Dipropylene Glycol in Cosmetics: Ensuring Formulation Integrity

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG in Cosmetics: Background and Objectives

Dipropylene glycol (DPG) has emerged as a crucial ingredient in the cosmetics industry, playing a pivotal role in ensuring formulation integrity. The evolution of DPG in cosmetics can be traced back to the mid-20th century when the demand for multifunctional ingredients in personal care products began to rise. As a versatile solvent and humectant, DPG quickly gained traction due to its ability to enhance product stability and improve the overall sensory experience.

The cosmetics industry has witnessed significant technological advancements over the past few decades, with a growing emphasis on product safety, efficacy, and sustainability. In this context, DPG has continued to evolve, adapting to changing regulatory landscapes and consumer preferences. Its low toxicity profile and excellent solubilizing properties have made it an indispensable component in a wide range of cosmetic formulations, including skincare, haircare, and color cosmetics.

The primary objective of incorporating DPG in cosmetics is to maintain formulation integrity throughout the product's lifecycle. This encompasses several key aspects, including preserving the stability of active ingredients, ensuring consistent texture and viscosity, and preventing microbial growth. By acting as a solvent and coupling agent, DPG facilitates the uniform distribution of various components within the formulation, thereby enhancing product performance and shelf life.

As the cosmetics industry continues to evolve, the role of DPG in formulation integrity faces new challenges and opportunities. The increasing demand for natural and sustainable products has prompted researchers to explore bio-based alternatives to traditional DPG. Additionally, the growing complexity of cosmetic formulations, incorporating advanced active ingredients and novel delivery systems, necessitates a deeper understanding of DPG's interactions with other components.

Looking ahead, the technical objectives for DPG in cosmetics focus on optimizing its functionality while addressing emerging concerns. These objectives include enhancing its compatibility with a broader range of ingredients, improving its moisture retention capabilities, and developing more environmentally friendly production methods. Furthermore, there is a growing interest in leveraging DPG's properties to create innovative textures and sensory experiences, aligning with the trend towards personalized and multifunctional cosmetic products.

The cosmetics industry has witnessed significant technological advancements over the past few decades, with a growing emphasis on product safety, efficacy, and sustainability. In this context, DPG has continued to evolve, adapting to changing regulatory landscapes and consumer preferences. Its low toxicity profile and excellent solubilizing properties have made it an indispensable component in a wide range of cosmetic formulations, including skincare, haircare, and color cosmetics.

The primary objective of incorporating DPG in cosmetics is to maintain formulation integrity throughout the product's lifecycle. This encompasses several key aspects, including preserving the stability of active ingredients, ensuring consistent texture and viscosity, and preventing microbial growth. By acting as a solvent and coupling agent, DPG facilitates the uniform distribution of various components within the formulation, thereby enhancing product performance and shelf life.

As the cosmetics industry continues to evolve, the role of DPG in formulation integrity faces new challenges and opportunities. The increasing demand for natural and sustainable products has prompted researchers to explore bio-based alternatives to traditional DPG. Additionally, the growing complexity of cosmetic formulations, incorporating advanced active ingredients and novel delivery systems, necessitates a deeper understanding of DPG's interactions with other components.

Looking ahead, the technical objectives for DPG in cosmetics focus on optimizing its functionality while addressing emerging concerns. These objectives include enhancing its compatibility with a broader range of ingredients, improving its moisture retention capabilities, and developing more environmentally friendly production methods. Furthermore, there is a growing interest in leveraging DPG's properties to create innovative textures and sensory experiences, aligning with the trend towards personalized and multifunctional cosmetic products.

Market Analysis for DPG-based Cosmetic Products

The global market for DPG-based cosmetic products has shown significant growth in recent years, driven by increasing consumer demand for high-performance and long-lasting beauty products. Dipropylene Glycol (DPG) plays a crucial role in cosmetic formulations, serving as a versatile solvent, humectant, and viscosity regulator. This multifunctionality has led to its widespread adoption across various cosmetic categories, including skincare, haircare, and color cosmetics.

In the skincare segment, DPG-based products have gained traction due to their ability to enhance the stability and efficacy of active ingredients. The market has witnessed a surge in demand for moisturizers, serums, and anti-aging creams incorporating DPG, as it helps improve product texture and skin feel. The haircare sector has also embraced DPG-based formulations, particularly in leave-in conditioners and styling products, where its moisture-retaining properties contribute to improved hair manageability and shine.

