Research on thermal barrier coatings ceramics in turbine engines

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coating Evolution and Objectives

Thermal barrier coatings (TBCs) have evolved significantly since their inception in the 1950s, initially developed for rocket engines and later adapted for gas turbine applications. The fundamental purpose of these ceramic coatings remains consistent: to provide thermal insulation for metallic components operating in extreme temperature environments, thereby extending component life and enabling higher operating temperatures for improved engine efficiency.

Early TBC systems utilized stabilized zirconia, particularly yttria-stabilized zirconia (YSZ), which remains the industry standard due to its exceptional combination of low thermal conductivity and relatively high coefficient of thermal expansion. The evolution of TBC technology has been driven by the continuous pursuit of higher turbine inlet temperatures, which directly correlates with improved engine efficiency and reduced fuel consumption.

The 1970s and 1980s witnessed significant advancements in deposition techniques, transitioning from simple flame spraying to more sophisticated methods such as atmospheric plasma spraying (APS) and electron beam physical vapor deposition (EB-PVD). These techniques enabled the creation of coatings with controlled microstructures that substantially enhanced thermal insulation properties and durability under cyclic thermal conditions.

By the 1990s, research focus shifted toward understanding failure mechanisms and developing multi-layer coating systems. The introduction of thermally grown oxide (TGO) layers and bond coats represented a critical advancement in extending coating lifespans under severe operating conditions. This period also saw increased attention to the role of sintering in coating degradation and efforts to develop sintering-resistant formulations.

The early 2000s brought renewed interest in alternative ceramic materials beyond traditional YSZ, including gadolinium zirconate, lanthanum zirconate, and various pyrochlore structures offering potentially lower thermal conductivity and enhanced phase stability at elevated temperatures. Concurrently, researchers began exploring nanostructured coatings and compositionally graded systems to optimize performance across the temperature gradient.

Current research objectives focus on developing "prime-reliant" TBCs capable of withstanding temperatures exceeding 1400°C without compromising mechanical integrity. Additional goals include reducing oxygen permeability to minimize oxidation of underlying components, enhancing erosion resistance against particulate impacts, and improving resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration—a significant cause of premature coating failure in dusty operating environments.

The ultimate objective remains the development of next-generation TBCs that enable turbine inlet temperatures approaching 1600°C while maintaining coating durability for thousands of operating hours. This ambitious target necessitates fundamental innovations in ceramic materials science, processing techniques, and predictive modeling capabilities to anticipate failure mechanisms under increasingly extreme conditions.

Early TBC systems utilized stabilized zirconia, particularly yttria-stabilized zirconia (YSZ), which remains the industry standard due to its exceptional combination of low thermal conductivity and relatively high coefficient of thermal expansion. The evolution of TBC technology has been driven by the continuous pursuit of higher turbine inlet temperatures, which directly correlates with improved engine efficiency and reduced fuel consumption.

The 1970s and 1980s witnessed significant advancements in deposition techniques, transitioning from simple flame spraying to more sophisticated methods such as atmospheric plasma spraying (APS) and electron beam physical vapor deposition (EB-PVD). These techniques enabled the creation of coatings with controlled microstructures that substantially enhanced thermal insulation properties and durability under cyclic thermal conditions.

By the 1990s, research focus shifted toward understanding failure mechanisms and developing multi-layer coating systems. The introduction of thermally grown oxide (TGO) layers and bond coats represented a critical advancement in extending coating lifespans under severe operating conditions. This period also saw increased attention to the role of sintering in coating degradation and efforts to develop sintering-resistant formulations.

The early 2000s brought renewed interest in alternative ceramic materials beyond traditional YSZ, including gadolinium zirconate, lanthanum zirconate, and various pyrochlore structures offering potentially lower thermal conductivity and enhanced phase stability at elevated temperatures. Concurrently, researchers began exploring nanostructured coatings and compositionally graded systems to optimize performance across the temperature gradient.

Current research objectives focus on developing "prime-reliant" TBCs capable of withstanding temperatures exceeding 1400°C without compromising mechanical integrity. Additional goals include reducing oxygen permeability to minimize oxidation of underlying components, enhancing erosion resistance against particulate impacts, and improving resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration—a significant cause of premature coating failure in dusty operating environments.

