Dipropylene Glycol in Modern Perfume Crafting: Developing Excellence

JUL 7, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dipropylene Glycol Evolution in Perfumery

Dipropylene glycol (DPG) has played a pivotal role in the evolution of modern perfumery, transforming the industry's approach to fragrance creation and formulation. Initially introduced as a solvent in the mid-20th century, DPG quickly gained prominence due to its unique properties that addressed several challenges faced by perfumers.

In the early stages of its adoption, DPG was primarily used as a diluent for essential oils and fragrance compounds. Its low odor profile and ability to dissolve a wide range of aromatic materials made it an ideal carrier for complex fragrance formulations. This allowed perfumers to create more intricate and layered scents, expanding the creative possibilities in fragrance design.

As the perfume industry progressed, the role of DPG evolved beyond that of a simple solvent. Perfumers discovered its potential as a fixative, helping to stabilize volatile fragrance components and extend the longevity of scents on the skin. This property became particularly valuable in the development of long-lasting perfumes and colognes, meeting the growing consumer demand for fragrances with improved staying power.

The 1980s and 1990s saw a significant shift in perfume formulation techniques, with DPG becoming an integral part of the perfumer's palette. Its low volatility and excellent solvency properties allowed for the creation of more complex and harmonious fragrance accords. This period marked the emergence of new fragrance families and innovative scent combinations that were previously challenging to achieve.

In recent years, the use of DPG has become more sophisticated, with perfumers leveraging its properties to enhance specific aspects of fragrance performance. Its ability to modulate the release of fragrance notes has been exploited to create perfumes with improved sillage and diffusion characteristics. Additionally, DPG has been instrumental in the development of alcohol-free and water-based fragrances, opening up new market segments and addressing environmental concerns.

The evolution of DPG in perfumery has also been influenced by advancements in analytical techniques and a deeper understanding of olfactory science. Perfumers now have a more nuanced appreciation of how DPG interacts with different fragrance materials at a molecular level, allowing for more precise and targeted use in formulations.

As the perfume industry continues to innovate, DPG remains a crucial component in modern fragrance crafting. Its versatility and compatibility with a wide range of ingredients make it an indispensable tool for perfumers striving to create exceptional and long-lasting fragrances. The ongoing evolution of DPG in perfumery underscores its enduring importance in the pursuit of olfactory excellence.

In the early stages of its adoption, DPG was primarily used as a diluent for essential oils and fragrance compounds. Its low odor profile and ability to dissolve a wide range of aromatic materials made it an ideal carrier for complex fragrance formulations. This allowed perfumers to create more intricate and layered scents, expanding the creative possibilities in fragrance design.

As the perfume industry progressed, the role of DPG evolved beyond that of a simple solvent. Perfumers discovered its potential as a fixative, helping to stabilize volatile fragrance components and extend the longevity of scents on the skin. This property became particularly valuable in the development of long-lasting perfumes and colognes, meeting the growing consumer demand for fragrances with improved staying power.

The 1980s and 1990s saw a significant shift in perfume formulation techniques, with DPG becoming an integral part of the perfumer's palette. Its low volatility and excellent solvency properties allowed for the creation of more complex and harmonious fragrance accords. This period marked the emergence of new fragrance families and innovative scent combinations that were previously challenging to achieve.

In recent years, the use of DPG has become more sophisticated, with perfumers leveraging its properties to enhance specific aspects of fragrance performance. Its ability to modulate the release of fragrance notes has been exploited to create perfumes with improved sillage and diffusion characteristics. Additionally, DPG has been instrumental in the development of alcohol-free and water-based fragrances, opening up new market segments and addressing environmental concerns.

The evolution of DPG in perfumery has also been influenced by advancements in analytical techniques and a deeper understanding of olfactory science. Perfumers now have a more nuanced appreciation of how DPG interacts with different fragrance materials at a molecular level, allowing for more precise and targeted use in formulations.

As the perfume industry continues to innovate, DPG remains a crucial component in modern fragrance crafting. Its versatility and compatibility with a wide range of ingredients make it an indispensable tool for perfumers striving to create exceptional and long-lasting fragrances. The ongoing evolution of DPG in perfumery underscores its enduring importance in the pursuit of olfactory excellence.

