Durability analysis of thermal barrier coatings ceramics under thermal shock

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TBC Ceramics Background and Research Objectives

Thermal Barrier Coatings (TBCs) have emerged as critical protective systems in high-temperature applications, particularly in aerospace, power generation, and automotive industries. These specialized ceramic coatings provide thermal insulation to metallic components operating in extreme temperature environments, effectively extending component lifespans and enabling higher operating temperatures for improved system efficiency. The evolution of TBC technology began in the 1950s with simple ceramic coatings and has progressively advanced through decades of materials science innovation and engineering optimization.

The current generation of TBCs typically consists of a multi-layer system: a ceramic top coat (commonly yttria-stabilized zirconia or YSZ), a thermally grown oxide (TGO) layer, a metallic bond coat, and the substrate material. While these systems have demonstrated remarkable performance improvements, their durability under thermal shock conditions remains a significant challenge that limits broader application and reliability.

Thermal shock—the rapid temperature fluctuations experienced during operational cycles—induces complex stress states within the coating system that can lead to premature failure through mechanisms including delamination, spallation, and cracking. These failure modes are particularly problematic in applications such as gas turbine engines, where components routinely experience temperature gradients exceeding 100°C/mm and thermal cycling between ambient and operating temperatures above 1200°C.

Recent advancements in materials science have introduced novel ceramic compositions and microstructural designs aimed at enhancing thermal shock resistance. These include rare-earth zirconates, gadolinium zirconate, lanthanum zirconate, and various composite structures with engineered porosity distributions. Despite these innovations, a comprehensive understanding of the fundamental degradation mechanisms under thermal shock conditions remains incomplete.

This research aims to systematically investigate the durability characteristics of advanced TBC ceramic materials under controlled thermal shock conditions. Specifically, we seek to: (1) quantify the relationship between ceramic composition, microstructure, and thermal shock resistance; (2) identify and characterize the primary failure mechanisms activated during rapid thermal cycling; (3) develop predictive models for TBC lifetime under various thermal shock regimes; and (4) propose design guidelines for next-generation TBC systems with enhanced durability.

The outcomes of this research will address critical knowledge gaps in TBC performance under extreme conditions and provide a foundation for developing more resilient coating systems. By improving thermal shock resistance, we anticipate enabling higher operating temperatures in turbine engines, potentially increasing efficiency by 1-2 percentage points—representing significant energy savings and emissions reductions across multiple industries.

The current generation of TBCs typically consists of a multi-layer system: a ceramic top coat (commonly yttria-stabilized zirconia or YSZ), a thermally grown oxide (TGO) layer, a metallic bond coat, and the substrate material. While these systems have demonstrated remarkable performance improvements, their durability under thermal shock conditions remains a significant challenge that limits broader application and reliability.

Thermal shock—the rapid temperature fluctuations experienced during operational cycles—induces complex stress states within the coating system that can lead to premature failure through mechanisms including delamination, spallation, and cracking. These failure modes are particularly problematic in applications such as gas turbine engines, where components routinely experience temperature gradients exceeding 100°C/mm and thermal cycling between ambient and operating temperatures above 1200°C.

Recent advancements in materials science have introduced novel ceramic compositions and microstructural designs aimed at enhancing thermal shock resistance. These include rare-earth zirconates, gadolinium zirconate, lanthanum zirconate, and various composite structures with engineered porosity distributions. Despite these innovations, a comprehensive understanding of the fundamental degradation mechanisms under thermal shock conditions remains incomplete.

This research aims to systematically investigate the durability characteristics of advanced TBC ceramic materials under controlled thermal shock conditions. Specifically, we seek to: (1) quantify the relationship between ceramic composition, microstructure, and thermal shock resistance; (2) identify and characterize the primary failure mechanisms activated during rapid thermal cycling; (3) develop predictive models for TBC lifetime under various thermal shock regimes; and (4) propose design guidelines for next-generation TBC systems with enhanced durability.

The outcomes of this research will address critical knowledge gaps in TBC performance under extreme conditions and provide a foundation for developing more resilient coating systems. By improving thermal shock resistance, we anticipate enabling higher operating temperatures in turbine engines, potentially increasing efficiency by 1-2 percentage points—representing significant energy savings and emissions reductions across multiple industries.

