How Dipropylene Glycol Complexifies Perfume Creation Methods?

JUL 7, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dipropylene Glycol in Perfumery: Background and Objectives

Dipropylene glycol (DPG) has emerged as a crucial component in modern perfumery, revolutionizing the art and science of fragrance creation. This versatile solvent, first synthesized in the early 20th century, has become an indispensable tool for perfumers worldwide. Its unique properties have significantly impacted the way fragrances are formulated, blended, and stabilized, marking a pivotal shift in perfume manufacturing techniques.

The primary objective of utilizing DPG in perfumery is to enhance the overall quality, longevity, and complexity of fragrances. By serving as an excellent carrier for a wide range of aromatic compounds, DPG allows perfumers to create more intricate and nuanced scent profiles. This capability has opened up new possibilities in fragrance design, enabling the development of sophisticated and long-lasting perfumes that were previously challenging to achieve.

DPG's role in perfume creation extends beyond its function as a solvent. It acts as a fixative, helping to slow down the evaporation rate of volatile fragrance components. This property is particularly valuable in creating fragrances with improved sillage and longevity, addressing one of the most persistent challenges in perfumery: making scents last longer on the skin.

The evolution of DPG usage in perfumery reflects broader trends in the fragrance industry towards more sustainable and versatile formulation methods. As consumer preferences shift towards lighter, more wearable fragrances, DPG's ability to create transparent, yet complex scent structures has become increasingly valuable. This aligns with the industry's move towards cleaner, more environmentally friendly formulations without compromising on scent quality or performance.

Furthermore, DPG has played a significant role in democratizing perfume creation. Its stability, relatively low cost, and ease of use have made it possible for smaller, niche perfume houses to enter the market and experiment with innovative fragrance compositions. This has led to a diversification of the perfume landscape, challenging traditional notions of what a fragrance can be and how it can be created.

As we look towards the future of perfumery, the ongoing exploration of DPG's capabilities continues to drive innovation in the field. Researchers and perfumers are constantly discovering new ways to leverage its properties, pushing the boundaries of scent creation and opening up exciting possibilities for the next generation of fragrances. The journey of DPG in perfumery serves as a testament to how a single ingredient can profoundly impact an entire industry, complexifying and enriching the art of fragrance creation.

The primary objective of utilizing DPG in perfumery is to enhance the overall quality, longevity, and complexity of fragrances. By serving as an excellent carrier for a wide range of aromatic compounds, DPG allows perfumers to create more intricate and nuanced scent profiles. This capability has opened up new possibilities in fragrance design, enabling the development of sophisticated and long-lasting perfumes that were previously challenging to achieve.

DPG's role in perfume creation extends beyond its function as a solvent. It acts as a fixative, helping to slow down the evaporation rate of volatile fragrance components. This property is particularly valuable in creating fragrances with improved sillage and longevity, addressing one of the most persistent challenges in perfumery: making scents last longer on the skin.

The evolution of DPG usage in perfumery reflects broader trends in the fragrance industry towards more sustainable and versatile formulation methods. As consumer preferences shift towards lighter, more wearable fragrances, DPG's ability to create transparent, yet complex scent structures has become increasingly valuable. This aligns with the industry's move towards cleaner, more environmentally friendly formulations without compromising on scent quality or performance.

Furthermore, DPG has played a significant role in democratizing perfume creation. Its stability, relatively low cost, and ease of use have made it possible for smaller, niche perfume houses to enter the market and experiment with innovative fragrance compositions. This has led to a diversification of the perfume landscape, challenging traditional notions of what a fragrance can be and how it can be created.

As we look towards the future of perfumery, the ongoing exploration of DPG's capabilities continues to drive innovation in the field. Researchers and perfumers are constantly discovering new ways to leverage its properties, pushing the boundaries of scent creation and opening up exciting possibilities for the next generation of fragrances. The journey of DPG in perfumery serves as a testament to how a single ingredient can profoundly impact an entire industry, complexifying and enriching the art of fragrance creation.

Market Demand for Complex Fragrances

The fragrance industry has witnessed a significant shift in consumer preferences towards more complex and sophisticated scents. This trend has been driven by several factors, including increased consumer knowledge, a desire for unique and personalized experiences, and the growing influence of niche perfumery.

