Thermoelectric Cooler Interfaces: TIM Choices, Clamping Force And Pump-Out Risks

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEC Interface Technology Background and Objectives

Thermoelectric cooling technology has evolved significantly since its discovery in the early 19th century through the Peltier effect. This solid-state heat transfer mechanism has gained substantial traction in various applications including electronics cooling, medical devices, and laboratory equipment due to its precision temperature control capabilities, compact size, and absence of moving parts. The evolution of thermoelectric coolers (TECs) has been marked by continuous improvements in materials science, manufacturing techniques, and interface management strategies.

The thermal interface between TECs and their heat sinks represents a critical junction that significantly impacts overall system performance. Historically, this interface has been managed through conventional thermal interface materials (TIMs) such as thermal greases and pads. However, the unique operational characteristics of TECs—including their bidirectional heat flow, temperature cycling, and high power density—create specific challenges for interface management that conventional approaches struggle to address effectively.

Recent technological trends indicate a growing focus on specialized TIM solutions designed specifically for TEC applications. These developments are driven by the increasing power densities in modern electronic systems and the corresponding demand for more efficient thermal management solutions. The industry has witnessed a shift from traditional silicone-based compounds toward more advanced materials including phase change materials, liquid metal composites, and graphene-enhanced interfaces.

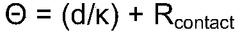

The primary technical objective in TEC interface management is to minimize thermal resistance while maintaining long-term reliability under operational conditions. This involves addressing several interconnected challenges: selecting appropriate TIM materials that balance thermal conductivity with mechanical compliance, determining optimal clamping force to minimize contact resistance without causing mechanical stress, and mitigating pump-out effects that can degrade thermal performance over time.

Another critical objective is to develop standardized testing and qualification methodologies specifically for TEC interfaces. Current industry standards for thermal interface materials often fail to account for the unique operational parameters of thermoelectric systems, leading to performance discrepancies between laboratory measurements and real-world applications.

The technological trajectory suggests an increasing integration of TEC systems into more diverse and demanding applications, from high-performance computing to automotive electronics and renewable energy systems. This expansion necessitates more robust and application-specific interface solutions that can withstand varied environmental conditions while maintaining optimal thermal performance throughout the device lifecycle.

Understanding the fundamental mechanisms of interface degradation, particularly the pump-out phenomenon under thermal cycling conditions, represents a key research priority. This knowledge will inform the development of next-generation interface materials and clamping methodologies designed specifically for the unique operational profile of thermoelectric cooling systems.

The thermal interface between TECs and their heat sinks represents a critical junction that significantly impacts overall system performance. Historically, this interface has been managed through conventional thermal interface materials (TIMs) such as thermal greases and pads. However, the unique operational characteristics of TECs—including their bidirectional heat flow, temperature cycling, and high power density—create specific challenges for interface management that conventional approaches struggle to address effectively.

Recent technological trends indicate a growing focus on specialized TIM solutions designed specifically for TEC applications. These developments are driven by the increasing power densities in modern electronic systems and the corresponding demand for more efficient thermal management solutions. The industry has witnessed a shift from traditional silicone-based compounds toward more advanced materials including phase change materials, liquid metal composites, and graphene-enhanced interfaces.

The primary technical objective in TEC interface management is to minimize thermal resistance while maintaining long-term reliability under operational conditions. This involves addressing several interconnected challenges: selecting appropriate TIM materials that balance thermal conductivity with mechanical compliance, determining optimal clamping force to minimize contact resistance without causing mechanical stress, and mitigating pump-out effects that can degrade thermal performance over time.

Another critical objective is to develop standardized testing and qualification methodologies specifically for TEC interfaces. Current industry standards for thermal interface materials often fail to account for the unique operational parameters of thermoelectric systems, leading to performance discrepancies between laboratory measurements and real-world applications.

The technological trajectory suggests an increasing integration of TEC systems into more diverse and demanding applications, from high-performance computing to automotive electronics and renewable energy systems. This expansion necessitates more robust and application-specific interface solutions that can withstand varied environmental conditions while maintaining optimal thermal performance throughout the device lifecycle.

