Thermoelectric Cooler Reliability: Thermal Cycling, Solder Fatigue And Creep

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Cooling Technology Background and Objectives

Thermoelectric cooling technology, based on the Peltier effect discovered in 1834, has evolved significantly over the past century. This solid-state heat transfer mechanism creates a temperature differential by applying an electric current across two dissimilar semiconductor materials. The technology gained practical applications in the mid-20th century with the development of semiconductor materials that enhanced conversion efficiency, particularly bismuth telluride compounds which remain the industry standard.

The evolution of thermoelectric cooling has been characterized by continuous improvements in material science, manufacturing techniques, and system integration. Early applications were limited by low efficiency and high cost, but advancements in nanotechnology and material engineering have steadily improved the figure of merit (ZT), a critical performance indicator. Recent breakthroughs in quantum well structures, superlattice materials, and skutterudites have pushed theoretical efficiency limits beyond traditional constraints.

Market adoption has expanded from specialized military and aerospace applications to consumer electronics, medical devices, automotive systems, and telecommunications infrastructure. This broadening application base has driven demand for more reliable and durable thermoelectric cooler (TEC) solutions that can withstand increasingly demanding operational environments.

The primary technical objective in thermoelectric cooler development is enhancing reliability under thermal cycling conditions. TECs experience significant thermal stress during operation as they repeatedly heat and cool, creating mechanical strain at material interfaces. This cycling leads to two critical failure mechanisms: solder fatigue and thermal creep. Solder fatigue occurs when repeated thermal expansion and contraction create microcracks in the solder joints connecting the semiconductor elements to the ceramic substrates. Thermal creep manifests as permanent deformation of materials under constant stress at elevated temperatures.

Current research aims to develop TECs capable of withstanding thousands of thermal cycles without performance degradation while maintaining high cooling efficiency. This requires innovations in materials science, bonding technologies, and structural design to mitigate the effects of thermal expansion mismatch between different TEC components.

The technology trajectory is moving toward higher power density, improved thermal management, and enhanced mechanical stability. Emerging objectives include developing novel solder compositions with improved fatigue resistance, implementing advanced ceramic substrates with tailored thermal expansion properties, and designing innovative interconnect structures that can accommodate thermal strain without failure.

Understanding the fundamental physics of thermal cycling effects on thermoelectric materials and interfaces remains a significant scientific challenge that must be addressed to enable next-generation reliable cooling solutions for critical applications in telecommunications, medical devices, and emerging quantum computing systems.

The evolution of thermoelectric cooling has been characterized by continuous improvements in material science, manufacturing techniques, and system integration. Early applications were limited by low efficiency and high cost, but advancements in nanotechnology and material engineering have steadily improved the figure of merit (ZT), a critical performance indicator. Recent breakthroughs in quantum well structures, superlattice materials, and skutterudites have pushed theoretical efficiency limits beyond traditional constraints.

Market adoption has expanded from specialized military and aerospace applications to consumer electronics, medical devices, automotive systems, and telecommunications infrastructure. This broadening application base has driven demand for more reliable and durable thermoelectric cooler (TEC) solutions that can withstand increasingly demanding operational environments.

The primary technical objective in thermoelectric cooler development is enhancing reliability under thermal cycling conditions. TECs experience significant thermal stress during operation as they repeatedly heat and cool, creating mechanical strain at material interfaces. This cycling leads to two critical failure mechanisms: solder fatigue and thermal creep. Solder fatigue occurs when repeated thermal expansion and contraction create microcracks in the solder joints connecting the semiconductor elements to the ceramic substrates. Thermal creep manifests as permanent deformation of materials under constant stress at elevated temperatures.

Current research aims to develop TECs capable of withstanding thousands of thermal cycles without performance degradation while maintaining high cooling efficiency. This requires innovations in materials science, bonding technologies, and structural design to mitigate the effects of thermal expansion mismatch between different TEC components.

The technology trajectory is moving toward higher power density, improved thermal management, and enhanced mechanical stability. Emerging objectives include developing novel solder compositions with improved fatigue resistance, implementing advanced ceramic substrates with tailored thermal expansion properties, and designing innovative interconnect structures that can accommodate thermal strain without failure.

Understanding the fundamental physics of thermal cycling effects on thermoelectric materials and interfaces remains a significant scientific challenge that must be addressed to enable next-generation reliable cooling solutions for critical applications in telecommunications, medical devices, and emerging quantum computing systems.