The ultimate objective remains the development of next-generation TBCs that enable turbine inlet temperatures approaching 1600°C while maintaining coating durability for thousands of operating hours. This ambitious target necessitates fundamental innovations in ceramic materials science, processing techniques, and predictive modeling capabilities to anticipate failure mechanisms under increasingly extreme conditions.

Market Analysis for High-Performance TBC Solutions

The global market for Thermal Barrier Coatings (TBCs) in turbine engines is experiencing robust growth, driven primarily by the aerospace and power generation sectors. Current market valuation stands at approximately $1.2 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is supported by increasing demand for fuel-efficient aircraft engines and higher-performance power generation turbines operating at elevated temperatures.

The aerospace segment currently dominates the TBC market, accounting for nearly 60% of total demand. Commercial aviation's recovery post-pandemic has accelerated replacement cycles for engine components, while military aerospace continues steady investment in advanced propulsion systems requiring superior thermal protection. Power generation represents the second-largest market segment at 30%, with particular growth in combined-cycle gas turbines where efficiency improvements directly correlate with operating temperature capabilities.

Regional analysis reveals North America leading with 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the fastest growth is occurring in Asia-Pacific markets, particularly China and India, where rapid industrialization and expanding aviation sectors are driving demand for advanced turbine technologies. These emerging markets are expected to grow at nearly twice the global average rate over the next five years.

Customer requirements are evolving toward TBC solutions that offer longer service life under more extreme conditions. End-users increasingly demand coatings capable of withstanding temperatures exceeding 1400°C while maintaining structural integrity through thousands of thermal cycles. This performance requirement is pushing manufacturers toward advanced ceramic formulations with enhanced phase stability and strain tolerance.

Price sensitivity varies significantly by application segment. While commercial aviation operators prioritize lifecycle cost benefits over initial investment, power generation customers typically demonstrate greater price sensitivity due to larger coating volumes required per installation. This market dynamic has created distinct product tiers, with premium solutions commanding 40-60% price premiums for applications where performance parameters are most critical.

The competitive landscape features both specialized coating technology providers and vertically integrated OEMs. Recent market consolidation has occurred through strategic acquisitions, with major players seeking to secure proprietary ceramic formulation expertise and application technologies. This trend reflects the increasing value placed on intellectual property in high-performance TBC development, particularly for next-generation turbine designs operating at the thermal limits of current materials.

The aerospace segment currently dominates the TBC market, accounting for nearly 60% of total demand. Commercial aviation's recovery post-pandemic has accelerated replacement cycles for engine components, while military aerospace continues steady investment in advanced propulsion systems requiring superior thermal protection. Power generation represents the second-largest market segment at 30%, with particular growth in combined-cycle gas turbines where efficiency improvements directly correlate with operating temperature capabilities.

Regional analysis reveals North America leading with 38% market share, followed by Europe (27%) and Asia-Pacific (25%). However, the fastest growth is occurring in Asia-Pacific markets, particularly China and India, where rapid industrialization and expanding aviation sectors are driving demand for advanced turbine technologies. These emerging markets are expected to grow at nearly twice the global average rate over the next five years.

Customer requirements are evolving toward TBC solutions that offer longer service life under more extreme conditions. End-users increasingly demand coatings capable of withstanding temperatures exceeding 1400°C while maintaining structural integrity through thousands of thermal cycles. This performance requirement is pushing manufacturers toward advanced ceramic formulations with enhanced phase stability and strain tolerance.

Price sensitivity varies significantly by application segment. While commercial aviation operators prioritize lifecycle cost benefits over initial investment, power generation customers typically demonstrate greater price sensitivity due to larger coating volumes required per installation. This market dynamic has created distinct product tiers, with premium solutions commanding 40-60% price premiums for applications where performance parameters are most critical.

The competitive landscape features both specialized coating technology providers and vertically integrated OEMs. Recent market consolidation has occurred through strategic acquisitions, with major players seeking to secure proprietary ceramic formulation expertise and application technologies. This trend reflects the increasing value placed on intellectual property in high-performance TBC development, particularly for next-generation turbine designs operating at the thermal limits of current materials.

Current TBC Technologies and Technical Barriers

Thermal Barrier Coatings (TBCs) have become an integral component of modern turbine engines, providing critical thermal protection to metallic components operating in extreme temperature environments. The current state-of-the-art TBC system typically consists of a multilayer structure including a ceramic top coat, a thermally grown oxide (TGO) layer, and a metallic bond coat on the substrate.