Understanding the fundamental mechanisms of interface degradation, particularly the pump-out phenomenon under thermal cycling conditions, represents a key research priority. This knowledge will inform the development of next-generation interface materials and clamping methodologies designed specifically for the unique operational profile of thermoelectric cooling systems.

Market Analysis for Thermoelectric Cooling Solutions

The global thermoelectric cooling solutions market has demonstrated robust growth, reaching approximately $1.2 billion in 2022 with projections to expand at a CAGR of 8.5% through 2028. This growth is primarily driven by increasing demand across multiple sectors including electronics, telecommunications, automotive, and medical devices where precise temperature control is critical for optimal performance.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The miniaturization trend in electronic devices has intensified thermal management challenges, creating substantial demand for efficient thermoelectric cooling solutions. Particularly, high-performance computing devices, gaming consoles, and mobile devices require advanced thermal interface materials to maintain operational efficiency and extend product lifespan.

The automotive sector has emerged as the fastest-growing segment, with a growth rate exceeding 10% annually. This surge is attributed to the rapid adoption of electric vehicles and advanced driver-assistance systems (ADAS), both requiring sophisticated thermal management solutions. Luxury vehicle manufacturers are increasingly incorporating thermoelectric cooling in climate control systems, further expanding market opportunities.

Geographically, North America leads the market with approximately 38% share, followed by Asia-Pacific at 32% and Europe at 25%. China and South Korea have become manufacturing hubs for thermoelectric modules, while research and development activities remain concentrated in the United States, Germany, and Japan.

The competitive landscape features both established players and innovative startups. Major companies like Ferrotec, Laird Thermal Systems, and II-VI Marlow control about 45% of the global market share, while specialized firms focusing on high-performance TIM solutions are gaining traction through technological differentiation.

Customer preferences are increasingly shifting toward solutions that offer longer operational lifespans and reduced maintenance requirements. This trend has elevated the importance of addressing pump-out risks and optimizing clamping force in thermoelectric cooler interfaces, as these factors directly impact long-term reliability and performance stability.

Market analysis indicates growing awareness among end-users regarding the critical role of thermal interface materials in system performance. Premium TIM solutions commanding higher prices are gaining market share, suggesting customers are willing to invest in quality materials that minimize thermal resistance and mitigate reliability issues associated with thermal cycling and mechanical stress.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The miniaturization trend in electronic devices has intensified thermal management challenges, creating substantial demand for efficient thermoelectric cooling solutions. Particularly, high-performance computing devices, gaming consoles, and mobile devices require advanced thermal interface materials to maintain operational efficiency and extend product lifespan.

The automotive sector has emerged as the fastest-growing segment, with a growth rate exceeding 10% annually. This surge is attributed to the rapid adoption of electric vehicles and advanced driver-assistance systems (ADAS), both requiring sophisticated thermal management solutions. Luxury vehicle manufacturers are increasingly incorporating thermoelectric cooling in climate control systems, further expanding market opportunities.

Geographically, North America leads the market with approximately 38% share, followed by Asia-Pacific at 32% and Europe at 25%. China and South Korea have become manufacturing hubs for thermoelectric modules, while research and development activities remain concentrated in the United States, Germany, and Japan.

The competitive landscape features both established players and innovative startups. Major companies like Ferrotec, Laird Thermal Systems, and II-VI Marlow control about 45% of the global market share, while specialized firms focusing on high-performance TIM solutions are gaining traction through technological differentiation.

Customer preferences are increasingly shifting toward solutions that offer longer operational lifespans and reduced maintenance requirements. This trend has elevated the importance of addressing pump-out risks and optimizing clamping force in thermoelectric cooler interfaces, as these factors directly impact long-term reliability and performance stability.

Market analysis indicates growing awareness among end-users regarding the critical role of thermal interface materials in system performance. Premium TIM solutions commanding higher prices are gaining market share, suggesting customers are willing to invest in quality materials that minimize thermal resistance and mitigate reliability issues associated with thermal cycling and mechanical stress.

Current Challenges in TEC Interface Management

The management of thermoelectric cooler (TEC) interfaces presents significant challenges that impact overall system performance and reliability. Current interface management practices face several critical issues that require careful consideration and innovative solutions. The primary challenge lies in the selection of appropriate thermal interface materials (TIMs) that can effectively bridge the microscopic gaps between the TEC and adjacent surfaces while maintaining optimal thermal conductivity.