Market Demand Analysis for High-Performance TBCs

The global market for high-performance Thermal Barrier Coatings (TBCs) has experienced significant growth driven by increasing demands across multiple industries, particularly aerospace, power generation, and automotive sectors. The primary market driver remains the aerospace industry, where TBCs are critical for enhancing the durability and efficiency of gas turbine engines operating at extreme temperatures.

Current market analysis indicates that the global TBC market is valued at approximately 1.5 billion USD, with projections showing a compound annual growth rate of 6.8% through 2028. This growth trajectory is largely attributed to the expanding commercial aviation sector and the increasing adoption of advanced gas turbines in power generation facilities worldwide.

The power generation industry represents the second-largest market segment for high-performance TBCs, with natural gas turbines being the predominant application. As global energy demands continue to rise and efficiency standards become more stringent, power generation companies are increasingly investing in advanced coating technologies to extend component lifespans and improve thermal efficiency.

Automotive applications, particularly in high-performance and racing vehicles, constitute an emerging market segment with substantial growth potential. The trend toward more efficient internal combustion engines and the development of new propulsion technologies have created new opportunities for TBC applications in this sector.

Market research reveals a growing demand specifically for TBCs with enhanced thermal shock resistance. End-users across industries are seeking coating systems that can withstand rapid temperature fluctuations without compromising structural integrity. This demand is particularly pronounced in applications involving frequent thermal cycling, such as aircraft engines during take-off and landing sequences or industrial gas turbines during start-up and shutdown operations.

Regional analysis shows that North America and Europe currently dominate the high-performance TBC market, accounting for approximately 60% of global demand. However, the Asia-Pacific region, led by China and India, is experiencing the fastest growth rate due to expanding aerospace manufacturing capabilities and increasing investments in power infrastructure.

Customer requirements are increasingly focused on coatings that offer longer service life under thermal shock conditions, with maintenance intervals being a key economic consideration. Industry surveys indicate that end-users are willing to pay premium prices for TBC systems that can demonstrably extend component life by 20% or more under thermal shock conditions, highlighting the strong market pull for innovation in this specific performance characteristic.

Current market analysis indicates that the global TBC market is valued at approximately 1.5 billion USD, with projections showing a compound annual growth rate of 6.8% through 2028. This growth trajectory is largely attributed to the expanding commercial aviation sector and the increasing adoption of advanced gas turbines in power generation facilities worldwide.

The power generation industry represents the second-largest market segment for high-performance TBCs, with natural gas turbines being the predominant application. As global energy demands continue to rise and efficiency standards become more stringent, power generation companies are increasingly investing in advanced coating technologies to extend component lifespans and improve thermal efficiency.

Automotive applications, particularly in high-performance and racing vehicles, constitute an emerging market segment with substantial growth potential. The trend toward more efficient internal combustion engines and the development of new propulsion technologies have created new opportunities for TBC applications in this sector.

Market research reveals a growing demand specifically for TBCs with enhanced thermal shock resistance. End-users across industries are seeking coating systems that can withstand rapid temperature fluctuations without compromising structural integrity. This demand is particularly pronounced in applications involving frequent thermal cycling, such as aircraft engines during take-off and landing sequences or industrial gas turbines during start-up and shutdown operations.

Regional analysis shows that North America and Europe currently dominate the high-performance TBC market, accounting for approximately 60% of global demand. However, the Asia-Pacific region, led by China and India, is experiencing the fastest growth rate due to expanding aerospace manufacturing capabilities and increasing investments in power infrastructure.

Customer requirements are increasingly focused on coatings that offer longer service life under thermal shock conditions, with maintenance intervals being a key economic consideration. Industry surveys indicate that end-users are willing to pay premium prices for TBC systems that can demonstrably extend component life by 20% or more under thermal shock conditions, highlighting the strong market pull for innovation in this specific performance characteristic.

Current State and Challenges in TBC Thermal Shock Resistance

Thermal Barrier Coatings (TBCs) have become essential components in high-temperature applications, particularly in gas turbine engines. Currently, the state-of-the-art TBC systems typically consist of a ceramic top coat, predominantly yttria-stabilized zirconia (YSZ), a thermally grown oxide (TGO) layer, and a metallic bond coat on the substrate. The global market for TBCs has been steadily growing, with significant investments from aerospace, power generation, and automotive industries.

Despite considerable advancements, thermal shock resistance remains a critical challenge for TBC durability. Recent studies indicate that approximately 60% of TBC failures in service conditions are attributed to thermal shock damage. The rapid temperature changes induce severe thermal gradients and mechanical stresses that exceed the material's capacity, leading to progressive degradation and eventual failure.

