How to Utilize Dipropylene Glycol for Product Enhancement?

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Background & Objectives

Dipropylene glycol (DPG) has emerged as a versatile chemical compound with a wide range of applications across various industries. Originally developed in the early 20th century, DPG has gained significant attention due to its unique properties and potential for product enhancement. This colorless, odorless, and hygroscopic liquid is a member of the glycol ether family, derived from the reaction of propylene oxide with water.

The primary objective of utilizing DPG for product enhancement is to leverage its multifaceted characteristics to improve the performance, stability, and overall quality of various products. DPG's excellent solvency, low volatility, and high boiling point make it an ideal candidate for numerous applications, including but not limited to cosmetics, personal care products, paints, coatings, and industrial cleaners.

In the realm of cosmetics and personal care, DPG serves as a humectant and solvent, helping to retain moisture and improve the texture of products. Its ability to dissolve both water-soluble and oil-soluble ingredients makes it invaluable in formulating stable and effective cosmetic preparations. The goal is to enhance product consistency, extend shelf life, and improve the overall user experience.

For the paint and coatings industry, DPG acts as a coalescing agent and solvent, contributing to the formation of uniform films and improving the flow and leveling properties of coatings. The objective here is to enhance the durability, appearance, and application characteristics of paints and coatings, ultimately leading to superior finished products.

In industrial applications, DPG's low toxicity and high solvency power make it an excellent choice for cleaning formulations. The aim is to develop more effective and environmentally friendly cleaning solutions that can tackle a wide range of contaminants while minimizing health and environmental risks.

As we explore the potential of DPG for product enhancement, it is crucial to consider the evolving regulatory landscape and increasing consumer demand for safer, more sustainable products. The objective is not only to improve product performance but also to align with global sustainability goals and stringent safety standards.

Looking ahead, the focus will be on developing innovative applications for DPG that push the boundaries of current product formulations. This includes exploring synergistic effects with other ingredients, optimizing concentration levels for specific applications, and investigating novel processing techniques to fully harness DPG's potential.

The primary objective of utilizing DPG for product enhancement is to leverage its multifaceted characteristics to improve the performance, stability, and overall quality of various products. DPG's excellent solvency, low volatility, and high boiling point make it an ideal candidate for numerous applications, including but not limited to cosmetics, personal care products, paints, coatings, and industrial cleaners.

In the realm of cosmetics and personal care, DPG serves as a humectant and solvent, helping to retain moisture and improve the texture of products. Its ability to dissolve both water-soluble and oil-soluble ingredients makes it invaluable in formulating stable and effective cosmetic preparations. The goal is to enhance product consistency, extend shelf life, and improve the overall user experience.

For the paint and coatings industry, DPG acts as a coalescing agent and solvent, contributing to the formation of uniform films and improving the flow and leveling properties of coatings. The objective here is to enhance the durability, appearance, and application characteristics of paints and coatings, ultimately leading to superior finished products.

In industrial applications, DPG's low toxicity and high solvency power make it an excellent choice for cleaning formulations. The aim is to develop more effective and environmentally friendly cleaning solutions that can tackle a wide range of contaminants while minimizing health and environmental risks.

As we explore the potential of DPG for product enhancement, it is crucial to consider the evolving regulatory landscape and increasing consumer demand for safer, more sustainable products. The objective is not only to improve product performance but also to align with global sustainability goals and stringent safety standards.

Looking ahead, the focus will be on developing innovative applications for DPG that push the boundaries of current product formulations. This includes exploring synergistic effects with other ingredients, optimizing concentration levels for specific applications, and investigating novel processing techniques to fully harness DPG's potential.

Market Demand Analysis

The market demand for dipropylene glycol (DPG) has been steadily increasing across various industries due to its versatile properties and applications in product enhancement. As a non-toxic, low-volatility solvent with excellent solvency and hygroscopic characteristics, DPG has found widespread use in personal care products, cleaning solutions, and industrial applications.

In the personal care and cosmetics industry, DPG is highly sought after as a humectant and solvent. Its ability to retain moisture and enhance product stability has led to increased incorporation in skincare formulations, hair care products, and fragrances. The growing consumer preference for long-lasting and effective personal care items has further driven the demand for DPG in this sector.