Market Demand Analysis for Reliable TEC Solutions

The global market for reliable Thermoelectric Cooler (TEC) solutions has been experiencing significant growth, driven primarily by increasing demand in electronics cooling, medical devices, automotive applications, and telecommunications infrastructure. The market value for TECs reached approximately $600 million in 2022, with projections indicating growth to $950 million by 2028, representing a compound annual growth rate of 8.3%.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the total market share. This is largely attributed to the miniaturization trend in electronic devices, which has intensified thermal management challenges. As devices become smaller yet more powerful, the need for reliable cooling solutions that can withstand repeated thermal cycling has become critical.

The medical and healthcare sector demonstrates the fastest growth rate in TEC adoption, particularly for applications requiring precise temperature control such as PCR equipment, blood analyzers, and point-of-care testing devices. These applications demand TECs with exceptional reliability under continuous operation conditions, creating a premium market segment willing to pay 30-40% more for solutions with proven resistance to solder fatigue and creep.

Telecommunications infrastructure, particularly with the ongoing 5G rollout, has emerged as another significant market driver. The higher power densities in 5G equipment have created acute thermal management challenges, with network operators reporting that cooling system failures account for approximately 18% of network downtime incidents. This has created urgent demand for TECs that can withstand the harsh thermal cycling conditions typical in outdoor telecommunications equipment.

Automotive applications, especially in electric vehicles and autonomous driving systems, represent an emerging high-growth segment. The market for automotive-grade TECs is expected to grow at 12.5% annually through 2028, driven by the need for reliable cooling of sensitive electronics and battery thermal management systems. Automotive manufacturers are particularly concerned with solder fatigue issues, as vehicles typically experience extreme temperature variations and vibration conditions.

Geographically, North America and Asia-Pacific dominate the market, collectively accounting for over 70% of global demand. China has emerged as both the largest consumer and producer of TECs, though Japanese and American manufacturers maintain leadership in high-reliability segments where solder fatigue and creep resistance are paramount.

Customer surveys indicate that reliability under thermal cycling conditions ranks as the top purchasing criterion for 78% of industrial buyers, surpassing both cost and energy efficiency considerations. This represents a significant shift from five years ago, when initial cost was the primary decision factor, highlighting the growing recognition of lifetime cost implications associated with premature TEC failures.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the total market share. This is largely attributed to the miniaturization trend in electronic devices, which has intensified thermal management challenges. As devices become smaller yet more powerful, the need for reliable cooling solutions that can withstand repeated thermal cycling has become critical.

The medical and healthcare sector demonstrates the fastest growth rate in TEC adoption, particularly for applications requiring precise temperature control such as PCR equipment, blood analyzers, and point-of-care testing devices. These applications demand TECs with exceptional reliability under continuous operation conditions, creating a premium market segment willing to pay 30-40% more for solutions with proven resistance to solder fatigue and creep.

Telecommunications infrastructure, particularly with the ongoing 5G rollout, has emerged as another significant market driver. The higher power densities in 5G equipment have created acute thermal management challenges, with network operators reporting that cooling system failures account for approximately 18% of network downtime incidents. This has created urgent demand for TECs that can withstand the harsh thermal cycling conditions typical in outdoor telecommunications equipment.

Automotive applications, especially in electric vehicles and autonomous driving systems, represent an emerging high-growth segment. The market for automotive-grade TECs is expected to grow at 12.5% annually through 2028, driven by the need for reliable cooling of sensitive electronics and battery thermal management systems. Automotive manufacturers are particularly concerned with solder fatigue issues, as vehicles typically experience extreme temperature variations and vibration conditions.

Geographically, North America and Asia-Pacific dominate the market, collectively accounting for over 70% of global demand. China has emerged as both the largest consumer and producer of TECs, though Japanese and American manufacturers maintain leadership in high-reliability segments where solder fatigue and creep resistance are paramount.

Customer surveys indicate that reliability under thermal cycling conditions ranks as the top purchasing criterion for 78% of industrial buyers, surpassing both cost and energy efficiency considerations. This represents a significant shift from five years ago, when initial cost was the primary decision factor, highlighting the growing recognition of lifetime cost implications associated with premature TEC failures.