The color cosmetics market has seen a notable shift towards long-wearing and transfer-resistant formulations, where DPG plays a vital role in enhancing product performance. Foundations, lipsticks, and eye makeup products utilizing DPG have shown increased market share, appealing to consumers seeking durable and smudge-proof cosmetics.

Geographically, North America and Europe lead the market for DPG-based cosmetic products, with established beauty industries and a strong consumer base for premium cosmetics. However, the Asia-Pacific region is emerging as a key growth driver, fueled by rising disposable incomes, changing lifestyle patterns, and increasing awareness of personal care products.

The market is characterized by intense competition among major cosmetic manufacturers, with companies investing heavily in research and development to create innovative DPG-based formulations. This has led to the introduction of advanced products with enhanced properties, such as improved skin compatibility and extended shelf life.

Consumer trends shaping the DPG-based cosmetics market include a growing preference for natural and organic products, driving the development of DPG formulations derived from sustainable sources. Additionally, the rise of personalized beauty solutions has created opportunities for customized DPG-based products tailored to individual skin types and concerns.

Looking ahead, the market for DPG-based cosmetic products is projected to continue its growth trajectory, supported by ongoing product innovations and expanding applications across various cosmetic categories. The increasing focus on multifunctional cosmetics and the growing demand for high-performance beauty products are expected to further drive the adoption of DPG in cosmetic formulations.

In the skincare segment, DPG-based products have gained traction due to their ability to enhance the stability and efficacy of active ingredients. The market has witnessed a surge in demand for moisturizers, serums, and anti-aging creams incorporating DPG, as it helps improve product texture and skin feel. The haircare sector has also embraced DPG-based formulations, particularly in leave-in conditioners and styling products, where its moisture-retaining properties contribute to improved hair manageability and shine.

The color cosmetics market has seen a notable shift towards long-wearing and transfer-resistant formulations, where DPG plays a vital role in enhancing product performance. Foundations, lipsticks, and eye makeup products utilizing DPG have shown increased market share, appealing to consumers seeking durable and smudge-proof cosmetics.

Geographically, North America and Europe lead the market for DPG-based cosmetic products, with established beauty industries and a strong consumer base for premium cosmetics. However, the Asia-Pacific region is emerging as a key growth driver, fueled by rising disposable incomes, changing lifestyle patterns, and increasing awareness of personal care products.

The market is characterized by intense competition among major cosmetic manufacturers, with companies investing heavily in research and development to create innovative DPG-based formulations. This has led to the introduction of advanced products with enhanced properties, such as improved skin compatibility and extended shelf life.

Consumer trends shaping the DPG-based cosmetics market include a growing preference for natural and organic products, driving the development of DPG formulations derived from sustainable sources. Additionally, the rise of personalized beauty solutions has created opportunities for customized DPG-based products tailored to individual skin types and concerns.

Looking ahead, the market for DPG-based cosmetic products is projected to continue its growth trajectory, supported by ongoing product innovations and expanding applications across various cosmetic categories. The increasing focus on multifunctional cosmetics and the growing demand for high-performance beauty products are expected to further drive the adoption of DPG in cosmetic formulations.

Current Challenges in DPG Formulation Stability

Dipropylene Glycol (DPG) has been widely used in cosmetic formulations due to its excellent solvent properties and compatibility with various ingredients. However, ensuring formulation stability with DPG presents several challenges that cosmetic manufacturers must address to maintain product integrity and efficacy.

One of the primary challenges in DPG formulation stability is its hygroscopic nature. DPG has a strong affinity for water, which can lead to moisture absorption from the environment. This property can cause changes in the formulation's viscosity, texture, and overall stability over time. In products such as creams and lotions, this moisture absorption can result in phase separation or alterations in the emulsion structure, compromising the product's appearance and performance.

Another significant challenge is the potential for DPG to interact with other ingredients in the formulation. As a solvent, DPG can affect the solubility and dispersion of active ingredients, preservatives, and fragrances. These interactions may lead to unexpected changes in the product's efficacy, scent profile, or preservation system. Formulators must carefully consider these potential interactions to maintain the desired product characteristics throughout its shelf life.

Temperature sensitivity is also a concern when working with DPG in cosmetic formulations. Extreme temperature fluctuations during storage or transportation can impact the stability of DPG-containing products. High temperatures may accelerate chemical reactions or cause separation of ingredients, while low temperatures could lead to crystallization or changes in viscosity. This sensitivity requires careful consideration of packaging and storage conditions to maintain product integrity.

