching, plasma cleaning, and ion bombardment to remove oxides and contaminants. Some processes incorporate interlayers or coatings to facilitate bonding between dissimilar materials. Surface roughness control at the micro and nano scales can significantly improve bond strength and hermeticity by increasing the effective contact area.Expand Specific Solutions05 Specialized diffusion bonding for electronic and aerospace applications

Specialized diffusion bonding techniques have been developed for electronic packaging and aerospace components requiring exceptional hermeticity and reliability. These include transient liquid phase bonding, solid-state diffusion bonding under vacuum or inert atmospheres, and pressure-assisted diffusion bonding. For electronic applications, hermetic sealing protects sensitive components from moisture and contaminants, while aerospace applications require bonds that maintain integrity under extreme temperature fluctuations and mechanical stress.Expand Specific Solutions

Key Industry Players in Diffusion Bonding Technology

Diffusion bonding for hermeticity validation is currently in a growth phase, with the market expanding due to increasing demand in aerospace, medical, and semiconductor industries. The global market for this technology is estimated to reach $2-3 billion by 2025, driven by applications requiring high-reliability hermetic seals. Technologically, the field shows varying maturity levels across players. Applied Materials and Lam Research lead in semiconductor applications, while SCHOTT AG and Corning demonstrate advanced capabilities in specialty glass-to-metal sealing. HRL Laboratories and Medtronic have made significant progress in medical device applications, with Tokamak Energy pioneering fusion reactor applications. Academic institutions like Harbin Institute of Technology and Northwestern Polytechnical University are advancing fundamental research, creating a competitive landscape balanced between established industrial players and emerging research-driven entities.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced diffusion bonding technology for hermetic sealing validation in semiconductor packaging. Their approach utilizes precision-controlled temperature and pressure conditions to create atomic-level bonds between similar or dissimilar materials without introducing intermediate layers. The company employs specialized vacuum furnaces with precise temperature control (typically 50-80% of the melting point) and uniform pressure application systems to ensure consistent bonding quality across large wafer surfaces. Their validation methodology incorporates helium leak detection systems capable of detecting leakage rates as low as 10^-10 mbar·l/s, alongside acoustic microscopy for non-destructive inspection of bond integrity. Applied Materials has also pioneered in-situ monitoring systems that track bond formation in real-time, allowing for process optimization and quality control during the diffusion bonding process itself rather than relying solely on post-process testing.

Strengths: Superior process control capabilities with industry-leading precision in temperature and pressure parameters; integrated quality monitoring systems that reduce validation time and increase throughput. Weaknesses: Higher implementation costs compared to conventional bonding methods; requires significant expertise and specialized equipment for proper implementation and validation.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered glass-to-metal diffusion bonding technology specifically designed for hermetic packaging applications in harsh environments. Their proprietary process involves creating molecular-level bonds between specialized glass compositions and metal alloys under precisely controlled thermal conditions. The company's GTMS (Glass-to-Metal Sealing) technology utilizes diffusion bonding principles to achieve hermeticity levels exceeding 10^-9 mbar·l/s, which is critical for applications in medical implants, aerospace components, and automotive sensors. SCHOTT's validation methodology combines traditional helium leak testing with advanced mechanical stress testing protocols that simulate real-world conditions, including thermal cycling (-55°C to +125°C), mechanical shock (up to 1500g), and vibration testing. Their process incorporates specialized glass formulations with carefully matched coefficient of thermal expansion (CTE) properties to the metal substrates, minimizing residual stresses at the bonding interface. This approach enables SCHOTT to produce hermetic seals with exceptional long-term reliability, validated through accelerated aging tests demonstrating stability over projected lifespans exceeding 15 years in implantable medical devices.

Strengths: Unparalleled expertise in glass-to-metal diffusion bonding with proprietary glass formulations; comprehensive validation protocols that exceed industry standards for hermeticity assurance. Weaknesses: Limited material combinations compared to some alternative bonding technologies; process requires precise material selection and preparation to achieve optimal results.

