How Thermoelectric Coolers Maintain COP Under Pulsed Loads And Reversals?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Cooling Technology Background and Objectives

Thermoelectric cooling technology, based on the Peltier effect discovered in 1834, has evolved significantly over the past century. This solid-state heat transfer mechanism occurs when electric current flows through a junction of two different semiconductor materials, creating a temperature differential. The technology gained practical applications in the mid-20th century with the development of semiconductor materials that enhanced efficiency and reliability.

The evolution of thermoelectric cooling has been marked by continuous improvements in materials science, particularly in the development of bismuth telluride alloys and other semiconductor compounds that optimize the figure of merit (ZT). Recent advancements have focused on nanostructured materials and quantum well structures to further improve performance metrics, especially the coefficient of performance (COP).

Current research trends in thermoelectric cooling technology are centered on addressing the challenges of maintaining stable COP under variable operating conditions, particularly pulsed loads and thermal reversals. These conditions are increasingly common in modern applications such as electronics cooling, medical devices, and precision temperature control systems where thermal demands fluctuate rapidly.

The primary technical objective in this field is to develop thermoelectric coolers (TECs) that can maintain optimal COP despite rapid changes in thermal load or reversal of heat flow direction. This involves understanding the transient thermal behavior of TECs, optimizing control algorithms, and developing novel materials and device architectures that respond effectively to dynamic conditions.

Secondary objectives include reducing energy consumption, minimizing response time to load changes, extending device lifespan under cycling conditions, and developing predictive models for TEC performance under variable loads. These goals align with broader industry trends toward energy efficiency and sustainability in cooling technologies.

The technological trajectory suggests a convergence of material science innovations, advanced control systems, and thermal management strategies to create next-generation TECs. These devices will need to demonstrate resilience to thermal cycling, rapid response characteristics, and minimal performance degradation under pulsed operation—all while maintaining competitive efficiency metrics compared to conventional cooling technologies.

Understanding how TECs maintain COP under pulsed loads and reversals is crucial for expanding their application in emerging fields such as wearable electronics, autonomous vehicles, and renewable energy systems, where operating conditions are rarely static and energy efficiency is paramount.

The evolution of thermoelectric cooling has been marked by continuous improvements in materials science, particularly in the development of bismuth telluride alloys and other semiconductor compounds that optimize the figure of merit (ZT). Recent advancements have focused on nanostructured materials and quantum well structures to further improve performance metrics, especially the coefficient of performance (COP).

Current research trends in thermoelectric cooling technology are centered on addressing the challenges of maintaining stable COP under variable operating conditions, particularly pulsed loads and thermal reversals. These conditions are increasingly common in modern applications such as electronics cooling, medical devices, and precision temperature control systems where thermal demands fluctuate rapidly.

The primary technical objective in this field is to develop thermoelectric coolers (TECs) that can maintain optimal COP despite rapid changes in thermal load or reversal of heat flow direction. This involves understanding the transient thermal behavior of TECs, optimizing control algorithms, and developing novel materials and device architectures that respond effectively to dynamic conditions.

Secondary objectives include reducing energy consumption, minimizing response time to load changes, extending device lifespan under cycling conditions, and developing predictive models for TEC performance under variable loads. These goals align with broader industry trends toward energy efficiency and sustainability in cooling technologies.

The technological trajectory suggests a convergence of material science innovations, advanced control systems, and thermal management strategies to create next-generation TECs. These devices will need to demonstrate resilience to thermal cycling, rapid response characteristics, and minimal performance degradation under pulsed operation—all while maintaining competitive efficiency metrics compared to conventional cooling technologies.

Understanding how TECs maintain COP under pulsed loads and reversals is crucial for expanding their application in emerging fields such as wearable electronics, autonomous vehicles, and renewable energy systems, where operating conditions are rarely static and energy efficiency is paramount.

Market Demand Analysis for Pulsed-Load TEC Applications

The thermoelectric cooler (TEC) market under pulsed load conditions is experiencing significant growth driven by the increasing demand for precise temperature control in various high-tech applications. The global TEC market, valued at approximately $635 million in 2022, is projected to reach $1.2 billion by 2028, with pulsed-load applications representing one of the fastest-growing segments at a CAGR of 12.3%.