The cleaning and household products market has also witnessed a surge in DPG usage. Its excellent solvency properties make it an ideal component in all-purpose cleaners, glass cleaners, and floor care products. The rising awareness of hygiene and sanitation, especially in the wake of global health concerns, has amplified the demand for effective cleaning solutions, thereby boosting DPG consumption.

Industrial applications of DPG have expanded significantly, particularly in the paints and coatings industry. Its low volatility and ability to improve flow and leveling characteristics have made it a preferred choice for formulators seeking to enhance product performance. The booming construction and automotive sectors have further propelled the demand for high-quality paints and coatings, indirectly driving DPG market growth.

The pharmaceutical industry has also recognized the potential of DPG in drug formulations. Its solvent properties and compatibility with various active pharmaceutical ingredients have led to increased adoption in oral, topical, and injectable medications. The growing pharmaceutical market, driven by an aging population and increased healthcare spending, has contributed to the rising demand for DPG.

Environmental regulations and consumer preferences for eco-friendly products have influenced the market dynamics of DPG. As a less toxic alternative to some traditional solvents, DPG has gained favor among manufacturers looking to comply with stricter environmental standards while maintaining product efficacy. This trend is expected to continue, potentially expanding DPG's market share in various applications.

The global DPG market is projected to experience steady growth in the coming years, driven by these diverse applications and the ongoing innovation in product formulations across industries. Manufacturers are likely to focus on developing specialized grades of DPG tailored to specific industry needs, further enhancing its market potential and applications in product enhancement.

In the personal care and cosmetics industry, DPG is highly sought after as a humectant and solvent. Its ability to retain moisture and enhance product stability has led to increased incorporation in skincare formulations, hair care products, and fragrances. The growing consumer preference for long-lasting and effective personal care items has further driven the demand for DPG in this sector.

The cleaning and household products market has also witnessed a surge in DPG usage. Its excellent solvency properties make it an ideal component in all-purpose cleaners, glass cleaners, and floor care products. The rising awareness of hygiene and sanitation, especially in the wake of global health concerns, has amplified the demand for effective cleaning solutions, thereby boosting DPG consumption.

Industrial applications of DPG have expanded significantly, particularly in the paints and coatings industry. Its low volatility and ability to improve flow and leveling characteristics have made it a preferred choice for formulators seeking to enhance product performance. The booming construction and automotive sectors have further propelled the demand for high-quality paints and coatings, indirectly driving DPG market growth.

The pharmaceutical industry has also recognized the potential of DPG in drug formulations. Its solvent properties and compatibility with various active pharmaceutical ingredients have led to increased adoption in oral, topical, and injectable medications. The growing pharmaceutical market, driven by an aging population and increased healthcare spending, has contributed to the rising demand for DPG.

Environmental regulations and consumer preferences for eco-friendly products have influenced the market dynamics of DPG. As a less toxic alternative to some traditional solvents, DPG has gained favor among manufacturers looking to comply with stricter environmental standards while maintaining product efficacy. This trend is expected to continue, potentially expanding DPG's market share in various applications.

The global DPG market is projected to experience steady growth in the coming years, driven by these diverse applications and the ongoing innovation in product formulations across industries. Manufacturers are likely to focus on developing specialized grades of DPG tailored to specific industry needs, further enhancing its market potential and applications in product enhancement.

DPG Technical Challenges

Dipropylene glycol (DPG) presents several technical challenges when utilized for product enhancement. One of the primary difficulties lies in its hygroscopic nature, which can lead to moisture absorption and potential degradation of product quality over time. This characteristic requires careful consideration in formulation and packaging to maintain product stability and shelf life.

Another significant challenge is achieving optimal solubility and compatibility with other ingredients in various product formulations. DPG's unique chemical structure can sometimes result in unexpected interactions with other components, necessitating extensive testing and reformulation efforts to ensure product efficacy and consistency.

The viscosity of DPG can also pose challenges in certain applications. While its moderate viscosity is beneficial in some products, it may require adjustment or the use of additional modifiers in others to achieve the desired flow properties and texture. This can complicate manufacturing processes and increase production costs.

Temperature sensitivity is another technical hurdle when working with DPG. Its properties can change significantly with temperature fluctuations, affecting product performance and stability across different environmental conditions. This necessitates thorough testing and potentially the development of temperature-controlled manufacturing and storage processes.

Regulatory compliance presents an ongoing challenge, particularly in industries such as cosmetics and personal care. As regulations evolve, ensuring that DPG-enhanced products meet safety standards and labeling requirements across different markets can be complex and resource-intensive.