Geographically, research on TBC thermal shock resistance is concentrated in the United States, Germany, Japan, China, and the United Kingdom, with emerging contributions from South Korea and Singapore. The distribution reflects the industrial bases where gas turbines and aerospace applications are prominent.

A significant technical challenge lies in the inherent mismatch of thermal expansion coefficients between ceramic top coats and metallic substrates. This mismatch generates substantial interfacial stresses during thermal cycling, promoting crack initiation and propagation. Current YSZ-based systems typically withstand 300-500 thermal cycles before critical failure, which falls short of industry requirements for advanced applications.

Another pressing challenge is the phase stability of ceramic materials at elevated temperatures. Conventional YSZ undergoes phase transformation from tetragonal to monoclinic at certain temperature ranges, accompanied by volume changes that compromise coating integrity. This transformation accelerates under thermal shock conditions, particularly when temperatures exceed 1200°C.

The development of reliable testing methodologies that accurately simulate real-world thermal shock conditions presents another obstacle. Standard laboratory tests often fail to replicate the complex thermal-mechanical loading patterns experienced in service environments, leading to discrepancies between predicted and actual performance.

Environmental factors further complicate TBC durability, with CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration emerging as a severe threat. These contaminants melt at high temperatures and penetrate the porous ceramic structure, significantly reducing thermal shock resistance upon solidification. Current mitigation strategies show limited effectiveness under combined thermal shock and CMAS attack scenarios.

The integration of advanced manufacturing techniques, such as suspension plasma spray and solution precursor plasma spray, offers improved microstructural control but introduces new challenges in ensuring consistent thermal shock performance across production batches.

Despite considerable advancements, thermal shock resistance remains a critical challenge for TBC durability. Recent studies indicate that approximately 60% of TBC failures in service conditions are attributed to thermal shock damage. The rapid temperature changes induce severe thermal gradients and mechanical stresses that exceed the material's capacity, leading to progressive degradation and eventual failure.

Geographically, research on TBC thermal shock resistance is concentrated in the United States, Germany, Japan, China, and the United Kingdom, with emerging contributions from South Korea and Singapore. The distribution reflects the industrial bases where gas turbines and aerospace applications are prominent.

A significant technical challenge lies in the inherent mismatch of thermal expansion coefficients between ceramic top coats and metallic substrates. This mismatch generates substantial interfacial stresses during thermal cycling, promoting crack initiation and propagation. Current YSZ-based systems typically withstand 300-500 thermal cycles before critical failure, which falls short of industry requirements for advanced applications.

Another pressing challenge is the phase stability of ceramic materials at elevated temperatures. Conventional YSZ undergoes phase transformation from tetragonal to monoclinic at certain temperature ranges, accompanied by volume changes that compromise coating integrity. This transformation accelerates under thermal shock conditions, particularly when temperatures exceed 1200°C.

The development of reliable testing methodologies that accurately simulate real-world thermal shock conditions presents another obstacle. Standard laboratory tests often fail to replicate the complex thermal-mechanical loading patterns experienced in service environments, leading to discrepancies between predicted and actual performance.

Environmental factors further complicate TBC durability, with CMAS (Calcium-Magnesium-Alumino-Silicate) infiltration emerging as a severe threat. These contaminants melt at high temperatures and penetrate the porous ceramic structure, significantly reducing thermal shock resistance upon solidification. Current mitigation strategies show limited effectiveness under combined thermal shock and CMAS attack scenarios.

The integration of advanced manufacturing techniques, such as suspension plasma spray and solution precursor plasma spray, offers improved microstructural control but introduces new challenges in ensuring consistent thermal shock performance across production batches.

Current Methodologies for TBC Thermal Shock Testing

01 Composition of ceramic thermal barrier coatings

Ceramic materials such as yttria-stabilized zirconia (YSZ) are commonly used in thermal barrier coatings due to their excellent thermal insulation properties. These materials can be modified with various dopants to enhance their durability and performance at high temperatures. The composition of the ceramic material significantly affects the coating's resistance to thermal cycling, oxidation, and erosion, which are critical factors for long-term durability in high-temperature applications.- Ceramic composition for thermal barrier coatings: Various ceramic materials are used in thermal barrier coatings to provide high temperature resistance and durability. These include yttria-stabilized zirconia (YSZ), rare earth zirconates, and other advanced ceramic compositions that offer superior thermal insulation properties. The specific composition of these ceramics significantly affects their thermal cycling resistance, phase stability, and overall durability in high-temperature applications.