Traditional TIM solutions often struggle to balance competing requirements in TEC applications. Thermal greases, while offering excellent initial thermal performance, frequently suffer from pump-out effects under the thermal cycling conditions typical in TEC operations. This phenomenon occurs as the TEC repeatedly expands and contracts, gradually forcing the TIM material away from the interface, resulting in degraded thermal performance over time.

Phase change materials (PCMs) present an alternative but face challenges with thickness consistency and potential migration under high-temperature conditions. The relatively high thermal resistance of PCMs compared to premium thermal greases can limit their effectiveness in high-performance cooling applications where every degree of thermal efficiency matters.

Clamping force management represents another significant challenge in TEC interface design. Insufficient clamping pressure leads to poor thermal contact and increased thermal resistance, while excessive force risks mechanical damage to the fragile ceramic plates of the TEC module. The industry currently lacks standardized guidelines for optimal clamping force across different TEC form factors and application scenarios.

The reliability of TEC interfaces under thermal cycling conditions remains problematic. Most TIMs exhibit performance degradation over time, with reliability data suggesting that interface thermal resistance can increase by 20-50% after extended cycling, depending on the material selection and mechanical design. This degradation directly impacts the cooling efficiency and operational lifespan of TEC-based systems.

Manufacturing consistency presents additional challenges, as the flatness and surface finish of both the TEC module and the heat sink or cold plate significantly influence interface quality. Variations in manufacturing tolerances can create inconsistent thermal performance across supposedly identical assemblies, complicating quality control processes.

Emerging applications in high-power electronics, medical devices, and aerospace systems are pushing the boundaries of TEC interface requirements, demanding solutions that can maintain performance under increasingly extreme conditions of temperature cycling, mechanical shock, and extended operational lifetimes. The current state of interface technology struggles to meet these evolving demands, creating a significant gap between application requirements and available solutions.

Traditional TIM solutions often struggle to balance competing requirements in TEC applications. Thermal greases, while offering excellent initial thermal performance, frequently suffer from pump-out effects under the thermal cycling conditions typical in TEC operations. This phenomenon occurs as the TEC repeatedly expands and contracts, gradually forcing the TIM material away from the interface, resulting in degraded thermal performance over time.

Phase change materials (PCMs) present an alternative but face challenges with thickness consistency and potential migration under high-temperature conditions. The relatively high thermal resistance of PCMs compared to premium thermal greases can limit their effectiveness in high-performance cooling applications where every degree of thermal efficiency matters.

Clamping force management represents another significant challenge in TEC interface design. Insufficient clamping pressure leads to poor thermal contact and increased thermal resistance, while excessive force risks mechanical damage to the fragile ceramic plates of the TEC module. The industry currently lacks standardized guidelines for optimal clamping force across different TEC form factors and application scenarios.

The reliability of TEC interfaces under thermal cycling conditions remains problematic. Most TIMs exhibit performance degradation over time, with reliability data suggesting that interface thermal resistance can increase by 20-50% after extended cycling, depending on the material selection and mechanical design. This degradation directly impacts the cooling efficiency and operational lifespan of TEC-based systems.

Manufacturing consistency presents additional challenges, as the flatness and surface finish of both the TEC module and the heat sink or cold plate significantly influence interface quality. Variations in manufacturing tolerances can create inconsistent thermal performance across supposedly identical assemblies, complicating quality control processes.

Emerging applications in high-power electronics, medical devices, and aerospace systems are pushing the boundaries of TEC interface requirements, demanding solutions that can maintain performance under increasingly extreme conditions of temperature cycling, mechanical shock, and extended operational lifetimes. The current state of interface technology struggles to meet these evolving demands, creating a significant gap between application requirements and available solutions.

