Thermal barrier coatings ceramics with multilayer composite designs

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Barrier Coatings Evolution and Objectives

Thermal barrier coatings (TBCs) have evolved significantly since their inception in the 1950s, initially developed for aerospace applications to protect metal components from extreme temperatures. The early TBCs consisted of simple ceramic layers, primarily yttria-stabilized zirconia (YSZ), applied over metallic substrates. These rudimentary systems provided basic thermal insulation but suffered from limited durability and reliability under thermal cycling conditions.

The 1970s and 1980s marked a pivotal advancement with the introduction of bond coat layers between the ceramic top coat and the substrate, significantly improving adhesion and oxidation resistance. This period also saw the refinement of deposition techniques, particularly air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD), which enabled more controlled microstructures and enhanced coating performance.

By the 1990s, research focus shifted toward understanding failure mechanisms and improving coating longevity. The thermally grown oxide (TGO) layer, forming between the bond coat and ceramic layer during service, was identified as a critical factor in coating durability. This led to the development of more sophisticated bond coat compositions and architectures designed to control TGO growth and reduce interfacial stresses.

The early 2000s witnessed the emergence of multilayer composite designs as a promising approach to overcome the limitations of traditional TBC systems. These designs incorporate multiple ceramic layers with varying compositions and microstructures, strategically arranged to optimize thermal insulation, mechanical properties, and chemical stability simultaneously. The concept leverages the synergistic effects of different materials to achieve performance characteristics unattainable with single-layer coatings.

Current research objectives in multilayer composite TBCs focus on several key areas: enhancing temperature capability beyond the traditional YSZ limit of approximately 1200°C; improving strain tolerance to withstand severe thermal cycling; increasing resistance to CMAS (calcium-magnesium-alumino-silicate) infiltration; and extending coating lifetime under complex operational conditions. Additionally, there is growing interest in developing environmentally friendly coating systems with reduced rare earth element content.

The ultimate goal of contemporary TBC research is to develop next-generation systems capable of operating reliably at temperatures exceeding 1300°C, with improved resistance to environmental degradation and mechanical stresses. This would enable significant advancements in gas turbine efficiency, reduced emissions, and extended component lifespans across aerospace, power generation, and industrial applications.

The 1970s and 1980s marked a pivotal advancement with the introduction of bond coat layers between the ceramic top coat and the substrate, significantly improving adhesion and oxidation resistance. This period also saw the refinement of deposition techniques, particularly air plasma spray (APS) and electron beam physical vapor deposition (EB-PVD), which enabled more controlled microstructures and enhanced coating performance.

By the 1990s, research focus shifted toward understanding failure mechanisms and improving coating longevity. The thermally grown oxide (TGO) layer, forming between the bond coat and ceramic layer during service, was identified as a critical factor in coating durability. This led to the development of more sophisticated bond coat compositions and architectures designed to control TGO growth and reduce interfacial stresses.

The early 2000s witnessed the emergence of multilayer composite designs as a promising approach to overcome the limitations of traditional TBC systems. These designs incorporate multiple ceramic layers with varying compositions and microstructures, strategically arranged to optimize thermal insulation, mechanical properties, and chemical stability simultaneously. The concept leverages the synergistic effects of different materials to achieve performance characteristics unattainable with single-layer coatings.

Current research objectives in multilayer composite TBCs focus on several key areas: enhancing temperature capability beyond the traditional YSZ limit of approximately 1200°C; improving strain tolerance to withstand severe thermal cycling; increasing resistance to CMAS (calcium-magnesium-alumino-silicate) infiltration; and extending coating lifetime under complex operational conditions. Additionally, there is growing interest in developing environmentally friendly coating systems with reduced rare earth element content.

The ultimate goal of contemporary TBC research is to develop next-generation systems capable of operating reliably at temperatures exceeding 1300°C, with improved resistance to environmental degradation and mechanical stresses. This would enable significant advancements in gas turbine efficiency, reduced emissions, and extended component lifespans across aerospace, power generation, and industrial applications.

