Dipropylene Glycol's Key Benefits for Advanced Product Development

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Background & Objectives

Dipropylene glycol (DPG) has emerged as a versatile chemical compound with a rich history and significant potential in advanced product development. Originally synthesized in the early 20th century, DPG has steadily gained prominence across various industries due to its unique properties and wide-ranging applications. This glycol ether, derived from the reaction of propylene oxide with water, has become an essential component in numerous products, from cosmetics and personal care items to industrial solvents and coatings.

The evolution of DPG's applications has been driven by the increasing demand for safer, more efficient, and environmentally friendly chemical solutions. As regulatory standards have become more stringent, particularly in consumer products and industrial processes, DPG has positioned itself as a favorable alternative to more hazardous solvents and additives. Its low toxicity, high solvency, and excellent stability have made it a preferred choice for formulators and manufacturers seeking to enhance product performance while meeting safety and environmental requirements.

In recent years, the focus on sustainable and bio-based chemicals has further propelled interest in DPG. Research efforts have been directed towards developing more eco-friendly production methods and exploring new applications that leverage DPG's unique chemical properties. The compound's ability to act as a coupling agent, solvent, and humectant simultaneously has opened up innovative possibilities in formulation science, particularly in the development of advanced personal care products, high-performance coatings, and specialized industrial solutions.

The primary objective of this research is to comprehensively explore and analyze the key benefits of dipropylene glycol in the context of advanced product development. This investigation aims to uncover how DPG's physicochemical properties can be leveraged to create superior products across various sectors, including but not limited to cosmetics, pharmaceuticals, and industrial applications. By examining current uses and emerging trends, this study seeks to identify novel opportunities for DPG integration in next-generation product formulations.

Furthermore, this research intends to evaluate the potential of DPG in addressing contemporary challenges faced by product developers, such as the need for multifunctional ingredients, improved product stability, and enhanced user experience. By analyzing case studies and experimental data, the study will provide insights into how DPG can contribute to the development of more effective, sustainable, and consumer-friendly products. Additionally, the research will explore the economic implications of DPG adoption in various industries, considering factors such as cost-effectiveness, supply chain dynamics, and market demand for DPG-enhanced products.

The evolution of DPG's applications has been driven by the increasing demand for safer, more efficient, and environmentally friendly chemical solutions. As regulatory standards have become more stringent, particularly in consumer products and industrial processes, DPG has positioned itself as a favorable alternative to more hazardous solvents and additives. Its low toxicity, high solvency, and excellent stability have made it a preferred choice for formulators and manufacturers seeking to enhance product performance while meeting safety and environmental requirements.

In recent years, the focus on sustainable and bio-based chemicals has further propelled interest in DPG. Research efforts have been directed towards developing more eco-friendly production methods and exploring new applications that leverage DPG's unique chemical properties. The compound's ability to act as a coupling agent, solvent, and humectant simultaneously has opened up innovative possibilities in formulation science, particularly in the development of advanced personal care products, high-performance coatings, and specialized industrial solutions.

The primary objective of this research is to comprehensively explore and analyze the key benefits of dipropylene glycol in the context of advanced product development. This investigation aims to uncover how DPG's physicochemical properties can be leveraged to create superior products across various sectors, including but not limited to cosmetics, pharmaceuticals, and industrial applications. By examining current uses and emerging trends, this study seeks to identify novel opportunities for DPG integration in next-generation product formulations.

Furthermore, this research intends to evaluate the potential of DPG in addressing contemporary challenges faced by product developers, such as the need for multifunctional ingredients, improved product stability, and enhanced user experience. By analyzing case studies and experimental data, the study will provide insights into how DPG can contribute to the development of more effective, sustainable, and consumer-friendly products. Additionally, the research will explore the economic implications of DPG adoption in various industries, considering factors such as cost-effectiveness, supply chain dynamics, and market demand for DPG-enhanced products.

Market Demand Analysis

The market demand for dipropylene glycol (DPG) has been steadily increasing due to its versatile applications across various industries. As a key ingredient in personal care products, cosmetics, and industrial solvents, DPG has witnessed a surge in demand driven by the growing consumer awareness of product safety and environmental sustainability.

