How Throttle Body Design Affects Engine Knock Tendency

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution and Knock Reduction Goals

The evolution of throttle body design has played a crucial role in addressing engine knock tendency, a persistent challenge in internal combustion engines. Historically, throttle bodies have undergone significant transformations, from simple mechanical designs to sophisticated electronic systems, all aimed at optimizing air-fuel mixture and reducing knock occurrence.

In the early days of automotive engineering, throttle bodies were primarily mechanical devices with limited control over air intake. This rudimentary design often led to inconsistent air-fuel ratios, particularly during rapid throttle changes, which increased the likelihood of engine knock. As technology progressed, the introduction of electronic throttle control (ETC) systems marked a significant milestone in throttle body evolution.

ETC systems, also known as drive-by-wire, replaced mechanical linkages with electronic sensors and actuators. This advancement allowed for more precise control over air intake, enabling real-time adjustments based on various engine parameters. The improved accuracy in air-fuel mixture management significantly contributed to reducing knock tendency, especially during transient operating conditions.

Further refinements in throttle body design focused on optimizing airflow characteristics. Engineers developed more aerodynamic throttle plate shapes and improved bore designs to minimize turbulence and ensure smoother airflow. These enhancements not only improved engine efficiency but also helped maintain more consistent cylinder pressures, reducing the likelihood of knock events.

The integration of variable geometry throttle bodies represents another leap in knock reduction efforts. These advanced designs can alter the effective cross-sectional area of the intake passage, allowing for optimized airflow across different engine speeds and loads. By maintaining ideal air velocity and turbulence levels, variable geometry throttle bodies contribute to more uniform air-fuel mixture distribution, further mitigating knock risks.

Recent developments have seen the incorporation of intelligent throttle body systems that utilize machine learning algorithms and predictive models. These systems can anticipate potential knock conditions based on historical data and real-time sensor inputs, proactively adjusting throttle position to prevent knock occurrence. This preemptive approach marks a significant advancement in knock reduction strategies.

The ongoing evolution of throttle body design continues to push the boundaries of knock reduction goals. Current research focuses on developing throttle bodies with integrated sensors capable of detecting early signs of knock precursors in the intake air. This real-time data could enable even more precise adjustments to air-fuel ratios, ignition timing, and other parameters critical to knock prevention.

As the automotive industry shifts towards electrification and alternative fuels, throttle body design goals are expanding to address new challenges. For instance, in hybrid powertrains, throttle bodies must adapt to rapid transitions between electric and combustion modes while maintaining optimal knock resistance. Similarly, for engines running on alternative fuels like hydrogen or synthetic fuels, throttle body designs are being refined to accommodate different combustion characteristics and knock tendencies specific to these fuel types.

In the early days of automotive engineering, throttle bodies were primarily mechanical devices with limited control over air intake. This rudimentary design often led to inconsistent air-fuel ratios, particularly during rapid throttle changes, which increased the likelihood of engine knock. As technology progressed, the introduction of electronic throttle control (ETC) systems marked a significant milestone in throttle body evolution.

ETC systems, also known as drive-by-wire, replaced mechanical linkages with electronic sensors and actuators. This advancement allowed for more precise control over air intake, enabling real-time adjustments based on various engine parameters. The improved accuracy in air-fuel mixture management significantly contributed to reducing knock tendency, especially during transient operating conditions.

Further refinements in throttle body design focused on optimizing airflow characteristics. Engineers developed more aerodynamic throttle plate shapes and improved bore designs to minimize turbulence and ensure smoother airflow. These enhancements not only improved engine efficiency but also helped maintain more consistent cylinder pressures, reducing the likelihood of knock events.

The integration of variable geometry throttle bodies represents another leap in knock reduction efforts. These advanced designs can alter the effective cross-sectional area of the intake passage, allowing for optimized airflow across different engine speeds and loads. By maintaining ideal air velocity and turbulence levels, variable geometry throttle bodies contribute to more uniform air-fuel mixture distribution, further mitigating knock risks.

Recent developments have seen the incorporation of intelligent throttle body systems that utilize machine learning algorithms and predictive models. These systems can anticipate potential knock conditions based on historical data and real-time sensor inputs, proactively adjusting throttle position to prevent knock occurrence. This preemptive approach marks a significant advancement in knock reduction strategies.