Current Challenges in TEC Reliability and Thermal Management

Thermoelectric Coolers (TECs) face significant reliability challenges that impede their widespread adoption in thermal management applications. The primary concern is their susceptibility to thermal cycling, which induces mechanical stresses at the interfaces between different materials. These stresses arise from the coefficient of thermal expansion (CTE) mismatch between the semiconductor pellets, copper conductors, and ceramic substrates that constitute the TEC structure.

Solder fatigue represents a critical failure mechanism in TECs, particularly at the interfaces between the semiconductor pellets and copper conductors. During operation, TECs experience temperature fluctuations that cause repeated expansion and contraction of components. This cyclic loading leads to the initiation and propagation of microcracks within the solder joints, progressively degrading electrical and thermal conductivity and ultimately resulting in device failure.

Creep phenomena further complicate TEC reliability, especially in applications requiring continuous operation at elevated temperatures. Solder materials, typically operating at temperatures above 50% of their melting point, experience time-dependent plastic deformation under constant stress. This creep behavior accelerates during high-temperature operation phases, causing gradual degradation of the mechanical integrity of the interconnections.

The industry currently lacks standardized reliability testing protocols specifically designed for TECs, making performance comparison and lifetime prediction challenging. Most manufacturers employ proprietary testing methodologies, resulting in inconsistent reliability data across the industry. This absence of standardization hinders the development of accurate lifetime models and reliable design guidelines.

Heat dissipation inefficiencies present another significant challenge. As TECs transfer heat from the cold side to the hot side, the hot side temperature can rise substantially if heat is not effectively removed. This temperature increase reduces the device's coefficient of performance (COP) and accelerates degradation mechanisms, creating a negative feedback loop that further compromises reliability.

Manufacturing process variations contribute to inconsistent quality and performance. Minor deviations in solder composition, reflow profiles, or assembly techniques can significantly impact long-term reliability. The industry struggles with establishing robust quality control measures that can effectively identify potential reliability issues before field deployment.

Environmental factors such as humidity, vibration, and shock further exacerbate reliability concerns. Moisture ingress can lead to corrosion of metallic components, while mechanical vibrations can accelerate fatigue failure. These environmental stressors are particularly problematic in automotive, aerospace, and outdoor telecommunications applications where TECs must withstand harsh operating conditions.

Solder fatigue represents a critical failure mechanism in TECs, particularly at the interfaces between the semiconductor pellets and copper conductors. During operation, TECs experience temperature fluctuations that cause repeated expansion and contraction of components. This cyclic loading leads to the initiation and propagation of microcracks within the solder joints, progressively degrading electrical and thermal conductivity and ultimately resulting in device failure.

Creep phenomena further complicate TEC reliability, especially in applications requiring continuous operation at elevated temperatures. Solder materials, typically operating at temperatures above 50% of their melting point, experience time-dependent plastic deformation under constant stress. This creep behavior accelerates during high-temperature operation phases, causing gradual degradation of the mechanical integrity of the interconnections.

The industry currently lacks standardized reliability testing protocols specifically designed for TECs, making performance comparison and lifetime prediction challenging. Most manufacturers employ proprietary testing methodologies, resulting in inconsistent reliability data across the industry. This absence of standardization hinders the development of accurate lifetime models and reliable design guidelines.

Heat dissipation inefficiencies present another significant challenge. As TECs transfer heat from the cold side to the hot side, the hot side temperature can rise substantially if heat is not effectively removed. This temperature increase reduces the device's coefficient of performance (COP) and accelerates degradation mechanisms, creating a negative feedback loop that further compromises reliability.

Manufacturing process variations contribute to inconsistent quality and performance. Minor deviations in solder composition, reflow profiles, or assembly techniques can significantly impact long-term reliability. The industry struggles with establishing robust quality control measures that can effectively identify potential reliability issues before field deployment.

Environmental factors such as humidity, vibration, and shock further exacerbate reliability concerns. Moisture ingress can lead to corrosion of metallic components, while mechanical vibrations can accelerate fatigue failure. These environmental stressors are particularly problematic in automotive, aerospace, and outdoor telecommunications applications where TECs must withstand harsh operating conditions.