Market Trends in DPG-based Fragrances

The fragrance industry has witnessed a significant shift towards DPG-based fragrances in recent years, driven by consumer preferences for longer-lasting and more complex scent profiles. This trend is particularly evident in the premium and luxury segments, where consumers are willing to pay a premium for high-quality, long-lasting fragrances.

Market research indicates that the global DPG-based fragrance market is experiencing steady growth, with a compound annual growth rate (CAGR) projected to exceed the overall fragrance market growth rate. This growth is attributed to the increasing demand for personal care products, rising disposable incomes, and changing consumer lifestyles.

One of the key drivers of this trend is the growing awareness of sustainability and eco-friendliness among consumers. DPG, being a biodegradable and non-toxic substance, aligns well with the increasing demand for environmentally responsible products. This has led to a surge in the development of "green" fragrances that utilize DPG as a primary solvent.

The Asia-Pacific region has emerged as a hotspot for DPG-based fragrances, with countries like China and India showing rapid market expansion. This growth is fueled by a rising middle class, urbanization, and increasing adoption of Western beauty standards. North America and Europe continue to be significant markets, with a focus on premium and niche fragrances incorporating DPG.

In terms of product categories, DPG-based fragrances are gaining traction in both personal fragrances and home care products. The personal fragrance segment, including perfumes, colognes, and body sprays, remains the largest market for DPG-based formulations. However, the home care segment, encompassing air fresheners, scented candles, and diffusers, is showing promising growth potential.

The trend towards customization and personalization in the fragrance industry is also influencing the DPG-based fragrance market. Consumers are increasingly seeking unique, tailored scent experiences, leading to the rise of bespoke fragrance services and niche perfume houses that often utilize DPG in their formulations.

Another notable trend is the integration of DPG-based fragrances with technology. Smart fragrance devices and IoT-enabled scent diffusers are emerging, offering consumers more control over their olfactory environments. These innovations often rely on DPG-based formulations for their stability and performance characteristics.

As the market for DPG-based fragrances continues to evolve, fragrance houses and perfumers are investing in research and development to create more sophisticated and nuanced scent profiles. This includes exploring new combinations of natural and synthetic ingredients that work synergistically with DPG to produce unique olfactory experiences.

Market research indicates that the global DPG-based fragrance market is experiencing steady growth, with a compound annual growth rate (CAGR) projected to exceed the overall fragrance market growth rate. This growth is attributed to the increasing demand for personal care products, rising disposable incomes, and changing consumer lifestyles.

One of the key drivers of this trend is the growing awareness of sustainability and eco-friendliness among consumers. DPG, being a biodegradable and non-toxic substance, aligns well with the increasing demand for environmentally responsible products. This has led to a surge in the development of "green" fragrances that utilize DPG as a primary solvent.

The Asia-Pacific region has emerged as a hotspot for DPG-based fragrances, with countries like China and India showing rapid market expansion. This growth is fueled by a rising middle class, urbanization, and increasing adoption of Western beauty standards. North America and Europe continue to be significant markets, with a focus on premium and niche fragrances incorporating DPG.

In terms of product categories, DPG-based fragrances are gaining traction in both personal fragrances and home care products. The personal fragrance segment, including perfumes, colognes, and body sprays, remains the largest market for DPG-based formulations. However, the home care segment, encompassing air fresheners, scented candles, and diffusers, is showing promising growth potential.

The trend towards customization and personalization in the fragrance industry is also influencing the DPG-based fragrance market. Consumers are increasingly seeking unique, tailored scent experiences, leading to the rise of bespoke fragrance services and niche perfume houses that often utilize DPG in their formulations.

Another notable trend is the integration of DPG-based fragrances with technology. Smart fragrance devices and IoT-enabled scent diffusers are emerging, offering consumers more control over their olfactory environments. These innovations often rely on DPG-based formulations for their stability and performance characteristics.

As the market for DPG-based fragrances continues to evolve, fragrance houses and perfumers are investing in research and development to create more sophisticated and nuanced scent profiles. This includes exploring new combinations of natural and synthetic ingredients that work synergistically with DPG to produce unique olfactory experiences.