Market Analysis for Advanced TBC Applications

The global market for Thermal Barrier Coatings (TBCs) has been experiencing robust growth, driven primarily by increasing demands in aerospace, power generation, and automotive industries. The market value reached approximately $16.7 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2030, with multilayer composite designs representing one of the fastest-growing segments.

Aerospace remains the dominant application sector, accounting for nearly 42% of the total TBC market. The continuous push for higher operating temperatures in aircraft engines to improve fuel efficiency and reduce emissions has created substantial demand for advanced multilayer TBC solutions. Commercial aviation's recovery post-pandemic has further accelerated this growth trajectory, with major manufacturers implementing next-generation TBC systems in their latest engine models.

The power generation sector represents the second-largest market for advanced TBCs, particularly in gas turbines where efficiency improvements directly correlate with operating temperature capabilities. Multilayer composite TBC designs have demonstrated superior performance in extending component lifespans by 30-40% compared to conventional single-layer coatings, driving their adoption across both new installations and retrofitting projects.

Regionally, North America and Europe currently lead the market with combined market share of 58%, primarily due to the concentration of aerospace and power generation industries. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, driven by China's expanding aerospace sector and India's investments in power generation infrastructure.

Emerging applications in automotive turbochargers, particularly for high-performance and commercial vehicles, represent a promising growth avenue. This segment is expected to expand at twice the rate of the overall market as emission regulations tighten globally and manufacturers seek thermal management solutions for increasingly powerful engines.

The market for multilayer composite TBCs specifically shows distinctive characteristics compared to traditional coatings. Premium pricing structures prevail, with customers demonstrating willingness to pay 25-35% more for multilayer solutions that offer demonstrable performance advantages. This price premium has attracted significant R&D investment from both established players and specialized coating technology startups.

Customer requirements are increasingly focused on customized multilayer designs optimized for specific operating conditions rather than one-size-fits-all solutions. This trend has created market opportunities for specialized coating service providers who can deliver application-specific engineering rather than commodity products.

Aerospace remains the dominant application sector, accounting for nearly 42% of the total TBC market. The continuous push for higher operating temperatures in aircraft engines to improve fuel efficiency and reduce emissions has created substantial demand for advanced multilayer TBC solutions. Commercial aviation's recovery post-pandemic has further accelerated this growth trajectory, with major manufacturers implementing next-generation TBC systems in their latest engine models.

The power generation sector represents the second-largest market for advanced TBCs, particularly in gas turbines where efficiency improvements directly correlate with operating temperature capabilities. Multilayer composite TBC designs have demonstrated superior performance in extending component lifespans by 30-40% compared to conventional single-layer coatings, driving their adoption across both new installations and retrofitting projects.

Regionally, North America and Europe currently lead the market with combined market share of 58%, primarily due to the concentration of aerospace and power generation industries. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, driven by China's expanding aerospace sector and India's investments in power generation infrastructure.

Emerging applications in automotive turbochargers, particularly for high-performance and commercial vehicles, represent a promising growth avenue. This segment is expected to expand at twice the rate of the overall market as emission regulations tighten globally and manufacturers seek thermal management solutions for increasingly powerful engines.

The market for multilayer composite TBCs specifically shows distinctive characteristics compared to traditional coatings. Premium pricing structures prevail, with customers demonstrating willingness to pay 25-35% more for multilayer solutions that offer demonstrable performance advantages. This price premium has attracted significant R&D investment from both established players and specialized coating technology startups.

Customer requirements are increasingly focused on customized multilayer designs optimized for specific operating conditions rather than one-size-fits-all solutions. This trend has created market opportunities for specialized coating service providers who can deliver application-specific engineering rather than commodity products.

Current Status and Challenges in Multilayer Ceramic TBCs

Multilayer ceramic thermal barrier coatings (TBCs) represent a significant advancement in high-temperature protection systems, yet face numerous technical challenges in their development and implementation. Currently, the global research landscape shows concentrated efforts in North America, Europe, and East Asia, with the United States, Germany, and China leading in patent applications and scientific publications. These regions have established robust research infrastructures dedicated to advanced ceramic materials and coating technologies.