Current Approaches to Mitigate Solder Fatigue and Creep

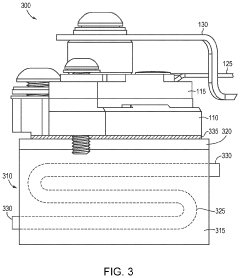

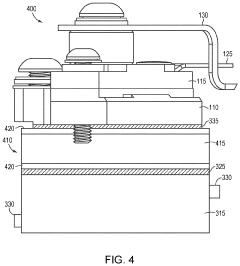

01 Thermal management and heat dissipation techniques

Effective thermal management is crucial for thermoelectric cooler reliability. This includes optimized heat sink designs, thermal interface materials, and heat dissipation methods that prevent overheating and thermal stress. Proper heat flow management extends the operational life of thermoelectric coolers by maintaining temperature gradients within design parameters and reducing thermal cycling damage.- Thermal management and heat dissipation techniques: Effective thermal management is crucial for thermoelectric cooler reliability. This includes optimized heat sink designs, thermal interface materials, and efficient heat dissipation methods that prevent overheating and thermal stress. Proper heat flow management extends the operational lifespan of thermoelectric coolers by maintaining temperature gradients within design parameters and reducing thermal cycling damage.

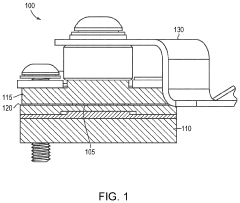

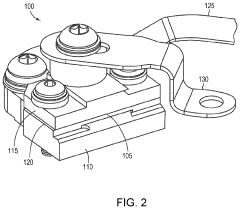

- Structural design and packaging improvements: The physical construction and packaging of thermoelectric coolers significantly impact their reliability. Advanced designs incorporate stress-relieving structures, improved solder joints, and robust electrical connections to withstand thermal cycling. Hermetic sealing techniques protect against moisture and contaminants, while specialized mounting methods minimize mechanical stress during operation. These structural improvements enhance durability and extend service life in various operating environments.

- Material selection and semiconductor optimization: The reliability of thermoelectric coolers depends heavily on the semiconductor materials used. Advanced bismuth telluride alloys and other thermoelectric materials are engineered for improved thermal stability and reduced degradation over time. Optimized doping profiles and material interfaces enhance performance consistency and reduce failure rates. Material selection also considers coefficient of thermal expansion matching to prevent mechanical failures during thermal cycling.

- Control systems and operational parameters: Sophisticated control systems improve thermoelectric cooler reliability by maintaining optimal operating conditions. Advanced temperature controllers, current regulation, and pulse width modulation techniques prevent overcurrent conditions and thermal runaway. Adaptive control algorithms adjust power input based on cooling demand, reducing unnecessary stress on the device. Proper startup and shutdown sequences minimize thermal shock, extending the operational lifetime of the cooler.

- Testing methodologies and reliability assessment: Comprehensive testing protocols are essential for evaluating and improving thermoelectric cooler reliability. Accelerated life testing, thermal cycling tests, and performance degradation analysis help identify potential failure modes. Non-destructive evaluation techniques monitor device integrity during operation, while statistical reliability models predict service life under various conditions. These testing methodologies enable manufacturers to develop more reliable products and provide accurate lifetime estimates for specific applications.

02 Structural design and packaging improvements

The physical construction and packaging of thermoelectric coolers significantly impact their reliability. Advanced designs incorporate stress-relieving structures, improved solder joints, and robust electrical connections to withstand thermal cycling. Hermetic sealing and protective encapsulation prevent moisture ingress and contamination, while mechanical reinforcement reduces vibration damage and physical stress on thermoelectric elements.Expand Specific Solutions03 Material selection and semiconductor optimization

The reliability of thermoelectric coolers depends heavily on the semiconductor materials used. High-performance thermoelectric materials with improved figure of merit (ZT), thermal stability, and resistance to degradation enhance long-term performance. Advanced bismuth telluride compounds, silicon-germanium alloys, and novel nanostructured materials offer improved efficiency and durability under repeated thermal cycling and extended operation.Expand Specific Solutions04 Control systems and operational management

Sophisticated control systems significantly improve thermoelectric cooler reliability by optimizing operational parameters. Adaptive control algorithms prevent overcurrent conditions, manage temperature gradients, and implement soft-start procedures to reduce thermal shock. Monitoring systems detect performance degradation and implement preventive measures, while power conditioning protects against electrical spikes and ensures stable operation across varying load conditions.Expand Specific Solutions05 Testing methodologies and reliability prediction