The industry standard ceramic material for TBCs remains yttria-stabilized zirconia (YSZ), typically with 7-8 wt% Y2O3 (7YSZ). This composition offers an optimal combination of low thermal conductivity (approximately 2.0-2.3 W/m·K), relatively high coefficient of thermal expansion (9-10×10^-6/K), and good phase stability up to about 1200°C. YSZ coatings are primarily deposited using two techniques: Air Plasma Spray (APS) and Electron Beam Physical Vapor Deposition (EB-PVD), each producing distinct microstructures with specific advantages.

Despite the widespread application of YSZ-based TBCs, several technical barriers limit their performance in next-generation turbine engines. The most significant limitation is the phase destabilization of YSZ at temperatures exceeding 1200°C, where the metastable tetragonal prime (t') phase transforms to tetragonal (t) and cubic (c) phases. Upon cooling, the tetragonal phase transforms to monoclinic, accompanied by a volume change that induces destructive stresses in the coating.

Another critical barrier is CMAS (Calcium-Magnesium-Alumino-Silicate) attack, which occurs when airborne contaminants melt on the hot TBC surface, infiltrate the porous structure, and cause premature failure through chemical degradation and thermomechanical damage. This phenomenon has become increasingly problematic as engine temperatures rise and operations in dusty environments increase.

Thermal cycling fatigue represents another significant challenge, as the repeated heating and cooling of the engine creates thermal expansion mismatch stresses between the ceramic coating and metallic substrate. These stresses eventually lead to coating spallation, particularly at the TGO interface where oxide growth adds additional stress.

The current deposition technologies also present limitations. APS coatings, while cost-effective, exhibit higher thermal conductivity due to splat boundaries oriented perpendicular to heat flow. EB-PVD coatings offer superior strain tolerance but come with higher production costs and slightly higher thermal conductivity than ideal.

Erosion resistance remains another persistent challenge, particularly for EB-PVD coatings with their columnar structure. The progressive thinning of TBCs due to particulate erosion significantly reduces their thermal protection capability and service life.

These technical barriers have driven extensive research into alternative ceramic compositions, novel microstructures, and advanced processing techniques to develop the next generation of TBCs capable of withstanding the increasingly demanding conditions of advanced turbine engines.

The industry standard ceramic material for TBCs remains yttria-stabilized zirconia (YSZ), typically with 7-8 wt% Y2O3 (7YSZ). This composition offers an optimal combination of low thermal conductivity (approximately 2.0-2.3 W/m·K), relatively high coefficient of thermal expansion (9-10×10^-6/K), and good phase stability up to about 1200°C. YSZ coatings are primarily deposited using two techniques: Air Plasma Spray (APS) and Electron Beam Physical Vapor Deposition (EB-PVD), each producing distinct microstructures with specific advantages.

Despite the widespread application of YSZ-based TBCs, several technical barriers limit their performance in next-generation turbine engines. The most significant limitation is the phase destabilization of YSZ at temperatures exceeding 1200°C, where the metastable tetragonal prime (t') phase transforms to tetragonal (t) and cubic (c) phases. Upon cooling, the tetragonal phase transforms to monoclinic, accompanied by a volume change that induces destructive stresses in the coating.

Another critical barrier is CMAS (Calcium-Magnesium-Alumino-Silicate) attack, which occurs when airborne contaminants melt on the hot TBC surface, infiltrate the porous structure, and cause premature failure through chemical degradation and thermomechanical damage. This phenomenon has become increasingly problematic as engine temperatures rise and operations in dusty environments increase.

Thermal cycling fatigue represents another significant challenge, as the repeated heating and cooling of the engine creates thermal expansion mismatch stresses between the ceramic coating and metallic substrate. These stresses eventually lead to coating spallation, particularly at the TGO interface where oxide growth adds additional stress.

The current deposition technologies also present limitations. APS coatings, while cost-effective, exhibit higher thermal conductivity due to splat boundaries oriented perpendicular to heat flow. EB-PVD coatings offer superior strain tolerance but come with higher production costs and slightly higher thermal conductivity than ideal.

Erosion resistance remains another persistent challenge, particularly for EB-PVD coatings with their columnar structure. The progressive thinning of TBCs due to particulate erosion significantly reduces their thermal protection capability and service life.