The purity of DPG used in product enhancement is crucial, yet maintaining consistent high-quality supply can be challenging. Variations in raw materials or manufacturing processes can lead to inconsistencies in DPG quality, potentially affecting the final product's performance and safety profile.

Odor management is another technical challenge associated with DPG. While generally considered to have a mild odor, in some applications, even this subtle scent can be undesirable. Developing effective masking or neutralizing strategies without compromising product efficacy can be technically demanding.

Lastly, the potential for skin irritation or sensitization in a small percentage of users poses a challenge in formulating DPG-enhanced products for widespread use. Extensive dermatological testing and the development of alternative formulations for sensitive individuals may be necessary to address this issue effectively.

Another significant challenge is achieving optimal solubility and compatibility with other ingredients in various product formulations. DPG's unique chemical structure can sometimes result in unexpected interactions with other components, necessitating extensive testing and reformulation efforts to ensure product efficacy and consistency.

The viscosity of DPG can also pose challenges in certain applications. While its moderate viscosity is beneficial in some products, it may require adjustment or the use of additional modifiers in others to achieve the desired flow properties and texture. This can complicate manufacturing processes and increase production costs.

Temperature sensitivity is another technical hurdle when working with DPG. Its properties can change significantly with temperature fluctuations, affecting product performance and stability across different environmental conditions. This necessitates thorough testing and potentially the development of temperature-controlled manufacturing and storage processes.

Regulatory compliance presents an ongoing challenge, particularly in industries such as cosmetics and personal care. As regulations evolve, ensuring that DPG-enhanced products meet safety standards and labeling requirements across different markets can be complex and resource-intensive.

The purity of DPG used in product enhancement is crucial, yet maintaining consistent high-quality supply can be challenging. Variations in raw materials or manufacturing processes can lead to inconsistencies in DPG quality, potentially affecting the final product's performance and safety profile.

Odor management is another technical challenge associated with DPG. While generally considered to have a mild odor, in some applications, even this subtle scent can be undesirable. Developing effective masking or neutralizing strategies without compromising product efficacy can be technically demanding.

Lastly, the potential for skin irritation or sensitization in a small percentage of users poses a challenge in formulating DPG-enhanced products for widespread use. Extensive dermatological testing and the development of alternative formulations for sensitive individuals may be necessary to address this issue effectively.

Current DPG Solutions

01 Use as a solvent in cosmetic formulations

Dipropylene glycol is commonly used as a solvent in various cosmetic and personal care products. It helps to dissolve and blend different ingredients, improving the overall stability and consistency of the formulation. This versatile solvent is particularly useful in products such as lotions, creams, and hair care items.- Use as a solvent in cosmetic formulations: Dipropylene glycol is commonly used as a solvent in various cosmetic and personal care products. It helps to dissolve and blend different ingredients, improving the overall stability and consistency of the formulation. This versatile compound can be found in a wide range of products, including skincare, haircare, and fragrances.

- Application in cleaning and disinfecting products: Dipropylene glycol is utilized in cleaning and disinfecting formulations due to its solvent properties and low toxicity. It can be found in household cleaners, industrial degreasers, and sanitizing solutions. The compound helps to improve the effectiveness of active ingredients and enhance the overall cleaning performance of these products.

- Use in pharmaceutical preparations: In the pharmaceutical industry, dipropylene glycol is employed as an excipient in various drug formulations. It can act as a solvent, stabilizer, or carrier for active pharmaceutical ingredients. The compound's properties make it suitable for use in oral, topical, and injectable medications.

- Application in industrial processes: Dipropylene glycol finds applications in various industrial processes, such as in the production of plastics, resins, and synthetic fibers. It can be used as a processing aid, plasticizer, or intermediate in chemical synthesis. The compound's thermal stability and low volatility make it suitable for high-temperature applications.

- Use as a humectant and moisturizer: Dipropylene glycol acts as a humectant and moisturizer in personal care and cosmetic products. It helps to attract and retain moisture, preventing dehydration of the skin and hair. This property makes it a valuable ingredient in lotions, creams, hair conditioners, and other hydrating formulations.

