How Dipropylene Glycol Inspires New Perfume Frontiers?

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG in Perfumery: Evolution and Objectives

Dipropylene glycol (DPG) has been a cornerstone in the perfume industry since its introduction in the mid-20th century. This versatile solvent has revolutionized the way fragrances are created, blended, and experienced. The evolution of DPG in perfumery is closely tied to the industry's quest for more stable, long-lasting, and complex scents.

Initially, perfumers relied primarily on alcohol-based solvents, which often led to rapid evaporation and limited the longevity of fragrances. The advent of DPG marked a significant turning point, offering a solution to these challenges. Its low volatility and excellent solvent properties allowed for better fixation of fragrance compounds, resulting in more enduring scents.

As the perfume industry expanded and consumer preferences evolved, DPG's role became increasingly crucial. It enabled perfumers to create more intricate and layered fragrances by facilitating the harmonious blending of diverse aromatic compounds. This capability aligned perfectly with the growing demand for sophisticated and multifaceted scents in the luxury perfume market.

The objectives of using DPG in modern perfumery are multifaceted. Primarily, it aims to enhance the overall performance and quality of fragrances. By improving the solubility of various fragrance ingredients, DPG allows for a more uniform and stable mixture, reducing the risk of separation or precipitation over time. This stability is crucial for maintaining the integrity of the scent profile from production to consumer use.

Another key objective is to extend the wear time of fragrances. DPG's slower evaporation rate compared to alcohol helps in creating a more persistent scent, addressing the common consumer complaint of short-lived fragrances. This property has become increasingly important in the competitive fragrance market, where longevity is often a key selling point.

Furthermore, DPG plays a vital role in achieving a balanced and gradual release of fragrance notes. It helps in creating a smoother transition between top, middle, and base notes, resulting in a more harmonious and evolving scent experience. This controlled release is essential for crafting complex fragrances that unfold over time, revealing different facets of their composition.

In recent years, the objectives of DPG use have expanded to include sustainability considerations. As the industry moves towards more environmentally friendly practices, the focus has shifted to optimizing DPG usage to reduce overall solvent consumption while maintaining or improving fragrance performance. This aligns with broader industry goals of minimizing environmental impact and meeting consumer demands for more sustainable products.

Initially, perfumers relied primarily on alcohol-based solvents, which often led to rapid evaporation and limited the longevity of fragrances. The advent of DPG marked a significant turning point, offering a solution to these challenges. Its low volatility and excellent solvent properties allowed for better fixation of fragrance compounds, resulting in more enduring scents.

As the perfume industry expanded and consumer preferences evolved, DPG's role became increasingly crucial. It enabled perfumers to create more intricate and layered fragrances by facilitating the harmonious blending of diverse aromatic compounds. This capability aligned perfectly with the growing demand for sophisticated and multifaceted scents in the luxury perfume market.

The objectives of using DPG in modern perfumery are multifaceted. Primarily, it aims to enhance the overall performance and quality of fragrances. By improving the solubility of various fragrance ingredients, DPG allows for a more uniform and stable mixture, reducing the risk of separation or precipitation over time. This stability is crucial for maintaining the integrity of the scent profile from production to consumer use.

Another key objective is to extend the wear time of fragrances. DPG's slower evaporation rate compared to alcohol helps in creating a more persistent scent, addressing the common consumer complaint of short-lived fragrances. This property has become increasingly important in the competitive fragrance market, where longevity is often a key selling point.

Furthermore, DPG plays a vital role in achieving a balanced and gradual release of fragrance notes. It helps in creating a smoother transition between top, middle, and base notes, resulting in a more harmonious and evolving scent experience. This controlled release is essential for crafting complex fragrances that unfold over time, revealing different facets of their composition.

In recent years, the objectives of DPG use have expanded to include sustainability considerations. As the industry moves towards more environmentally friendly practices, the focus has shifted to optimizing DPG usage to reduce overall solvent consumption while maintaining or improving fragrance performance. This aligns with broader industry goals of minimizing environmental impact and meeting consumer demands for more sustainable products.