These technical barriers have driven extensive research into alternative ceramic compositions, novel microstructures, and advanced processing techniques to develop the next generation of TBCs capable of withstanding the increasingly demanding conditions of advanced turbine engines.

State-of-the-Art Ceramic TBC Systems

01 Yttria-stabilized zirconia (YSZ) thermal barrier coatings

Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high temperature stability. These coatings typically consist of a ceramic top coat of YSZ applied over a metallic bond coat, providing protection to underlying metal components in high-temperature environments such as gas turbine engines. The YSZ microstructure can be engineered to enhance thermal resistance and durability through controlled porosity and crack propagation resistance.- Yttria-stabilized zirconia (YSZ) thermal barrier coatings: Yttria-stabilized zirconia (YSZ) is widely used as a thermal barrier coating material due to its excellent thermal insulation properties and high temperature stability. These coatings typically consist of a ceramic top coat of YSZ applied over a metallic bond coat. The YSZ provides thermal protection to the underlying metal components in high-temperature environments such as gas turbine engines, while the bond coat enhances adhesion and provides oxidation resistance.

- Advanced ceramic compositions for enhanced thermal barrier performance: Novel ceramic compositions have been developed to enhance the performance of thermal barrier coatings beyond traditional YSZ. These include rare earth zirconates, hafnates, and complex oxides that offer improved phase stability, lower thermal conductivity, and better resistance to sintering at elevated temperatures. These advanced compositions can withstand higher operating temperatures, extending component life and enabling more efficient engine operation.

- Multilayer and graded thermal barrier coating systems: Multilayer and functionally graded thermal barrier coating systems incorporate different ceramic materials in layers or with gradual compositional changes to optimize performance. These systems can combine the beneficial properties of different ceramics, such as the erosion resistance of one material with the thermal insulation of another. The layered or graded structure helps manage thermal stresses, improve durability, and enhance overall coating performance in extreme environments.

- Deposition methods for ceramic thermal barrier coatings: Various deposition techniques are used to apply ceramic thermal barrier coatings, including atmospheric plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), suspension plasma spraying, and solution precursor plasma spraying. Each method produces coatings with different microstructures and properties. For example, EB-PVD creates columnar structures with superior strain tolerance, while plasma spraying typically produces more porous coatings with lower thermal conductivity.

- Porosity control and microstructure engineering in ceramic thermal barriers: Controlling porosity and engineering the microstructure of ceramic thermal barrier coatings is crucial for optimizing their performance. Techniques include introducing specific pore formers, creating segmentation cracks, or developing specific crystalline structures. These approaches can reduce thermal conductivity, improve strain tolerance, and enhance durability. The controlled porosity provides pathways for stress relief during thermal cycling while maintaining the coating's structural integrity.

02 Advanced ceramic compositions for enhanced thermal protection

Novel ceramic compositions have been developed to improve upon traditional thermal barrier coating materials. These include rare-earth zirconates, hafnates, and complex oxides that offer superior high-temperature capabilities and reduced thermal conductivity compared to conventional YSZ. These advanced ceramics often incorporate elements such as gadolinium, lanthanum, or ytterbium to create pyrochlore or fluorite structures with enhanced phase stability and resistance to sintering at elevated temperatures, extending the service life and maximum operating temperature of thermal barrier systems.Expand Specific Solutions03 Deposition techniques for thermal barrier ceramic coatings

Various deposition methods are employed to apply ceramic thermal barrier coatings, including atmospheric plasma spraying (APS), electron beam physical vapor deposition (EB-PVD), and solution precursor plasma spraying. Each technique produces distinct microstructures that influence coating performance characteristics such as strain tolerance, erosion resistance, and thermal insulation efficiency. EB-PVD typically creates columnar structures with superior strain tolerance, while plasma spraying produces lamellar structures with lower thermal conductivity. Novel deposition approaches continue to be developed to optimize coating properties and application efficiency.Expand Specific Solutions04 Multilayer and functionally graded thermal barrier systems