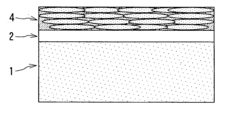

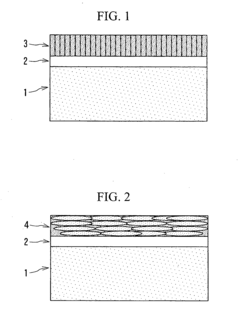

- Multilayer coating structures for enhanced durability: Multilayer thermal barrier coating systems incorporate different ceramic layers with complementary properties to enhance overall durability. These systems typically include a bond coat, a thermally grown oxide layer, and one or more ceramic top coats. The strategic layering of different ceramic materials helps to accommodate thermal expansion mismatch, improve strain tolerance, and provide better protection against environmental degradation, thereby extending the service life of components in extreme environments.

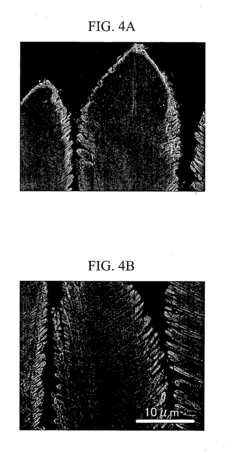

- Deposition methods affecting coating durability: The method used to deposit ceramic thermal barrier coatings significantly impacts their microstructure and durability. Common deposition techniques include air plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spray (SPPS). Each method produces distinct microstructures with different porosity levels, columnar structures, and strain tolerance capabilities, which directly affect the coating's resistance to thermal cycling, erosion, and foreign object damage.

- Surface modifications and treatments for durability enhancement: Various surface modifications and post-deposition treatments can significantly enhance the durability of ceramic thermal barrier coatings. These include laser glazing, infiltration with sealants, surface densification, and controlled segmentation. Such treatments can reduce surface roughness, seal porosity, create beneficial crack networks, and improve erosion resistance while maintaining the coating's thermal insulation properties, resulting in extended service life under severe operating conditions.

- Novel additives and dopants for improved coating performance: Incorporating specific additives and dopants into ceramic thermal barrier coatings can dramatically improve their high-temperature stability and durability. Elements such as rare earth oxides, tantalum, hafnium, and various transition metals can be added to stabilize crystal structures, inhibit sintering, improve phase stability, and enhance resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration. These modifications help maintain coating integrity during thermal cycling and extend component life in aggressive environments.

02 Microstructure engineering for enhanced durability

The microstructure of ceramic thermal barrier coatings plays a crucial role in determining their durability. Engineered porosity, columnar structures, and controlled grain boundaries can significantly improve strain tolerance and thermal shock resistance. Advanced processing techniques can create optimized microstructures that accommodate thermal expansion mismatch between the coating and substrate, thereby extending the service life of the coating under extreme thermal cycling conditions.Expand Specific Solutions03 Bond coat optimization for thermal barrier systems

The bond coat layer between the ceramic top coat and the metal substrate is critical for the overall durability of thermal barrier coating systems. MCrAlY-type bond coats (where M represents Ni, Co, or a combination) or aluminide diffusion coatings provide oxidation resistance and improve adhesion. The composition, thickness, and surface preparation of the bond coat significantly affect the formation of the thermally grown oxide layer, which is crucial for coating longevity and preventing spallation during thermal cycling.Expand Specific Solutions04 Novel deposition techniques for improved coating performance

Advanced deposition methods such as electron beam physical vapor deposition (EB-PVD), solution precursor plasma spray, and suspension plasma spray can create thermal barrier coatings with superior durability characteristics. These techniques allow for precise control over the coating architecture, including the creation of strain-tolerant columnar structures, segmented cracks, or layered composites. The deposition parameters significantly influence the coating's resistance to sintering, erosion, and thermal fatigue.Expand Specific Solutions05 Environmental barrier additions for harsh operating conditions

To enhance durability in harsh environments, thermal barrier coatings can be modified with environmental barrier components that resist specific degradation mechanisms. These include rare earth oxides or silicates that provide resistance against calcium-magnesium-alumino-silicate (CMAS) infiltration, which is a common cause of premature coating failure in gas turbines. Additionally, coatings can be designed with self-healing capabilities or with phases that resist volatilization in water vapor environments, extending their operational lifetime in combustion environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TBC Industry