Current Challenges in DPG Utilization

Despite the widespread use of Dipropylene Glycol (DPG) in modern perfumery, several challenges persist in its utilization, hindering the full realization of its potential in fragrance development. One of the primary concerns is the variability in DPG quality across different suppliers. This inconsistency can lead to unpredictable interactions with fragrance compounds, potentially altering the intended scent profile and stability of the final product.

Another significant challenge lies in the solubility limitations of certain fragrance ingredients in DPG. While DPG is an excellent solvent for many aroma chemicals, some natural essential oils and complex molecules exhibit limited solubility, necessitating the use of additional solvents or careful formulation adjustments. This can complicate the perfume creation process and potentially impact the overall cost-effectiveness of production.

The hygroscopic nature of DPG presents another hurdle for perfumers. Its tendency to absorb moisture from the air can affect the long-term stability of fragrances, particularly in humid environments. This characteristic requires careful consideration in packaging design and storage recommendations to maintain the integrity of the perfume over time.

Furthermore, the regulatory landscape surrounding DPG usage in cosmetics and fragrances is becoming increasingly complex. While generally recognized as safe, evolving regulations in different global markets may impose new restrictions or labeling requirements, necessitating ongoing vigilance and potential reformulation efforts to ensure compliance across diverse geographical regions.

The environmental impact of DPG production and disposal is also emerging as a concern in the context of sustainability initiatives within the fragrance industry. As consumers become more environmentally conscious, there is growing pressure to develop and utilize more sustainable alternatives or improve the eco-friendly credentials of DPG manufacturing processes.

Lastly, the optimization of DPG concentration in fragrance formulations remains a delicate balancing act. Too little DPG may compromise the diffusion and longevity of the scent, while excessive use can dilute the fragrance intensity or introduce unwanted olfactory characteristics. Achieving the ideal balance requires extensive experimentation and expertise, presenting an ongoing challenge in perfume crafting excellence.

Another significant challenge lies in the solubility limitations of certain fragrance ingredients in DPG. While DPG is an excellent solvent for many aroma chemicals, some natural essential oils and complex molecules exhibit limited solubility, necessitating the use of additional solvents or careful formulation adjustments. This can complicate the perfume creation process and potentially impact the overall cost-effectiveness of production.

The hygroscopic nature of DPG presents another hurdle for perfumers. Its tendency to absorb moisture from the air can affect the long-term stability of fragrances, particularly in humid environments. This characteristic requires careful consideration in packaging design and storage recommendations to maintain the integrity of the perfume over time.

Furthermore, the regulatory landscape surrounding DPG usage in cosmetics and fragrances is becoming increasingly complex. While generally recognized as safe, evolving regulations in different global markets may impose new restrictions or labeling requirements, necessitating ongoing vigilance and potential reformulation efforts to ensure compliance across diverse geographical regions.

The environmental impact of DPG production and disposal is also emerging as a concern in the context of sustainability initiatives within the fragrance industry. As consumers become more environmentally conscious, there is growing pressure to develop and utilize more sustainable alternatives or improve the eco-friendly credentials of DPG manufacturing processes.

Lastly, the optimization of DPG concentration in fragrance formulations remains a delicate balancing act. Too little DPG may compromise the diffusion and longevity of the scent, while excessive use can dilute the fragrance intensity or introduce unwanted olfactory characteristics. Achieving the ideal balance requires extensive experimentation and expertise, presenting an ongoing challenge in perfume crafting excellence.

Modern DPG Formulation Techniques

01 Solvent properties of dipropylene glycol

Dipropylene glycol is widely used as a solvent in various applications due to its excellent solubility and compatibility with other substances. It is particularly effective in dissolving both polar and non-polar compounds, making it versatile in formulations for cosmetics, personal care products, and industrial applications.- Solvent properties of dipropylene glycol: Dipropylene glycol is widely used as a solvent in various applications due to its excellent solubility properties. It can dissolve a wide range of substances, making it useful in formulations for cosmetics, personal care products, and industrial applications. Its low volatility and high boiling point contribute to its effectiveness as a solvent.

- Humectant and moisturizing properties: Dipropylene glycol exhibits excellent humectant and moisturizing properties, making it a valuable ingredient in skincare and personal care products. It helps to attract and retain moisture, improving the hydration of the skin and hair. This property also makes it useful in various industrial applications where moisture retention is important.