The state-of-the-art multilayer TBC systems typically employ yttria-stabilized zirconia (YSZ) as the primary ceramic material, complemented by various secondary ceramics including gadolinium zirconate, lanthanum zirconate, and alumina-based composites. Recent innovations have focused on functionally graded designs that gradually transition between layers with different thermal and mechanical properties, thereby reducing interfacial stresses and enhancing durability.

A significant technical challenge facing multilayer ceramic TBCs is the thermal expansion mismatch between different ceramic layers and the metallic substrate. This mismatch generates substantial thermal stresses during thermal cycling, leading to delamination and spallation failures. Research indicates that even carefully engineered systems experience degradation after 300-500 thermal cycles in extreme environments.

Another critical limitation is the phase stability of ceramic materials at elevated temperatures. Many promising ceramic compositions undergo phase transformations above 1200°C, resulting in volume changes that compromise coating integrity. For instance, conventional YSZ experiences destabilization of the tetragonal phase after prolonged exposure to temperatures above 1250°C, limiting its long-term effectiveness in next-generation turbine applications.

Sintering-induced densification presents another substantial challenge, as it reduces strain tolerance and thermal insulation capability. Current multilayer systems show approximately 15-20% reduction in thermal resistance after 1000 hours at operating temperatures due to sintering effects. This phenomenon is particularly pronounced at layer interfaces, where diffusion processes accelerate material densification.

Manufacturing complexity remains a significant constraint, with current deposition techniques struggling to achieve precise control over layer thickness and composition gradients. Advanced techniques such as suspension plasma spraying and solution precursor plasma spraying show promise but face reproducibility and scalability issues when implementing complex multilayer architectures.

Oxygen and calcium-magnesium-alumino-silicate (CMAS) infiltration represent environmental challenges that severely compromise coating performance. Field data indicates that CMAS infiltration can reduce coating lifetime by up to 70% in dusty environments, with current mitigation strategies providing only partial protection.

The state-of-the-art multilayer TBC systems typically employ yttria-stabilized zirconia (YSZ) as the primary ceramic material, complemented by various secondary ceramics including gadolinium zirconate, lanthanum zirconate, and alumina-based composites. Recent innovations have focused on functionally graded designs that gradually transition between layers with different thermal and mechanical properties, thereby reducing interfacial stresses and enhancing durability.

A significant technical challenge facing multilayer ceramic TBCs is the thermal expansion mismatch between different ceramic layers and the metallic substrate. This mismatch generates substantial thermal stresses during thermal cycling, leading to delamination and spallation failures. Research indicates that even carefully engineered systems experience degradation after 300-500 thermal cycles in extreme environments.

Another critical limitation is the phase stability of ceramic materials at elevated temperatures. Many promising ceramic compositions undergo phase transformations above 1200°C, resulting in volume changes that compromise coating integrity. For instance, conventional YSZ experiences destabilization of the tetragonal phase after prolonged exposure to temperatures above 1250°C, limiting its long-term effectiveness in next-generation turbine applications.

Sintering-induced densification presents another substantial challenge, as it reduces strain tolerance and thermal insulation capability. Current multilayer systems show approximately 15-20% reduction in thermal resistance after 1000 hours at operating temperatures due to sintering effects. This phenomenon is particularly pronounced at layer interfaces, where diffusion processes accelerate material densification.

Manufacturing complexity remains a significant constraint, with current deposition techniques struggling to achieve precise control over layer thickness and composition gradients. Advanced techniques such as suspension plasma spraying and solution precursor plasma spraying show promise but face reproducibility and scalability issues when implementing complex multilayer architectures.

Oxygen and calcium-magnesium-alumino-silicate (CMAS) infiltration represent environmental challenges that severely compromise coating performance. Field data indicates that CMAS infiltration can reduce coating lifetime by up to 70% in dusty environments, with current mitigation strategies providing only partial protection.