Market Analysis: DPG-based Fragrances

The market for DPG-based fragrances has experienced significant growth in recent years, driven by the versatility and performance advantages of dipropylene glycol (DPG) in perfume formulations. DPG's unique properties as a solvent and fixative have made it an essential ingredient in modern fragrance development, inspiring new frontiers in scent creation and longevity.

The global fragrance market, valued at approximately $50 billion in 2020, is projected to grow at a CAGR of 4.5% through 2025. Within this market, DPG-based fragrances are gaining traction due to their enhanced stability, improved sillage, and extended wear time. Consumer demand for long-lasting fragrances with consistent scent profiles has been a key driver for the adoption of DPG in perfume formulations.

DPG's low volatility and excellent solvent properties have enabled perfumers to create more complex and nuanced scent compositions. This has led to the development of innovative fragrance families and unique olfactory experiences that were previously challenging to achieve. As a result, DPG-based fragrances have found applications across various product categories, including fine fragrances, personal care products, and home fragrances.

The market for DPG-based fragrances has also benefited from the growing trend towards natural and sustainable ingredients. DPG's biodegradability and low environmental impact have positioned it as a preferred choice for eco-conscious consumers and brands seeking to reduce their carbon footprint. This alignment with sustainability goals has further accelerated the adoption of DPG in fragrance formulations.

In terms of regional market dynamics, North America and Europe currently lead in the consumption of DPG-based fragrances, driven by mature perfume markets and high consumer awareness. However, the Asia-Pacific region is emerging as a significant growth opportunity, with rising disposable incomes and changing consumer preferences fueling demand for premium and long-lasting fragrances.

The competitive landscape for DPG-based fragrances is characterized by a mix of established fragrance houses and innovative start-ups. Major players are investing in research and development to create proprietary DPG-based formulations that offer unique scent profiles and performance characteristics. This has led to a surge in patent filings related to DPG applications in perfumery, indicating a robust innovation pipeline in the industry.

Looking ahead, the market for DPG-based fragrances is poised for continued growth, driven by ongoing technological advancements in fragrance chemistry and evolving consumer preferences. The ability of DPG to enable new fragrance experiences while addressing sustainability concerns positions it as a key ingredient in shaping the future of the perfume industry.

The global fragrance market, valued at approximately $50 billion in 2020, is projected to grow at a CAGR of 4.5% through 2025. Within this market, DPG-based fragrances are gaining traction due to their enhanced stability, improved sillage, and extended wear time. Consumer demand for long-lasting fragrances with consistent scent profiles has been a key driver for the adoption of DPG in perfume formulations.

DPG's low volatility and excellent solvent properties have enabled perfumers to create more complex and nuanced scent compositions. This has led to the development of innovative fragrance families and unique olfactory experiences that were previously challenging to achieve. As a result, DPG-based fragrances have found applications across various product categories, including fine fragrances, personal care products, and home fragrances.

The market for DPG-based fragrances has also benefited from the growing trend towards natural and sustainable ingredients. DPG's biodegradability and low environmental impact have positioned it as a preferred choice for eco-conscious consumers and brands seeking to reduce their carbon footprint. This alignment with sustainability goals has further accelerated the adoption of DPG in fragrance formulations.

In terms of regional market dynamics, North America and Europe currently lead in the consumption of DPG-based fragrances, driven by mature perfume markets and high consumer awareness. However, the Asia-Pacific region is emerging as a significant growth opportunity, with rising disposable incomes and changing consumer preferences fueling demand for premium and long-lasting fragrances.

The competitive landscape for DPG-based fragrances is characterized by a mix of established fragrance houses and innovative start-ups. Major players are investing in research and development to create proprietary DPG-based formulations that offer unique scent profiles and performance characteristics. This has led to a surge in patent filings related to DPG applications in perfumery, indicating a robust innovation pipeline in the industry.