The volatility of DPG, although lower than some other glycols, can still pose challenges in certain formulations. Over time, there may be a gradual loss of DPG from the product, particularly in formulations with high DPG concentrations or those packaged in containers that are not completely airtight. This loss can affect the product's performance and potentially alter its sensory properties.

Compatibility with packaging materials is another critical aspect of DPG formulation stability. DPG can interact with certain plastics and coatings used in packaging, potentially leading to leaching of packaging components into the product or degradation of the packaging itself. This necessitates thorough compatibility testing to ensure that the chosen packaging materials are suitable for long-term storage of DPG-containing formulations.

Lastly, the regulatory landscape surrounding DPG usage in cosmetics presents ongoing challenges. While DPG is generally recognized as safe, formulators must stay abreast of evolving regulations and guidelines regarding its concentration limits and labeling requirements in different markets. Ensuring compliance while maintaining formulation stability adds another layer of complexity to product development and manufacturing processes.

One of the primary challenges in DPG formulation stability is its hygroscopic nature. DPG has a strong affinity for water, which can lead to moisture absorption from the environment. This property can cause changes in the formulation's viscosity, texture, and overall stability over time. In products such as creams and lotions, this moisture absorption can result in phase separation or alterations in the emulsion structure, compromising the product's appearance and performance.

Another significant challenge is the potential for DPG to interact with other ingredients in the formulation. As a solvent, DPG can affect the solubility and dispersion of active ingredients, preservatives, and fragrances. These interactions may lead to unexpected changes in the product's efficacy, scent profile, or preservation system. Formulators must carefully consider these potential interactions to maintain the desired product characteristics throughout its shelf life.

Temperature sensitivity is also a concern when working with DPG in cosmetic formulations. Extreme temperature fluctuations during storage or transportation can impact the stability of DPG-containing products. High temperatures may accelerate chemical reactions or cause separation of ingredients, while low temperatures could lead to crystallization or changes in viscosity. This sensitivity requires careful consideration of packaging and storage conditions to maintain product integrity.

The volatility of DPG, although lower than some other glycols, can still pose challenges in certain formulations. Over time, there may be a gradual loss of DPG from the product, particularly in formulations with high DPG concentrations or those packaged in containers that are not completely airtight. This loss can affect the product's performance and potentially alter its sensory properties.

Compatibility with packaging materials is another critical aspect of DPG formulation stability. DPG can interact with certain plastics and coatings used in packaging, potentially leading to leaching of packaging components into the product or degradation of the packaging itself. This necessitates thorough compatibility testing to ensure that the chosen packaging materials are suitable for long-term storage of DPG-containing formulations.

Lastly, the regulatory landscape surrounding DPG usage in cosmetics presents ongoing challenges. While DPG is generally recognized as safe, formulators must stay abreast of evolving regulations and guidelines regarding its concentration limits and labeling requirements in different markets. Ensuring compliance while maintaining formulation stability adds another layer of complexity to product development and manufacturing processes.

Existing Strategies for DPG Formulation Integrity

01 Dipropylene glycol as a solvent in formulations

Dipropylene glycol is widely used as a solvent in various formulations due to its ability to dissolve both polar and non-polar substances. It helps maintain the integrity of formulations by ensuring proper dissolution and dispersion of active ingredients. This versatile solvent is particularly useful in personal care products, pharmaceuticals, and industrial applications.- Stability enhancement in cosmetic formulations: Dipropylene glycol is used to improve the stability and integrity of cosmetic formulations. It acts as a solvent and humectant, helping to maintain product consistency and prevent separation of ingredients over time. This enhances the overall formulation integrity and shelf life of cosmetic products.

- Solvent properties in personal care products: Dipropylene glycol serves as an effective solvent in personal care formulations, aiding in the dissolution and incorporation of various active ingredients. Its solvent properties contribute to the formulation integrity by ensuring uniform distribution of components and maintaining product homogeneity.

- Moisture retention in skincare formulations: As a humectant, dipropylene glycol helps retain moisture in skincare formulations. This property is crucial for maintaining the integrity of products designed to hydrate and nourish the skin, ensuring that the formulation remains effective throughout its shelf life.

- Viscosity modification in liquid formulations: Dipropylene glycol can be used to adjust the viscosity of liquid formulations, contributing to the overall formulation integrity. By modifying the flow properties, it helps achieve the desired consistency and texture in various personal care and cosmetic products.