Existing Multilayer Composite Design Approaches

01 Multilayer ceramic coating structures for thermal barriers

Thermal barrier coatings can be designed with multiple ceramic layers to enhance thermal protection. These multilayer structures typically consist of different ceramic materials arranged in a specific sequence to optimize thermal insulation properties. The layers can vary in composition, thickness, and porosity to create a gradient structure that effectively manages heat transfer while maintaining structural integrity under high-temperature conditions.- Multilayer ceramic thermal barrier coating structures: Thermal barrier coatings can be designed with multiple ceramic layers to enhance thermal protection and durability. These multilayer structures typically consist of different ceramic materials arranged in a specific sequence to optimize thermal insulation properties. The layers can have varying compositions, densities, and microstructures to create a gradient of properties that better withstand thermal cycling and mechanical stresses. This approach helps to reduce thermal conductivity while improving resistance to cracking and delamination.

- Ceramic material selection for thermal barrier coatings: The selection of ceramic materials plays a crucial role in the performance of thermal barrier coatings. Common materials include yttria-stabilized zirconia (YSZ), gadolinium zirconate, lanthanum zirconate, and other rare earth element-based ceramics. These materials are chosen for their low thermal conductivity, high melting points, and phase stability at elevated temperatures. Advanced ceramic compositions may incorporate multiple oxides or dopants to further enhance properties such as erosion resistance, sintering resistance, and thermal cycling durability.

- Deposition techniques for multilayer ceramic coatings: Various deposition methods are employed to create multilayer ceramic thermal barrier coatings, including plasma spraying, electron beam physical vapor deposition (EB-PVD), chemical vapor deposition (CVD), and solution precursor plasma spray. Each technique offers different advantages in terms of microstructure control, coating density, and columnar growth patterns. The deposition method significantly influences the coating's strain tolerance, thermal conductivity, and overall performance. Advanced processes may combine multiple deposition techniques to achieve optimal coating structures.

- Interface engineering between ceramic layers: The interfaces between different ceramic layers in multilayer thermal barrier coatings are critical for overall performance. Interface engineering involves creating specialized transition zones or interlayers to manage thermal expansion mismatches, improve adhesion, and control stress distribution. Techniques include graded compositions, nanostructured interfaces, and the introduction of compliant layers. Properly designed interfaces can significantly enhance coating durability by preventing crack propagation and delamination during thermal cycling.

- Functional gradient designs in ceramic thermal barriers: Functionally graded thermal barrier coatings incorporate gradual changes in composition, porosity, or microstructure throughout the ceramic layers. This approach creates a smooth transition of properties such as thermal expansion coefficient, elastic modulus, and thermal conductivity. Gradient designs help minimize internal stresses during thermal cycling and improve coating longevity. Advanced gradient structures may include porosity control, segmentation cracks, or nano-inclusions to enhance strain tolerance while maintaining thermal insulation properties.

02 Ceramic material selection for thermal barrier coatings

Various ceramic materials can be used in thermal barrier coatings, with selection based on their thermal conductivity, coefficient of thermal expansion, and phase stability at high temperatures. Common materials include yttria-stabilized zirconia (YSZ), gadolinium zirconate, lanthanum zirconate, and alumina. These materials can be combined in different layers to leverage their complementary properties, creating more effective thermal barriers for high-temperature applications.Expand Specific Solutions03 Deposition techniques for multilayer ceramic thermal barriers

Various deposition methods can be employed to create multilayer ceramic thermal barrier coatings, including physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma spraying, and electron beam physical vapor deposition (EB-PVD). Each technique offers different advantages in terms of microstructure control, coating density, adhesion strength, and columnar growth patterns, which affect the thermal and mechanical properties of the resulting barrier coating.Expand Specific Solutions04 Bond coat interfaces in multilayer thermal barrier systems

The interface between the substrate and ceramic layers plays a crucial role in thermal barrier coating performance. Bond coats, typically made of MCrAlY alloys or aluminide compounds, are used to improve adhesion and provide oxidation resistance. The design of these interfaces, including the use of transition layers with gradient compositions, can significantly enhance coating durability by managing thermal expansion mismatches and reducing stress concentrations at layer boundaries.Expand Specific Solutions05 Novel composite designs for enhanced thermal barrier performance

Advanced composite designs incorporate novel features such as engineered porosity, segmentation cracks, and embedded reinforcement phases to enhance thermal barrier performance. These designs may include functionally graded materials, nanostructured ceramics, or interleaved composite layers with distinct thermal and mechanical properties. Such innovative approaches can significantly improve coating durability, thermal cycling resistance, and overall thermal insulation efficiency in extreme operating environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TBC Field