Market research indicates that consumers are becoming more discerning in their fragrance choices, seeking scents that evolve over time and offer a multi-layered olfactory experience. This demand for complexity has led to a surge in the popularity of fragrances that incorporate a wider range of notes and accords, often utilizing innovative ingredients and blending techniques.

The luxury fragrance segment, in particular, has seen substantial growth, with consumers willing to pay premium prices for high-quality, complex scents. This trend is reflected in the increasing market share of niche and artisanal perfume brands, which often focus on creating intricate and unconventional fragrance compositions.

The rise of social media and online fragrance communities has also contributed to the demand for complex fragrances. Consumers are now more educated about perfume ingredients, composition techniques, and the artistry behind fragrance creation. This heightened awareness has led to a greater appreciation for sophisticated scents and a willingness to explore beyond traditional fragrance categories.

In response to this market demand, major fragrance houses and niche brands alike have been investing in research and development to create more complex and innovative scent profiles. This has led to the exploration of new ingredients, including synthetic molecules and rare natural extracts, as well as the development of advanced blending techniques to achieve greater depth and longevity in fragrances.

The use of dipropylene glycol in perfume creation has become increasingly important in meeting this demand for complexity. Its unique properties allow perfumers to create more intricate and layered scent compositions, enhancing the overall olfactory experience and contributing to the creation of fragrances that evolve over time.

Furthermore, the growing interest in sustainable and eco-friendly products has also influenced the demand for complex fragrances. Consumers are seeking scents that not only offer a sophisticated olfactory experience but also align with their values regarding environmental responsibility and ethical sourcing of ingredients.

Market research indicates that consumers are becoming more discerning in their fragrance choices, seeking scents that evolve over time and offer a multi-layered olfactory experience. This demand for complexity has led to a surge in the popularity of fragrances that incorporate a wider range of notes and accords, often utilizing innovative ingredients and blending techniques.

The luxury fragrance segment, in particular, has seen substantial growth, with consumers willing to pay premium prices for high-quality, complex scents. This trend is reflected in the increasing market share of niche and artisanal perfume brands, which often focus on creating intricate and unconventional fragrance compositions.

The rise of social media and online fragrance communities has also contributed to the demand for complex fragrances. Consumers are now more educated about perfume ingredients, composition techniques, and the artistry behind fragrance creation. This heightened awareness has led to a greater appreciation for sophisticated scents and a willingness to explore beyond traditional fragrance categories.

In response to this market demand, major fragrance houses and niche brands alike have been investing in research and development to create more complex and innovative scent profiles. This has led to the exploration of new ingredients, including synthetic molecules and rare natural extracts, as well as the development of advanced blending techniques to achieve greater depth and longevity in fragrances.

The use of dipropylene glycol in perfume creation has become increasingly important in meeting this demand for complexity. Its unique properties allow perfumers to create more intricate and layered scent compositions, enhancing the overall olfactory experience and contributing to the creation of fragrances that evolve over time.

Furthermore, the growing interest in sustainable and eco-friendly products has also influenced the demand for complex fragrances. Consumers are seeking scents that not only offer a sophisticated olfactory experience but also align with their values regarding environmental responsibility and ethical sourcing of ingredients.

Current Challenges in Perfume Formulation

The perfume industry faces several significant challenges in formulation, particularly when incorporating complex ingredients like dipropylene glycol (DPG). One of the primary issues is achieving consistent fragrance performance across different product types and environmental conditions. DPG, while beneficial for its solvent properties and ability to enhance fragrance longevity, introduces complexities in maintaining the intended scent profile throughout the product's lifecycle.

Stability is another critical concern in perfume formulation. The interaction between DPG and other fragrance components can lead to unexpected chemical reactions over time, potentially altering the scent or causing discoloration. Formulators must carefully balance the concentration of DPG with other ingredients to ensure long-term stability without compromising the fragrance's integrity.

Volatility management presents a significant challenge when working with DPG in perfume creation. As a less volatile solvent compared to ethanol, DPG can affect the evaporation rate of different fragrance notes, potentially disrupting the carefully crafted top, middle, and base note progression. This requires perfumers to recalibrate their formulations to account for DPG's impact on the overall scent development and longevity.