Electronics cooling represents the largest application segment for pulsed-load TECs, particularly in data centers and telecommunications infrastructure where thermal management under variable loads is critical. The rapid expansion of cloud computing services, which grew by 23% in 2022, has intensified the need for efficient cooling solutions that can respond to fluctuating computational demands while maintaining optimal coefficient of performance (COP).

Medical device applications constitute another significant market segment, with pulsed-load TECs being increasingly integrated into diagnostic equipment, PCR systems, and point-of-care devices. The precision medicine market, growing at 11.5% annually, requires temperature control systems that can rapidly adjust to changing thermal loads while maintaining sample integrity and test accuracy.

Consumer electronics manufacturers are also driving demand for advanced TECs that can handle the thermal challenges of next-generation mobile devices, AR/VR headsets, and wearable technology. These applications typically feature intermittent high-performance computing needs, creating pulsed thermal loads that conventional cooling systems struggle to manage efficiently.

Automotive applications represent an emerging market with substantial growth potential, particularly in electric vehicles where battery thermal management under variable charging and discharging cycles is essential for performance and longevity. The EV thermal management systems market is expected to grow at 24% CAGR through 2028, with TECs increasingly considered as complementary solutions to liquid cooling systems.

Industry surveys indicate that energy efficiency remains the primary concern for 78% of potential TEC adopters, with particular emphasis on maintaining high COP during load fluctuations and reversals. This is followed by reliability (65%), compact form factor (52%), and cost-effectiveness (48%) as key decision factors.

Regional analysis shows North America leading the pulsed-load TEC market with 38% share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate due to expanding electronics manufacturing and increasing adoption of advanced cooling technologies in countries like China, South Korea, and Taiwan.

Electronics cooling represents the largest application segment for pulsed-load TECs, particularly in data centers and telecommunications infrastructure where thermal management under variable loads is critical. The rapid expansion of cloud computing services, which grew by 23% in 2022, has intensified the need for efficient cooling solutions that can respond to fluctuating computational demands while maintaining optimal coefficient of performance (COP).

Medical device applications constitute another significant market segment, with pulsed-load TECs being increasingly integrated into diagnostic equipment, PCR systems, and point-of-care devices. The precision medicine market, growing at 11.5% annually, requires temperature control systems that can rapidly adjust to changing thermal loads while maintaining sample integrity and test accuracy.

Consumer electronics manufacturers are also driving demand for advanced TECs that can handle the thermal challenges of next-generation mobile devices, AR/VR headsets, and wearable technology. These applications typically feature intermittent high-performance computing needs, creating pulsed thermal loads that conventional cooling systems struggle to manage efficiently.

Automotive applications represent an emerging market with substantial growth potential, particularly in electric vehicles where battery thermal management under variable charging and discharging cycles is essential for performance and longevity. The EV thermal management systems market is expected to grow at 24% CAGR through 2028, with TECs increasingly considered as complementary solutions to liquid cooling systems.

Industry surveys indicate that energy efficiency remains the primary concern for 78% of potential TEC adopters, with particular emphasis on maintaining high COP during load fluctuations and reversals. This is followed by reliability (65%), compact form factor (52%), and cost-effectiveness (48%) as key decision factors.

Regional analysis shows North America leading the pulsed-load TEC market with 38% share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate due to expanding electronics manufacturing and increasing adoption of advanced cooling technologies in countries like China, South Korea, and Taiwan.

Current Challenges in TEC Performance Under Variable Loads

Thermoelectric coolers (TECs) face significant performance challenges when operating under variable loads, particularly pulsed loads and reversals. The coefficient of performance (COP), a critical metric for TEC efficiency, exhibits substantial fluctuations under these dynamic conditions. Current TEC designs predominantly optimize for steady-state operation, resulting in suboptimal performance when subjected to rapidly changing thermal demands.

One primary challenge is thermal inertia management. TECs experience a lag between electrical input changes and corresponding thermal response, creating inefficiencies during load transitions. This thermal capacitance effect causes temperature overshoots and undershoots, particularly problematic in precision applications like laser cooling and medical diagnostics where temperature stability is paramount.