02 Application in fragrance and perfume industry

In the fragrance and perfume industry, dipropylene glycol serves as an important carrier and fixative for scents. It helps to enhance the longevity of fragrances and allows for better dispersion of aromatic compounds. This property makes it a valuable ingredient in perfumes, colognes, and other scented products.Expand Specific Solutions03 Use in industrial cleaning and degreasing agents

Dipropylene glycol is utilized in the formulation of industrial cleaning and degreasing agents. Its solvent properties make it effective in removing oils, greases, and other stubborn contaminants from various surfaces. It is often incorporated into cleaning solutions for machinery, equipment, and hard surfaces.Expand Specific Solutions04 Application in pharmaceutical preparations

In the pharmaceutical industry, dipropylene glycol is used as an excipient in various drug formulations. It can act as a solvent, stabilizer, or humectant in medications, helping to improve their shelf life and effectiveness. This compound is particularly useful in liquid and semi-solid pharmaceutical preparations.Expand Specific Solutions05 Use in polyurethane production

Dipropylene glycol plays a role in the production of polyurethane materials. It can be used as a chain extender or cross-linking agent in polyurethane formulations, influencing the physical properties of the final product. This application is relevant in the manufacturing of foams, coatings, and adhesives.Expand Specific Solutions

Key Industry Players

The utilization of Dipropylene Glycol for product enhancement is in a mature stage of industry development, with a significant global market size estimated to be in the billions of dollars. The technology has reached a high level of maturity, as evidenced by its widespread use across various industries. Key players in this field include major chemical companies such as China Petroleum & Chemical Corp., Colgate-Palmolive Co., and L'Oréal SA, who have integrated Dipropylene Glycol into their product formulations. Specialized chemical manufacturers like Renewable Alternatives LLC and UOP LLC are also contributing to the advancement of this technology. The competitive landscape is characterized by ongoing research and development efforts to improve product performance and find new applications, with academic institutions like Jiangnan University and the University of Wyoming also contributing to the field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative applications of dipropylene glycol (DPG) in their product enhancement strategies. They have implemented DPG as a key component in their eco-friendly hydraulic fluids, which offer improved lubricity and thermal stability[1]. Sinopec's research has shown that DPG-based hydraulic fluids can operate effectively in a wider temperature range, from -40°C to 120°C, outperforming traditional mineral oil-based fluids[2]. Additionally, they have incorporated DPG into their line of high-performance coolants, where it acts as an efficient heat transfer medium while providing excellent corrosion protection for engine components[3]. Sinopec has also explored the use of DPG in their polymer production processes, where it serves as a chain extender and plasticizer, enhancing the flexibility and durability of certain plastic products[4].

Strengths: Extensive research capabilities, diverse product applications, and strong market presence. Weaknesses: Potential environmental concerns associated with petrochemical production and reliance on fossil fuel-based raw materials.

Colgate-Palmolive Co.

Technical Solution: Colgate-Palmolive Co. has integrated dipropylene glycol (DPG) into their product enhancement strategies, particularly in their oral care and personal care lines. In their toothpaste formulations, DPG is used as a solvent and humectant, helping to maintain product consistency and prevent drying out[1]. The company's research has shown that DPG can enhance the solubility of certain active ingredients, such as fluoride, potentially improving their efficacy in dental care products[2]. In their mouthwash products, Colgate-Palmolive utilizes DPG as a flavor carrier and solubilizer, ensuring a uniform distribution of flavoring agents and active ingredients throughout the solution[3]. The company has also incorporated DPG into their personal care products, such as deodorants and antiperspirants, where it functions as a moisture-retaining agent and helps to improve the product's overall feel on the skin[4]. Additionally, Colgate-Palmolive has explored the use of DPG in their liquid soap formulations, where it acts as a solvent for fragrances and helps to maintain product viscosity[5].

Strengths: Strong brand recognition, extensive distribution network, and significant R&D capabilities. Weaknesses: Increasing consumer demand for natural and organic products may pose challenges for synthetic ingredient use.

DPG Innovation Insights

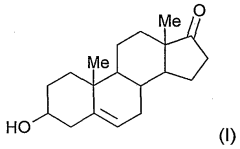

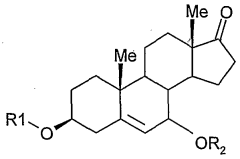

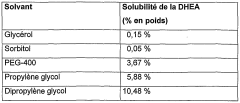

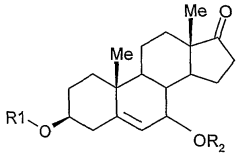

Composition containing a steroid and a glycol

PatentWO2003011244A1

Innovation

- Incorporating dipropylene glycol as a solubilizer for DHEA and its derivatives, which can be mixed at various temperatures to prevent recrystallization and enhance solubility, allowing for stable and effective topical formulations without compromising cosmetic properties.