Looking ahead, the market for DPG-based fragrances is poised for continued growth, driven by ongoing technological advancements in fragrance chemistry and evolving consumer preferences. The ability of DPG to enable new fragrance experiences while addressing sustainability concerns positions it as a key ingredient in shaping the future of the perfume industry.

Current DPG Applications and Challenges

Dipropylene glycol (DPG) has become a cornerstone in the fragrance industry, serving multiple functions that have revolutionized perfume formulation. Its primary applications include acting as a solvent, fixative, and diluent in perfumes and other scented products. As a solvent, DPG effectively dissolves a wide range of fragrance ingredients, ensuring a homogeneous blend and enhancing the overall stability of the perfume. Its fixative properties help to prolong the longevity of scents, allowing fragrances to maintain their intended olfactory profile for extended periods.

In the realm of personal care and cosmetic products, DPG is extensively used in deodorants, antiperspirants, and body sprays. Its low toxicity and skin-friendly nature make it an ideal carrier for fragrance compounds in these applications. Additionally, DPG's ability to control evaporation rates contributes to the balanced release of fragrance notes, crucial for creating complex and long-lasting scent experiences.

Despite its widespread use, DPG faces several challenges in the perfume industry. One significant issue is its potential to alter the intended scent profile of a fragrance. While DPG is considered relatively odorless, it can subtly influence the overall olfactory experience, particularly in high concentrations. This necessitates careful formulation to maintain the integrity of the original scent composition.

Another challenge lies in the growing demand for natural and sustainable ingredients in the fragrance industry. As a synthetic compound, DPG may not align with consumer preferences for "clean" or "green" beauty products. This has led to increased research into natural alternatives that can match DPG's versatile properties.

The regulatory landscape also presents challenges for DPG usage. While generally recognized as safe, there are ongoing discussions about potential allergenicity and environmental impact. Perfume manufacturers must navigate varying regulations across different markets, which can affect formulation strategies and product distribution.

Furthermore, the quest for innovative fragrance experiences pushes the boundaries of DPG's capabilities. Perfumers and formulators are constantly seeking ways to create unique scent profiles, improve longevity, and enhance the overall sensory experience. This drive for innovation challenges the traditional applications of DPG and demands continuous research into new formulation techniques and complementary ingredients.

As the fragrance industry evolves, addressing these challenges while leveraging DPG's strengths remains crucial. The future of DPG in perfumery lies in finding the delicate balance between its proven efficacy and the industry's push towards more sustainable, natural, and technologically advanced fragrance solutions.

In the realm of personal care and cosmetic products, DPG is extensively used in deodorants, antiperspirants, and body sprays. Its low toxicity and skin-friendly nature make it an ideal carrier for fragrance compounds in these applications. Additionally, DPG's ability to control evaporation rates contributes to the balanced release of fragrance notes, crucial for creating complex and long-lasting scent experiences.

Despite its widespread use, DPG faces several challenges in the perfume industry. One significant issue is its potential to alter the intended scent profile of a fragrance. While DPG is considered relatively odorless, it can subtly influence the overall olfactory experience, particularly in high concentrations. This necessitates careful formulation to maintain the integrity of the original scent composition.

Another challenge lies in the growing demand for natural and sustainable ingredients in the fragrance industry. As a synthetic compound, DPG may not align with consumer preferences for "clean" or "green" beauty products. This has led to increased research into natural alternatives that can match DPG's versatile properties.

The regulatory landscape also presents challenges for DPG usage. While generally recognized as safe, there are ongoing discussions about potential allergenicity and environmental impact. Perfume manufacturers must navigate varying regulations across different markets, which can affect formulation strategies and product distribution.

Furthermore, the quest for innovative fragrance experiences pushes the boundaries of DPG's capabilities. Perfumers and formulators are constantly seeking ways to create unique scent profiles, improve longevity, and enhance the overall sensory experience. This drive for innovation challenges the traditional applications of DPG and demands continuous research into new formulation techniques and complementary ingredients.