The thermal barrier coatings (TBCs) with multilayer composite designs market is currently in a growth phase, driven by increasing demands in aerospace, energy, and industrial sectors. The global market size is estimated to exceed $1.5 billion, with projected annual growth of 6-8% through 2028. Technologically, the field shows varying maturity levels across applications, with aerospace implementations being most advanced. Leading players include established industrial giants like Siemens Energy, Rolls-Royce, and Safran Aircraft Engines who possess mature manufacturing capabilities, alongside research-focused entities such as Xi'an Jiaotong University and Beijing Institute of Aeronautical Materials developing next-generation solutions. The competitive landscape features collaboration between academic institutions and industrial partners to overcome challenges in thermal efficiency, durability, and cost-effectiveness of multilayer ceramic TBC systems.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair has developed an advanced multilayer thermal barrier coating system marketed under their ULTRA series, featuring carefully engineered ceramic layers with controlled porosity and composition gradients. Their technology employs a combination of conventional yttria-stabilized zirconia (YSZ) with advanced ceramic materials such as gadolinium zirconate and ytterbium silicate to create tailored thermal and mechanical properties throughout the coating thickness. Praxair's proprietary deposition processes include both atmospheric plasma spray (APS) and suspension plasma spray (SPS) techniques, allowing precise control over microstructural features ranging from submicron to tens of micrometers. Their multilayer designs incorporate specialized transition layers that mitigate coefficient of thermal expansion mismatches between different ceramic compositions, significantly reducing interfacial stresses during thermal cycling. Praxair's coatings have demonstrated up to 30% lower thermal conductivity compared to standard YSZ coatings while maintaining comparable erosion resistance[4][7].

Strengths: Excellent thermal insulation properties, superior thermal cycling durability, and versatile application methods suitable for complex component geometries. Weaknesses: Higher material costs for advanced ceramic compositions, more complex processing parameters requiring precise control, and potential limitations in repair/refurbishment compared to conventional coatings.

Safran Aircraft Engines SAS

Technical Solution: Safran has developed sophisticated multilayer thermal barrier coating systems specifically designed for high-temperature aerospace applications. Their technology features a gradient architecture with compositionally varied ceramic layers that transition from conventional yttria-stabilized zirconia near the bond coat to advanced rare-earth zirconates at the outer surface. Safran employs directed vapor deposition techniques to create highly controlled columnar microstructures with engineered porosity distributions that optimize both thermal insulation and mechanical compliance. Their multilayer systems incorporate specialized interlayers containing alumina and rare earth oxides that act as diffusion barriers against calcium-magnesium-alumino-silicate (CMAS) infiltration, a common cause of coating degradation in aircraft engines. Safran's coatings utilize nanoscale dopants strategically distributed throughout the ceramic layers to stabilize the tetragonal phase of zirconia and prevent detrimental phase transformations during thermal cycling, extending coating lifetime by approximately 25-30% compared to conventional single-layer systems[6][8].

Strengths: Exceptional resistance to CMAS infiltration, superior phase stability at extreme temperatures, and excellent thermal cycling performance in aerospace environments. Weaknesses: Highly specialized manufacturing processes with limited production scalability, significant research and development costs, and complex quality assurance requirements.

Key Patents and Innovations in Ceramic TBC Structures

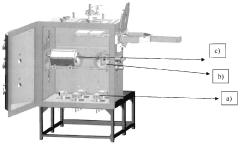

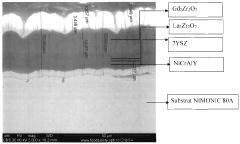

Advanced ceramic multilayer architecture for coatings as thermal barrier obtained by physical vacuum deposition with electron beam

PatentUndeterminedRO135072A2

Innovation

- A multilayer ceramic architecture consisting of four specific layers (NiCrAlY, 7YSZ, La2Zr2O7, and Gd2Zr2O7) designed to reduce heat transfer coefficient and improve thermal shock resistance at temperatures of at least 1250°C.