- Use in fragrance and flavor formulations: Dipropylene glycol is commonly used in fragrance and flavor formulations due to its ability to dissolve and carry aromatic compounds. It helps to stabilize and enhance the performance of fragrances and flavors in various products, including perfumes, air fresheners, and food additives.

- Application in polyurethane production: Dipropylene glycol is an important raw material in the production of polyurethanes. It serves as a chain extender and crosslinking agent, contributing to the flexibility, durability, and other physical properties of polyurethane products. This makes it valuable in the manufacture of foams, coatings, adhesives, and elastomers.

- Use in heat transfer fluids: Dipropylene glycol's excellent thermal stability and low freezing point make it suitable for use in heat transfer fluids. It is often used in cooling systems, antifreeze formulations, and other applications where efficient heat transfer is required. Its low toxicity also makes it a safer alternative to some other heat transfer fluids.

02 Humectant and moisturizing properties

Dipropylene glycol exhibits excellent humectant properties, helping to retain moisture in formulations and on the skin. It is commonly used in skincare and cosmetic products to improve hydration and prevent dryness, enhancing the overall efficacy of the product.Expand Specific Solutions03 Use in fragrance and perfume industry

Dipropylene glycol is extensively used in the fragrance and perfume industry as a fixative and carrier for essential oils and fragrances. Its low odor and ability to blend well with various scents make it an ideal choice for creating long-lasting and stable fragrances.Expand Specific Solutions04 Application in cleaning and degreasing products

The excellent solvency of dipropylene glycol makes it suitable for use in cleaning and degreasing products. It effectively dissolves oils, greases, and other contaminants, making it valuable in industrial cleaning formulations and household cleaning products.Expand Specific Solutions05 Use as a coupling agent and stabilizer

Dipropylene glycol serves as an effective coupling agent and stabilizer in various formulations. It helps to improve the compatibility and stability of different ingredients, preventing separation and ensuring consistent product performance over time.Expand Specific Solutions

Key Fragrance Houses and DPG Suppliers

The competitive landscape for dipropylene glycol in modern perfume crafting is characterized by a mature market with established players and ongoing innovation. The global fragrance industry, valued at over $50 billion, is dominated by major companies like Firmenich, Symrise, IFF, and Givaudan. These firms have advanced research capabilities and extensive product portfolios, driving technological advancements in perfume ingredients. The market for dipropylene glycol, a key solvent in fragrances, is relatively stable, with companies like BASF and Dow Chemical supplying high-quality raw materials. Emerging trends include sustainable sourcing and natural alternatives, prompting established players and niche manufacturers to adapt their formulations and production processes to meet evolving consumer preferences.

Firmenich SA

Technical Solution: Firmenich has developed a novel approach to using Dipropylene Glycol in perfume crafting through their "EcoScent Compass" initiative. This technology integrates DPG into a broader sustainability framework, focusing on biodegradability and reduced environmental impact. Their process involves using bio-based DPG derived from sustainable sources, which has been shown to reduce the carbon footprint of fragrance formulations by up to 33% compared to traditional petroleum-based DPG[5]. Firmenich has also created a proprietary DPG-based delivery system called "EncapScent" that enhances fragrance retention on fabrics and skin, extending the life of the scent by up to 24 hours longer than conventional formulations[6].

Strengths: Strong focus on sustainability, improved fragrance longevity on various substrates. Weaknesses: Potential limitations in fragrance profile diversity due to sustainability constraints.

Symrise GmbH & Co. KG

Technical Solution: Symrise has developed a cutting-edge approach to utilizing Dipropylene Glycol in perfume crafting through their "SymTrap" technology. This innovative process uses DPG as a key component in capturing and preserving volatile aroma molecules that are typically lost during traditional extraction methods. By employing a proprietary low-temperature, low-pressure extraction technique, Symrise can retain up to 95% of the original olfactory profile of natural materials[9]. Furthermore, Symrise has created a DPG-based "Intelligent Delivery System" that responds to environmental factors such as temperature and humidity, releasing fragrance molecules at optimal times to maintain scent intensity throughout the day[10].