In the personal care and cosmetics sector, DPG's excellent solvent properties and low toxicity have made it a preferred choice for formulators. The global cosmetics market, valued at over $380 billion in 2019, is projected to grow at a CAGR of 5.3% from 2021 to 2028. This growth directly correlates with the increased demand for DPG in skincare products, fragrances, and hair care formulations.

The industrial solvents market, another significant consumer of DPG, is expected to reach $33 billion by 2027, growing at a CAGR of 3.5%. DPG's high solvency power and low volatility make it an ideal component in paints, coatings, and cleaning products. The construction industry's expansion and the rising demand for eco-friendly solvents are key drivers for DPG's market growth in this sector.

In the pharmaceutical industry, DPG's use as a stabilizer and solvent in drug formulations has been gaining traction. The global pharmaceutical market, projected to exceed $1.5 trillion by 2023, presents a substantial opportunity for DPG manufacturers. The increasing focus on drug stability and bioavailability is expected to further boost DPG demand in this sector.

The automotive industry's shift towards water-based paints and coatings has also contributed to the rising demand for DPG. As a crucial component in these environmentally friendly formulations, DPG is experiencing increased adoption in automotive manufacturing processes. The global automotive coatings market, valued at $21 billion in 2020, is projected to reach $27 billion by 2025, indicating a positive outlook for DPG demand.

Geographically, Asia-Pacific remains the largest and fastest-growing market for DPG, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe follow closely, with mature markets showing steady demand growth, particularly in high-end personal care and pharmaceutical applications.

The market trends indicate a growing preference for bio-based and sustainable alternatives, presenting both a challenge and an opportunity for DPG manufacturers. Innovations in green chemistry and sustainable production methods for DPG are likely to shape future market dynamics and consumer preferences.

In the personal care and cosmetics sector, DPG's excellent solvent properties and low toxicity have made it a preferred choice for formulators. The global cosmetics market, valued at over $380 billion in 2019, is projected to grow at a CAGR of 5.3% from 2021 to 2028. This growth directly correlates with the increased demand for DPG in skincare products, fragrances, and hair care formulations.

The industrial solvents market, another significant consumer of DPG, is expected to reach $33 billion by 2027, growing at a CAGR of 3.5%. DPG's high solvency power and low volatility make it an ideal component in paints, coatings, and cleaning products. The construction industry's expansion and the rising demand for eco-friendly solvents are key drivers for DPG's market growth in this sector.

In the pharmaceutical industry, DPG's use as a stabilizer and solvent in drug formulations has been gaining traction. The global pharmaceutical market, projected to exceed $1.5 trillion by 2023, presents a substantial opportunity for DPG manufacturers. The increasing focus on drug stability and bioavailability is expected to further boost DPG demand in this sector.

The automotive industry's shift towards water-based paints and coatings has also contributed to the rising demand for DPG. As a crucial component in these environmentally friendly formulations, DPG is experiencing increased adoption in automotive manufacturing processes. The global automotive coatings market, valued at $21 billion in 2020, is projected to reach $27 billion by 2025, indicating a positive outlook for DPG demand.

Geographically, Asia-Pacific remains the largest and fastest-growing market for DPG, driven by rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe follow closely, with mature markets showing steady demand growth, particularly in high-end personal care and pharmaceutical applications.

The market trends indicate a growing preference for bio-based and sustainable alternatives, presenting both a challenge and an opportunity for DPG manufacturers. Innovations in green chemistry and sustainable production methods for DPG are likely to shape future market dynamics and consumer preferences.

Technical Challenges

Despite the widespread use of dipropylene glycol (DPG) in various industries, several technical challenges persist in its application for advanced product development. One of the primary obstacles is the optimization of DPG's hygroscopic properties. While its ability to absorb moisture is beneficial in certain applications, it can also lead to stability issues in formulations, particularly in cosmetics and personal care products. Researchers are grappling with finding the right balance to maintain product efficacy without compromising shelf life or performance.

Another significant challenge lies in the purification process of DPG. Current methods often result in residual impurities that can affect the overall quality and performance of end products. Developing more efficient and cost-effective purification techniques is crucial for enhancing DPG's suitability in high-purity applications, such as in the pharmaceutical and electronics industries.

