Heterogeneous Integration Thermal Design: Hot-Spot Sharing, TIMs And Microfluidics

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heterogeneous Integration Thermal Management Background and Objectives

Heterogeneous integration (HI) has emerged as a pivotal technology in the semiconductor industry, enabling the combination of disparate components fabricated using different process technologies into a single package. This integration approach has evolved significantly over the past two decades, transitioning from simple multi-chip modules to complex 2.5D and 3D architectures that incorporate diverse materials and components.

The thermal management challenges associated with heterogeneous integration have become increasingly critical as power densities continue to rise. Historical trends show that while transistor dimensions have shrunk according to Moore's Law, power densities have escalated dramatically, creating thermal bottlenecks that limit system performance. The industry has progressed from simple heat sinks to sophisticated cooling solutions, yet thermal issues remain a primary constraint in advanced electronic systems.

Current technological trajectories indicate that heterogeneous integration will continue to accelerate, driven by applications in high-performance computing, artificial intelligence, and edge computing that demand unprecedented levels of performance and energy efficiency. This evolution necessitates innovative thermal management approaches that can address the unique challenges of heterogeneous systems.

The primary objective of thermal design in heterogeneous integration is to maintain all components within their specified operating temperature ranges while maximizing system performance and reliability. This requires holistic thermal solutions that can effectively manage heat across different materials with varying thermal properties and across components with disparate power profiles.

Hot-spot sharing represents an emerging thermal management strategy that leverages the spatial distribution of heat-generating components to minimize peak temperatures. Thermal Interface Materials (TIMs) continue to evolve, with research focused on developing materials with higher thermal conductivity, improved reliability, and compatibility with heterogeneous integration processes.

Microfluidic cooling has emerged as a promising advanced thermal management technique, offering significantly higher heat removal capabilities compared to conventional air cooling. The integration of microfluidic channels directly into electronic packages enables targeted cooling of high-power components and hot spots, potentially revolutionizing thermal management in heterogeneous systems.

The technical goals for heterogeneous integration thermal design include developing predictive thermal modeling capabilities for complex heterogeneous systems, creating novel materials and structures that enhance heat dissipation, and establishing design methodologies that optimize thermal performance while considering electrical, mechanical, and manufacturing constraints. Additionally, there is a critical need for standardized thermal testing and characterization methods specific to heterogeneous integrated systems.

The thermal management challenges associated with heterogeneous integration have become increasingly critical as power densities continue to rise. Historical trends show that while transistor dimensions have shrunk according to Moore's Law, power densities have escalated dramatically, creating thermal bottlenecks that limit system performance. The industry has progressed from simple heat sinks to sophisticated cooling solutions, yet thermal issues remain a primary constraint in advanced electronic systems.

Current technological trajectories indicate that heterogeneous integration will continue to accelerate, driven by applications in high-performance computing, artificial intelligence, and edge computing that demand unprecedented levels of performance and energy efficiency. This evolution necessitates innovative thermal management approaches that can address the unique challenges of heterogeneous systems.

The primary objective of thermal design in heterogeneous integration is to maintain all components within their specified operating temperature ranges while maximizing system performance and reliability. This requires holistic thermal solutions that can effectively manage heat across different materials with varying thermal properties and across components with disparate power profiles.

Hot-spot sharing represents an emerging thermal management strategy that leverages the spatial distribution of heat-generating components to minimize peak temperatures. Thermal Interface Materials (TIMs) continue to evolve, with research focused on developing materials with higher thermal conductivity, improved reliability, and compatibility with heterogeneous integration processes.

Microfluidic cooling has emerged as a promising advanced thermal management technique, offering significantly higher heat removal capabilities compared to conventional air cooling. The integration of microfluidic channels directly into electronic packages enables targeted cooling of high-power components and hot spots, potentially revolutionizing thermal management in heterogeneous systems.

The technical goals for heterogeneous integration thermal design include developing predictive thermal modeling capabilities for complex heterogeneous systems, creating novel materials and structures that enhance heat dissipation, and establishing design methodologies that optimize thermal performance while considering electrical, mechanical, and manufacturing constraints. Additionally, there is a critical need for standardized thermal testing and characterization methods specific to heterogeneous integrated systems.