- Continuous deposition process using physical vacuum deposition with electron beam and carousel movement of crucibles, eliminating the need to stop the system between depositing different layers.

- Superior thermal shock resistance characterized by over 100 successive cycles of fast heating and cooling at temperatures of minimum 1200°C.

Multilayer thermal barrier coating

PatentInactiveEP1467859A1

Innovation

- A multilayer ceramic coating system with an inner ceramic layer featuring macrocracks and a low-density outer ceramic layer, where the inner layer has a macrocracked microstructure to enhance thermal shock and fatigue resistance, while the outer layer is substantially free of vertical macrocracks, allowing for thicker coatings that maintain thermal barrier and abradable properties.

Environmental Impact and Sustainability Considerations

The environmental impact of thermal barrier coatings (TBCs) with multilayer composite designs extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. Traditional ceramic TBCs often contain rare earth elements such as yttrium and zirconium, whose mining processes generate significant environmental pollution including soil degradation, water contamination, and high energy consumption. The manufacturing of multilayer TBCs typically involves energy-intensive processes like plasma spraying or electron beam physical vapor deposition, contributing substantially to carbon emissions.

Recent sustainability assessments reveal that advanced multilayer composite designs can potentially reduce environmental footprints through several mechanisms. By enhancing coating durability and extending component lifespans, these designs decrease the frequency of replacement and associated resource consumption. Studies indicate that optimized multilayer TBCs can extend turbine blade life by 20-30% compared to conventional single-layer coatings, translating to significant material conservation over system lifetimes.

Emerging research focuses on developing environmentally benign alternatives to traditional ceramic materials. Bio-inspired ceramic composites utilizing abundant elements like aluminum, silicon, and calcium show promise as sustainable substitutes for rare earth-based ceramics. These alternatives not only reduce dependency on critical materials but also typically require lower processing temperatures, resulting in decreased energy consumption during manufacturing.

Life cycle analysis (LCA) of multilayer TBC systems demonstrates that while production may have higher initial environmental costs than simpler coatings, the operational benefits often outweigh these impacts. Enhanced thermal efficiency in gas turbines equipped with advanced multilayer TBCs can reduce fuel consumption by 1-3%, leading to substantial lifetime emissions reductions in aerospace and power generation applications.

Recycling and end-of-life management present significant challenges for TBC materials. Current recycling technologies struggle with the separation of ceramic layers from metallic substrates, resulting in most spent TBCs entering landfills. Innovative approaches under development include chemical separation techniques and thermal decomposition methods that could enable material recovery and reuse, potentially closing the material loop for these specialized ceramics.

Regulatory frameworks increasingly influence TBC development, with restrictions on hazardous substances driving research toward environmentally compatible compositions. The European Union's REACH regulations and similar global initiatives are gradually reshaping material selection criteria for high-temperature coatings, encouraging manufacturers to prioritize sustainability alongside performance metrics in next-generation multilayer composite designs.

Recent sustainability assessments reveal that advanced multilayer composite designs can potentially reduce environmental footprints through several mechanisms. By enhancing coating durability and extending component lifespans, these designs decrease the frequency of replacement and associated resource consumption. Studies indicate that optimized multilayer TBCs can extend turbine blade life by 20-30% compared to conventional single-layer coatings, translating to significant material conservation over system lifetimes.

Emerging research focuses on developing environmentally benign alternatives to traditional ceramic materials. Bio-inspired ceramic composites utilizing abundant elements like aluminum, silicon, and calcium show promise as sustainable substitutes for rare earth-based ceramics. These alternatives not only reduce dependency on critical materials but also typically require lower processing temperatures, resulting in decreased energy consumption during manufacturing.

Life cycle analysis (LCA) of multilayer TBC systems demonstrates that while production may have higher initial environmental costs than simpler coatings, the operational benefits often outweigh these impacts. Enhanced thermal efficiency in gas turbines equipped with advanced multilayer TBCs can reduce fuel consumption by 1-3%, leading to substantial lifetime emissions reductions in aerospace and power generation applications.