Current TIM Solutions for Thermoelectric Coolers

01 Thermal Interface Materials (TIM) Selection for Thermoelectric Coolers

Various thermal interface materials can be used between thermoelectric coolers and heat sinks to improve thermal conductivity. These materials include thermal greases, phase change materials, thermal pads, and metal-based TIMs. The selection of appropriate TIM depends on the specific application requirements, operating temperature range, and thermal resistance needs. Proper TIM selection helps minimize thermal resistance at the interface and improves overall cooling efficiency.- Thermal Interface Materials (TIM) Selection for Thermoelectric Coolers: The selection of appropriate thermal interface materials is critical for thermoelectric cooler performance. Various TIM options include thermal greases, phase change materials, thermal pads, and metal-based compounds. These materials help minimize thermal resistance between the thermoelectric module and heat sinks by filling microscopic air gaps. The proper TIM selection depends on application requirements, operating temperature range, and thermal conductivity needs.

- Clamping Force Optimization for Thermoelectric Assemblies: Clamping force plays a crucial role in thermoelectric cooler performance by ensuring proper contact between components. Insufficient force leads to poor thermal contact and reduced efficiency, while excessive force can damage the thermoelectric elements. Optimal clamping mechanisms include spring-loaded designs, torque-controlled fasteners, and specialized mounting brackets that maintain consistent pressure across the thermoelectric module surface while accommodating thermal expansion and contraction during operation.

- Pump-Out Risk Mitigation Strategies: Pump-out risks in thermoelectric cooler interfaces occur when thermal cycling causes TIM materials to migrate away from the interface, creating voids and reducing thermal performance. Mitigation strategies include using high-viscosity thermal compounds, containment barriers around the interface, phase-change materials with controlled flow characteristics, and specialized formulations that resist migration under thermal cycling. Proper application techniques and interface designs that limit material displacement also help minimize pump-out effects.

- Thermal Management System Integration: Effective integration of thermoelectric coolers into thermal management systems requires holistic design approaches. This includes optimizing heat sink designs, incorporating proper insulation to prevent condensation, implementing temperature control feedback systems, and ensuring adequate airflow or liquid cooling for hot-side heat dissipation. The interface design must consider the entire thermal path and system requirements to maximize cooling efficiency and reliability while minimizing power consumption.

- Advanced Interface Technologies for Enhanced Performance: Emerging technologies are improving thermoelectric cooler interfaces through innovative approaches. These include direct bonding techniques that eliminate the need for traditional TIMs, nano-engineered interface materials with superior thermal conductivity, composite materials that combine mechanical compliance with high thermal performance, and specialized coatings that enhance surface wettability and adhesion. These advanced solutions address traditional interface limitations while improving reliability under thermal cycling conditions.

02 Clamping Force Optimization for Thermoelectric Modules

The clamping force applied to thermoelectric coolers significantly impacts their thermal performance. Insufficient clamping force can lead to poor thermal contact, while excessive force may damage the thermoelectric elements. Optimal clamping mechanisms distribute pressure evenly across the module surface to minimize thermal resistance. Various mounting techniques and hardware configurations can be employed to achieve the ideal clamping force for different thermoelectric cooling applications.Expand Specific Solutions03 Pump-Out Risk Mitigation Strategies

Pump-out refers to the migration of thermal interface materials away from the contact area due to thermal cycling and mechanical stress. This phenomenon can significantly degrade thermal performance over time. Strategies to mitigate pump-out risks include using containment barriers, selecting TIMs with appropriate viscosity and flow characteristics, implementing edge sealing techniques, and designing interface geometries that minimize material displacement. Proper consideration of these factors extends the operational lifetime of thermoelectric cooling systems.Expand Specific Solutions04 Thermal Cycling Effects on TEC Interfaces

Thermoelectric coolers often operate under conditions involving frequent thermal cycling, which can stress the interface materials and connections. These thermal cycles can lead to interface degradation through mechanisms such as material fatigue, differential thermal expansion, and micro-cracking. Advanced interface designs incorporate materials with matched coefficients of thermal expansion, stress-relieving structures, and flexible bonding agents to withstand repeated thermal cycling without performance degradation.Expand Specific Solutions05 Advanced Mounting and Integration Techniques

Innovative mounting and integration techniques can enhance the performance and reliability of thermoelectric cooler interfaces. These include precision machining of contact surfaces, specialized bonding methods, integrated heat spreading structures, and hybrid interface systems. Some designs incorporate spring-loaded mechanisms to maintain optimal contact pressure despite dimensional changes from thermal expansion. Advanced integration approaches also consider system-level thermal management and may combine multiple cooling technologies for optimal performance.Expand Specific Solutions