Market Demand Analysis for Advanced Thermal Solutions

The market for advanced thermal management solutions in heterogeneous integration is experiencing unprecedented growth, driven primarily by the increasing power densities and thermal challenges in modern electronic systems. According to recent industry analyses, the global thermal management market is projected to reach $16.2 billion by 2026, with solutions specifically for heterogeneous integration representing one of the fastest-growing segments at a CAGR of 8.7%.

The demand for innovative thermal solutions is particularly acute in high-performance computing, telecommunications, automotive electronics, and consumer electronics sectors. Data centers alone have seen a 35% increase in cooling solution investments over the past three years, as rack densities continue to climb beyond 30kW per rack in many facilities.

Hot-spot management has become a critical concern as processing units in heterogeneous systems can generate localized heat fluxes exceeding 500 W/cm², far beyond the capabilities of conventional cooling technologies. This has created a substantial market opportunity for hot-spot sharing technologies that can effectively distribute thermal loads across integrated systems.

Thermal Interface Materials (TIMs) represent another high-growth segment, with the market for advanced TIMs growing at 11.3% annually. The demand is driven by requirements for materials with thermal conductivities above 20 W/mK while maintaining compliance and reliability through thousands of thermal cycles. Industries are willing to pay premium prices for TIMs that can reduce thermal resistance below 5 mm²K/W while offering long-term stability.

Microfluidic cooling solutions are emerging as the most promising technology for ultra-high-power density applications. Market research indicates that 67% of high-performance computing manufacturers are actively exploring or implementing microfluidic cooling technologies. The market for microfluidic cooling systems is expected to triple in size by 2028, with particular growth in applications requiring cooling capacities above 1000 W/cm².

Customer requirements are increasingly focused on solutions that not only provide superior thermal performance but also contribute to overall system efficiency. Energy consumption for cooling now represents up to 40% of total data center operating costs, creating strong market pull for thermally efficient designs that reduce this overhead.

Geographically, North America leads in adoption of advanced thermal solutions with 38% market share, followed by Asia-Pacific at 34%, which is showing the fastest growth rate. The European market, while smaller at 22%, is distinguished by stringent efficiency requirements driving innovation in sustainable cooling technologies.

The demand for innovative thermal solutions is particularly acute in high-performance computing, telecommunications, automotive electronics, and consumer electronics sectors. Data centers alone have seen a 35% increase in cooling solution investments over the past three years, as rack densities continue to climb beyond 30kW per rack in many facilities.

Hot-spot management has become a critical concern as processing units in heterogeneous systems can generate localized heat fluxes exceeding 500 W/cm², far beyond the capabilities of conventional cooling technologies. This has created a substantial market opportunity for hot-spot sharing technologies that can effectively distribute thermal loads across integrated systems.

Thermal Interface Materials (TIMs) represent another high-growth segment, with the market for advanced TIMs growing at 11.3% annually. The demand is driven by requirements for materials with thermal conductivities above 20 W/mK while maintaining compliance and reliability through thousands of thermal cycles. Industries are willing to pay premium prices for TIMs that can reduce thermal resistance below 5 mm²K/W while offering long-term stability.

Microfluidic cooling solutions are emerging as the most promising technology for ultra-high-power density applications. Market research indicates that 67% of high-performance computing manufacturers are actively exploring or implementing microfluidic cooling technologies. The market for microfluidic cooling systems is expected to triple in size by 2028, with particular growth in applications requiring cooling capacities above 1000 W/cm².

Customer requirements are increasingly focused on solutions that not only provide superior thermal performance but also contribute to overall system efficiency. Energy consumption for cooling now represents up to 40% of total data center operating costs, creating strong market pull for thermally efficient designs that reduce this overhead.

Geographically, North America leads in adoption of advanced thermal solutions with 38% market share, followed by Asia-Pacific at 34%, which is showing the fastest growth rate. The European market, while smaller at 22%, is distinguished by stringent efficiency requirements driving innovation in sustainable cooling technologies.

Current Thermal Management Challenges in Heterogeneous Integration

Heterogeneous integration has emerged as a critical approach in modern semiconductor packaging, enabling the combination of diverse components into a single package. However, this integration introduces significant thermal management challenges that must be addressed to ensure reliable operation and optimal performance of these complex systems.

The primary thermal challenge in heterogeneous integration stems from the increased power density resulting from the close proximity of multiple active components. With different devices operating at varying power levels, localized hot spots form that can significantly exceed the average package temperature. These thermal gradients create mechanical stresses due to coefficient of thermal expansion (CTE) mismatches between different materials, potentially leading to reliability issues such as delamination, cracking, or solder joint failures.