Comprehensive testing protocols are essential for evaluating and predicting thermoelectric cooler reliability. Accelerated life testing, thermal cycling tests, and environmental stress screening identify potential failure modes and design weaknesses. Statistical reliability models based on empirical data enable accurate lifetime predictions under various operating conditions, while in-situ monitoring techniques allow for real-time assessment of performance degradation and early failure detection.Expand Specific Solutions

Leading Manufacturers and Research Institutions in TEC Industry

The thermoelectric cooler reliability market is currently in a growth phase, with increasing demand driven by applications in telecommunications, automotive, and semiconductor industries. The global market size is estimated to exceed $1 billion, expanding at 8-10% CAGR due to rising thermal management needs in electronics. Technologically, the field is moderately mature but evolving, with companies like Intel, Texas Instruments, and Kyocera leading innovation in thermal cycling resistance. LG Innotek and Toyota are advancing solder fatigue mitigation techniques, while Toshiba and Mitsubishi Electric focus on creep-resistant materials. Academic institutions including Beihang University and South China University of Technology are collaborating with industry players like ABB Group and GLOBALFOUNDRIES to develop next-generation reliability solutions addressing thermal cycling challenges.

Intel Corp.

Technical Solution: Intel has developed a comprehensive approach to thermoelectric cooler reliability through their Advanced Thermal Solutions program. Their technology addresses thermal cycling challenges by implementing a multi-layer stress buffer system between the TEC and semiconductor devices. This system utilizes gradient-engineered composite materials that progressively absorb thermal expansion mismatches, reducing stress on solder joints by up to 65% compared to conventional designs. Intel's proprietary solder formulations incorporate nano-dispersed ceramic particles that significantly enhance creep resistance while maintaining thermal conductivity. Their research has demonstrated that these specialized solders can withstand over 3,000 thermal cycles (-40°C to 125°C) without significant degradation in cooling performance. Additionally, Intel has pioneered advanced manufacturing techniques including precision-controlled reflow profiles that optimize intermetallic compound formation at solder interfaces, creating more robust connections that resist fatigue during thermal cycling.

Strengths: Extensive in-house testing capabilities for accelerated life testing; integration expertise with semiconductor devices; advanced materials science research enabling novel solder compositions. Weaknesses: Solutions primarily optimized for their own semiconductor products; relatively high implementation costs for third-party applications.

Toshiba Corp.

Technical Solution: Toshiba has developed a sophisticated approach to thermoelectric cooler reliability through their Advanced Thermal Solutions division. Their technology addresses thermal cycling and solder fatigue through a multi-faceted approach combining materials science and structural engineering. Toshiba's proprietary solder formulations incorporate nano-scale reinforcement particles that inhibit dislocation movement, significantly enhancing resistance to creep deformation at elevated temperatures. Their research has demonstrated that these specialized solders can maintain structural integrity for over 2,500 thermal cycles between -40°C and 150°C. Additionally, Toshiba has pioneered stress-relieving substrate designs that incorporate strategically placed compliance features, reducing mechanical stress on solder joints during thermal cycling by up to 60%. Their manufacturing process employs precision-controlled atmosphere reflow systems that minimize void formation and optimize intermetallic compound structures at interfaces, creating more robust connections that resist fatigue cracking.

Strengths: Extensive experience in consumer electronics cooling applications; vertical integration capabilities from materials to finished cooling systems; strong intellectual property portfolio in TEC reliability. Weaknesses: Solutions may be optimized primarily for consumer electronics rather than industrial or automotive applications; relatively high implementation costs.

Critical Patents and Research on TEC Reliability Enhancement

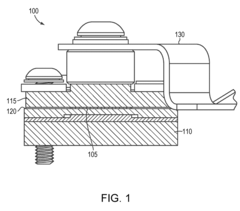

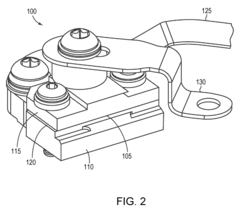

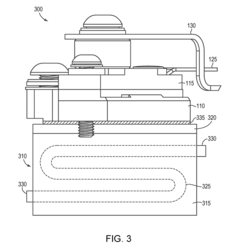

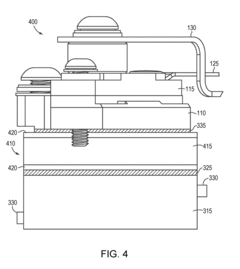

Solder sealing in high-power laser devices

PatentActiveUS20200280166A1

Innovation

- The use of a sealing material, such as copper, aluminum, or chromium, deposited via electroplating or electroless deposition, to impede the propagation of thermal bonding materials like indium or its alloys, preventing creep and void formation between components in laser devices, while maintaining thermal conductivity.