Leading Manufacturers and Suppliers in TEC Industry

The thermoelectric cooler interface market is currently in a growth phase, with increasing demand driven by thermal management needs in electronics, telecommunications, and automotive sectors. The global market size is estimated at approximately $1.5 billion, with projected annual growth of 8-10%. Technologically, the field is moderately mature but evolving rapidly, with companies focusing on addressing thermal interface material (TIM) challenges, optimizing clamping force requirements, and mitigating pump-out risks. Key players include established semiconductor and materials companies like Intel, IBM, and Dow Silicones leading innovation in high-performance TIMs, while specialized firms such as Indium Corporation and Phononic are developing advanced solutions for specific applications. Taiwan Semiconductor, GLOBALFOUNDRIES, and Huawei are increasingly investing in this space to support their high-performance computing and telecommunications infrastructure needs.

The Indium Corporation of America

Technical Solution: Indium Corporation has developed specialized metal-based thermal interface materials optimized for thermoelectric cooler applications. Their portfolio includes indium and indium alloy TIMs that provide exceptional thermal conductivity (86 W/m·K for pure indium) while addressing the unique challenges of TEC interfaces. Their research has established that indium-based TIMs perform optimally with clamping pressures between 25-35 psi, significantly lower than required for conventional TIMs. This reduced pressure requirement helps prevent damage to fragile TEC ceramic plates. Indium's metal TIMs feature natural wetting properties that fill microscopic surface irregularities, reducing thermal resistance at the interface. Their materials maintain performance across thousands of thermal cycles without the pump-out effects common with paste-type TIMs. For applications requiring electrical isolation, Indium offers composite solutions combining metal thermal paths with dielectric barriers. Their Heat-Spring® technology specifically addresses the thermal cycling challenges of TEC applications by providing a compliant metal interface that accommodates differential expansion.

Strengths: Exceptional thermal conductivity (5-10x higher than polymer-based TIMs); excellent long-term stability without pump-out; requires lower clamping force than conventional TIMs. Weaknesses: Higher cost than polymer-based solutions; requires specific surface preparation for optimal wetting; potential for galvanic corrosion if not properly matched to contact materials.

Dow Silicones Corp.

Technical Solution: Dow Silicones has developed specialized silicone-based thermal interface materials specifically engineered for thermoelectric cooler applications. Their DOWSIL™ TC series includes advanced gap fillers and thermally conductive adhesives with optimized viscosity profiles that resist pump-out under the thermal cycling conditions typical of TEC operations. Their materials feature controlled volatility silicones with less than 1% siloxane outgassing, critical for preventing contamination in sensitive electronic components. Dow's research has demonstrated that their silicone elastomer TIMs with 3-4 W/m·K thermal conductivity maintain performance after 1000+ thermal cycles when applied with their recommended clamping force protocol. The company has also pioneered hybrid silicone-ceramic composites that provide enhanced shear resistance while maintaining the compliance needed to accommodate the differential expansion between TECs and heat sinks.

Strengths: Excellent stability under thermal cycling; low outgassing formulations protect sensitive components; wide operating temperature range (-40°C to 150°C). Weaknesses: Lower thermal conductivity compared to metal-based TIMs; requires specific surface preparation for optimal adhesion; some formulations have longer cure times affecting manufacturing efficiency.

Critical Analysis of TIM Performance Under Clamping Force

Thermal Interface Material System

PatentActiveUS20160169598A1

Innovation

- A thermally conductive porous matrix with interstitial voids and a high-temperature resistant colloidal suspension applied on both sides, forming a porous thermal pad that inhibits thermal migration and maintains low thermal resistance.

Thermal interface material

PatentWO2022133850A1

Innovation

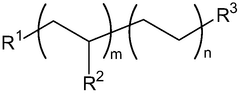

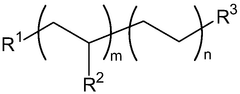

- A thermal interface material composition that becomes softer with increasing temperature while maintaining resistance to pump-out during power cycling, comprising a polyolefin with at least two hydroxy groups, thermally conductive filler (≥80 mass%), and a phase change material (melting point 25-150°C).