Traditional cooling solutions like heat sinks and fans are becoming inadequate for addressing the thermal demands of heterogeneous integrated packages. The thermal resistance between different layers and interfaces presents a substantial barrier to efficient heat dissipation. As package thickness decreases and integration density increases, the thermal pathways become more constrained, exacerbating the challenge of removing heat effectively from the system.

Another significant challenge is the thermal coupling between different components within the package. Heat generated by high-power components can adversely affect the performance and reliability of temperature-sensitive neighboring devices. This thermal crosstalk necessitates sophisticated thermal isolation strategies or innovative heat spreading techniques to maintain optimal operating conditions for all integrated components.

The interface materials used between different layers present their own set of challenges. Thermal interface materials (TIMs) often represent the weakest link in the thermal path, with their performance degrading over time due to pump-out, dry-out, or delamination effects. The trade-off between thermal conductivity, mechanical compliance, and long-term reliability remains a significant obstacle in TIM selection and application.

Emerging 3D integration approaches further complicate thermal management by creating structures with limited access for cooling solutions. The vertical stacking of dies creates thermal bottlenecks, particularly for components located in the middle layers that lack direct paths to heat sinks or other cooling mechanisms.

The increasing integration of high-power components such as GPUs, CPUs, and power devices alongside sensitive components like memory and sensors demands more sophisticated thermal management approaches. Conventional cooling methods are reaching their physical limits, necessitating exploration of advanced solutions like microfluidic cooling, phase change materials, and novel heat spreading technologies.

The primary thermal challenge in heterogeneous integration stems from the increased power density resulting from the close proximity of multiple active components. With different devices operating at varying power levels, localized hot spots form that can significantly exceed the average package temperature. These thermal gradients create mechanical stresses due to coefficient of thermal expansion (CTE) mismatches between different materials, potentially leading to reliability issues such as delamination, cracking, or solder joint failures.

Traditional cooling solutions like heat sinks and fans are becoming inadequate for addressing the thermal demands of heterogeneous integrated packages. The thermal resistance between different layers and interfaces presents a substantial barrier to efficient heat dissipation. As package thickness decreases and integration density increases, the thermal pathways become more constrained, exacerbating the challenge of removing heat effectively from the system.

Another significant challenge is the thermal coupling between different components within the package. Heat generated by high-power components can adversely affect the performance and reliability of temperature-sensitive neighboring devices. This thermal crosstalk necessitates sophisticated thermal isolation strategies or innovative heat spreading techniques to maintain optimal operating conditions for all integrated components.

The interface materials used between different layers present their own set of challenges. Thermal interface materials (TIMs) often represent the weakest link in the thermal path, with their performance degrading over time due to pump-out, dry-out, or delamination effects. The trade-off between thermal conductivity, mechanical compliance, and long-term reliability remains a significant obstacle in TIM selection and application.

Emerging 3D integration approaches further complicate thermal management by creating structures with limited access for cooling solutions. The vertical stacking of dies creates thermal bottlenecks, particularly for components located in the middle layers that lack direct paths to heat sinks or other cooling mechanisms.

The increasing integration of high-power components such as GPUs, CPUs, and power devices alongside sensitive components like memory and sensors demands more sophisticated thermal management approaches. Conventional cooling methods are reaching their physical limits, necessitating exploration of advanced solutions like microfluidic cooling, phase change materials, and novel heat spreading technologies.

Hot-Spot Sharing, TIMs and Microfluidics Solutions Overview

01 Thermal Interface Materials (TIMs) for Heat Dissipation

Advanced thermal interface materials are used to enhance heat transfer between different components in heterogeneous integrated systems. These materials fill microscopic air gaps between surfaces to improve thermal conductivity. High-performance TIMs include metal-based composites, phase change materials, and polymer matrices with thermally conductive fillers that can significantly reduce thermal resistance at interfaces, allowing for more efficient heat dissipation from hot spots.- Thermal Interface Materials (TIMs) for Heat Dissipation: Advanced thermal interface materials are used to enhance heat transfer between different components in heterogeneous integrated systems. These materials fill microscopic air gaps between surfaces to maximize thermal conductivity. High-performance TIMs include metal-based composites, phase change materials, and carbon-based solutions that efficiently transfer heat away from hot spots to heat sinks or other cooling structures, significantly improving thermal management in densely packed semiconductor devices.