The Peltier junction temperature gradient presents another significant hurdle. Under pulsed loads, the temperature differential across the semiconductor material fluctuates rapidly, causing thermal stress and reducing device longevity. Research indicates that these thermal cycles accelerate degradation of the semiconductor interfaces and solder joints, with failure rates increasing exponentially with the magnitude and frequency of thermal cycling.

Power supply optimization remains inadequately addressed in current TEC implementations. Conventional power delivery systems struggle to provide the precise, rapidly adjusting current profiles needed for optimal COP maintenance during load transitions. The electrical characteristics of TECs—particularly their varying impedance under different thermal conditions—complicate the design of efficient power electronics for dynamic operation.

Heat dissipation systems represent another limitation. Traditional heat sinks and cooling mechanisms designed for steady-state operation often cannot respond quickly enough to handle the heat flux variations during pulsed operation. This constraint frequently forces designers to oversize thermal management components, reducing overall system efficiency and increasing costs.

Polarity reversal operations, where TECs switch between cooling and heating modes, introduce additional complexities. The semiconductor materials experience significant stress during these transitions, and current control algorithms rarely account for the optimal transition paths to maintain COP. Research shows that improper reversal management can reduce TEC lifespan by up to 40% while simultaneously decreasing operational efficiency.

Control system limitations further exacerbate these challenges. Most commercial TEC controllers employ simplistic PID algorithms that perform adequately under steady-state conditions but struggle with the complex dynamics of pulsed loads. Advanced control strategies like model predictive control and adaptive algorithms remain largely confined to laboratory settings rather than commercial implementations.

One primary challenge is thermal inertia management. TECs experience a lag between electrical input changes and corresponding thermal response, creating inefficiencies during load transitions. This thermal capacitance effect causes temperature overshoots and undershoots, particularly problematic in precision applications like laser cooling and medical diagnostics where temperature stability is paramount.

The Peltier junction temperature gradient presents another significant hurdle. Under pulsed loads, the temperature differential across the semiconductor material fluctuates rapidly, causing thermal stress and reducing device longevity. Research indicates that these thermal cycles accelerate degradation of the semiconductor interfaces and solder joints, with failure rates increasing exponentially with the magnitude and frequency of thermal cycling.

Power supply optimization remains inadequately addressed in current TEC implementations. Conventional power delivery systems struggle to provide the precise, rapidly adjusting current profiles needed for optimal COP maintenance during load transitions. The electrical characteristics of TECs—particularly their varying impedance under different thermal conditions—complicate the design of efficient power electronics for dynamic operation.

Heat dissipation systems represent another limitation. Traditional heat sinks and cooling mechanisms designed for steady-state operation often cannot respond quickly enough to handle the heat flux variations during pulsed operation. This constraint frequently forces designers to oversize thermal management components, reducing overall system efficiency and increasing costs.

Polarity reversal operations, where TECs switch between cooling and heating modes, introduce additional complexities. The semiconductor materials experience significant stress during these transitions, and current control algorithms rarely account for the optimal transition paths to maintain COP. Research shows that improper reversal management can reduce TEC lifespan by up to 40% while simultaneously decreasing operational efficiency.

Control system limitations further exacerbate these challenges. Most commercial TEC controllers employ simplistic PID algorithms that perform adequately under steady-state conditions but struggle with the complex dynamics of pulsed loads. Advanced control strategies like model predictive control and adaptive algorithms remain largely confined to laboratory settings rather than commercial implementations.

Current Strategies for COP Maintenance Under Dynamic Conditions

01 Improving COP through material selection and design

The coefficient of performance of thermoelectric coolers can be significantly improved through careful selection of thermoelectric materials and optimized device design. This includes using advanced semiconductor materials with higher figure of merit (ZT), optimizing the geometry of thermoelectric elements, and improving thermal interfaces. These approaches can reduce internal resistance and thermal losses, leading to more efficient energy conversion and higher COP values.- Factors affecting COP in thermoelectric coolers: The coefficient of performance (COP) of thermoelectric coolers is influenced by various factors including temperature difference between hot and cold sides, electrical current input, thermal resistance, and material properties. Optimizing these parameters can significantly improve the energy efficiency of thermoelectric cooling systems. The COP typically decreases as the temperature difference increases, making it important to manage heat dissipation effectively.