The environmental impact of DPG production and usage also presents a technical hurdle. As sustainability becomes increasingly important, there is a growing need to develop greener synthesis routes and improve the biodegradability of DPG-based products. This challenge extends to finding ways to reduce energy consumption and minimize waste generation during the manufacturing process.

Compatibility issues with certain materials pose another technical challenge. DPG's solvent properties, while advantageous in many scenarios, can lead to degradation or unwanted interactions with some polymers and plastics. This limits its application in certain packaging materials and requires ongoing research to develop compatible alternatives or protective measures.

Furthermore, the viscosity of DPG at different temperatures and concentrations can be problematic in some applications. Formulating products that maintain consistent flow properties across various environmental conditions remains a challenge, particularly in industries such as automotive and aerospace where temperature fluctuations are common.

Lastly, the regulatory landscape surrounding DPG usage is becoming increasingly complex. Meeting stringent safety and quality standards while maintaining the desired functional properties of DPG in various applications requires continuous innovation in formulation and testing methodologies. This challenge is particularly acute in the food and beverage industry, where regulations on food-contact materials are becoming more rigorous.

Addressing these technical challenges is crucial for unlocking the full potential of DPG in advanced product development. Overcoming these hurdles will not only enhance the versatility and effectiveness of DPG-based products but also open up new avenues for innovation across multiple industries.

Another significant challenge lies in the purification process of DPG. Current methods often result in residual impurities that can affect the overall quality and performance of end products. Developing more efficient and cost-effective purification techniques is crucial for enhancing DPG's suitability in high-purity applications, such as in the pharmaceutical and electronics industries.

The environmental impact of DPG production and usage also presents a technical hurdle. As sustainability becomes increasingly important, there is a growing need to develop greener synthesis routes and improve the biodegradability of DPG-based products. This challenge extends to finding ways to reduce energy consumption and minimize waste generation during the manufacturing process.

Compatibility issues with certain materials pose another technical challenge. DPG's solvent properties, while advantageous in many scenarios, can lead to degradation or unwanted interactions with some polymers and plastics. This limits its application in certain packaging materials and requires ongoing research to develop compatible alternatives or protective measures.

Furthermore, the viscosity of DPG at different temperatures and concentrations can be problematic in some applications. Formulating products that maintain consistent flow properties across various environmental conditions remains a challenge, particularly in industries such as automotive and aerospace where temperature fluctuations are common.

Lastly, the regulatory landscape surrounding DPG usage is becoming increasingly complex. Meeting stringent safety and quality standards while maintaining the desired functional properties of DPG in various applications requires continuous innovation in formulation and testing methodologies. This challenge is particularly acute in the food and beverage industry, where regulations on food-contact materials are becoming more rigorous.

Addressing these technical challenges is crucial for unlocking the full potential of DPG in advanced product development. Overcoming these hurdles will not only enhance the versatility and effectiveness of DPG-based products but also open up new avenues for innovation across multiple industries.

Current DPG Applications

01 Solvent and carrier properties

Dipropylene glycol is widely used as a solvent and carrier in various applications due to its excellent solvency and ability to dissolve both polar and non-polar substances. It can effectively dissolve and carry active ingredients in cosmetics, personal care products, and industrial formulations, enhancing their performance and stability.- Solvent and carrier properties: Dipropylene glycol is widely used as a solvent and carrier in various applications due to its excellent solvency and low volatility. It can dissolve a wide range of substances, making it useful in formulations for cosmetics, personal care products, and industrial applications. Its ability to act as a carrier helps in the even distribution of active ingredients.

- Humectant and moisturizing properties: As a humectant, dipropylene glycol helps to retain moisture in formulations and on the skin. It attracts and holds water, making it valuable in skincare and haircare products. This property also makes it useful in industrial applications where moisture retention is important, such as in paints and coatings.

- Viscosity control and stabilization: Dipropylene glycol can be used to adjust the viscosity of formulations and improve their stability. It helps in creating the desired texture and flow properties in various products, from cosmetics to industrial fluids. Its stabilizing effect can extend the shelf life of products and prevent separation of ingredients.