As the fragrance industry evolves, addressing these challenges while leveraging DPG's strengths remains crucial. The future of DPG in perfumery lies in finding the delicate balance between its proven efficacy and the industry's push towards more sustainable, natural, and technologically advanced fragrance solutions.

DPG Formulation Techniques

01 Use as a solvent in cosmetic formulations

Dipropylene glycol is commonly used as a solvent in various cosmetic and personal care products. It helps to dissolve and blend different ingredients, improving the overall stability and consistency of the formulation. This versatile solvent is particularly useful in products such as fragrances, skin care, and hair care items.- Use as a solvent in cosmetic formulations: Dipropylene glycol is commonly used as a solvent in various cosmetic and personal care products. It helps to dissolve and blend different ingredients, improving the overall stability and consistency of the formulation. This versatile solvent is particularly useful in products such as lotions, creams, and hair care items.

- Application in fragrance and perfume industry: In the fragrance and perfume industry, dipropylene glycol serves as an important carrier and fixative. It helps to disperse and stabilize fragrance oils, enhancing their longevity and performance. This compound is often used in perfumes, colognes, and other scented products to improve their overall quality and lasting power.

- Role in industrial cleaning and degreasing agents: Dipropylene glycol is utilized in the formulation of industrial cleaning and degreasing agents. Its solvent properties make it effective in removing oils, greases, and other stubborn contaminants from various surfaces. It is often incorporated into cleaning solutions for machinery, equipment, and hard surfaces in industrial settings.

- Use in pharmaceutical and medical applications: In the pharmaceutical and medical fields, dipropylene glycol finds applications as a solvent and excipient in various formulations. It can be used in oral medications, topical preparations, and other medical products to improve solubility, stability, and absorption of active ingredients. Its low toxicity and compatibility with many pharmaceutical compounds make it a valuable ingredient in this sector.

- Application in polyurethane production: Dipropylene glycol is an important raw material in the production of polyurethanes. It serves as a chain extender and crosslinking agent in polyurethane formulations, influencing the final properties of the polymer. This compound is used in the manufacture of various polyurethane products, including foams, coatings, and adhesives, contributing to their flexibility, durability, and overall performance.

02 Application in cleaning and degreasing products

Dipropylene glycol is utilized in cleaning and degreasing formulations due to its excellent solvency properties. It can effectively dissolve oils and greases, making it suitable for industrial cleaning products, household cleaners, and degreasers. Its low volatility and mild odor contribute to its effectiveness in these applications.Expand Specific Solutions03 Use as a humectant and moisturizer

In personal care and cosmetic products, dipropylene glycol functions as a humectant and moisturizer. It helps to attract and retain moisture, keeping the skin hydrated and preventing dryness. This property makes it valuable in lotions, creams, and other skincare formulations.Expand Specific Solutions04 Application in pharmaceutical formulations

Dipropylene glycol is used in pharmaceutical formulations as a solvent and carrier for active ingredients. It can help improve the solubility and stability of certain drugs, enhancing their effectiveness. Additionally, it may be used in topical medications and ointments to aid in the delivery of active compounds through the skin.Expand Specific Solutions05 Use in industrial applications

Beyond personal care and pharmaceuticals, dipropylene glycol finds applications in various industrial processes. It is used as a component in hydraulic fluids, brake fluids, and antifreeze formulations. Its properties make it suitable for heat transfer applications and as a raw material in the production of polyurethanes and other polymers.Expand Specific Solutions

Key Players in DPG Fragrance Industry

The fragrance industry, driven by innovations like dipropylene glycol, is in a mature yet evolving stage. The global perfume market, valued at over $40 billion, continues to grow steadily. Technological advancements in fragrance creation are at an intermediate maturity level, with established players like Givaudan, Firmenich, and International Flavors & Fragrances leading innovation. These companies, along with Symrise and Takasago, are investing heavily in R&D to develop novel fragrance compounds and sustainable production methods. Emerging players such as P2 Science are also contributing to the industry's technological progress, focusing on renewable ingredients and green chemistry approaches.