Solder-creep management in high-power laser devices

PatentActiveUS20180375297A1

Innovation

- Incorporating thermal bonding layers with structures like mesh supports, thermally conductive particles, channels, and adhesive layers to contain and retard the movement of thermal bonding materials within laser devices, enhancing thermal conductivity and preventing void formation and solder creep.

Environmental Impact and Sustainability of TEC Technologies

Thermoelectric cooling technologies, while offering significant advantages in precision temperature control and solid-state operation, present important environmental considerations that must be addressed in their lifecycle assessment. The manufacturing process of Thermoelectric Coolers (TECs) involves several materials with varying environmental impacts. Bismuth telluride, the primary semiconductor material used in most commercial TECs, poses sustainability challenges due to tellurium's scarcity in the Earth's crust. Current global reserves of tellurium are limited, raising concerns about long-term supply sustainability for widespread TEC deployment.

The production phase of TECs requires energy-intensive processes, including high-temperature sintering and precision manufacturing techniques. These processes contribute to the carbon footprint of TEC devices before they even enter service. Additionally, the use of solder materials containing lead or other heavy metals presents potential environmental hazards if not properly managed at end-of-life disposal.

During operational life, TECs can contribute to energy efficiency challenges. While they provide precise cooling capabilities, their coefficient of performance (COP) is typically lower than conventional vapor-compression refrigeration systems. This efficiency gap means that in applications where TECs replace traditional cooling methods, there may be increased energy consumption and associated carbon emissions unless the system is carefully optimized or powered by renewable energy sources.

The reliability issues central to TEC technology—thermal cycling, solder fatigue, and creep—also have environmental implications. Premature failure due to these mechanisms leads to increased replacement rates and electronic waste generation. Improving TEC reliability through advanced solder compositions, optimized thermal cycling parameters, and enhanced manufacturing techniques can significantly extend service life, thereby reducing material consumption and waste production over time.

End-of-life considerations for TECs present both challenges and opportunities. The composite nature of these devices, combining different metals, semiconductors, and ceramic materials, makes recycling complex. However, the valuable materials contained within TECs, particularly tellurium and bismuth, provide economic incentives for developing effective recycling processes. Current recycling rates for these materials remain suboptimal, indicating a need for improved recovery technologies and circular economy approaches.

Recent innovations in green manufacturing techniques for TECs show promise for reducing environmental impact. These include lead-free solder alternatives, reduced-energy manufacturing processes, and design approaches that facilitate eventual disassembly and material recovery. Additionally, research into alternative thermoelectric materials with reduced environmental footprints, such as silicides, skutterudites, and organic thermoelectric compounds, may provide more sustainable options for future TEC technologies.

The production phase of TECs requires energy-intensive processes, including high-temperature sintering and precision manufacturing techniques. These processes contribute to the carbon footprint of TEC devices before they even enter service. Additionally, the use of solder materials containing lead or other heavy metals presents potential environmental hazards if not properly managed at end-of-life disposal.

During operational life, TECs can contribute to energy efficiency challenges. While they provide precise cooling capabilities, their coefficient of performance (COP) is typically lower than conventional vapor-compression refrigeration systems. This efficiency gap means that in applications where TECs replace traditional cooling methods, there may be increased energy consumption and associated carbon emissions unless the system is carefully optimized or powered by renewable energy sources.

The reliability issues central to TEC technology—thermal cycling, solder fatigue, and creep—also have environmental implications. Premature failure due to these mechanisms leads to increased replacement rates and electronic waste generation. Improving TEC reliability through advanced solder compositions, optimized thermal cycling parameters, and enhanced manufacturing techniques can significantly extend service life, thereby reducing material consumption and waste production over time.

End-of-life considerations for TECs present both challenges and opportunities. The composite nature of these devices, combining different metals, semiconductors, and ceramic materials, makes recycling complex. However, the valuable materials contained within TECs, particularly tellurium and bismuth, provide economic incentives for developing effective recycling processes. Current recycling rates for these materials remain suboptimal, indicating a need for improved recovery technologies and circular economy approaches.