Composition containing a steroid and a glycol

PatentInactiveEP1414403A1

Innovation

- Incorporating dipropylene glycol as a solubilizer for DHEA and its derivatives, allowing for their dissolution and stabilization, thereby preventing recrystallization and maintaining cosmetic properties.

Regulatory Compliance

Regulatory compliance is a critical aspect of utilizing dipropylene glycol (DPG) for product enhancement. As a widely used chemical compound in various industries, DPG is subject to numerous regulations and guidelines to ensure its safe and responsible use.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting requirements and adhere to specific guidelines for handling, storage, and disposal. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace exposure limits and safety measures when handling DPG.

The European Union regulates DPG under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Companies must register DPG with the European Chemicals Agency (ECHA) and provide detailed information on its properties, uses, and potential risks. The Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper labeling and packaging of DPG-containing products.

For food and beverage applications, DPG must comply with regulations set by the Food and Drug Administration (FDA) in the US and the European Food Safety Authority (EFSA) in the EU. These agencies establish acceptable daily intake levels and specific use conditions for DPG as a food additive or indirect food contact substance.

In the cosmetics industry, DPG is regulated by the FDA's Federal Food, Drug, and Cosmetic Act in the US and the EU Cosmetics Regulation. These regulations ensure that DPG is used within safe concentration limits and that products containing DPG are properly labeled.

Companies utilizing DPG for product enhancement must also consider international regulations, as many countries have their own specific requirements. For example, China's Ministry of Environmental Protection regulates DPG under the Measures for Environmental Management of New Chemical Substances.

To ensure compliance, companies should implement robust quality control systems, maintain detailed documentation of DPG usage and handling procedures, and regularly update their knowledge of relevant regulations. This may include conducting periodic audits, providing employee training on regulatory requirements, and staying informed about any changes in legislation that may affect DPG use.

Furthermore, companies should consider obtaining relevant certifications, such as ISO 9001 for quality management or ISO 14001 for environmental management, to demonstrate their commitment to regulatory compliance and product safety.

As regulations continue to evolve, particularly in response to growing environmental and health concerns, companies must remain vigilant and adaptable. This may involve investing in research and development to find alternative substances or developing new formulations that meet stricter regulatory standards while still achieving desired product enhancements.

In the United States, the Environmental Protection Agency (EPA) regulates DPG under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting requirements and adhere to specific guidelines for handling, storage, and disposal. The Occupational Safety and Health Administration (OSHA) also sets standards for workplace exposure limits and safety measures when handling DPG.

The European Union regulates DPG under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Companies must register DPG with the European Chemicals Agency (ECHA) and provide detailed information on its properties, uses, and potential risks. The Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper labeling and packaging of DPG-containing products.

For food and beverage applications, DPG must comply with regulations set by the Food and Drug Administration (FDA) in the US and the European Food Safety Authority (EFSA) in the EU. These agencies establish acceptable daily intake levels and specific use conditions for DPG as a food additive or indirect food contact substance.

In the cosmetics industry, DPG is regulated by the FDA's Federal Food, Drug, and Cosmetic Act in the US and the EU Cosmetics Regulation. These regulations ensure that DPG is used within safe concentration limits and that products containing DPG are properly labeled.

Companies utilizing DPG for product enhancement must also consider international regulations, as many countries have their own specific requirements. For example, China's Ministry of Environmental Protection regulates DPG under the Measures for Environmental Management of New Chemical Substances.

To ensure compliance, companies should implement robust quality control systems, maintain detailed documentation of DPG usage and handling procedures, and regularly update their knowledge of relevant regulations. This may include conducting periodic audits, providing employee training on regulatory requirements, and staying informed about any changes in legislation that may affect DPG use.

Furthermore, companies should consider obtaining relevant certifications, such as ISO 9001 for quality management or ISO 14001 for environmental management, to demonstrate their commitment to regulatory compliance and product safety.