Givaudan SA

Technical Solution: Givaudan has pioneered the use of Dipropylene Glycol (DPG) in perfumery, leveraging its unique properties to create innovative fragrances. Their approach involves using DPG as a solvent and fixative, enhancing the longevity and diffusion of scents. Givaudan's researchers have developed a proprietary process that optimizes the interaction between DPG and fragrance molecules, resulting in more stable and long-lasting perfumes[1]. This technology allows for the creation of complex, multi-layered scents that evolve over time, providing a more dynamic olfactory experience[3]. Additionally, Givaudan has explored the use of DPG in combination with natural ingredients, creating hybrid fragrances that blend synthetic and natural elements seamlessly[5].

Strengths: Enhanced fragrance longevity, improved scent diffusion, and ability to create complex, evolving scents. Weaknesses: Potential for increased production costs and the need for specialized formulation expertise.

Firmenich SA

Technical Solution: Firmenich has developed a novel approach to utilizing Dipropylene Glycol in perfumery, focusing on its potential as a sustainable and versatile ingredient. Their research has led to the creation of a patented "Green DPG" process, which produces DPG from renewable resources, reducing the carbon footprint of fragrance production[2]. Firmenich's technology also explores the synergistic effects of DPG with other fragrance ingredients, particularly in enhancing the performance of natural extracts. They have developed a proprietary encapsulation technique that uses DPG to protect volatile fragrance molecules, extending the life of perfumes and improving their resistance to environmental factors[4]. Furthermore, Firmenich has invested in AI-driven formulation tools that optimize DPG usage in fragrance compositions, allowing for more efficient and targeted application of this versatile ingredient[6].

Strengths: Sustainable production methods, enhanced fragrance stability, and AI-driven formulation optimization. Weaknesses: Higher initial investment costs and potential limitations in scaling up the "Green DPG" production.

Innovative DPG Fragrance Patents

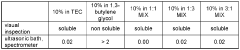

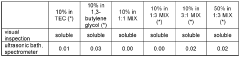

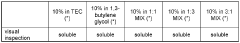

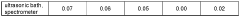

Solvent mixtures comprising 1,3-butylene glycol and triethyl- citrate

PatentWO2023144363A1

Innovation

- A solvent mixture comprising 1,3-butylene glycol and triethyl citrate, which is derived from renewable resources, is nearly odorless, colorless, and biodegradable, offering excellent solubility properties for a broad range of fragrance compounds and compositions, and is stable under various conditions, making it a suitable replacement for existing solvents like dipropylene glycol.

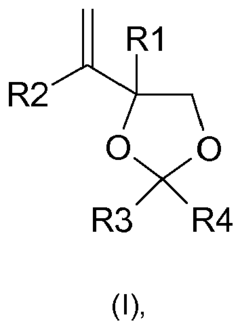

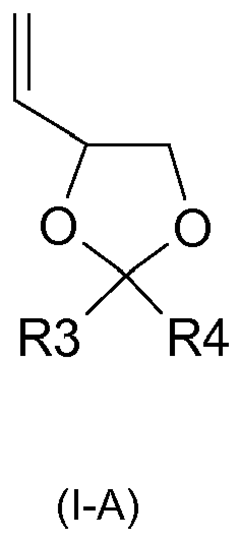

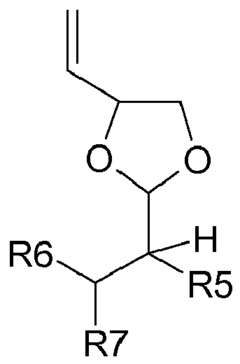

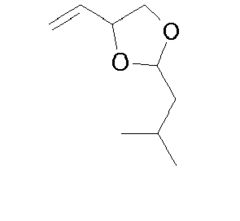

Dioxolanes containing olfactory and/or aromatic substances

PatentActiveEP2524959A1

Innovation

- The use of specific dioxolane compounds, such as 2-isobutyl-4-vinyl-[1,3]dioxolane, which are synthesized through a novel process involving copper(I) chloride and aldehydes or ketones, offering a unique fragrance profile and improved stability, particularly in alkaline and oxidizing media.