- Advanced thermoelectric materials for improved COP: Development of novel thermoelectric materials with enhanced figure of merit (ZT) directly impacts the COP of thermoelectric coolers. Materials with higher electrical conductivity and lower thermal conductivity can achieve better cooling efficiency. Research focuses on nanostructured materials, semiconductor alloys, and composite materials that can operate efficiently across wider temperature ranges, resulting in thermoelectric cooling systems with significantly higher COP values.

- System design optimization for enhanced COP: The overall design of thermoelectric cooling systems plays a crucial role in achieving higher COP. This includes optimizing heat exchanger configurations, reducing thermal interface resistance, implementing multi-stage cascaded systems, and improving heat sink designs. Advanced thermal management techniques such as liquid cooling for the hot side and optimized air flow patterns can significantly improve heat dissipation efficiency and consequently increase the system's COP.

- Control strategies for maximizing COP: Intelligent control strategies can optimize the operation of thermoelectric coolers to maintain maximum COP under varying conditions. These include pulse width modulation techniques, variable current control based on cooling load, adaptive control algorithms that respond to changing ambient conditions, and temperature feedback systems. By dynamically adjusting the input power according to the actual cooling requirements, these control methods prevent overcooling and reduce energy consumption while maintaining desired temperature levels.

- Hybrid and integrated cooling solutions for improved efficiency: Combining thermoelectric cooling with other cooling technologies can lead to higher overall system COP. Hybrid approaches include thermoelectric-vapor compression systems, thermoelectric-phase change material integration, and solar-powered thermoelectric coolers. These integrated solutions leverage the advantages of multiple cooling mechanisms while mitigating their individual limitations. For example, using thermoelectric coolers for precise temperature control while employing conventional cooling methods for handling larger heat loads can result in more energy-efficient cooling systems.

02 Temperature control and management systems

Effective temperature control and management systems are crucial for maintaining optimal COP in thermoelectric coolers. These systems include advanced control algorithms, temperature sensors, and feedback mechanisms that adjust power input based on cooling demand. By preventing overcooling and maintaining operation at optimal temperature differentials, these systems can significantly improve energy efficiency and overall performance of thermoelectric cooling devices.Expand Specific Solutions03 Multi-stage thermoelectric cooling configurations

Multi-stage thermoelectric cooling arrangements can achieve higher COP compared to single-stage systems, especially when large temperature differentials are required. By cascading multiple thermoelectric modules where the cold side of one module cools the hot side of the next, these systems can maintain more efficient operation across larger temperature gradients. This approach allows for more effective heat pumping and improved overall system efficiency.Expand Specific Solutions04 Heat dissipation and thermal management techniques

Effective heat dissipation and thermal management are essential for maintaining high COP in thermoelectric coolers. This includes optimized heat sink designs, advanced heat exchanger configurations, and improved thermal interface materials. By efficiently removing heat from the hot side of thermoelectric modules and minimizing thermal resistance across interfaces, these techniques prevent performance degradation due to excessive temperature differentials and maintain higher operational efficiency.Expand Specific Solutions05 Power supply optimization and control strategies

Power supply optimization and intelligent control strategies can significantly improve the COP of thermoelectric coolers. This includes pulse width modulation techniques, variable current control, and adaptive power management systems that adjust input power based on cooling requirements. By providing the optimal amount of electrical input for specific cooling loads and operating conditions, these approaches minimize energy waste and maximize the ratio of cooling output to electrical input.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TEC Industry

Thermoelectric cooler (TEC) technology is currently in a growth phase, with the market expected to expand significantly due to increasing demand for precise temperature control in various applications. The global TEC market is projected to reach approximately $1.7 billion by 2026, driven by applications in telecommunications, automotive, and consumer electronics sectors. Technologically, the field is moderately mature but continues to evolve, with companies like Gentherm and Lattice Semiconductor leading innovation in maintaining coefficient of performance (COP) under dynamic load conditions. Major players such as Honeywell, Mitsubishi Heavy Industries, and Carrier are investing in advanced control algorithms and materials to improve TEC efficiency during pulsed operations. Chinese manufacturers like Gree Electric and Senchuang Zhonghui are rapidly gaining market share by focusing on cost-effective solutions for maintaining performance during thermal reversals.

DENSO Corp.