- Fragrance and flavor enhancer: In the fragrance and flavor industry, dipropylene glycol is used as a diluent and fixative. It helps to blend and stabilize fragrances, allowing for better dispersion and longevity of scents. In food applications, it can be used as a solvent for flavors, enhancing their distribution and stability in various products.

- Heat transfer and antifreeze properties: Dipropylene glycol exhibits excellent heat transfer properties, making it suitable for use in cooling systems and heat transfer fluids. Its antifreeze properties also make it valuable in applications where low-temperature stability is required, such as in automotive and industrial cooling systems.

02 Humectant and moisturizing agent

As a humectant, dipropylene glycol helps to retain moisture in formulations and on the skin. It attracts and holds water, making it an effective moisturizing agent in skincare and personal care products. This property also helps to prevent products from drying out and maintains their consistency over time.Expand Specific Solutions03 Viscosity modifier and stabilizer

Dipropylene glycol can be used to adjust the viscosity of formulations, improving their texture and flow properties. It also acts as a stabilizer, helping to maintain the consistency and prevent separation of ingredients in various products, including cosmetics, pharmaceuticals, and industrial applications.Expand Specific Solutions04 Low toxicity and skin-friendly

Dipropylene glycol is known for its low toxicity and good skin compatibility. It is less irritating compared to other glycols, making it suitable for use in a wide range of personal care and cosmetic products. This property also makes it a preferred choice in pharmaceutical formulations and food-grade applications.Expand Specific Solutions05 Heat transfer and antifreeze properties

In industrial applications, dipropylene glycol is used as a heat transfer fluid and antifreeze agent. It has a high boiling point and low freezing point, making it suitable for use in cooling systems, heat exchangers, and other applications where temperature control is critical. Its thermal stability contributes to the efficiency and longevity of these systems.Expand Specific Solutions

Key Industry Players

The research on Dipropylene Glycol's key benefits for advanced product development is currently in a growth phase, with increasing market demand and technological advancements. The global market for this versatile chemical is expanding, driven by its applications in various industries such as personal care, pharmaceuticals, and industrial solvents. Major players like BASF Corp., Shell Oil Co., and Dow Global Technologies LLC are at the forefront of innovation, investing in R&D to enhance product performance and sustainability. Emerging companies like Hyconix, Inc. and GlycosBio, Inc. are also contributing to the field with novel approaches. The technology is reaching maturity, with established production processes, but there is still room for optimization and new applications, particularly in eco-friendly formulations.

BASF Corp.

Technical Solution: BASF has developed advanced production methods for dipropylene glycol (DPG) using their proprietary HPPO (hydrogen peroxide to propylene oxide) technology. This process offers improved selectivity and yield, resulting in higher purity DPG[1]. BASF's research focuses on enhancing DPG's performance in various applications, including polyurethanes, unsaturated polyester resins, and plasticizers. They have also explored the use of bio-based feedstocks to produce more sustainable DPG variants, aligning with growing market demands for eco-friendly chemicals[2].

Strengths: High-purity product, sustainable production methods, wide application range. Weaknesses: Potentially higher production costs, dependence on specific raw materials.

Shell Oil Co.

Technical Solution: Shell has invested in research to optimize the production of dipropylene glycol as a co-product of their propylene oxide manufacturing process. Their approach focuses on maximizing the yield and quality of DPG while minimizing energy consumption. Shell's scientists have developed novel catalysts that improve selectivity towards DPG formation, reducing unwanted by-products[3]. Additionally, they have explored the use of DPG in next-generation heat transfer fluids and as a key component in high-performance lubricants, leveraging its excellent thermal stability and low volatility[4].

Strengths: Efficient production process, high-quality product, diverse application development. Weaknesses: Limited focus on bio-based alternatives, potential environmental concerns with traditional production methods.

DPG Properties Analysis

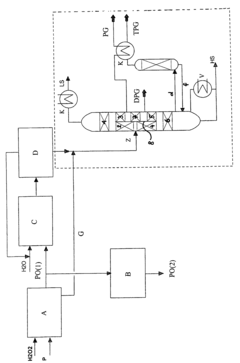

Method for the continuous production of propylene glycol

PatentInactiveUS7084310B2

Innovation

- A continuous process where propylene is reacted with hydrogen peroxide to form propylene oxide and glycols, followed by reaction with water to produce propylene glycols, using a dividing wall column and a thermally coupled column for separation, allowing the use of crude propylene oxide and reducing the number of distillation columns needed.