Regulatory Framework for DPG in Cosmetics

The regulatory framework for Dipropylene Glycol (DPG) in cosmetics is a critical aspect of its use in the perfume industry. Globally, DPG is generally recognized as safe for use in cosmetic products, including fragrances. However, the specific regulations and guidelines vary across different regions and countries.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of cosmetics, including perfumes. DPG is listed as a Generally Recognized as Safe (GRAS) substance by the FDA, allowing its use in cosmetic formulations. The Cosmetic Ingredient Review (CIR) Expert Panel has also evaluated DPG and concluded that it is safe for use in cosmetic products when formulated to be non-irritating.

The European Union (EU) has more stringent regulations for cosmetic ingredients. Under the EU Cosmetics Regulation (EC) No 1223/2009, DPG is listed in Annex V as a permitted preservative in cosmetic products. The regulation sets a maximum concentration limit of 1.0% for DPG when used as a preservative. However, when used for other purposes, such as a solvent or fragrance ingredient, different concentration limits may apply.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetic ingredients. DPG is included in the list of approved ingredients for use in cosmetics under the Japanese Standards for Cosmetics Ingredients (JSCI). The regulatory framework in Japan allows for the use of DPG in various cosmetic applications, including perfumes.

The International Fragrance Association (IFRA) plays a crucial role in setting global standards for the safe use of fragrance ingredients. IFRA has established guidelines for the use of DPG in fragrances, considering factors such as potential skin sensitization and environmental impact. These guidelines are widely adopted by the fragrance industry and influence regulatory decisions in many countries.

Regulatory bodies often require manufacturers to provide safety data and conduct risk assessments for cosmetic products containing DPG. This includes evaluating potential skin irritation, sensitization, and systemic toxicity. Manufacturers must also ensure that their products comply with labeling requirements, which may include listing DPG as an ingredient on the product packaging.

As sustainability and environmental concerns gain prominence, regulatory frameworks are evolving to address these aspects. Some regions are implementing regulations that consider the environmental impact of cosmetic ingredients, including their biodegradability and potential effects on aquatic ecosystems. This trend may influence future regulations regarding the use of DPG in perfumes and other cosmetic products.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of cosmetics, including perfumes. DPG is listed as a Generally Recognized as Safe (GRAS) substance by the FDA, allowing its use in cosmetic formulations. The Cosmetic Ingredient Review (CIR) Expert Panel has also evaluated DPG and concluded that it is safe for use in cosmetic products when formulated to be non-irritating.

The European Union (EU) has more stringent regulations for cosmetic ingredients. Under the EU Cosmetics Regulation (EC) No 1223/2009, DPG is listed in Annex V as a permitted preservative in cosmetic products. The regulation sets a maximum concentration limit of 1.0% for DPG when used as a preservative. However, when used for other purposes, such as a solvent or fragrance ingredient, different concentration limits may apply.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetic ingredients. DPG is included in the list of approved ingredients for use in cosmetics under the Japanese Standards for Cosmetics Ingredients (JSCI). The regulatory framework in Japan allows for the use of DPG in various cosmetic applications, including perfumes.

The International Fragrance Association (IFRA) plays a crucial role in setting global standards for the safe use of fragrance ingredients. IFRA has established guidelines for the use of DPG in fragrances, considering factors such as potential skin sensitization and environmental impact. These guidelines are widely adopted by the fragrance industry and influence regulatory decisions in many countries.

Regulatory bodies often require manufacturers to provide safety data and conduct risk assessments for cosmetic products containing DPG. This includes evaluating potential skin irritation, sensitization, and systemic toxicity. Manufacturers must also ensure that their products comply with labeling requirements, which may include listing DPG as an ingredient on the product packaging.

As sustainability and environmental concerns gain prominence, regulatory frameworks are evolving to address these aspects. Some regions are implementing regulations that consider the environmental impact of cosmetic ingredients, including their biodegradability and potential effects on aquatic ecosystems. This trend may influence future regulations regarding the use of DPG in perfumes and other cosmetic products.