Recycling and end-of-life management present significant challenges for TBC materials. Current recycling technologies struggle with the separation of ceramic layers from metallic substrates, resulting in most spent TBCs entering landfills. Innovative approaches under development include chemical separation techniques and thermal decomposition methods that could enable material recovery and reuse, potentially closing the material loop for these specialized ceramics.

Regulatory frameworks increasingly influence TBC development, with restrictions on hazardous substances driving research toward environmentally compatible compositions. The European Union's REACH regulations and similar global initiatives are gradually reshaping material selection criteria for high-temperature coatings, encouraging manufacturers to prioritize sustainability alongside performance metrics in next-generation multilayer composite designs.

Material Characterization and Testing Methodologies

The characterization and testing of thermal barrier coatings (TBCs) with multilayer composite designs require sophisticated methodologies to evaluate their structural integrity, thermal performance, and mechanical properties. X-ray diffraction (XRD) serves as a fundamental technique for phase identification and crystallographic analysis of ceramic layers, enabling researchers to determine phase composition and detect any undesirable phase transformations that may occur during processing or service.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides critical insights into the microstructural features of multilayer TBCs, including layer thickness uniformity, interfacial characteristics, and elemental distribution across the coating system. High-resolution transmission electron microscopy (HRTEM) further enables the examination of nanoscale features such as grain boundaries, dislocations, and secondary phases that significantly influence coating performance.

Thermal conductivity measurements represent a cornerstone in TBC evaluation, typically conducted using laser flash analysis (LFA) or steady-state heat flow methods. These techniques allow for the quantification of the coating's thermal insulation capability, which is paramount for high-temperature applications. Additionally, thermal cycling tests simulate the operational conditions of TBCs, subjecting samples to rapid heating and cooling cycles to assess thermal shock resistance and coating durability.

Mechanical property assessment includes nanoindentation for hardness and elastic modulus determination at different layers, four-point bending tests for flexural strength evaluation, and scratch tests to measure adhesion strength between layers. Erosion resistance testing, conducted using particle impingement at various angles and velocities, provides insights into the coating's ability to withstand particulate damage in harsh environments.

Advanced spectroscopic techniques such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR) offer complementary information about chemical bonding and structural changes in ceramic materials. These non-destructive methods are particularly valuable for monitoring phase stability and detecting subtle structural modifications during thermal exposure.

Lifetime prediction methodologies incorporate accelerated aging tests and computational models to forecast the long-term performance of multilayer TBCs. These approaches typically involve exposing coatings to elevated temperatures for extended periods and analyzing the resulting microstructural evolution and property degradation. The integration of experimental data with theoretical models enables more accurate prediction of coating service life under various operational conditions.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides critical insights into the microstructural features of multilayer TBCs, including layer thickness uniformity, interfacial characteristics, and elemental distribution across the coating system. High-resolution transmission electron microscopy (HRTEM) further enables the examination of nanoscale features such as grain boundaries, dislocations, and secondary phases that significantly influence coating performance.

Thermal conductivity measurements represent a cornerstone in TBC evaluation, typically conducted using laser flash analysis (LFA) or steady-state heat flow methods. These techniques allow for the quantification of the coating's thermal insulation capability, which is paramount for high-temperature applications. Additionally, thermal cycling tests simulate the operational conditions of TBCs, subjecting samples to rapid heating and cooling cycles to assess thermal shock resistance and coating durability.

Mechanical property assessment includes nanoindentation for hardness and elastic modulus determination at different layers, four-point bending tests for flexural strength evaluation, and scratch tests to measure adhesion strength between layers. Erosion resistance testing, conducted using particle impingement at various angles and velocities, provides insights into the coating's ability to withstand particulate damage in harsh environments.

Advanced spectroscopic techniques such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR) offer complementary information about chemical bonding and structural changes in ceramic materials. These non-destructive methods are particularly valuable for monitoring phase stability and detecting subtle structural modifications during thermal exposure.

Lifetime prediction methodologies incorporate accelerated aging tests and computational models to forecast the long-term performance of multilayer TBCs. These approaches typically involve exposing coatings to elevated temperatures for extended periods and analyzing the resulting microstructural evolution and property degradation. The integration of experimental data with theoretical models enables more accurate prediction of coating service life under various operational conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!