Regulatory compliance adds another layer of complexity to perfume formulation with DPG. As regulations governing fragrance ingredients become increasingly stringent, formulators must ensure that the use of DPG and its interactions with other components meet safety standards and labeling requirements across different markets. This often necessitates reformulation or adjustment of existing fragrances to comply with evolving regulations.

The challenge of maintaining natural and authentic scent profiles while incorporating synthetic ingredients like DPG is also significant. Consumers increasingly demand natural and sustainable products, creating pressure on perfumers to minimize synthetic components. However, DPG's benefits in terms of fragrance performance and stability make it a valuable ingredient, requiring formulators to strike a delicate balance between natural and synthetic elements.

Lastly, the complexity introduced by DPG in perfume creation methods impacts the scalability and consistency of production. Ensuring that fragrances perform consistently when scaled from small laboratory batches to large-scale manufacturing requires precise control over ingredient interactions and environmental factors. This challenge is amplified when working with DPG due to its influence on fragrance behavior and stability.

Stability is another critical concern in perfume formulation. The interaction between DPG and other fragrance components can lead to unexpected chemical reactions over time, potentially altering the scent or causing discoloration. Formulators must carefully balance the concentration of DPG with other ingredients to ensure long-term stability without compromising the fragrance's integrity.

Volatility management presents a significant challenge when working with DPG in perfume creation. As a less volatile solvent compared to ethanol, DPG can affect the evaporation rate of different fragrance notes, potentially disrupting the carefully crafted top, middle, and base note progression. This requires perfumers to recalibrate their formulations to account for DPG's impact on the overall scent development and longevity.

Regulatory compliance adds another layer of complexity to perfume formulation with DPG. As regulations governing fragrance ingredients become increasingly stringent, formulators must ensure that the use of DPG and its interactions with other components meet safety standards and labeling requirements across different markets. This often necessitates reformulation or adjustment of existing fragrances to comply with evolving regulations.

The challenge of maintaining natural and authentic scent profiles while incorporating synthetic ingredients like DPG is also significant. Consumers increasingly demand natural and sustainable products, creating pressure on perfumers to minimize synthetic components. However, DPG's benefits in terms of fragrance performance and stability make it a valuable ingredient, requiring formulators to strike a delicate balance between natural and synthetic elements.

Lastly, the complexity introduced by DPG in perfume creation methods impacts the scalability and consistency of production. Ensuring that fragrances perform consistently when scaled from small laboratory batches to large-scale manufacturing requires precise control over ingredient interactions and environmental factors. This challenge is amplified when working with DPG due to its influence on fragrance behavior and stability.

Existing Methods for Dipropylene Glycol Integration

01 Complexation of dipropylene glycol with other compounds

Dipropylene glycol can form complexes with various compounds, enhancing its properties and applications. This complexation process can improve stability, solubility, or functionality of the resulting mixture, making it useful in different industrial and consumer products.- Complexation of dipropylene glycol with other compounds: Dipropylene glycol can form complexes with various compounds, enhancing its properties or creating new functionalities. This complexation process can be used in different applications, such as improving solubility, stability, or delivery of active ingredients in formulations.

- Use of dipropylene glycol in personal care products: Dipropylene glycol is utilized in personal care formulations due to its moisturizing and solvent properties. It can be complexed with other ingredients to improve product stability, texture, and efficacy in cosmetics, skincare, and haircare products.

- Industrial applications of dipropylene glycol complexes: Complexes involving dipropylene glycol find applications in various industrial processes. These complexes can be used in manufacturing, as solvents, or as intermediates in the production of other chemicals, offering improved performance or specific properties.

- Pharmaceutical formulations using dipropylene glycol complexes: In pharmaceutical applications, dipropylene glycol complexes can be used to enhance drug delivery, improve solubility of active ingredients, or stabilize formulations. These complexes may contribute to increased bioavailability or controlled release of medications.

- Environmental and safety considerations of dipropylene glycol complexification: The complexification of dipropylene glycol may have implications for environmental impact and safety. Research in this area focuses on developing eco-friendly complexes, assessing toxicity, and ensuring compliance with regulatory standards for various applications.