- Microfluidic Cooling Systems for Hot Spot Management: Microfluidic cooling technologies incorporate miniaturized fluid channels directly into or adjacent to semiconductor devices to target and mitigate hot spots. These systems use liquid coolants that flow through microscale channels to efficiently remove heat from critical areas. The design includes precise fluid routing to high-heat-generating components, optimized channel geometries, and specialized coolants that can be actively controlled to respond to dynamic thermal loads, providing superior cooling performance compared to traditional air-based solutions.

- Thermal Design for 3D and Heterogeneous Integration: Thermal management strategies specifically designed for three-dimensional and heterogeneously integrated semiconductor packages address the unique challenges of stacked die configurations. These approaches include strategic placement of components to distribute heat generation, incorporation of thermal vias and through-silicon vias (TSVs) for vertical heat conduction, and implementation of intermediate heat spreading layers. The designs focus on balancing electrical performance with thermal considerations to prevent localized overheating while maintaining the benefits of high-density integration.

- Hot-Spot Sharing and Thermal Load Distribution: Hot-spot sharing techniques distribute thermal loads across integrated systems to prevent localized overheating. These methods include dynamic workload management that shifts processing tasks between different functional units, strategic placement of high-heat-generating components to optimize heat spreading, and the use of embedded thermal sensors for real-time temperature monitoring. Advanced algorithms analyze thermal profiles to make intelligent decisions about power management and task scheduling, effectively balancing thermal loads across the entire system.

- Thermal Testing and Characterization for Heterogeneous Systems: Specialized thermal testing and characterization methods are developed for heterogeneous integrated systems to identify hot spots and validate cooling solutions. These approaches include high-resolution thermal imaging, embedded temperature sensor arrays, and computational fluid dynamics simulations to predict thermal behavior. Testing protocols evaluate the performance of thermal management solutions under various operating conditions and workloads, ensuring reliability and optimal performance of complex integrated systems throughout their operational lifetime.

02 Microfluidic Cooling Solutions for Hot Spot Management

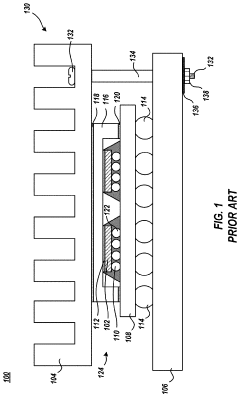

Microfluidic cooling systems incorporate small channels directly into or adjacent to semiconductor devices to circulate cooling fluids near heat-generating components. These systems enable targeted cooling of hot spots through direct liquid cooling, which offers higher heat transfer coefficients compared to traditional air cooling. Advanced designs include 3D microchannels, impingement cooling, and two-phase cooling techniques that can be integrated into heterogeneous packages to address localized thermal challenges.Expand Specific Solutions03 Thermal Design for 3D Stacked Architectures

Thermal management strategies for 3D stacked architectures focus on distributing heat-generating components to avoid thermal coupling of hot spots. These designs incorporate thermal through-silicon vias (TSVs), interposer layers with embedded cooling structures, and strategic die placement to facilitate heat spreading. Advanced thermal modeling techniques are used to predict and mitigate thermal issues in complex 3D integrated circuits, ensuring reliable operation despite the increased power density.Expand Specific Solutions04 Dynamic Thermal Management and Hot-Spot Sharing

Dynamic thermal management techniques involve real-time monitoring and control of temperature distributions across heterogeneously integrated systems. These approaches include workload migration, frequency scaling, and power gating to distribute heat generation temporally and spatially. Hot-spot sharing strategies deliberately distribute computational loads across multiple processing elements to prevent localized overheating, using thermal-aware task scheduling algorithms and adaptive power management to maintain optimal thermal profiles.Expand Specific Solutions05 Novel Materials and Structures for Thermal Conductivity Enhancement

Innovative materials and structural designs are being developed to enhance thermal conductivity in heterogeneous integrated systems. These include graphene-based composites, diamond-like carbon films, and engineered metamaterials with directional heat transfer properties. Advanced packaging technologies incorporate thermal spreaders, embedded heat pipes, and vapor chambers to efficiently distribute heat away from hot spots. These materials and structures are designed to accommodate the thermal expansion mismatch between different integrated components while maintaining mechanical integrity.Expand Specific Solutions