Multilayer and functionally graded thermal barrier coating systems incorporate varying compositions and microstructures through the coating thickness to optimize performance. These systems typically feature gradual transitions between layers with different thermal expansion coefficients, enhancing adhesion and reducing stress concentrations at interfaces. The composition and porosity can be tailored to provide maximum thermal insulation at the surface while ensuring strong bonding to the substrate. This approach helps mitigate common failure modes such as spallation and improves overall durability in cyclic thermal environments.Expand Specific Solutions05 Environmental barrier additions for harsh operating conditions

Thermal barrier ceramic coatings can be modified with environmental barrier additions to protect against specific operational challenges such as calcium-magnesium-alumino-silicate (CMAS) infiltration, hot corrosion, and erosion. These specialized formulations incorporate elements like aluminum, tantalum, or rare earth oxides that react with molten deposits to form protective compounds, preventing further degradation of the coating. Self-healing capabilities can also be engineered into these systems through the incorporation of phases that expand upon oxidation to seal cracks. These advancements are particularly important for applications in dusty environments or those involving alternative fuels.Expand Specific Solutions

Leading Companies and Research Institutions in TBC Field

The thermal barrier coatings (TBC) ceramics market for turbine engines is in a mature growth phase, characterized by established technologies and steady innovation. The global market size is substantial, driven by increasing demand for high-performance engines in aerospace, power generation, and industrial applications. Leading players include major aerospace corporations like RTX Corp. (formerly United Technologies), Rolls-Royce, and General Electric, who possess advanced manufacturing capabilities and extensive R&D resources. Academic institutions such as Beihang University and William Marsh Rice University contribute significantly to technological advancement through research partnerships. The technology has reached high maturity levels with ongoing refinements focused on extending coating lifespans, improving thermal resistance, and enhancing durability under extreme operating conditions, particularly in next-generation turbine applications.

ROLLS ROYCE PLC

Technical Solution: Rolls Royce has developed advanced thermal barrier coatings (TBCs) using yttria-stabilized zirconia (YSZ) with enhanced strain tolerance through engineered microstructures. Their proprietary electron beam physical vapor deposition (EB-PVD) process creates columnar microstructures that provide superior strain tolerance and thermal cycling resistance[1]. The company has pioneered multi-layer TBC systems incorporating gadolinium zirconate as a top layer with YSZ underneath, achieving lower thermal conductivity while maintaining mechanical integrity[3]. Recent innovations include the development of erosion-resistant TBCs with nano-structured rare earth additions that improve both durability and thermal performance. Rolls Royce has also implemented advanced manufacturing techniques for precise thickness control and optimized bond coat compositions to enhance coating adhesion during thermal cycling[5]. Their research focuses on extending TBC lifetimes under extreme temperature conditions exceeding 1200°C while maintaining structural integrity against CMAS (calcium-magnesium-alumino-silicate) infiltration.

Strengths: Superior strain tolerance through columnar microstructure; excellent thermal cycling resistance; advanced multi-layer systems with optimized thermal properties. Weaknesses: Higher manufacturing costs associated with EB-PVD process; potential challenges with repair and maintenance of complex multi-layer systems; performance degradation in environments with high particulate content.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed advanced thermal barrier coating systems featuring multi-component rare earth zirconate ceramics with engineered defect structures. Their TBC technology utilizes a combination of air plasma spray and solution precursor plasma spray techniques to create functionally graded coatings with optimized thermal and mechanical properties[2]. RTX has pioneered the use of gadolinium-ytterbium co-doped zirconia compositions that demonstrate thermal conductivity reductions of up to 40% compared to conventional YSZ while maintaining phase stability at temperatures exceeding 1300°C[5]. Their coating systems incorporate specialized MCrAlY bond coats with reactive element additions (Y, Hf) that improve oxide scale adhesion during thermal cycling. Recent innovations include the development of self-healing TBC concepts utilizing embedded healing agents that activate during thermal exposure to repair microstructural damage. RTX has also implemented advanced manufacturing controls for precise thickness and microstructure optimization across complex turbine component geometries, including internal cooling passages[8]. Their research focuses on extending TBC durability under combined thermomechanical fatigue and CMAS attack conditions.

Strengths: Superior thermal insulation properties through advanced material compositions; excellent high-temperature phase stability; innovative self-healing capabilities. Weaknesses: Higher manufacturing costs associated with complex material systems; potential challenges with quality control of multi-component ceramics; limited field service history compared to conventional YSZ systems.