Critical Technical Innovations in Hermeticity Testing

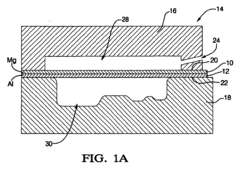

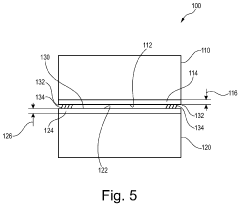

Method for diffusion bonding magnesium/aluminum components

PatentInactiveEP1273385A3

Innovation

- A method involving contacting aluminum and magnesium substrates with at least 50% aluminum and 50% magnesium, respectively, at elevated temperatures above 440°C, with pressure applied to bond them together, utilizing the diffusion of magnesium and aluminum to form a lower melting point intermetallic phase for bonding, which can occur without special surface preparation or fluxing agents.

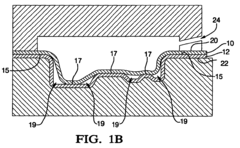

Method of diffusion bonding

PatentInactiveUS20200023460A1

Innovation

- A method involving cold working processes such as rolling, burnishing, or laser shock peening to refine the grain structure of the bonding surfaces, eliminating the need for interlayers and enhancing dislocation density, thereby improving joint integrity and efficiency by creating a pure solid-state bond without intermetallic layers.

Standards and Certification Requirements for Hermetic Seals

The regulatory landscape for hermetic seals encompasses a comprehensive framework of standards and certification requirements that manufacturers must adhere to when implementing diffusion bonding processes. Key international standards include MIL-STD-883 Method 1014, which defines specific testing procedures for hermetic seals in microelectronic devices, with particular emphasis on fine and gross leak detection methodologies critical for validating diffusion-bonded components.

ASTM F1269 provides standardized test methods for evaluating the hermeticity of sealed packages using helium mass spectrometry, offering quantitative metrics for assessing diffusion bond quality. This standard is particularly valuable for high-reliability applications where precise hermeticity validation is essential. Similarly, MIL-PRF-38534 outlines performance specifications for hybrid microcircuits, including detailed requirements for hermetic sealing processes and acceptance criteria.

For mechanical acceptance, standards such as ASTM E8 govern tensile testing procedures that evaluate the mechanical integrity of diffusion-bonded joints. These tests typically measure ultimate tensile strength, yield strength, and elongation parameters to ensure bonds meet minimum structural requirements. Additionally, ASTM E399 provides standardized methods for fracture toughness testing, which is crucial for understanding the failure mechanisms of diffusion-bonded interfaces.

Industry-specific certification requirements add another layer of compliance complexity. The aerospace sector follows AS9100 quality management standards, which incorporate specific provisions for special processes like diffusion bonding. Medical device manufacturers must comply with ISO 13485, which mandates validation protocols for hermetic sealing processes used in implantable devices and other critical medical applications.

Certification bodies such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) provide specialized accreditation for diffusion bonding processes, requiring manufacturers to demonstrate process control, personnel qualification, and consistent quality outcomes. This certification has become increasingly important for suppliers serving aerospace and defense markets.

Recent regulatory trends indicate a movement toward harmonized global standards, with increased emphasis on statistical process control methodologies and non-destructive evaluation techniques. Regulatory bodies are increasingly requiring manufacturers to implement process validation protocols that demonstrate both short-term capability and long-term reliability of diffusion-bonded hermetic seals, particularly for applications in harsh environments or mission-critical systems.

ASTM F1269 provides standardized test methods for evaluating the hermeticity of sealed packages using helium mass spectrometry, offering quantitative metrics for assessing diffusion bond quality. This standard is particularly valuable for high-reliability applications where precise hermeticity validation is essential. Similarly, MIL-PRF-38534 outlines performance specifications for hybrid microcircuits, including detailed requirements for hermetic sealing processes and acceptance criteria.

For mechanical acceptance, standards such as ASTM E8 govern tensile testing procedures that evaluate the mechanical integrity of diffusion-bonded joints. These tests typically measure ultimate tensile strength, yield strength, and elongation parameters to ensure bonds meet minimum structural requirements. Additionally, ASTM E399 provides standardized methods for fracture toughness testing, which is crucial for understanding the failure mechanisms of diffusion-bonded interfaces.

Industry-specific certification requirements add another layer of compliance complexity. The aerospace sector follows AS9100 quality management standards, which incorporate specific provisions for special processes like diffusion bonding. Medical device manufacturers must comply with ISO 13485, which mandates validation protocols for hermetic sealing processes used in implantable devices and other critical medical applications.

Certification bodies such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) provide specialized accreditation for diffusion bonding processes, requiring manufacturers to demonstrate process control, personnel qualification, and consistent quality outcomes. This certification has become increasingly important for suppliers serving aerospace and defense markets.