Leading Companies and Research Institutions in Thermal Management

Heterogeneous Integration Thermal Design is currently in a transitional growth phase, with the market expanding rapidly due to increasing demand for advanced thermal management solutions in high-performance computing and electronics. The global market is projected to reach significant scale as thermal challenges become critical bottlenecks in semiconductor advancement. Technologically, the field is maturing with various approaches gaining traction. Intel and IBM lead in microfluidic cooling research, while companies like Indium Corporation and Henkel focus on advanced Thermal Interface Materials (TIMs). Arieca and Phononics represent innovative startups developing novel materials. Academic institutions like Tsinghua University and Industrial Technology Research Institute collaborate with industry leaders including Apple and Huawei to address hot-spot sharing challenges, indicating a collaborative ecosystem developing around this critical technology area.

Intel Corp.

Technical Solution: Intel has developed advanced heterogeneous integration thermal management solutions focusing on three key areas. For hot-spot sharing, they've implemented embedded silicon bridges and EMIB (Embedded Multi-die Interconnect Bridge) technology that distributes heat more evenly across the package. Their TIM (Thermal Interface Material) strategy employs Indium-based solders and polymer matrix composites with high thermal conductivity (>5 W/mK) specifically engineered for high-performance computing applications. Intel's microfluidic cooling solution integrates directly into the silicon interposer, with microchannels etched into the substrate allowing coolant to flow within microns of the heat source. Their recent developments include two-phase cooling systems that utilize the latent heat of vaporization to achieve cooling power densities exceeding 1000 W/cm² in laboratory settings, addressing thermal challenges in their most advanced heterogeneous packages.

Strengths: Intel's solutions offer industry-leading thermal performance for high-power computing applications with exceptional integration capabilities in complex multi-die packages. Their extensive manufacturing infrastructure enables mass production of advanced thermal solutions. Weaknesses: Higher implementation costs compared to traditional cooling methods and increased system complexity requiring specialized design expertise.

International Business Machines Corp.

Technical Solution: IBM has pioneered heterogeneous integration thermal management through their "Power Flow" architecture that addresses hot-spot sharing challenges in high-performance computing systems. Their approach utilizes a hierarchical cooling strategy with specialized TIMs at different interface levels. For critical thermal interfaces, IBM employs metal-based TIMs with thermal conductivities exceeding 80 W/mK, significantly outperforming conventional materials. The cornerstone of IBM's thermal solution is their advanced microfluidic cooling technology featuring 3D-printed microchannels that conform to chip topography. Their "Interlayer Cooling" approach places cooling channels between stacked silicon layers, allowing direct cooling of each tier in 3D integrated circuits. IBM has demonstrated cooling capabilities exceeding 350 W/cm² using single-phase water cooling and up to 600 W/cm² with two-phase refrigerants in their laboratory prototypes. This technology has been implemented in their most advanced supercomputing systems, including components of the Summit supercomputer.

Strengths: IBM's solutions provide exceptional cooling performance for high-density computing applications with demonstrated implementation in production systems. Their microfluidic technology enables effective cooling of 3D stacked architectures that traditional methods cannot address. Weaknesses: Complex manufacturing processes increase production costs, and the liquid cooling infrastructure requires additional maintenance considerations and potential reliability concerns in data center environments.

Critical Patents and Research in Heterogeneous Cooling Technologies

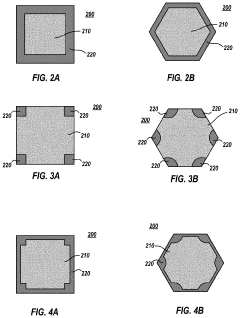

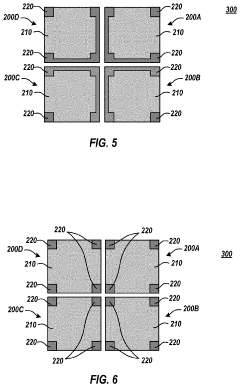

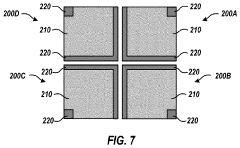

Heterogeneous Thermal Interface Material for Corner and or Edge Degradation Mitigation

PatentInactiveUS20200294880A1

Innovation

- A heterogeneous thermal interface material (TIM) is used, comprising high modulus TIM at the corners and edges and low modulus TIM on the remaining surface, to mitigate strain and thermal resistance by providing differential mechanical bonding and heat transfer properties.