- The TIM formulation specifically addresses the critical issue of pump-out in bare die designs (such as GPU or AI chips) where different coefficients of thermal expansion between components typically cause TIM separation during power cycling.

- The material maintains stability through at least 5000 power cycles with minimal pump-out (<5%), making it suitable for high-end applications where changes in bulk and interfacial thermal resistance are unacceptable.

Reliability Testing Methods for TEC Interfaces

Reliability testing for thermoelectric cooler (TEC) interfaces requires comprehensive methodologies to ensure long-term performance under various operating conditions. Standard testing protocols typically include thermal cycling, power cycling, and environmental stress tests that simulate accelerated aging conditions.

Thermal cycling tests evaluate interface integrity by subjecting the TEC assembly to repeated temperature fluctuations between extreme operating points, typically ranging from -40°C to +125°C. These tests reveal potential interface degradation mechanisms such as thermal interface material (TIM) pump-out, delamination, or mechanical fatigue at contact points. Industry standards recommend 1,000 to 3,000 cycles for consumer electronics applications, while aerospace and military applications may require up to 10,000 cycles.

Power cycling tests complement thermal cycling by introducing electrical stress factors. The TEC is repeatedly powered on and off while monitoring thermal resistance changes across the interface. This methodology specifically targets the interface's response to thermal expansion and contraction stresses that occur during normal operation. Degradation is typically quantified by measuring increases in thermal resistance over time.

Mechanical shock and vibration testing evaluates the robustness of TEC interfaces under physical stress conditions. These tests are particularly important for applications in transportation, aerospace, and portable electronics where devices experience significant mechanical forces. JEDEC standards JESD22-B104 and MIL-STD-810 provide standardized testing protocols that can be adapted specifically for TEC interface evaluation.

High-temperature storage tests assess TIM stability and potential material migration under sustained elevated temperatures. Samples are typically held at maximum operating temperature plus a 20-30°C margin for periods ranging from 500 to 2,000 hours. Post-test analysis includes visual inspection for pump-out effects and thermal performance measurements to quantify degradation.

Humidity and environmental exposure tests evaluate interface performance in high-moisture environments, which can accelerate chemical degradation of certain TIM materials. The 85°C/85% relative humidity test is commonly employed, with periodic thermal performance measurements to track degradation rates.

Advanced reliability assessment techniques include acoustic microscopy to detect delamination and void formation without destructive testing, and cross-sectional analysis to examine interface microstructure changes after stress testing. Thermal transient testing provides quantitative data on thermal resistance changes with microsecond-level temporal resolution, enabling early detection of interface degradation.

Thermal cycling tests evaluate interface integrity by subjecting the TEC assembly to repeated temperature fluctuations between extreme operating points, typically ranging from -40°C to +125°C. These tests reveal potential interface degradation mechanisms such as thermal interface material (TIM) pump-out, delamination, or mechanical fatigue at contact points. Industry standards recommend 1,000 to 3,000 cycles for consumer electronics applications, while aerospace and military applications may require up to 10,000 cycles.

Power cycling tests complement thermal cycling by introducing electrical stress factors. The TEC is repeatedly powered on and off while monitoring thermal resistance changes across the interface. This methodology specifically targets the interface's response to thermal expansion and contraction stresses that occur during normal operation. Degradation is typically quantified by measuring increases in thermal resistance over time.

Mechanical shock and vibration testing evaluates the robustness of TEC interfaces under physical stress conditions. These tests are particularly important for applications in transportation, aerospace, and portable electronics where devices experience significant mechanical forces. JEDEC standards JESD22-B104 and MIL-STD-810 provide standardized testing protocols that can be adapted specifically for TEC interface evaluation.

High-temperature storage tests assess TIM stability and potential material migration under sustained elevated temperatures. Samples are typically held at maximum operating temperature plus a 20-30°C margin for periods ranging from 500 to 2,000 hours. Post-test analysis includes visual inspection for pump-out effects and thermal performance measurements to quantify degradation.

Humidity and environmental exposure tests evaluate interface performance in high-moisture environments, which can accelerate chemical degradation of certain TIM materials. The 85°C/85% relative humidity test is commonly employed, with periodic thermal performance measurements to track degradation rates.