- Preservation enhancement in water-based formulations: In water-based formulations, dipropylene glycol can enhance the efficacy of preservatives, contributing to the overall formulation integrity. It helps create an environment less conducive to microbial growth, thus extending the shelf life and maintaining the quality of the product over time.

02 Stabilizing effect of dipropylene glycol

Dipropylene glycol contributes to the stability of formulations by acting as a humectant and preventing the evaporation of water-based components. This property helps maintain the consistency and effectiveness of products over time, particularly in cosmetics and personal care items. The stabilizing effect of dipropylene glycol is crucial for preserving the integrity of formulations during storage and use.Expand Specific Solutions03 Compatibility with other ingredients

Dipropylene glycol exhibits excellent compatibility with a wide range of ingredients, including both water-soluble and oil-soluble components. This characteristic allows for the creation of stable emulsions and suspensions, enhancing the overall formulation integrity. Its compatibility also enables the incorporation of various active ingredients without compromising their efficacy or the product's stability.Expand Specific Solutions04 Temperature stability in formulations

Formulations containing dipropylene glycol often demonstrate improved temperature stability. This property is particularly beneficial for products that may be exposed to varying environmental conditions during storage or transportation. The temperature stability provided by dipropylene glycol helps maintain the integrity of the formulation across a range of temperatures, preventing separation or degradation of components.Expand Specific Solutions05 Enhancing penetration and absorption

Dipropylene glycol can act as a penetration enhancer in certain formulations, improving the absorption of active ingredients through the skin or other biological membranes. This property is particularly useful in topical pharmaceutical and cosmetic products, where it can increase the efficacy of the formulation by facilitating the delivery of active components to their target sites.Expand Specific Solutions

Key Players in DPG Production and Cosmetic Formulation

The market for dipropylene glycol in cosmetics is in a mature growth stage, with a steady global demand driven by the personal care industry. The market size is substantial, estimated to be in the hundreds of millions of dollars annually. Technologically, dipropylene glycol is well-established, with major players like L'Oréal, Shiseido, and Colgate-Palmolive incorporating it into various formulations. Companies such as Kao Corp. and Amorepacific are investing in R&D to enhance its efficacy and sustainability. The competitive landscape is characterized by these large multinationals alongside specialized chemical suppliers like NOF Corp. and DuPont Tate & Lyle Bio Products, who focus on developing innovative, high-purity grades for cosmetic applications.

L'Oréal SA

Technical Solution: L'Oréal has developed advanced formulation techniques for incorporating Dipropylene Glycol (DPG) in cosmetics. Their approach focuses on optimizing the concentration of DPG to enhance product stability and performance. L'Oréal utilizes a proprietary microemulsion technology that allows for better dispersion of DPG in various cosmetic formulations, resulting in improved moisture retention and texture[1]. The company has also implemented a rigorous quality control process to ensure the purity and consistency of DPG used in their products, minimizing the risk of irritation or allergic reactions[3]. Additionally, L'Oréal has invested in research to explore the synergistic effects of DPG with other ingredients, leading to the development of multi-functional formulations that offer enhanced benefits to consumers[5].

Strengths: Advanced formulation expertise, proprietary microemulsion technology, and extensive research capabilities. Weaknesses: Potential higher production costs due to rigorous quality control and specialized formulation processes.

Shiseido Co., Ltd.

Technical Solution: Shiseido has developed a novel approach to incorporating Dipropylene Glycol in cosmetics, focusing on its role as a solvent and humectant. Their research has led to the creation of a unique "Aqua-in-oil" emulsion system that utilizes DPG to enhance the stability and efficacy of water-soluble active ingredients in oil-based formulations[2]. This technology allows for better penetration of hydrophilic compounds into the skin, improving overall product performance. Shiseido has also explored the use of DPG in combination with their proprietary bio-hyaluronic acid complex, resulting in formulations with superior moisturizing properties and long-lasting hydration effects[4]. The company's commitment to safety has led to the development of a specialized purification process for DPG, ensuring minimal impurities and reducing the risk of skin sensitization[6].

Strengths: Innovative "Aqua-in-oil" emulsion system, synergistic use with proprietary ingredients, and advanced purification techniques. Weaknesses: Potential limitations in formulating products for sensitive skin types due to the presence of DPG.

Innovative Approaches to DPG Stability Enhancement

Hydroglycolic cosmetic composition with a high active content

PatentPendingUS20220192961A1

Innovation

- A hydroglycolic cosmetic composition with a high active content, comprising glycols such as dipropylene glycol, pentylene glycol, and hexylene glycol, along with antioxidants like ascorbic acid and Vitamin E, which maintains solubility and stability at temperatures from 5°C to 45°C and pH 3.0 to 3.5 for extended periods, preventing precipitation and phase separation.