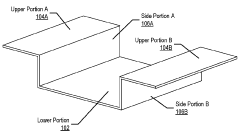

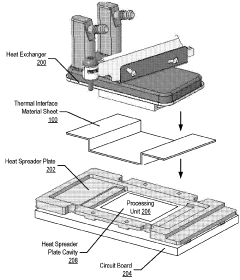

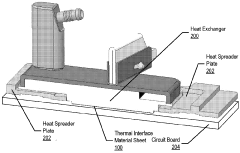

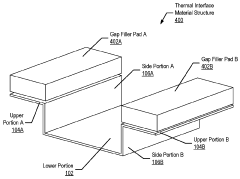

Thermal interface material structures for directing heat in a three-dimensional space

PatentActiveIN202247058378A

Innovation

- A three-dimensional thermal interface material (TIM) sheet with a unique folding structure, allowing for precise placement and retention, providing a large surface area for continuous heat transfer and gap filling, and accommodating components at different elevations and load requirements, while being highly compressible and conductive.

Materials Science Advancements for Next-Generation TIMs

Recent advancements in materials science have significantly propelled the development of next-generation Thermal Interface Materials (TIMs) for heterogeneous integration applications. These innovations address the critical thermal management challenges posed by increasing power densities and the proliferation of hot spots in modern integrated circuits.

Polymer-based TIMs have undergone substantial transformation with the incorporation of high thermal conductivity fillers such as graphene, carbon nanotubes, and boron nitride. These nano-enhanced polymers demonstrate thermal conductivity values exceeding 10 W/m·K, representing a five-fold improvement over conventional polymer TIMs while maintaining the compliance necessary for accommodating surface irregularities and thermal expansion mismatches.

Metal-based TIMs have evolved beyond traditional indium and gallium alloys to include liquid metal composites with suspended nanoparticles. These advanced formulations offer thermal conductivity values approaching 80 W/m·K while addressing historical challenges related to pump-out effects and long-term reliability. The development of non-toxic alternatives to gallium-based liquid metals represents a particularly promising research direction.

Phase change materials (PCMs) have been engineered to operate at precisely defined temperature thresholds aligned with semiconductor junction temperature limits. Novel encapsulation techniques prevent PCM migration during thermal cycling, while the integration of nanostructured carbon materials has enhanced thermal conductivity without compromising phase change properties.

Carbon-based TIMs represent perhaps the most revolutionary advancement, with vertically aligned carbon nanotube (VACNT) arrays demonstrating thermal conductivity values exceeding 200 W/m·K in laboratory settings. Recent manufacturing breakthroughs have reduced production costs by approximately 60%, bringing these materials closer to commercial viability for high-performance computing applications.

Hybrid TIMs combining multiple material classes have emerged as particularly effective solutions. These composites leverage the complementary properties of different materials—such as the compliance of polymers with the thermal conductivity of metals or carbon structures—to create tailored thermal solutions for specific integration challenges.

The development of self-healing TIMs represents another significant advancement, with materials capable of autonomously restoring thermal pathways after mechanical or thermal stress events. These materials incorporate microencapsulated healing agents that release upon crack formation, ensuring sustained thermal performance throughout device lifetime.

Polymer-based TIMs have undergone substantial transformation with the incorporation of high thermal conductivity fillers such as graphene, carbon nanotubes, and boron nitride. These nano-enhanced polymers demonstrate thermal conductivity values exceeding 10 W/m·K, representing a five-fold improvement over conventional polymer TIMs while maintaining the compliance necessary for accommodating surface irregularities and thermal expansion mismatches.

Metal-based TIMs have evolved beyond traditional indium and gallium alloys to include liquid metal composites with suspended nanoparticles. These advanced formulations offer thermal conductivity values approaching 80 W/m·K while addressing historical challenges related to pump-out effects and long-term reliability. The development of non-toxic alternatives to gallium-based liquid metals represents a particularly promising research direction.

Phase change materials (PCMs) have been engineered to operate at precisely defined temperature thresholds aligned with semiconductor junction temperature limits. Novel encapsulation techniques prevent PCM migration during thermal cycling, while the integration of nanostructured carbon materials has enhanced thermal conductivity without compromising phase change properties.