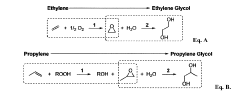

Direct oxidation of olefins to oxygenated species

PatentWO2018218186A1

Innovation

- A process involving the direct oxidation of alkenes using an oxidizing electrophile with a main group element in a liquid medium containing an oxygen acid and optional additives, which selectively forms oxygenates that can be separated and hydrolyzed to produce glycols without the need for epoxide intermediates or halides.

Regulatory Considerations

Regulatory considerations play a crucial role in the development and application of dipropylene glycol (DPG) in advanced product formulations. As a widely used industrial solvent and chemical intermediate, DPG is subject to various regulations and guidelines across different regions and industries.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). The substance is listed on the TSCA Inventory, which means it has been assessed for potential risks to human health and the environment. Manufacturers and importers must comply with reporting requirements and any specific regulations related to its use.

The Food and Drug Administration (FDA) also has oversight on DPG when used in food contact materials, cosmetics, and certain pharmaceutical applications. For instance, DPG is generally recognized as safe (GRAS) for use as a direct food additive in specific applications, subject to certain limitations.

In the European Union, DPG falls under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Companies manufacturing or importing DPG in quantities of one tonne or more per year are required to register the substance with the European Chemicals Agency (ECHA) and provide safety data.

The Classification, Labeling, and Packaging (CLP) Regulation in the EU also applies to DPG, ensuring that the hazards presented by chemicals are clearly communicated to workers and consumers through classification and labeling.

For cosmetic applications, DPG is listed in the EU Cosmetic Regulation (EC) No 1223/2009 as an approved ingredient, subject to specific concentration limits and usage restrictions.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the registration and management of new chemical substances, which includes DPG. Japan's Chemical Substances Control Law (CSCL) similarly regulates the manufacture, import, and use of chemical substances.

Globally, the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, which many countries have adopted or are in the process of implementing.

When developing advanced products using DPG, manufacturers must consider these regulatory frameworks and ensure compliance with relevant standards. This includes maintaining proper documentation, conducting necessary safety assessments, and adhering to labeling and packaging requirements.

Moreover, as sustainability becomes increasingly important, regulations around environmental impact and disposal of DPG-containing products are likely to evolve. Manufacturers should stay informed about emerging regulations and industry best practices to ensure long-term compliance and product viability.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). The substance is listed on the TSCA Inventory, which means it has been assessed for potential risks to human health and the environment. Manufacturers and importers must comply with reporting requirements and any specific regulations related to its use.

The Food and Drug Administration (FDA) also has oversight on DPG when used in food contact materials, cosmetics, and certain pharmaceutical applications. For instance, DPG is generally recognized as safe (GRAS) for use as a direct food additive in specific applications, subject to certain limitations.

In the European Union, DPG falls under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Companies manufacturing or importing DPG in quantities of one tonne or more per year are required to register the substance with the European Chemicals Agency (ECHA) and provide safety data.

The Classification, Labeling, and Packaging (CLP) Regulation in the EU also applies to DPG, ensuring that the hazards presented by chemicals are clearly communicated to workers and consumers through classification and labeling.

For cosmetic applications, DPG is listed in the EU Cosmetic Regulation (EC) No 1223/2009 as an approved ingredient, subject to specific concentration limits and usage restrictions.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the registration and management of new chemical substances, which includes DPG. Japan's Chemical Substances Control Law (CSCL) similarly regulates the manufacture, import, and use of chemical substances.

Globally, the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, which many countries have adopted or are in the process of implementing.

When developing advanced products using DPG, manufacturers must consider these regulatory frameworks and ensure compliance with relevant standards. This includes maintaining proper documentation, conducting necessary safety assessments, and adhering to labeling and packaging requirements.

Moreover, as sustainability becomes increasingly important, regulations around environmental impact and disposal of DPG-containing products are likely to evolve. Manufacturers should stay informed about emerging regulations and industry best practices to ensure long-term compliance and product viability.