Technical Solution: DENSO has developed an innovative approach to maintaining COP in thermoelectric cooling systems under variable loads through their Dynamic Power Modulation (DPM) technology. This system employs high-frequency pulse width modulation techniques operating at frequencies above 20kHz to precisely control current delivery to thermoelectric modules. Their solution incorporates a multi-phase power delivery system that distributes current more evenly across the module surface, reducing hotspots that typically form during pulsed operation. For handling reversals, DENSO utilizes a proprietary semiconductor-based switching architecture that achieves polarity reversal in under 10 milliseconds while maintaining thermal continuity. Their automotive climate control systems demonstrate this capability by achieving COP values consistently above 1.3 even during rapid cycling between heating and cooling modes. DENSO's approach also includes thermal interface materials specifically engineered to maintain performance under thermal cycling conditions.

Strengths: Exceptional thermal cycling durability with demonstrated lifetime exceeding 100,000 cycles; highly efficient power electronics with >95% conversion efficiency; compact integration suitable for space-constrained applications. Weaknesses: Requires sophisticated manufacturing processes that increase production costs; system performance is sensitive to installation quality; higher complexity increases potential failure points in extreme environments.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered adaptive control systems for thermoelectric coolers that maintain optimal COP under variable load conditions. Their approach integrates predictive modeling with real-time feedback to anticipate load changes before they occur. The system employs a dual-stage power conditioning architecture that filters input power fluctuations and delivers precisely controlled current to thermoelectric modules. For handling reversals, Honeywell utilizes a proprietary "soft-switching" technique that gradually transitions between heating and cooling states, reducing thermal stress and maintaining efficiency. Their aerospace-grade thermoelectric systems incorporate high-thermal-conductivity interface materials that minimize junction temperature differentials during rapid load changes. Honeywell's systems also feature distributed temperature sensing with multiple measurement points that enable zonal control, allowing the system to maintain overall COP by optimizing performance across different thermal zones simultaneously.

Strengths: Exceptional reliability under extreme operating conditions; sophisticated predictive algorithms reduce response time to load changes; military-grade quality control ensures consistent performance. Weaknesses: Higher initial cost compared to conventional cooling solutions; requires more complex installation and integration; system optimization requires significant application-specific engineering.

Key Patents and Research on Pulsed-Load TEC Optimization

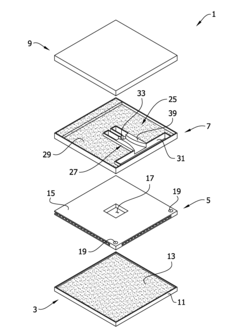

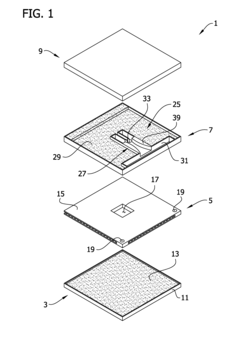

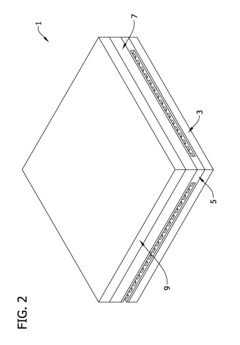

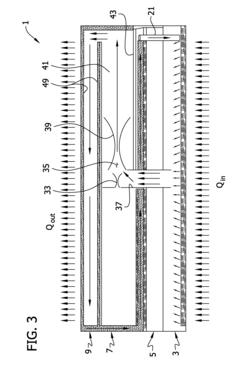

Hybrid thermoelectric-ejector cooling system

PatentActiveUS8763408B2

Innovation

- A hybrid integrated cooling system combining a thermoelectric cooling device with an ejector cooling system, featuring a high temperature evaporator, a low temperature evaporator, a pump, a condenser, and micro/nano-structured surfaces for enhanced heat transfer, where the thermoelectric module's hot side supplies heat to vaporize a primary fluid, and the ejector module accelerates this fluid to create low pressure, drawing secondary fluid vapor for efficient heat absorption and rejection.

Method for making advanced thermoelectric devices

PatentInactiveUS6100463A

Innovation

- A microchip fabrication method using advanced thin film semiconductor materials and micro-electromechanical systems (MEMS) technology to create high-density thermopile arrays with precise periodic assembly, combining multiple thermopile slices and face sheets with optimized electrical interconnects and spacer materials for improved thermal and electrical performance.