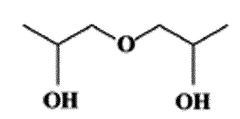

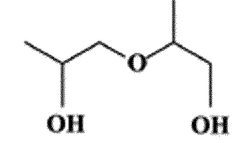

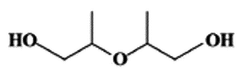

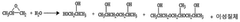

Dipropylene glycol composition and preparation method therefor

PatentWO2021075923A1

Innovation

- A dipropylene glycol composition with a specific content range of 99.5% or more, combined with isomers like 1,1'-oxybis(2-propanol), 2-(2-hydroxypropoxy)-1-propanol, and 2,2-oxybis(1-propanol, and a deodorizing method involving heating with alcohol to remove odor-causing substances, ensuring high purity and reduced odor.

Regulatory Framework for DPG in Cosmetics

The regulatory framework for Dipropylene Glycol (DPG) in cosmetics is a complex and evolving landscape that varies across different regions and jurisdictions. In the United States, the Food and Drug Administration (FDA) oversees the use of DPG in cosmetic products under the Federal Food, Drug, and Cosmetic Act. While the FDA does not require pre-market approval for cosmetic ingredients, it mandates that all cosmetics must be safe for consumers when used as directed.

The European Union (EU) regulates DPG under the Cosmetic Products Regulation (EC) No 1223/2009. This regulation sets strict guidelines for the use of cosmetic ingredients, including DPG, and requires a comprehensive safety assessment for each product before it can be placed on the market. The EU's Scientific Committee on Consumer Safety (SCCS) has evaluated DPG and deemed it safe for use in cosmetic products at current concentration levels.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics through the Pharmaceutical Affairs Law. DPG is listed as an approved ingredient in the Japanese Standards of Cosmetic Ingredients (JSCI), which outlines the permitted uses and concentrations for cosmetic ingredients.

China's regulatory framework for cosmetics, including the use of DPG, is governed by the National Medical Products Administration (NMPA). The Cosmetic Supervision and Administration Regulation (CSAR) requires that all cosmetic ingredients, including DPG, must be registered or filed with the authorities before use in cosmetic products.

Globally, the International Cooperation on Cosmetics Regulation (ICCR) works to harmonize cosmetic regulations across different regions. While not a regulatory body itself, the ICCR's recommendations influence the regulatory approaches of its member countries, potentially affecting the use of DPG in cosmetics worldwide.

Many countries have adopted the International Nomenclature of Cosmetic Ingredients (INCI) system, which provides a standardized naming convention for cosmetic ingredients. DPG is listed in the INCI directory, facilitating its identification and regulation across different markets.

As sustainability and environmental concerns gain prominence, regulatory bodies are increasingly focusing on the environmental impact of cosmetic ingredients. This trend may lead to additional regulations or guidelines for the use of DPG in cosmetics, particularly regarding its biodegradability and potential environmental persistence.

The European Union (EU) regulates DPG under the Cosmetic Products Regulation (EC) No 1223/2009. This regulation sets strict guidelines for the use of cosmetic ingredients, including DPG, and requires a comprehensive safety assessment for each product before it can be placed on the market. The EU's Scientific Committee on Consumer Safety (SCCS) has evaluated DPG and deemed it safe for use in cosmetic products at current concentration levels.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics through the Pharmaceutical Affairs Law. DPG is listed as an approved ingredient in the Japanese Standards of Cosmetic Ingredients (JSCI), which outlines the permitted uses and concentrations for cosmetic ingredients.

China's regulatory framework for cosmetics, including the use of DPG, is governed by the National Medical Products Administration (NMPA). The Cosmetic Supervision and Administration Regulation (CSAR) requires that all cosmetic ingredients, including DPG, must be registered or filed with the authorities before use in cosmetic products.

Globally, the International Cooperation on Cosmetics Regulation (ICCR) works to harmonize cosmetic regulations across different regions. While not a regulatory body itself, the ICCR's recommendations influence the regulatory approaches of its member countries, potentially affecting the use of DPG in cosmetics worldwide.

Many countries have adopted the International Nomenclature of Cosmetic Ingredients (INCI) system, which provides a standardized naming convention for cosmetic ingredients. DPG is listed in the INCI directory, facilitating its identification and regulation across different markets.