02 Use of dipropylene glycol complexes in personal care products

Complexes involving dipropylene glycol are utilized in personal care formulations such as cosmetics, skincare, and haircare products. These complexes can enhance the product's performance, improve texture, or act as stabilizers and solubilizers for active ingredients.Expand Specific Solutions03 Industrial applications of dipropylene glycol complexes

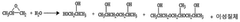

Dipropylene glycol complexes find applications in various industrial processes and products. They can be used as solvents, plasticizers, or intermediates in the production of polymers, resins, and other chemical compounds, offering improved properties or processing characteristics.Expand Specific Solutions04 Synthesis methods for dipropylene glycol complexes

Various methods are employed to synthesize dipropylene glycol complexes, including chemical reactions, physical blending, or advanced processing techniques. These methods aim to create stable and effective complexes with desired properties for specific applications.Expand Specific Solutions05 Environmental and safety considerations of dipropylene glycol complexes

Research and development efforts focus on improving the environmental profile and safety aspects of dipropylene glycol complexes. This includes developing eco-friendly formulations, reducing toxicity, and ensuring compliance with regulatory standards for various applications.Expand Specific Solutions

Key Players in Fragrance and Solvent Industry

The competitive landscape for dipropylene glycol in perfume creation is characterized by a mature market with established players and ongoing innovation. The global fragrance industry, valued at over $50 billion, is experiencing steady growth driven by consumer demand for unique scents. Major companies like Firmenich, Symrise, and International Flavors & Fragrances are investing in research and development to enhance dipropylene glycol's efficacy in perfume formulations. The technology is well-established but continues to evolve, with firms exploring novel applications and improved production methods. Smaller specialized companies are also contributing to advancements, creating a dynamic and competitive environment in this niche sector of the fragrance industry.

Firmenich SA

Technical Solution: Firmenich has developed an innovative approach to using dipropylene glycol in perfume creation, focusing on sustainability and performance. Their method involves combining DPG with bio-based solvents to create hybrid fragrance systems that offer improved environmental profiles without compromising scent quality[3]. Firmenich's proprietary "EcoScent Compass" technology incorporates DPG to optimize fragrance performance while reducing overall environmental impact[4]. The company has also invested in research to understand how DPG interacts with various fragrance molecules, leading to more precise and efficient formulation techniques. This approach has allowed Firmenich to create complex, long-lasting fragrances that meet both consumer preferences and sustainability goals.

Strengths: Sustainable approach, optimized fragrance performance, and precise formulation techniques. Weaknesses: Potential higher costs associated with bio-based materials and specialized technology.

Symrise GmbH & Co. KG

Technical Solution: Symrise has developed a sophisticated approach to using dipropylene glycol in perfume creation, focusing on enhancing the olfactory experience and improving fragrance stability. Their method involves using DPG as a carrier for their proprietary "SymTrap" technology, which captures and preserves volatile aroma molecules[5]. This technique allows for the creation of more complex and nuanced fragrances by retaining delicate top notes that might otherwise be lost during the perfume-making process. Symrise has also developed a patented "Genealogy" approach that utilizes DPG to create multi-layered fragrances with improved longevity and sillage[6]. By carefully balancing DPG concentrations with other solvents and fixatives, Symrise can tailor fragrance release profiles to suit different product applications and consumer preferences.

Strengths: Enhanced olfactory complexity, improved fragrance stability, and tailored release profiles. Weaknesses: Potential increased production time and costs due to complex formulation processes.

Innovations in Dipropylene Glycol Application

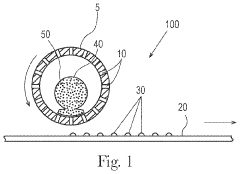

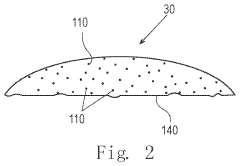

Particles comprising polyalkylene glycol, an effervescent system and perfume

PatentPendingUS20240182815A1

Innovation

- The development of Effervescent Perfume Particles comprising polyalkylene glycol, an effervescent system, and perfume, which significantly improves the dissolution rate and cleaning performance by incorporating an effervescent system into the particles, allowing them to dissolve quickly and release fragrance effectively in aqueous solutions.