The ongoing evolution of throttle body design continues to push the boundaries of knock reduction goals. Current research focuses on developing throttle bodies with integrated sensors capable of detecting early signs of knock precursors in the intake air. This real-time data could enable even more precise adjustments to air-fuel ratios, ignition timing, and other parameters critical to knock prevention.

As the automotive industry shifts towards electrification and alternative fuels, throttle body design goals are expanding to address new challenges. For instance, in hybrid powertrains, throttle bodies must adapt to rapid transitions between electric and combustion modes while maintaining optimal knock resistance. Similarly, for engines running on alternative fuels like hydrogen or synthetic fuels, throttle body designs are being refined to accommodate different combustion characteristics and knock tendencies specific to these fuel types.

Market Demand for Efficient Engine Performance

The market demand for efficient engine performance has been steadily increasing in recent years, driven by a combination of regulatory pressures, consumer preferences, and technological advancements. As automotive manufacturers strive to meet stringent emissions standards and fuel economy regulations, the need for engines that deliver optimal performance while minimizing fuel consumption has become paramount.

Consumers are increasingly seeking vehicles that offer a balance between power and efficiency, leading to a growing demand for engines that can provide responsive acceleration and smooth operation without sacrificing fuel economy. This trend is particularly evident in the mid-range and premium vehicle segments, where customers expect high performance coupled with reasonable running costs.

The automotive industry has responded to this demand by investing heavily in research and development of advanced engine technologies. Innovations in areas such as direct fuel injection, variable valve timing, and turbocharging have all contributed to significant improvements in engine efficiency. These technologies allow engines to extract more power from each unit of fuel, resulting in better performance and reduced emissions.

The market for efficient engine performance is not limited to passenger vehicles. Commercial vehicle manufacturers are also under pressure to improve fuel efficiency and reduce operating costs for their customers. This has led to increased demand for advanced engine technologies in trucks, buses, and other heavy-duty vehicles.

In the context of throttle body design and its impact on engine knock tendency, there is a growing market interest in solutions that can mitigate knock while maintaining or improving engine efficiency. Engine knock, or pre-ignition, is a significant concern as it can lead to reduced performance, increased fuel consumption, and potential engine damage. Manufacturers and suppliers are actively seeking innovative throttle body designs that can help control air-fuel mixture and combustion timing to minimize knock occurrence.

The aftermarket sector has also seen increased demand for performance-enhancing products that can improve engine efficiency and reduce knock tendency. This includes advanced throttle bodies, intake systems, and engine management solutions that allow enthusiasts and performance-oriented consumers to optimize their vehicles' performance while maintaining reliability.

As the automotive industry continues to evolve towards electrification, the demand for efficient internal combustion engines remains strong in the near to medium term. Hybrid powertrains, which combine electric motors with internal combustion engines, require highly efficient engines to maximize overall system performance. This has further intensified the focus on advanced engine technologies, including those related to throttle body design and knock prevention.

Consumers are increasingly seeking vehicles that offer a balance between power and efficiency, leading to a growing demand for engines that can provide responsive acceleration and smooth operation without sacrificing fuel economy. This trend is particularly evident in the mid-range and premium vehicle segments, where customers expect high performance coupled with reasonable running costs.

The automotive industry has responded to this demand by investing heavily in research and development of advanced engine technologies. Innovations in areas such as direct fuel injection, variable valve timing, and turbocharging have all contributed to significant improvements in engine efficiency. These technologies allow engines to extract more power from each unit of fuel, resulting in better performance and reduced emissions.

The market for efficient engine performance is not limited to passenger vehicles. Commercial vehicle manufacturers are also under pressure to improve fuel efficiency and reduce operating costs for their customers. This has led to increased demand for advanced engine technologies in trucks, buses, and other heavy-duty vehicles.

In the context of throttle body design and its impact on engine knock tendency, there is a growing market interest in solutions that can mitigate knock while maintaining or improving engine efficiency. Engine knock, or pre-ignition, is a significant concern as it can lead to reduced performance, increased fuel consumption, and potential engine damage. Manufacturers and suppliers are actively seeking innovative throttle body designs that can help control air-fuel mixture and combustion timing to minimize knock occurrence.