As regulations continue to evolve, particularly in response to growing environmental and health concerns, companies must remain vigilant and adaptable. This may involve investing in research and development to find alternative substances or developing new formulations that meet stricter regulatory standards while still achieving desired product enhancements.

Environmental Impact

The utilization of dipropylene glycol (DPG) for product enhancement raises important considerations regarding its environmental impact. DPG, a synthetic organic compound, is widely used in various industries due to its versatile properties. However, its production, use, and disposal can have significant implications for the environment.

In terms of production, DPG is typically synthesized through the hydration of propylene oxide, a process that requires energy and resources. The manufacturing process may contribute to greenhouse gas emissions and potentially generate hazardous waste byproducts. However, advancements in green chemistry and sustainable manufacturing practices have led to more environmentally friendly production methods, reducing the overall ecological footprint of DPG production.

When considering the use phase of DPG-enhanced products, it is essential to evaluate the compound's biodegradability and potential for bioaccumulation. Studies have shown that DPG is generally biodegradable under aerobic conditions, with a relatively short half-life in the environment. This characteristic reduces the risk of long-term environmental persistence and accumulation in ecosystems.

Water solubility is another crucial factor in assessing the environmental impact of DPG. The compound's high water solubility can lead to its dispersion in aquatic environments if not properly managed. While DPG itself has low toxicity to aquatic organisms, its presence in water bodies may alter the natural balance of ecosystems. Proper wastewater treatment and responsible disposal practices are essential to mitigate potential adverse effects on aquatic life.

Air quality is also a consideration when evaluating the environmental impact of DPG. The compound has a low vapor pressure, which means it is less likely to contribute significantly to air pollution through evaporation. However, in certain applications where DPG-containing products are aerosolized or heated, there may be localized air quality concerns that require appropriate ventilation and emission control measures.

From a lifecycle perspective, the environmental impact of DPG extends to its end-of-life management. Proper disposal and recycling of DPG-containing products are crucial to prevent environmental contamination. Many industries have implemented closed-loop systems and recycling programs to recover and reuse DPG, reducing waste generation and minimizing the need for virgin material production.

It is worth noting that the environmental impact of DPG can vary depending on its specific application and the product it enhances. For instance, when used in personal care products, the potential for direct release into the environment through rinsing or washing may be higher compared to its use in industrial applications with controlled processes. Therefore, a comprehensive assessment of the environmental impact should consider the entire lifecycle of DPG-enhanced products, from raw material extraction to disposal or recycling.

In terms of production, DPG is typically synthesized through the hydration of propylene oxide, a process that requires energy and resources. The manufacturing process may contribute to greenhouse gas emissions and potentially generate hazardous waste byproducts. However, advancements in green chemistry and sustainable manufacturing practices have led to more environmentally friendly production methods, reducing the overall ecological footprint of DPG production.

When considering the use phase of DPG-enhanced products, it is essential to evaluate the compound's biodegradability and potential for bioaccumulation. Studies have shown that DPG is generally biodegradable under aerobic conditions, with a relatively short half-life in the environment. This characteristic reduces the risk of long-term environmental persistence and accumulation in ecosystems.

Water solubility is another crucial factor in assessing the environmental impact of DPG. The compound's high water solubility can lead to its dispersion in aquatic environments if not properly managed. While DPG itself has low toxicity to aquatic organisms, its presence in water bodies may alter the natural balance of ecosystems. Proper wastewater treatment and responsible disposal practices are essential to mitigate potential adverse effects on aquatic life.

Air quality is also a consideration when evaluating the environmental impact of DPG. The compound has a low vapor pressure, which means it is less likely to contribute significantly to air pollution through evaporation. However, in certain applications where DPG-containing products are aerosolized or heated, there may be localized air quality concerns that require appropriate ventilation and emission control measures.

From a lifecycle perspective, the environmental impact of DPG extends to its end-of-life management. Proper disposal and recycling of DPG-containing products are crucial to prevent environmental contamination. Many industries have implemented closed-loop systems and recycling programs to recover and reuse DPG, reducing waste generation and minimizing the need for virgin material production.

It is worth noting that the environmental impact of DPG can vary depending on its specific application and the product it enhances. For instance, when used in personal care products, the potential for direct release into the environment through rinsing or washing may be higher compared to its use in industrial applications with controlled processes. Therefore, a comprehensive assessment of the environmental impact should consider the entire lifecycle of DPG-enhanced products, from raw material extraction to disposal or recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!