Advanced reliability assessment techniques include acoustic microscopy to detect delamination and void formation without destructive testing, and cross-sectional analysis to examine interface microstructure changes after stress testing. Thermal transient testing provides quantitative data on thermal resistance changes with microsecond-level temporal resolution, enabling early detection of interface degradation.

Environmental Impact of TIM Materials in Cooling Applications

The environmental impact of Thermal Interface Materials (TIMs) in cooling applications, particularly in thermoelectric cooler interfaces, represents a growing concern as electronic devices become more ubiquitous. Traditional TIM materials often contain environmentally problematic components such as heavy metals, silicones, and other non-biodegradable compounds that pose significant end-of-life disposal challenges.

Metal-based TIMs, including those containing gallium, indium, and other rare earth elements, raise particular concerns regarding resource depletion and mining impacts. The extraction processes for these materials often involve substantial energy consumption, habitat destruction, and potential water contamination. Additionally, the limited global supply of these elements raises questions about the long-term sustainability of their use in thermal management solutions.

Polymer-based TIMs present different environmental considerations. While they typically require less energy-intensive manufacturing processes compared to metal-based alternatives, many contain synthetic compounds derived from petroleum sources. These materials often demonstrate poor biodegradability and may release microplastics during degradation, contributing to persistent environmental pollution.

The manufacturing processes for TIMs also merit environmental scrutiny. Production often involves energy-intensive mixing, curing, and processing steps that contribute to carbon emissions. Chemical treatments used to enhance thermal conductivity or adhesion properties may introduce additional toxins that require careful handling and disposal protocols to prevent environmental contamination.

The application method and clamping force requirements for TIMs also influence their environmental footprint. Systems requiring frequent TIM replacement due to pump-out issues or degradation increase material consumption and waste generation. Higher clamping force requirements may necessitate more robust mechanical components, increasing the overall material footprint of cooling systems.

Recent industry trends show growing interest in developing environmentally friendly TIM alternatives. Bio-based thermal interface materials derived from renewable resources such as cellulose, plant oils, and agricultural byproducts are emerging as potential substitutes. These materials offer promising biodegradability profiles while maintaining acceptable thermal performance characteristics for less demanding applications.

Regulatory frameworks worldwide are increasingly addressing the environmental impacts of electronic components, including TIMs. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives have prompted manufacturers to develop TIM formulations with reduced environmental impact. Similar regulations in other regions are driving global shifts toward greener thermal management solutions.

Metal-based TIMs, including those containing gallium, indium, and other rare earth elements, raise particular concerns regarding resource depletion and mining impacts. The extraction processes for these materials often involve substantial energy consumption, habitat destruction, and potential water contamination. Additionally, the limited global supply of these elements raises questions about the long-term sustainability of their use in thermal management solutions.

Polymer-based TIMs present different environmental considerations. While they typically require less energy-intensive manufacturing processes compared to metal-based alternatives, many contain synthetic compounds derived from petroleum sources. These materials often demonstrate poor biodegradability and may release microplastics during degradation, contributing to persistent environmental pollution.

The manufacturing processes for TIMs also merit environmental scrutiny. Production often involves energy-intensive mixing, curing, and processing steps that contribute to carbon emissions. Chemical treatments used to enhance thermal conductivity or adhesion properties may introduce additional toxins that require careful handling and disposal protocols to prevent environmental contamination.

The application method and clamping force requirements for TIMs also influence their environmental footprint. Systems requiring frequent TIM replacement due to pump-out issues or degradation increase material consumption and waste generation. Higher clamping force requirements may necessitate more robust mechanical components, increasing the overall material footprint of cooling systems.

Recent industry trends show growing interest in developing environmentally friendly TIM alternatives. Bio-based thermal interface materials derived from renewable resources such as cellulose, plant oils, and agricultural byproducts are emerging as potential substitutes. These materials offer promising biodegradability profiles while maintaining acceptable thermal performance characteristics for less demanding applications.

Regulatory frameworks worldwide are increasingly addressing the environmental impacts of electronic components, including TIMs. The European Union's Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives have prompted manufacturers to develop TIM formulations with reduced environmental impact. Similar regulations in other regions are driving global shifts toward greener thermal management solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!