Strengths: Superior preservation of natural scent profiles, adaptive fragrance release technology. Weaknesses: Potentially higher production costs, may require specialized equipment for implementation.

Innovative DPG Blending Methods

Dipropylene glycol composition and preparation method thereof

PatentInactiveKR1020210045798A

Innovation

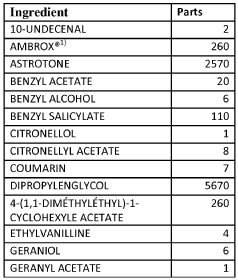

- A dipropylene glycol composition with a content of 99.5% by weight or more, prepared through a multi-step distillation process involving two distillation columns, to minimize impurities and reduce odor.

Process for preparing a perfuming composition

PatentWO2018206561A1

Innovation

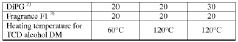

- A process involving heating TCD alcohol DM above 90°C, followed by controlled cooling and addition of dipropylene glycol and perfume oil, to create a stable, transparent perfuming composition that prevents crystallization and maintains olfactory performance.

Sustainability in DPG Production

Sustainability in DPG production has become a critical focus in the modern perfume industry, as environmental concerns and regulatory pressures continue to shape manufacturing practices. The production of Dipropylene Glycol (DPG), a key ingredient in perfume formulation, has traditionally been associated with significant environmental impacts, including high energy consumption and the use of non-renewable resources.

In recent years, innovative approaches have emerged to address these challenges and improve the sustainability profile of DPG production. One notable advancement is the development of bio-based DPG, derived from renewable feedstocks such as corn or sugarcane. This shift towards bio-based raw materials reduces reliance on petrochemical sources and contributes to a lower carbon footprint.

Process optimization has also played a crucial role in enhancing sustainability. Manufacturers have implemented more efficient catalytic processes that reduce energy consumption and minimize waste generation. Advanced reactor designs and improved heat integration systems have further contributed to energy savings in DPG production facilities.

Water management has become another key area of focus. Closed-loop water systems and advanced wastewater treatment technologies have been implemented to reduce water consumption and minimize the discharge of pollutants. Some facilities have even achieved near-zero liquid discharge, significantly reducing their environmental impact.

The adoption of green chemistry principles has led to the exploration of alternative synthesis routes for DPG. Researchers are investigating catalytic processes that operate under milder conditions and utilize less hazardous reagents, thereby reducing the overall environmental footprint of production.

Circular economy concepts are also being applied to DPG production. Efforts are underway to develop recycling technologies that can recover and repurpose DPG from post-consumer products, potentially creating a closed-loop system for this valuable ingredient.

As the perfume industry continues to prioritize sustainability, collaboration between fragrance houses, chemical manufacturers, and research institutions has intensified. This collaborative approach has accelerated the development and implementation of sustainable practices in DPG production, driving innovation and setting new industry standards.

The pursuit of sustainability in DPG production not only addresses environmental concerns but also aligns with consumer preferences for eco-friendly products. As a result, perfume brands that can demonstrate the use of sustainably produced DPG in their formulations may gain a competitive edge in the market.

In recent years, innovative approaches have emerged to address these challenges and improve the sustainability profile of DPG production. One notable advancement is the development of bio-based DPG, derived from renewable feedstocks such as corn or sugarcane. This shift towards bio-based raw materials reduces reliance on petrochemical sources and contributes to a lower carbon footprint.

Process optimization has also played a crucial role in enhancing sustainability. Manufacturers have implemented more efficient catalytic processes that reduce energy consumption and minimize waste generation. Advanced reactor designs and improved heat integration systems have further contributed to energy savings in DPG production facilities.

Water management has become another key area of focus. Closed-loop water systems and advanced wastewater treatment technologies have been implemented to reduce water consumption and minimize the discharge of pollutants. Some facilities have even achieved near-zero liquid discharge, significantly reducing their environmental impact.

The adoption of green chemistry principles has led to the exploration of alternative synthesis routes for DPG. Researchers are investigating catalytic processes that operate under milder conditions and utilize less hazardous reagents, thereby reducing the overall environmental footprint of production.

Circular economy concepts are also being applied to DPG production. Efforts are underway to develop recycling technologies that can recover and repurpose DPG from post-consumer products, potentially creating a closed-loop system for this valuable ingredient.