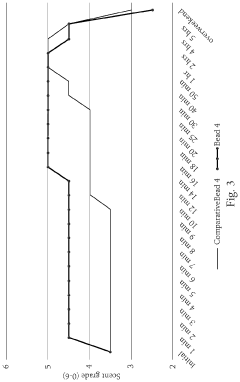

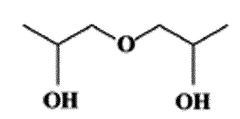

Dipropylene glycol composition and preparation method therefor

PatentWO2021075923A1

Innovation

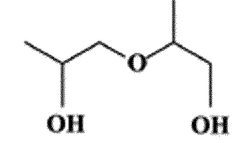

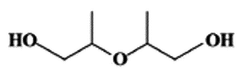

- A dipropylene glycol composition with a specific content range of 99.5% or more, combined with isomers like 1,1'-oxybis(2-propanol), 2-(2-hydroxypropoxy)-1-propanol, and 2,2-oxybis(1-propanol, and a deodorizing method involving heating with alcohol to remove odor-causing substances, ensuring high purity and reduced odor.

Regulatory Compliance in Fragrance Industry

The fragrance industry operates within a complex regulatory framework designed to ensure product safety, quality, and consumer protection. Compliance with these regulations is crucial for perfume creators using dipropylene glycol (DPG) in their formulations. The International Fragrance Association (IFRA) sets global standards for the safe use of fragrance materials, including guidelines for DPG usage in various product categories.

In the United States, the Food and Drug Administration (FDA) regulates fragrances under the Federal Food, Drug, and Cosmetic Act. While DPG is generally recognized as safe (GRAS) by the FDA, its use in perfumes must adhere to good manufacturing practices and labeling requirements. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict guidelines on the use of chemicals in consumer products, including fragrances containing DPG.

Perfume creators must navigate these regulatory landscapes when incorporating DPG into their formulations. This includes conducting safety assessments, ensuring proper documentation, and adhering to concentration limits set by regulatory bodies. The use of DPG may also impact labeling requirements, as some jurisdictions mandate the disclosure of certain ingredients on product packaging.

Regulatory compliance extends to environmental considerations as well. Many regions have implemented regulations to minimize the environmental impact of fragrance production and disposal. Perfume creators must consider these factors when using DPG, ensuring that their manufacturing processes and final products meet sustainability standards and waste management regulations.

The globalization of the fragrance industry further complicates regulatory compliance. Perfume creators must be aware of and adhere to regulations in multiple markets, as formulations containing DPG may need to meet different standards in various countries. This often necessitates the development of region-specific formulations or the adoption of the most stringent global standards to ensure compliance across all markets.

As regulations evolve, perfume creators must stay informed about changes that may affect the use of DPG in their formulations. This requires ongoing monitoring of regulatory updates, participation in industry associations, and collaboration with regulatory experts. The complexity of regulatory compliance in the fragrance industry underscores the need for robust quality management systems and thorough documentation practices throughout the perfume creation process.

In the United States, the Food and Drug Administration (FDA) regulates fragrances under the Federal Food, Drug, and Cosmetic Act. While DPG is generally recognized as safe (GRAS) by the FDA, its use in perfumes must adhere to good manufacturing practices and labeling requirements. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict guidelines on the use of chemicals in consumer products, including fragrances containing DPG.

Perfume creators must navigate these regulatory landscapes when incorporating DPG into their formulations. This includes conducting safety assessments, ensuring proper documentation, and adhering to concentration limits set by regulatory bodies. The use of DPG may also impact labeling requirements, as some jurisdictions mandate the disclosure of certain ingredients on product packaging.

Regulatory compliance extends to environmental considerations as well. Many regions have implemented regulations to minimize the environmental impact of fragrance production and disposal. Perfume creators must consider these factors when using DPG, ensuring that their manufacturing processes and final products meet sustainability standards and waste management regulations.

The globalization of the fragrance industry further complicates regulatory compliance. Perfume creators must be aware of and adhere to regulations in multiple markets, as formulations containing DPG may need to meet different standards in various countries. This often necessitates the development of region-specific formulations or the adoption of the most stringent global standards to ensure compliance across all markets.

As regulations evolve, perfume creators must stay informed about changes that may affect the use of DPG in their formulations. This requires ongoing monitoring of regulatory updates, participation in industry associations, and collaboration with regulatory experts. The complexity of regulatory compliance in the fragrance industry underscores the need for robust quality management systems and thorough documentation practices throughout the perfume creation process.