Recent innovations in green manufacturing techniques for TECs show promise for reducing environmental impact. These include lead-free solder alternatives, reduced-energy manufacturing processes, and design approaches that facilitate eventual disassembly and material recovery. Additionally, research into alternative thermoelectric materials with reduced environmental footprints, such as silicides, skutterudites, and organic thermoelectric compounds, may provide more sustainable options for future TEC technologies.

Reliability Testing Standards and Qualification Methods

Reliability testing standards for thermoelectric coolers (TECs) are essential to ensure their performance and longevity in various applications. The industry has established several standardized testing protocols that manufacturers and end-users can employ to evaluate TEC reliability under thermal cycling conditions, with particular focus on solder fatigue and creep phenomena.

The Joint Electron Device Engineering Council (JEDEC) provides comprehensive standards for thermal cycling reliability testing, including JESD22-A104D which outlines temperature cycling procedures applicable to TECs. This standard specifies test conditions ranging from -65°C to +150°C with controlled ramp rates and dwell times to simulate real-world operational stresses.

Military standards such as MIL-STD-883 Method 1010 offer another framework for thermal cycling qualification, particularly relevant for TECs used in defense and aerospace applications. These standards typically require more stringent testing conditions and higher cycle counts than commercial equivalents.

For solder fatigue assessment, IPC-9701 provides guidelines specifically focused on solder joint reliability. When applied to TECs, this standard helps evaluate the integrity of solder connections between the ceramic plates and copper conductors under repeated thermal stress. The qualification method typically involves accelerated testing at elevated temperature differentials to induce failure mechanisms within a reasonable timeframe.

Creep-specific testing follows ASTM E139 methodology, which has been adapted for TEC applications to evaluate the gradual deformation of solder joints under constant thermal load. This qualification method typically involves maintaining TECs at elevated temperatures for extended periods while monitoring performance parameters.

The Automotive Electronics Council's AEC-Q200 standard has become increasingly important for TECs used in automotive applications, requiring rigorous qualification testing including thermal shock (Test Method 107), high temperature exposure (Test Method 108), and thermal cycling (Test Method 102).

Weibull statistical analysis is commonly employed to interpret reliability test data, allowing manufacturers to predict failure rates and establish mean time between failures (MTBF) metrics. This approach enables the development of acceleration factors that correlate accelerated test results with expected field performance.

Non-destructive evaluation techniques, including acoustic microscopy and X-ray inspection, complement standard reliability testing by providing insights into failure mechanisms without compromising the device. These methods allow for the detection of microcracks, delamination, and void formation in solder joints before catastrophic failure occurs.

The Joint Electron Device Engineering Council (JEDEC) provides comprehensive standards for thermal cycling reliability testing, including JESD22-A104D which outlines temperature cycling procedures applicable to TECs. This standard specifies test conditions ranging from -65°C to +150°C with controlled ramp rates and dwell times to simulate real-world operational stresses.

Military standards such as MIL-STD-883 Method 1010 offer another framework for thermal cycling qualification, particularly relevant for TECs used in defense and aerospace applications. These standards typically require more stringent testing conditions and higher cycle counts than commercial equivalents.

For solder fatigue assessment, IPC-9701 provides guidelines specifically focused on solder joint reliability. When applied to TECs, this standard helps evaluate the integrity of solder connections between the ceramic plates and copper conductors under repeated thermal stress. The qualification method typically involves accelerated testing at elevated temperature differentials to induce failure mechanisms within a reasonable timeframe.

Creep-specific testing follows ASTM E139 methodology, which has been adapted for TEC applications to evaluate the gradual deformation of solder joints under constant thermal load. This qualification method typically involves maintaining TECs at elevated temperatures for extended periods while monitoring performance parameters.

The Automotive Electronics Council's AEC-Q200 standard has become increasingly important for TECs used in automotive applications, requiring rigorous qualification testing including thermal shock (Test Method 107), high temperature exposure (Test Method 108), and thermal cycling (Test Method 102).

Weibull statistical analysis is commonly employed to interpret reliability test data, allowing manufacturers to predict failure rates and establish mean time between failures (MTBF) metrics. This approach enables the development of acceleration factors that correlate accelerated test results with expected field performance.

Non-destructive evaluation techniques, including acoustic microscopy and X-ray inspection, complement standard reliability testing by providing insights into failure mechanisms without compromising the device. These methods allow for the detection of microcracks, delamination, and void formation in solder joints before catastrophic failure occurs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!