Environmental Impact

Dipropylene glycol (DPG) has gained significant attention in advanced product development due to its versatile properties and potential environmental benefits. When considering the environmental impact of DPG, several key factors come into play, including its production process, biodegradability, and overall lifecycle assessment.

The production of DPG involves the reaction of propylene oxide with water, resulting in a mixture of isomers. This process is generally considered to have a lower environmental footprint compared to the production of some other glycols. The raw materials used in DPG production are readily available and can be derived from both petrochemical and renewable sources, offering flexibility in terms of resource utilization.

One of the most notable environmental advantages of DPG is its biodegradability. Studies have shown that DPG can be readily biodegraded in both aerobic and anaerobic conditions, reducing its long-term environmental persistence. This characteristic makes DPG an attractive option for products that may eventually be released into the environment, such as personal care items or cleaning products.

In terms of toxicity, DPG has demonstrated low acute toxicity to aquatic organisms and is not considered to be bioaccumulative. This further supports its use in environmentally sensitive applications and contributes to its overall positive environmental profile.

The use of DPG in various products can also lead to indirect environmental benefits. For instance, when used as a solvent or carrier in paints and coatings, DPG can help reduce the overall volatile organic compound (VOC) content, contributing to improved air quality and reduced smog formation. Similarly, its use in hydraulic fluids can provide better thermal stability and reduced leakage, potentially decreasing the frequency of fluid changes and disposal.

From a lifecycle perspective, the environmental impact of DPG extends beyond its production and use phases. Its ability to enhance product performance and extend product lifespans in certain applications can lead to reduced material consumption and waste generation over time. For example, when used in lubricants or coolants, DPG can improve efficiency and longevity, potentially reducing the need for frequent replacements.

However, it is important to note that the environmental impact of DPG is not entirely without concerns. Like many chemical compounds, its production still relies on energy-intensive processes and may contribute to greenhouse gas emissions. Additionally, while DPG is biodegradable, improper disposal or accidental release in large quantities could still have localized environmental effects.

As industries continue to prioritize sustainability, ongoing research and development efforts are focused on further improving the environmental profile of DPG. This includes exploring more efficient production methods, increasing the use of renewable feedstocks, and optimizing its application in various products to maximize environmental benefits while minimizing potential drawbacks.

The production of DPG involves the reaction of propylene oxide with water, resulting in a mixture of isomers. This process is generally considered to have a lower environmental footprint compared to the production of some other glycols. The raw materials used in DPG production are readily available and can be derived from both petrochemical and renewable sources, offering flexibility in terms of resource utilization.

One of the most notable environmental advantages of DPG is its biodegradability. Studies have shown that DPG can be readily biodegraded in both aerobic and anaerobic conditions, reducing its long-term environmental persistence. This characteristic makes DPG an attractive option for products that may eventually be released into the environment, such as personal care items or cleaning products.

In terms of toxicity, DPG has demonstrated low acute toxicity to aquatic organisms and is not considered to be bioaccumulative. This further supports its use in environmentally sensitive applications and contributes to its overall positive environmental profile.

The use of DPG in various products can also lead to indirect environmental benefits. For instance, when used as a solvent or carrier in paints and coatings, DPG can help reduce the overall volatile organic compound (VOC) content, contributing to improved air quality and reduced smog formation. Similarly, its use in hydraulic fluids can provide better thermal stability and reduced leakage, potentially decreasing the frequency of fluid changes and disposal.

From a lifecycle perspective, the environmental impact of DPG extends beyond its production and use phases. Its ability to enhance product performance and extend product lifespans in certain applications can lead to reduced material consumption and waste generation over time. For example, when used in lubricants or coolants, DPG can improve efficiency and longevity, potentially reducing the need for frequent replacements.

However, it is important to note that the environmental impact of DPG is not entirely without concerns. Like many chemical compounds, its production still relies on energy-intensive processes and may contribute to greenhouse gas emissions. Additionally, while DPG is biodegradable, improper disposal or accidental release in large quantities could still have localized environmental effects.

As industries continue to prioritize sustainability, ongoing research and development efforts are focused on further improving the environmental profile of DPG. This includes exploring more efficient production methods, increasing the use of renewable feedstocks, and optimizing its application in various products to maximize environmental benefits while minimizing potential drawbacks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!