Carbon-based TIMs represent perhaps the most revolutionary advancement, with vertically aligned carbon nanotube (VACNT) arrays demonstrating thermal conductivity values exceeding 200 W/m·K in laboratory settings. Recent manufacturing breakthroughs have reduced production costs by approximately 60%, bringing these materials closer to commercial viability for high-performance computing applications.

Hybrid TIMs combining multiple material classes have emerged as particularly effective solutions. These composites leverage the complementary properties of different materials—such as the compliance of polymers with the thermal conductivity of metals or carbon structures—to create tailored thermal solutions for specific integration challenges.

The development of self-healing TIMs represents another significant advancement, with materials capable of autonomously restoring thermal pathways after mechanical or thermal stress events. These materials incorporate microencapsulated healing agents that release upon crack formation, ensuring sustained thermal performance throughout device lifetime.

Environmental Impact and Sustainability of Cooling Solutions

The environmental impact of cooling solutions for heterogeneous integration has become increasingly significant as computing demands grow exponentially. Traditional cooling methods often rely on materials and processes that pose substantial environmental challenges. Refrigerants used in some advanced cooling systems may have high global warming potential (GWP), contributing to climate change when leaked or improperly disposed of. Additionally, the manufacturing of thermal interface materials (TIMs) frequently involves environmentally harmful chemicals and energy-intensive processes.

Water consumption represents another critical environmental concern, particularly for microfluidic cooling solutions. Data centers implementing liquid cooling systems can consume millions of gallons of water annually, placing strain on local water resources. This becomes especially problematic in regions already experiencing water scarcity, where the technology sector competes with agricultural and residential needs.

Energy efficiency presents both a challenge and an opportunity for sustainable cooling design. While advanced cooling technologies require power to operate pumps and refrigeration systems, they can significantly reduce the overall energy consumption of computing systems by maintaining optimal operating temperatures. Research indicates that efficient thermal management can reduce total system energy consumption by 15-30%, translating to substantial carbon footprint reductions over device lifespans.

Material sustainability is emerging as a priority in thermal design innovation. Biodegradable TIMs derived from cellulose and other plant-based materials show promising thermal conductivity while reducing end-of-life environmental impact. Similarly, recyclable heat sink materials and non-toxic coolants are gaining traction in environmentally conscious designs, though performance trade-offs remain a challenge for widespread adoption.

Lifecycle assessment (LCA) methodologies are increasingly being applied to cooling solution development, evaluating environmental impacts from raw material extraction through manufacturing, use, and disposal. These assessments reveal that while microfluidic cooling may have higher manufacturing complexity, its superior cooling efficiency often results in lower lifetime environmental impact compared to conventional air cooling for high-performance applications.

Regulatory frameworks worldwide are evolving to address the environmental implications of electronic cooling systems. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact thermal material selection, while energy efficiency standards indirectly drive cooling innovation toward more sustainable approaches.

Water consumption represents another critical environmental concern, particularly for microfluidic cooling solutions. Data centers implementing liquid cooling systems can consume millions of gallons of water annually, placing strain on local water resources. This becomes especially problematic in regions already experiencing water scarcity, where the technology sector competes with agricultural and residential needs.

Energy efficiency presents both a challenge and an opportunity for sustainable cooling design. While advanced cooling technologies require power to operate pumps and refrigeration systems, they can significantly reduce the overall energy consumption of computing systems by maintaining optimal operating temperatures. Research indicates that efficient thermal management can reduce total system energy consumption by 15-30%, translating to substantial carbon footprint reductions over device lifespans.

Material sustainability is emerging as a priority in thermal design innovation. Biodegradable TIMs derived from cellulose and other plant-based materials show promising thermal conductivity while reducing end-of-life environmental impact. Similarly, recyclable heat sink materials and non-toxic coolants are gaining traction in environmentally conscious designs, though performance trade-offs remain a challenge for widespread adoption.

Lifecycle assessment (LCA) methodologies are increasingly being applied to cooling solution development, evaluating environmental impacts from raw material extraction through manufacturing, use, and disposal. These assessments reveal that while microfluidic cooling may have higher manufacturing complexity, its superior cooling efficiency often results in lower lifetime environmental impact compared to conventional air cooling for high-performance applications.

Regulatory frameworks worldwide are evolving to address the environmental implications of electronic cooling systems. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly impact thermal material selection, while energy efficiency standards indirectly drive cooling innovation toward more sustainable approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!