Key Patents and Innovations in TBC Ceramics

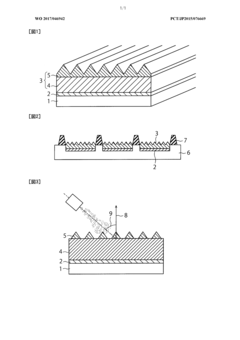

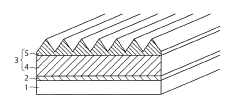

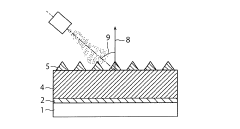

Thermal barrier coating and power generation system

PatentWO2017046942A1

Innovation

- A thermal barrier coating composed of ceramics with a higher melting point than metal, featuring a bonding layer and two ceramic layers with specific surface roughness and porosity, applied to turbine components to enhance durability and sealing performance.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal barrier coatings (TBCs) in turbine engines extends beyond their primary function of thermal protection. As global environmental regulations become increasingly stringent, the sustainability aspects of TBC materials and manufacturing processes have gained significant attention from both industry and regulatory bodies.

Traditional ceramic TBCs, particularly yttria-stabilized zirconia (YSZ), involve energy-intensive production processes that contribute to considerable carbon emissions. The manufacturing of these coatings typically requires high-temperature sintering and plasma spraying techniques, consuming substantial energy resources. Recent life cycle assessments indicate that the production phase of ceramic TBCs accounts for approximately 40-60% of their total environmental footprint.

The raw material extraction for TBC ceramics presents another environmental concern. Rare earth elements used in advanced TBCs, such as gadolinium, lanthanum, and yttrium, are often mined using processes that can lead to habitat destruction, water pollution, and soil contamination if not properly managed. The geopolitical concentration of these resources in specific regions also raises questions about supply chain sustainability and resource security.

During operation, TBCs contribute positively to environmental sustainability by improving engine efficiency and reducing fuel consumption. Studies demonstrate that advanced TBC systems can improve turbine efficiency by 1-2%, translating to significant reductions in greenhouse gas emissions over an engine's operational lifetime. This efficiency gain partially offsets the environmental impact of their production.

End-of-life considerations for TBC components present both challenges and opportunities. The complex multi-layer structure of modern TBCs complicates recycling efforts, often resulting in these materials entering waste streams after decommissioning. Innovative recycling technologies are emerging, including hydrometallurgical processes that can recover valuable rare earth elements from spent TBC components with recovery rates approaching 80%.

Research trends indicate growing interest in environmentally benign TBC alternatives. Bio-inspired ceramic compositions, water-based slurry deposition methods, and additive manufacturing techniques show promise for reducing environmental impact. Additionally, the development of TBCs with extended service life directly contributes to sustainability by reducing replacement frequency and associated resource consumption.

Regulatory frameworks worldwide are increasingly incorporating environmental performance metrics into material qualification standards for aerospace and power generation applications. This shift is driving manufacturers to adopt cleaner production methods and explore more sustainable material compositions for next-generation TBC systems.

Traditional ceramic TBCs, particularly yttria-stabilized zirconia (YSZ), involve energy-intensive production processes that contribute to considerable carbon emissions. The manufacturing of these coatings typically requires high-temperature sintering and plasma spraying techniques, consuming substantial energy resources. Recent life cycle assessments indicate that the production phase of ceramic TBCs accounts for approximately 40-60% of their total environmental footprint.

The raw material extraction for TBC ceramics presents another environmental concern. Rare earth elements used in advanced TBCs, such as gadolinium, lanthanum, and yttrium, are often mined using processes that can lead to habitat destruction, water pollution, and soil contamination if not properly managed. The geopolitical concentration of these resources in specific regions also raises questions about supply chain sustainability and resource security.

During operation, TBCs contribute positively to environmental sustainability by improving engine efficiency and reducing fuel consumption. Studies demonstrate that advanced TBC systems can improve turbine efficiency by 1-2%, translating to significant reductions in greenhouse gas emissions over an engine's operational lifetime. This efficiency gain partially offsets the environmental impact of their production.

End-of-life considerations for TBC components present both challenges and opportunities. The complex multi-layer structure of modern TBCs complicates recycling efforts, often resulting in these materials entering waste streams after decommissioning. Innovative recycling technologies are emerging, including hydrometallurgical processes that can recover valuable rare earth elements from spent TBC components with recovery rates approaching 80%.