The thermal barrier coatings (TBC) ceramics durability analysis market is currently in a growth phase, driven by increasing demands in aerospace, power generation, and automotive industries. The global market size for TBC technologies is expanding at approximately 6-7% annually, reaching nearly $1.5 billion. Leading industrial players include Siemens Energy, GE, Mitsubishi Heavy Industries, and RTX Corp, who are advancing commercial applications, while research institutions like Beihang University and Xi'an Jiaotong University are developing next-generation solutions. Technical maturity varies across applications, with aerospace implementations being most advanced. Companies like Oerlikon Metco and Praxair S.T. Technology are focusing on specialized coating processes, while Japan Fine Ceramics Center and HRL Laboratories are pioneering fundamental research in thermal shock resistance to extend TBC lifespans in extreme environments.

Siemens AG

Technical Solution: Siemens has developed a comprehensive approach to thermal barrier coating durability analysis focusing on advanced ceramic formulations with enhanced thermal shock resistance. Their technology employs gadolinium zirconate-based TBCs with carefully engineered porosity structures that provide superior thermal cycling performance compared to conventional YSZ coatings[2]. Siemens' analytical framework combines thermomechanical fatigue testing with acoustic emission monitoring to detect microcrack initiation and propagation during thermal shock events. Their methodology incorporates a unique "thermal gradient mechanical fatigue" test rig that simultaneously applies thermal gradients and mechanical loads to simulate real-world operating conditions in gas turbines[4]. Siemens has pioneered the use of digital twin modeling for TBC systems, creating virtual representations of coated components that predict degradation patterns and optimize maintenance intervals based on actual operating histories and material-specific degradation mechanisms[5].

Strengths: Exceptional integration of materials science with digital modeling capabilities; strong focus on practical implementation in commercial power generation systems. Weaknesses: Some solutions are optimized for land-based turbines and may require adaptation for aerospace applications; higher initial development costs compared to conventional coating systems.

General Electric Company

Technical Solution: GE's thermal barrier coating durability analysis focuses on advanced ceramic materials systems, primarily yttria-stabilized zirconia (YSZ) with enhanced strain tolerance. Their proprietary solution incorporates dense vertically cracked (DVC) microstructures that allow controlled segmentation to accommodate thermal expansion mismatch during thermal shock events[1]. GE has developed multi-layered TBC systems with gradient compositions that distribute thermal stresses more effectively, reducing spallation risks during rapid temperature changes. Their analysis methodology combines finite element modeling with accelerated thermal cycling tests that simulate engine operating conditions, allowing prediction of coating lifespans under various thermal shock scenarios[3]. GE's approach integrates non-destructive evaluation techniques including infrared thermography and photoluminescence piezospectroscopy to monitor progressive damage accumulation in ceramic top coats without destructive testing.

Strengths: Industry-leading computational modeling capabilities that accurately predict failure mechanisms; extensive field validation data from aircraft engines and power generation turbines. Weaknesses: Higher manufacturing costs associated with complex multi-layer systems; some solutions are optimized for specific operating conditions and may not perform optimally across all thermal shock scenarios.

Key Patents and Literature on TBC Durability Enhancement

Thermal barrier coating system method of manufacturing the same

PatentInactiveUS20050129972A1

Innovation

- A thermal barrier coating system with a ceramics thermal barrier layer formed by electron beam physical vapor deposition (EB-PVD) method, incorporating 0.1 to 10 mol% lanthanum oxide (La2O3) in a columnar structure of stabilized zirconia (ZrO2) or zirconia-hafnia (ZrO2-HfO2) solid solution, which reduces thermal conductivity and enhances durability.

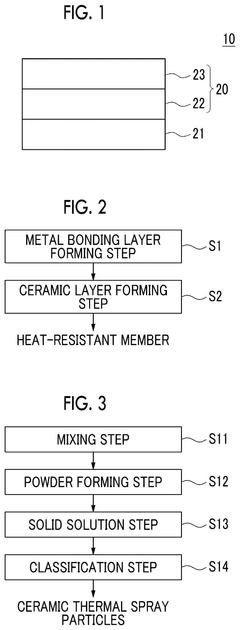

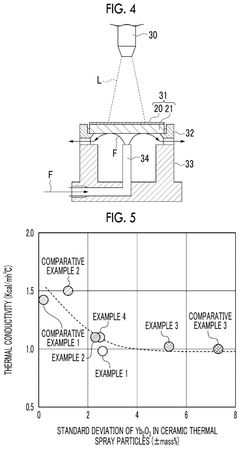

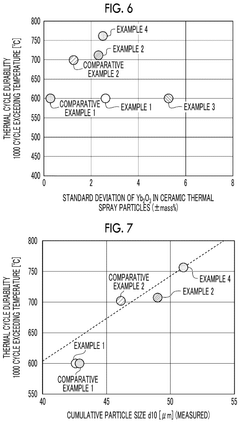

Ceramic thermal spray particles and method for forming thermal barrier coating layer