As sustainability and environmental concerns gain prominence, regulatory bodies are increasingly focusing on the environmental impact of cosmetic ingredients. This trend may lead to additional regulations or guidelines for the use of DPG in cosmetics, particularly regarding its biodegradability and potential environmental persistence.

Environmental Impact of DPG in Cosmetic Products

The environmental impact of Dipropylene Glycol (DPG) in cosmetic products is a growing concern as the beauty industry strives for sustainability. DPG, a synthetic organic compound, is widely used in cosmetics as a solvent, viscosity decreaser, and fragrance ingredient. While it offers numerous benefits in formulations, its environmental footprint requires careful consideration.

DPG's production process involves petrochemical derivatives, which raises questions about its sustainability. The manufacturing of DPG consumes significant energy and resources, contributing to carbon emissions and potential environmental degradation. However, compared to some alternative ingredients, DPG's production may have a lower environmental impact due to its efficient synthesis methods.

When released into the environment, DPG demonstrates relatively low toxicity to aquatic organisms. Studies have shown that it biodegrades readily in both water and soil, with a half-life typically ranging from 1 to 10 days under aerobic conditions. This rapid biodegradation reduces its long-term environmental persistence and accumulation in ecosystems.

Despite its biodegradability, the widespread use of DPG in cosmetics leads to continuous release into wastewater systems. While most modern wastewater treatment facilities can effectively remove DPG, areas with inadequate treatment infrastructure may face challenges in managing its environmental presence. This highlights the importance of considering regional variations in environmental impact assessments.

The volatility of DPG is another factor influencing its environmental impact. As a low-volatility compound, DPG has minimal contribution to atmospheric pollution and ozone depletion. This characteristic makes it preferable to more volatile alternatives in cosmetic formulations from an air quality perspective.

Efforts to mitigate the environmental impact of DPG in cosmetics focus on several areas. Manufacturers are exploring green chemistry approaches to synthesize DPG from renewable resources, potentially reducing its carbon footprint. Additionally, optimizing formulations to use DPG more efficiently can decrease overall consumption and environmental release.

The cosmetic industry is also investigating alternatives to DPG, such as naturally derived glycols or other multifunctional ingredients with similar properties but potentially lower environmental impacts. However, these alternatives often come with their own set of environmental considerations, necessitating comprehensive life cycle assessments to make informed decisions.

In conclusion, while DPG in cosmetics does have environmental implications, its impact is moderated by its biodegradability and low toxicity. The challenge lies in balancing its functional benefits with environmental considerations, driving the industry towards more sustainable practices and formulations.

DPG's production process involves petrochemical derivatives, which raises questions about its sustainability. The manufacturing of DPG consumes significant energy and resources, contributing to carbon emissions and potential environmental degradation. However, compared to some alternative ingredients, DPG's production may have a lower environmental impact due to its efficient synthesis methods.

When released into the environment, DPG demonstrates relatively low toxicity to aquatic organisms. Studies have shown that it biodegrades readily in both water and soil, with a half-life typically ranging from 1 to 10 days under aerobic conditions. This rapid biodegradation reduces its long-term environmental persistence and accumulation in ecosystems.

Despite its biodegradability, the widespread use of DPG in cosmetics leads to continuous release into wastewater systems. While most modern wastewater treatment facilities can effectively remove DPG, areas with inadequate treatment infrastructure may face challenges in managing its environmental presence. This highlights the importance of considering regional variations in environmental impact assessments.

The volatility of DPG is another factor influencing its environmental impact. As a low-volatility compound, DPG has minimal contribution to atmospheric pollution and ozone depletion. This characteristic makes it preferable to more volatile alternatives in cosmetic formulations from an air quality perspective.

Efforts to mitigate the environmental impact of DPG in cosmetics focus on several areas. Manufacturers are exploring green chemistry approaches to synthesize DPG from renewable resources, potentially reducing its carbon footprint. Additionally, optimizing formulations to use DPG more efficiently can decrease overall consumption and environmental release.

The cosmetic industry is also investigating alternatives to DPG, such as naturally derived glycols or other multifunctional ingredients with similar properties but potentially lower environmental impacts. However, these alternatives often come with their own set of environmental considerations, necessitating comprehensive life cycle assessments to make informed decisions.

In conclusion, while DPG in cosmetics does have environmental implications, its impact is moderated by its biodegradability and low toxicity. The challenge lies in balancing its functional benefits with environmental considerations, driving the industry towards more sustainable practices and formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!