Sustainability in Perfume Creation

Sustainability has become a crucial consideration in the perfume industry, driven by increasing consumer awareness and environmental concerns. The use of dipropylene glycol (DPG) in perfume creation methods presents both challenges and opportunities for sustainable practices.

DPG, a synthetic compound, has traditionally been used as a solvent and fixative in perfumery. While it offers excellent stability and longevity to fragrances, its production process relies on petrochemicals, raising sustainability concerns. However, recent advancements in green chemistry have led to the development of bio-based DPG alternatives, derived from renewable resources such as corn or sugarcane.

The complexification of perfume creation methods through DPG usage has prompted the industry to explore more sustainable approaches. One such approach involves optimizing formulations to reduce the overall amount of DPG required, thereby minimizing environmental impact without compromising fragrance quality. This has led to the development of concentrated perfume oils that require less solvent, resulting in reduced packaging and transportation needs.

Another sustainable innovation in perfume creation is the use of supercritical CO2 extraction techniques. This method allows for the extraction of fragrance compounds without the need for traditional solvents like DPG, significantly reducing the carbon footprint of the production process. Additionally, this technique preserves the natural integrity of the fragrance materials, aligning with the growing consumer demand for more natural and sustainable products.

The perfume industry has also begun to explore circular economy principles in relation to DPG usage. Some companies are investigating methods to recycle and reuse DPG from returned or unsold products, reducing waste and resource consumption. This approach not only addresses sustainability concerns but also offers potential cost savings for manufacturers.

Furthermore, the complexification introduced by DPG has spurred research into alternative natural fixatives and solvents. Essential oils with fixative properties, such as patchouli and vetiver, are being increasingly utilized to replace or reduce the need for synthetic compounds like DPG. This shift towards natural ingredients not only enhances sustainability but also caters to the growing market demand for clean and green fragrances.

As the industry continues to evolve, the role of DPG in perfume creation is being reevaluated through the lens of sustainability. Perfumers and formulators are now challenged to balance the technical benefits of DPG with environmental considerations, leading to more innovative and eco-friendly approaches to fragrance development. This ongoing transformation demonstrates the perfume industry's commitment to adapting its practices to meet the demands of a more environmentally conscious market.

DPG, a synthetic compound, has traditionally been used as a solvent and fixative in perfumery. While it offers excellent stability and longevity to fragrances, its production process relies on petrochemicals, raising sustainability concerns. However, recent advancements in green chemistry have led to the development of bio-based DPG alternatives, derived from renewable resources such as corn or sugarcane.

The complexification of perfume creation methods through DPG usage has prompted the industry to explore more sustainable approaches. One such approach involves optimizing formulations to reduce the overall amount of DPG required, thereby minimizing environmental impact without compromising fragrance quality. This has led to the development of concentrated perfume oils that require less solvent, resulting in reduced packaging and transportation needs.

Another sustainable innovation in perfume creation is the use of supercritical CO2 extraction techniques. This method allows for the extraction of fragrance compounds without the need for traditional solvents like DPG, significantly reducing the carbon footprint of the production process. Additionally, this technique preserves the natural integrity of the fragrance materials, aligning with the growing consumer demand for more natural and sustainable products.

The perfume industry has also begun to explore circular economy principles in relation to DPG usage. Some companies are investigating methods to recycle and reuse DPG from returned or unsold products, reducing waste and resource consumption. This approach not only addresses sustainability concerns but also offers potential cost savings for manufacturers.

Furthermore, the complexification introduced by DPG has spurred research into alternative natural fixatives and solvents. Essential oils with fixative properties, such as patchouli and vetiver, are being increasingly utilized to replace or reduce the need for synthetic compounds like DPG. This shift towards natural ingredients not only enhances sustainability but also caters to the growing market demand for clean and green fragrances.

As the industry continues to evolve, the role of DPG in perfume creation is being reevaluated through the lens of sustainability. Perfumers and formulators are now challenged to balance the technical benefits of DPG with environmental considerations, leading to more innovative and eco-friendly approaches to fragrance development. This ongoing transformation demonstrates the perfume industry's commitment to adapting its practices to meet the demands of a more environmentally conscious market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!