PatentPendingUS20250146117A1

Innovation

- Ceramic thermal spray particles containing ZrO2 and Yb2O3 with a standard deviation of Yb2O3 content between 2 mass % and 7.0 mass % are used to form a thermal barrier coating layer, which includes a metal bonding layer and a ceramic layer formed by thermal spraying.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal barrier coating (TBC) systems extends beyond their primary function of thermal protection. Manufacturing processes for ceramic TBCs, particularly those involving yttria-stabilized zirconia (YSZ), require significant energy inputs and generate emissions. The high-temperature sintering processes necessary for ceramic production contribute substantially to the carbon footprint of these protective systems.

Raw material extraction for TBC components presents additional environmental concerns. Mining operations for zirconia, yttria, and other rare earth elements used in advanced ceramics can lead to habitat disruption, soil degradation, and water contamination if not properly managed. The geographical concentration of these resources in specific regions also raises questions about supply chain sustainability and resource depletion rates.

During service life, TBCs contribute positively to environmental sustainability by improving the energy efficiency of gas turbines and other high-temperature systems. By enabling higher operating temperatures, these coatings facilitate more complete combustion and reduced fuel consumption, thereby lowering greenhouse gas emissions. Studies indicate that properly designed TBC systems can improve turbine efficiency by 1-2%, translating to significant emission reductions over equipment lifetime.

End-of-life considerations for TBC systems present both challenges and opportunities. The complex multi-layer structure of modern TBCs complicates recycling efforts, as separation of ceramic top coats from metallic bond coats and substrates requires specialized processes. However, recent advances in recycling technologies show promise for recovering valuable elements from spent TBCs, particularly from those containing rare earth elements.

Thermal shock resistance improvements in TBCs also contribute to sustainability through extended component lifespans. Each additional hour of service life achieved through enhanced durability represents avoided environmental impacts from manufacturing replacement parts. Research indicates that doubling the thermal shock resistance of a TBC system can extend component life by 30-40% under cyclic thermal loading conditions.

Future sustainability improvements in TBC technology are focusing on several promising directions. These include development of more environmentally benign manufacturing processes, substitution of rare earth elements with more abundant alternatives, and design of TBC systems specifically optimized for recyclability without compromising thermal shock performance. Computational modeling approaches are increasingly being employed to predict environmental impacts across the full lifecycle of TBC systems, enabling more holistic sustainability assessments.

Raw material extraction for TBC components presents additional environmental concerns. Mining operations for zirconia, yttria, and other rare earth elements used in advanced ceramics can lead to habitat disruption, soil degradation, and water contamination if not properly managed. The geographical concentration of these resources in specific regions also raises questions about supply chain sustainability and resource depletion rates.

During service life, TBCs contribute positively to environmental sustainability by improving the energy efficiency of gas turbines and other high-temperature systems. By enabling higher operating temperatures, these coatings facilitate more complete combustion and reduced fuel consumption, thereby lowering greenhouse gas emissions. Studies indicate that properly designed TBC systems can improve turbine efficiency by 1-2%, translating to significant emission reductions over equipment lifetime.

End-of-life considerations for TBC systems present both challenges and opportunities. The complex multi-layer structure of modern TBCs complicates recycling efforts, as separation of ceramic top coats from metallic bond coats and substrates requires specialized processes. However, recent advances in recycling technologies show promise for recovering valuable elements from spent TBCs, particularly from those containing rare earth elements.

Thermal shock resistance improvements in TBCs also contribute to sustainability through extended component lifespans. Each additional hour of service life achieved through enhanced durability represents avoided environmental impacts from manufacturing replacement parts. Research indicates that doubling the thermal shock resistance of a TBC system can extend component life by 30-40% under cyclic thermal loading conditions.