Research trends indicate growing interest in environmentally benign TBC alternatives. Bio-inspired ceramic compositions, water-based slurry deposition methods, and additive manufacturing techniques show promise for reducing environmental impact. Additionally, the development of TBCs with extended service life directly contributes to sustainability by reducing replacement frequency and associated resource consumption.

Regulatory frameworks worldwide are increasingly incorporating environmental performance metrics into material qualification standards for aerospace and power generation applications. This shift is driving manufacturers to adopt cleaner production methods and explore more sustainable material compositions for next-generation TBC systems.

Durability Testing and Performance Validation Methods

Durability testing and performance validation of thermal barrier coatings (TBCs) in turbine engines require rigorous methodologies to ensure reliability under extreme operating conditions. The primary testing approaches include thermal cycling tests, which simulate the rapid temperature changes experienced during engine operation. These tests typically involve heating the coated components to temperatures exceeding 1200°C followed by forced air cooling, with cycles repeated thousands of times to evaluate coating adhesion and thermal fatigue resistance.

Erosion resistance testing constitutes another critical validation method, where coated specimens are subjected to high-velocity particle impacts using specialized rigs that simulate the particulate environment within turbine engines. Parameters such as impact angle, particle size, and velocity are carefully controlled to replicate real-world conditions, with weight loss measurements providing quantitative erosion resistance data.

Hot corrosion testing evaluates TBC performance in chemically aggressive environments containing sulfates, vanadates, and other contaminants present in fuel. These tests typically involve exposure to molten salt mixtures at elevated temperatures for extended periods, followed by microstructural analysis to assess degradation mechanisms and corrosion penetration depth.

Non-destructive evaluation techniques play an essential role in performance validation, including thermography, which detects subsurface delamination through thermal imaging; acoustic emission monitoring, which identifies crack formation during thermal cycling; and impedance spectroscopy, which characterizes electrochemical properties and detects microstructural changes within the coating system.

Engine testing represents the ultimate validation method, where coated components are installed in actual turbine engines or specialized test rigs that replicate engine operating conditions. These tests provide comprehensive performance data under combined thermal, mechanical, and chemical stresses. Post-test analysis typically involves microstructural examination using scanning electron microscopy, X-ray diffraction, and other advanced characterization techniques to identify failure mechanisms and degradation patterns.

Accelerated life testing protocols have been developed to compress decades of service life into manageable test durations. These methods employ mathematical models based on damage accumulation theories to correlate accelerated test results with expected field performance. The development of standardized testing procedures by organizations such as ASTM International and ISO has been crucial for enabling meaningful comparisons between different coating systems and establishing industry benchmarks for durability requirements.

Erosion resistance testing constitutes another critical validation method, where coated specimens are subjected to high-velocity particle impacts using specialized rigs that simulate the particulate environment within turbine engines. Parameters such as impact angle, particle size, and velocity are carefully controlled to replicate real-world conditions, with weight loss measurements providing quantitative erosion resistance data.

Hot corrosion testing evaluates TBC performance in chemically aggressive environments containing sulfates, vanadates, and other contaminants present in fuel. These tests typically involve exposure to molten salt mixtures at elevated temperatures for extended periods, followed by microstructural analysis to assess degradation mechanisms and corrosion penetration depth.

Non-destructive evaluation techniques play an essential role in performance validation, including thermography, which detects subsurface delamination through thermal imaging; acoustic emission monitoring, which identifies crack formation during thermal cycling; and impedance spectroscopy, which characterizes electrochemical properties and detects microstructural changes within the coating system.

Engine testing represents the ultimate validation method, where coated components are installed in actual turbine engines or specialized test rigs that replicate engine operating conditions. These tests provide comprehensive performance data under combined thermal, mechanical, and chemical stresses. Post-test analysis typically involves microstructural examination using scanning electron microscopy, X-ray diffraction, and other advanced characterization techniques to identify failure mechanisms and degradation patterns.

Accelerated life testing protocols have been developed to compress decades of service life into manageable test durations. These methods employ mathematical models based on damage accumulation theories to correlate accelerated test results with expected field performance. The development of standardized testing procedures by organizations such as ASTM International and ISO has been crucial for enabling meaningful comparisons between different coating systems and establishing industry benchmarks for durability requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!