As the perfume industry continues to prioritize sustainability, collaboration between fragrance houses, chemical manufacturers, and research institutions has intensified. This collaborative approach has accelerated the development and implementation of sustainable practices in DPG production, driving innovation and setting new industry standards.

The pursuit of sustainability in DPG production not only addresses environmental concerns but also aligns with consumer preferences for eco-friendly products. As a result, perfume brands that can demonstrate the use of sustainably produced DPG in their formulations may gain a competitive edge in the market.

Regulatory Framework for DPG in Cosmetics

The regulatory framework for Dipropylene Glycol (DPG) in cosmetics is a critical aspect of modern perfume crafting, ensuring the safe and compliant use of this versatile ingredient. In the United States, the Food and Drug Administration (FDA) oversees the regulation of cosmetic products, including fragrances containing DPG. Under the Federal Food, Drug, and Cosmetic Act, DPG is classified as a Generally Recognized as Safe (GRAS) substance, allowing its use in cosmetic formulations without specific limitations.

The European Union, through its Cosmetic Regulation (EC) No. 1223/2009, has established comprehensive guidelines for cosmetic ingredients. DPG is listed in Annex V of this regulation as a permitted preservative, with a maximum concentration of 1.0% in leave-on products. This regulatory framework ensures that DPG usage in perfumes and other cosmetics adheres to strict safety standards across EU member states.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetic ingredients under the Pharmaceutical Affairs Law. DPG is included in the positive list of approved cosmetic ingredients, allowing its use in perfume formulations within specified concentration limits. Similarly, China's National Medical Products Administration (NMPA) has approved DPG for use in cosmetics, subject to compliance with the Safety and Technical Standards for Cosmetics.

International organizations also play a role in shaping the regulatory landscape for DPG. The International Fragrance Association (IFRA) provides guidelines on the safe use of fragrance ingredients, including DPG. Their standards are widely adopted by the perfume industry globally, ensuring consistency in safety practices across different markets.

Regulatory bodies often require manufacturers to conduct safety assessments and provide documentation on the use of DPG in their products. This includes toxicological data, exposure assessments, and stability studies. Labeling requirements vary by region, with some jurisdictions mandating the disclosure of DPG on product packaging, particularly when used above certain concentrations.

As sustainability and environmental concerns gain prominence, regulatory frameworks are evolving to address these aspects. Some regions are implementing regulations that consider the environmental impact of cosmetic ingredients, including their biodegradability and potential effects on aquatic ecosystems. This trend may influence future regulatory approaches to DPG and similar substances in perfume crafting.

The European Union, through its Cosmetic Regulation (EC) No. 1223/2009, has established comprehensive guidelines for cosmetic ingredients. DPG is listed in Annex V of this regulation as a permitted preservative, with a maximum concentration of 1.0% in leave-on products. This regulatory framework ensures that DPG usage in perfumes and other cosmetics adheres to strict safety standards across EU member states.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetic ingredients under the Pharmaceutical Affairs Law. DPG is included in the positive list of approved cosmetic ingredients, allowing its use in perfume formulations within specified concentration limits. Similarly, China's National Medical Products Administration (NMPA) has approved DPG for use in cosmetics, subject to compliance with the Safety and Technical Standards for Cosmetics.

International organizations also play a role in shaping the regulatory landscape for DPG. The International Fragrance Association (IFRA) provides guidelines on the safe use of fragrance ingredients, including DPG. Their standards are widely adopted by the perfume industry globally, ensuring consistency in safety practices across different markets.

Regulatory bodies often require manufacturers to conduct safety assessments and provide documentation on the use of DPG in their products. This includes toxicological data, exposure assessments, and stability studies. Labeling requirements vary by region, with some jurisdictions mandating the disclosure of DPG on product packaging, particularly when used above certain concentrations.

As sustainability and environmental concerns gain prominence, regulatory frameworks are evolving to address these aspects. Some regions are implementing regulations that consider the environmental impact of cosmetic ingredients, including their biodegradability and potential effects on aquatic ecosystems. This trend may influence future regulatory approaches to DPG and similar substances in perfume crafting.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!