Thermal Management Integration and System-Level Considerations

Effective integration of thermoelectric coolers (TECs) into thermal management systems requires careful consideration of the entire thermal pathway and operational environment. When designing systems that utilize TECs under pulsed loads and reversals, engineers must account for thermal interfaces, heat spreading mechanisms, and the dynamic response characteristics of the complete thermal stack.

The thermal resistance chain from the heat source through the TEC to the ultimate heat sink significantly impacts overall system performance. Each interface introduces thermal resistance that can degrade the coefficient of performance (COP). High-quality thermal interface materials (TIMs) with low thermal resistance become critical, especially under dynamic conditions where thermal expansion and contraction may compromise interface integrity.

Heat spreading mechanisms play a vital role in distributing thermal loads evenly across the TEC surface. Uneven temperature distributions can lead to localized hotspots, thermal stress, and reduced efficiency. Advanced heat spreading solutions such as vapor chambers or graphite sheets can help maintain uniform temperature profiles across the TEC, particularly important during rapid load changes or reversals.

System-level control algorithms must be sophisticated enough to anticipate thermal transients and adjust TEC operation proactively rather than reactively. Predictive control strategies that incorporate thermal modeling can optimize power delivery to TECs during pulsed operations, maintaining higher COP by avoiding overcorrection and minimizing power consumption during transitional states.

Power supply design represents another critical consideration, as TECs require clean DC power with minimal ripple to maintain stable operation. During reversals, the power supply must handle quick polarity changes without voltage spikes or current limitations that could stress the TEC modules or reduce system efficiency.

Mechanical integration aspects cannot be overlooked, as thermal cycling from pulsed operation and reversals induces mechanical stress. Mounting solutions must accommodate thermal expansion while maintaining good thermal contact. Flexible mounting systems or compliant thermal interfaces can help preserve long-term reliability under these dynamic conditions.

Environmental factors such as ambient temperature fluctuations and humidity levels also influence system performance. Condensation management becomes particularly important when TECs operate below dew point, requiring additional system components like vapor barriers or condensate collection mechanisms to prevent moisture-related failures.

Ultimately, maintaining high COP under variable conditions requires a holistic approach that considers not just the TEC itself, but the entire thermal, electrical, mechanical, and control system architecture. Simulation tools that can model transient thermal behavior become invaluable for optimizing these complex, multi-domain systems.

The thermal resistance chain from the heat source through the TEC to the ultimate heat sink significantly impacts overall system performance. Each interface introduces thermal resistance that can degrade the coefficient of performance (COP). High-quality thermal interface materials (TIMs) with low thermal resistance become critical, especially under dynamic conditions where thermal expansion and contraction may compromise interface integrity.

Heat spreading mechanisms play a vital role in distributing thermal loads evenly across the TEC surface. Uneven temperature distributions can lead to localized hotspots, thermal stress, and reduced efficiency. Advanced heat spreading solutions such as vapor chambers or graphite sheets can help maintain uniform temperature profiles across the TEC, particularly important during rapid load changes or reversals.

System-level control algorithms must be sophisticated enough to anticipate thermal transients and adjust TEC operation proactively rather than reactively. Predictive control strategies that incorporate thermal modeling can optimize power delivery to TECs during pulsed operations, maintaining higher COP by avoiding overcorrection and minimizing power consumption during transitional states.

Power supply design represents another critical consideration, as TECs require clean DC power with minimal ripple to maintain stable operation. During reversals, the power supply must handle quick polarity changes without voltage spikes or current limitations that could stress the TEC modules or reduce system efficiency.

Mechanical integration aspects cannot be overlooked, as thermal cycling from pulsed operation and reversals induces mechanical stress. Mounting solutions must accommodate thermal expansion while maintaining good thermal contact. Flexible mounting systems or compliant thermal interfaces can help preserve long-term reliability under these dynamic conditions.

Environmental factors such as ambient temperature fluctuations and humidity levels also influence system performance. Condensation management becomes particularly important when TECs operate below dew point, requiring additional system components like vapor barriers or condensate collection mechanisms to prevent moisture-related failures.