Sustainability in DPG Perfume Production

The perfume industry's shift towards sustainability has placed a spotlight on the production and use of Dipropylene Glycol (DPG) in fragrances. As a key ingredient in many perfume formulations, DPG plays a crucial role in the industry's sustainability efforts. Manufacturers are increasingly focusing on developing eco-friendly production methods for DPG, aiming to reduce its environmental impact while maintaining its efficacy in perfume applications.

One of the primary sustainability initiatives in DPG production involves the use of renewable feedstocks. Traditional DPG production relies heavily on petrochemical sources, but innovative approaches are exploring bio-based alternatives. These include the utilization of plant-based materials and agricultural waste products as raw materials, significantly reducing the carbon footprint associated with DPG manufacturing.

Energy efficiency in DPG production processes is another area of focus for sustainability improvements. Companies are investing in advanced technologies and optimized production methods to minimize energy consumption during the manufacturing of DPG. This includes the implementation of heat recovery systems, process integration, and the use of more efficient catalysts to reduce reaction times and energy requirements.

Water conservation is a critical aspect of sustainable DPG production. Manufacturers are developing closed-loop water systems and advanced water treatment technologies to minimize water usage and reduce wastewater generation. These efforts not only conserve a precious resource but also help in reducing the overall environmental impact of DPG production.

The concept of green chemistry is being increasingly applied to DPG production, with a focus on reducing or eliminating the use and generation of hazardous substances. This involves the development of safer synthesis routes, the use of less toxic solvents, and the implementation of more environmentally benign catalysts in the production process.

Circular economy principles are also being integrated into DPG production and use in the perfume industry. This includes exploring ways to recycle and reuse DPG, as well as developing more concentrated perfume formulations that require less DPG, thereby reducing overall material consumption and waste generation.

As the perfume industry continues to evolve, the sustainability of DPG production remains a key focus area. Ongoing research and development efforts are aimed at further improving the environmental profile of DPG, ensuring its continued role in creating sustainable and high-quality fragrances. These advancements not only contribute to the industry's sustainability goals but also inspire new frontiers in perfume creation, where eco-friendliness and performance go hand in hand.

One of the primary sustainability initiatives in DPG production involves the use of renewable feedstocks. Traditional DPG production relies heavily on petrochemical sources, but innovative approaches are exploring bio-based alternatives. These include the utilization of plant-based materials and agricultural waste products as raw materials, significantly reducing the carbon footprint associated with DPG manufacturing.

Energy efficiency in DPG production processes is another area of focus for sustainability improvements. Companies are investing in advanced technologies and optimized production methods to minimize energy consumption during the manufacturing of DPG. This includes the implementation of heat recovery systems, process integration, and the use of more efficient catalysts to reduce reaction times and energy requirements.

Water conservation is a critical aspect of sustainable DPG production. Manufacturers are developing closed-loop water systems and advanced water treatment technologies to minimize water usage and reduce wastewater generation. These efforts not only conserve a precious resource but also help in reducing the overall environmental impact of DPG production.

The concept of green chemistry is being increasingly applied to DPG production, with a focus on reducing or eliminating the use and generation of hazardous substances. This involves the development of safer synthesis routes, the use of less toxic solvents, and the implementation of more environmentally benign catalysts in the production process.

Circular economy principles are also being integrated into DPG production and use in the perfume industry. This includes exploring ways to recycle and reuse DPG, as well as developing more concentrated perfume formulations that require less DPG, thereby reducing overall material consumption and waste generation.

As the perfume industry continues to evolve, the sustainability of DPG production remains a key focus area. Ongoing research and development efforts are aimed at further improving the environmental profile of DPG, ensuring its continued role in creating sustainable and high-quality fragrances. These advancements not only contribute to the industry's sustainability goals but also inspire new frontiers in perfume creation, where eco-friendliness and performance go hand in hand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!