Future sustainability improvements in TBC technology are focusing on several promising directions. These include development of more environmentally benign manufacturing processes, substitution of rare earth elements with more abundant alternatives, and design of TBC systems specifically optimized for recyclability without compromising thermal shock performance. Computational modeling approaches are increasingly being employed to predict environmental impacts across the full lifecycle of TBC systems, enabling more holistic sustainability assessments.

Standardization and Quality Control Protocols

Standardization and quality control protocols are essential for ensuring the reliability and reproducibility of thermal barrier coatings (TBCs) under thermal shock conditions. The development of comprehensive testing standards has become increasingly important as TBCs find wider applications in aerospace, power generation, and automotive industries.

Current international standards for thermal shock testing of ceramic coatings include ASTM C1525 and ISO 13124, which provide guidelines for evaluating thermal shock resistance of advanced ceramics. However, these standards require adaptation for the specific requirements of TBCs, which typically operate under more extreme temperature gradients and cycling conditions than traditional ceramics.

Quality control protocols for TBC manufacturing must address multiple parameters that influence durability under thermal shock. These include coating thickness uniformity, porosity distribution, interface roughness, and chemical composition consistency. Variations in these parameters can significantly impact thermal shock resistance, making standardized measurement techniques crucial for reliable performance prediction.

Non-destructive evaluation (NDE) methods have emerged as critical components of quality control protocols. Techniques such as infrared thermography, acoustic emission monitoring, and impedance spectroscopy enable real-time assessment of coating integrity before, during, and after thermal shock exposure. The standardization of these NDE approaches requires establishing acceptance criteria and calibration procedures specific to TBC systems.

Statistical process control (SPC) methodologies are increasingly being integrated into TBC manufacturing to ensure consistent quality. These approaches involve monitoring key process variables and implementing control charts to detect deviations that might compromise thermal shock resistance. The establishment of process capability indices (Cpk) for critical parameters provides quantitative measures of manufacturing consistency.

Round-robin testing programs involving multiple laboratories have been instrumental in validating standardized protocols for thermal shock evaluation. These collaborative efforts help identify sources of variability in test results and establish reproducibility limits for different testing methodologies. Recent international initiatives have focused on harmonizing testing procedures across different regions to facilitate global technology transfer and comparison of research outcomes.

Accelerated aging protocols represent another important aspect of standardization efforts. These protocols aim to simulate long-term thermal shock exposure in compressed timeframes, enabling more efficient durability assessment. Correlation between accelerated test results and actual service performance remains an active area of research, with validation studies seeking to establish appropriate acceleration factors for different application environments.

Current international standards for thermal shock testing of ceramic coatings include ASTM C1525 and ISO 13124, which provide guidelines for evaluating thermal shock resistance of advanced ceramics. However, these standards require adaptation for the specific requirements of TBCs, which typically operate under more extreme temperature gradients and cycling conditions than traditional ceramics.

Quality control protocols for TBC manufacturing must address multiple parameters that influence durability under thermal shock. These include coating thickness uniformity, porosity distribution, interface roughness, and chemical composition consistency. Variations in these parameters can significantly impact thermal shock resistance, making standardized measurement techniques crucial for reliable performance prediction.

Non-destructive evaluation (NDE) methods have emerged as critical components of quality control protocols. Techniques such as infrared thermography, acoustic emission monitoring, and impedance spectroscopy enable real-time assessment of coating integrity before, during, and after thermal shock exposure. The standardization of these NDE approaches requires establishing acceptance criteria and calibration procedures specific to TBC systems.

Statistical process control (SPC) methodologies are increasingly being integrated into TBC manufacturing to ensure consistent quality. These approaches involve monitoring key process variables and implementing control charts to detect deviations that might compromise thermal shock resistance. The establishment of process capability indices (Cpk) for critical parameters provides quantitative measures of manufacturing consistency.

Round-robin testing programs involving multiple laboratories have been instrumental in validating standardized protocols for thermal shock evaluation. These collaborative efforts help identify sources of variability in test results and establish reproducibility limits for different testing methodologies. Recent international initiatives have focused on harmonizing testing procedures across different regions to facilitate global technology transfer and comparison of research outcomes.

Accelerated aging protocols represent another important aspect of standardization efforts. These protocols aim to simulate long-term thermal shock exposure in compressed timeframes, enabling more efficient durability assessment. Correlation between accelerated test results and actual service performance remains an active area of research, with validation studies seeking to establish appropriate acceleration factors for different application environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!