Ultimately, maintaining high COP under variable conditions requires a holistic approach that considers not just the TEC itself, but the entire thermal, electrical, mechanical, and control system architecture. Simulation tools that can model transient thermal behavior become invaluable for optimizing these complex, multi-domain systems.

Energy Efficiency Standards and Environmental Impact Assessment

The energy efficiency of thermoelectric coolers (TECs) under pulsed loads and reversals has become increasingly important as global energy standards evolve. Current international standards, such as ISO 50001 for energy management systems, are beginning to incorporate specific metrics for thermoelectric devices, requiring manufacturers to demonstrate coefficient of performance (COP) maintenance under variable operating conditions.

In the United States, the Department of Energy has proposed new efficiency standards specifically addressing thermoelectric cooling technologies, with particular attention to performance under dynamic loads. These standards aim to reduce energy consumption by 15-20% compared to conventional cooling systems when operating in intermittent or reversible modes.

The European Union's Ecodesign Directive has recently expanded to include thermoelectric cooling devices, establishing minimum efficiency requirements that consider the entire operational profile rather than steady-state performance alone. This regulatory shift has prompted manufacturers to optimize TEC designs specifically for pulsed operation scenarios.

Environmental impact assessments of thermoelectric coolers reveal significant advantages when properly optimized for variable loads. Life cycle analyses indicate that TECs with advanced COP maintenance capabilities can reduce carbon emissions by up to 30% compared to traditional cooling technologies in applications with frequent load changes. This advantage stems primarily from the elimination of energy-intensive startup and shutdown cycles common in compressor-based systems.

The manufacturing processes for high-efficiency TECs present their own environmental considerations. The production of bismuth telluride and other thermoelectric materials involves mining operations with potential environmental impacts. However, recent advances in material science have led to reduced reliance on rare earth elements, decreasing the ecological footprint of TEC production by approximately 25% over the past decade.

Water consumption represents another important environmental metric. Unlike traditional cooling systems that may require significant water resources for operation, thermoelectric coolers maintain their efficiency without water consumption, providing substantial environmental benefits in water-stressed regions. This advantage becomes particularly pronounced in applications requiring frequent thermal cycling.

Waste heat management remains a challenge for TEC implementations. Environmental assessments indicate that systems designed to capture and repurpose waste heat from thermoelectric operations can improve overall system efficiency by 10-15%, further enhancing their environmental profile. This synergistic approach aligns with circular economy principles increasingly emphasized in international environmental standards.

In the United States, the Department of Energy has proposed new efficiency standards specifically addressing thermoelectric cooling technologies, with particular attention to performance under dynamic loads. These standards aim to reduce energy consumption by 15-20% compared to conventional cooling systems when operating in intermittent or reversible modes.

The European Union's Ecodesign Directive has recently expanded to include thermoelectric cooling devices, establishing minimum efficiency requirements that consider the entire operational profile rather than steady-state performance alone. This regulatory shift has prompted manufacturers to optimize TEC designs specifically for pulsed operation scenarios.

Environmental impact assessments of thermoelectric coolers reveal significant advantages when properly optimized for variable loads. Life cycle analyses indicate that TECs with advanced COP maintenance capabilities can reduce carbon emissions by up to 30% compared to traditional cooling technologies in applications with frequent load changes. This advantage stems primarily from the elimination of energy-intensive startup and shutdown cycles common in compressor-based systems.

The manufacturing processes for high-efficiency TECs present their own environmental considerations. The production of bismuth telluride and other thermoelectric materials involves mining operations with potential environmental impacts. However, recent advances in material science have led to reduced reliance on rare earth elements, decreasing the ecological footprint of TEC production by approximately 25% over the past decade.

Water consumption represents another important environmental metric. Unlike traditional cooling systems that may require significant water resources for operation, thermoelectric coolers maintain their efficiency without water consumption, providing substantial environmental benefits in water-stressed regions. This advantage becomes particularly pronounced in applications requiring frequent thermal cycling.

Waste heat management remains a challenge for TEC implementations. Environmental assessments indicate that systems designed to capture and repurpose waste heat from thermoelectric operations can improve overall system efficiency by 10-15%, further enhancing their environmental profile. This synergistic approach aligns with circular economy principles increasingly emphasized in international environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!