Recent regulatory trends indicate a movement toward harmonized global standards, with increased emphasis on statistical process control methodologies and non-destructive evaluation techniques. Regulatory bodies are increasingly requiring manufacturers to implement process validation protocols that demonstrate both short-term capability and long-term reliability of diffusion-bonded hermetic seals, particularly for applications in harsh environments or mission-critical systems.

Material Compatibility Considerations in Diffusion Bonding

Material compatibility represents a critical factor in the success of diffusion bonding processes, directly impacting both hermeticity and mechanical integrity of the resulting bonds. The selection of materials for diffusion bonding must consider several fundamental properties including thermal expansion coefficients, melting points, crystal structures, and chemical reactivity between the bonding interfaces.

When materials with significantly different coefficients of thermal expansion (CTE) are bonded, thermal cycling can induce substantial stress at the interface, potentially compromising hermeticity and mechanical strength. For optimal bonding, materials should have CTE values within 10% of each other to minimize these stresses during processing and subsequent operation.

Surface chemistry plays an equally important role in diffusion bonding compatibility. Materials that form stable, continuous intermetallic compounds generally produce stronger bonds with better hermeticity characteristics. Conversely, materials that form brittle intermetallics or exhibit limited mutual solubility often result in weaker bonds with compromised hermeticity.

The crystallographic structure of bonding materials significantly influences diffusion rates and bond formation. Face-centered cubic (FCC) materials typically demonstrate superior diffusion bonding characteristics compared to body-centered cubic (BCC) or hexagonal close-packed (HCP) structures due to their higher atomic packing factor and more numerous slip systems, facilitating atom migration across the interface.

Impurity elements and surface contamination can severely impact material compatibility. Even trace amounts of certain elements can segregate at grain boundaries during the bonding process, forming low-melting-point phases that compromise both mechanical strength and hermeticity. Oxygen, carbon, and sulfur are particularly problematic contaminants that can form oxides, carbides, or sulfides at the interface.

Pre-bond surface preparation techniques must be tailored to specific material combinations. Noble metals like gold and platinum typically require minimal surface preparation due to their resistance to oxidation, while reactive metals such as titanium and aluminum demand more rigorous cleaning protocols to remove native oxide layers that inhibit diffusion.

For hermetic applications, the gas permeability characteristics of the selected materials must be considered. Materials with low hydrogen, helium, and other gas permeability rates are preferred for applications requiring long-term hermeticity. This is particularly important in microelectronic packaging, aerospace components, and medical implants where hermeticity failure can lead to catastrophic consequences.

When materials with significantly different coefficients of thermal expansion (CTE) are bonded, thermal cycling can induce substantial stress at the interface, potentially compromising hermeticity and mechanical strength. For optimal bonding, materials should have CTE values within 10% of each other to minimize these stresses during processing and subsequent operation.

Surface chemistry plays an equally important role in diffusion bonding compatibility. Materials that form stable, continuous intermetallic compounds generally produce stronger bonds with better hermeticity characteristics. Conversely, materials that form brittle intermetallics or exhibit limited mutual solubility often result in weaker bonds with compromised hermeticity.

The crystallographic structure of bonding materials significantly influences diffusion rates and bond formation. Face-centered cubic (FCC) materials typically demonstrate superior diffusion bonding characteristics compared to body-centered cubic (BCC) or hexagonal close-packed (HCP) structures due to their higher atomic packing factor and more numerous slip systems, facilitating atom migration across the interface.

Impurity elements and surface contamination can severely impact material compatibility. Even trace amounts of certain elements can segregate at grain boundaries during the bonding process, forming low-melting-point phases that compromise both mechanical strength and hermeticity. Oxygen, carbon, and sulfur are particularly problematic contaminants that can form oxides, carbides, or sulfides at the interface.

Pre-bond surface preparation techniques must be tailored to specific material combinations. Noble metals like gold and platinum typically require minimal surface preparation due to their resistance to oxidation, while reactive metals such as titanium and aluminum demand more rigorous cleaning protocols to remove native oxide layers that inhibit diffusion.

For hermetic applications, the gas permeability characteristics of the selected materials must be considered. Materials with low hydrogen, helium, and other gas permeability rates are preferred for applications requiring long-term hermeticity. This is particularly important in microelectronic packaging, aerospace components, and medical implants where hermeticity failure can lead to catastrophic consequences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!