The aftermarket sector has also seen increased demand for performance-enhancing products that can improve engine efficiency and reduce knock tendency. This includes advanced throttle bodies, intake systems, and engine management solutions that allow enthusiasts and performance-oriented consumers to optimize their vehicles' performance while maintaining reliability.

As the automotive industry continues to evolve towards electrification, the demand for efficient internal combustion engines remains strong in the near to medium term. Hybrid powertrains, which combine electric motors with internal combustion engines, require highly efficient engines to maximize overall system performance. This has further intensified the focus on advanced engine technologies, including those related to throttle body design and knock prevention.

Current Throttle Body Designs and Knock Challenges

Current throttle body designs primarily focus on optimizing airflow into the engine, but their impact on knock tendency is becoming increasingly important. Traditional butterfly valve throttle bodies, while effective for controlling airflow, can create turbulence and uneven air distribution, potentially contributing to engine knock. More advanced designs, such as barrel-type throttle bodies, aim to provide smoother airflow and better atomization of fuel, which can help mitigate knock issues.

One of the main challenges in throttle body design is balancing the need for precise airflow control with the requirement to minimize pressure drops and turbulence. Pressure drops across the throttle body can lead to inconsistent air-fuel mixtures in different cylinders, increasing the likelihood of knock in some cylinders. Additionally, turbulence created by the throttle body can affect fuel atomization and distribution, potentially creating hot spots or areas of lean mixture that are prone to knock.

Another significant challenge is the integration of electronic control systems with throttle body design. Modern throttle bodies often incorporate electronic throttle control (ETC) systems, which can provide more precise control over airflow. However, the interaction between these electronic systems and the physical design of the throttle body can introduce complexities in managing knock tendency, particularly during rapid throttle changes or under varying engine loads.

The geometry of the throttle body passage also plays a crucial role in knock prevention. Designs that promote a more uniform air velocity profile across the throttle opening can help ensure consistent air-fuel mixing in all cylinders. However, achieving this while maintaining the necessary flow characteristics across a wide range of engine operating conditions remains a significant engineering challenge.

Furthermore, the location and orientation of the throttle body relative to the intake manifold and fuel injectors can influence knock tendency. Designs that promote better fuel atomization and more even distribution of the air-fuel mixture to all cylinders can help reduce the likelihood of knock. This often involves careful consideration of the throttle body's position and its interaction with other intake system components.

As engines become more advanced and emissions regulations more stringent, the role of throttle body design in knock prevention is likely to become even more critical. Future designs may need to incorporate more sophisticated flow control mechanisms, advanced materials to manage heat transfer, and integrated sensors for real-time monitoring of airflow characteristics. These developments will need to be balanced against cost considerations and the need for reliability in diverse operating conditions.

One of the main challenges in throttle body design is balancing the need for precise airflow control with the requirement to minimize pressure drops and turbulence. Pressure drops across the throttle body can lead to inconsistent air-fuel mixtures in different cylinders, increasing the likelihood of knock in some cylinders. Additionally, turbulence created by the throttle body can affect fuel atomization and distribution, potentially creating hot spots or areas of lean mixture that are prone to knock.

Another significant challenge is the integration of electronic control systems with throttle body design. Modern throttle bodies often incorporate electronic throttle control (ETC) systems, which can provide more precise control over airflow. However, the interaction between these electronic systems and the physical design of the throttle body can introduce complexities in managing knock tendency, particularly during rapid throttle changes or under varying engine loads.

The geometry of the throttle body passage also plays a crucial role in knock prevention. Designs that promote a more uniform air velocity profile across the throttle opening can help ensure consistent air-fuel mixing in all cylinders. However, achieving this while maintaining the necessary flow characteristics across a wide range of engine operating conditions remains a significant engineering challenge.

Furthermore, the location and orientation of the throttle body relative to the intake manifold and fuel injectors can influence knock tendency. Designs that promote better fuel atomization and more even distribution of the air-fuel mixture to all cylinders can help reduce the likelihood of knock. This often involves careful consideration of the throttle body's position and its interaction with other intake system components.

As engines become more advanced and emissions regulations more stringent, the role of throttle body design in knock prevention is likely to become even more critical. Future designs may need to incorporate more sophisticated flow control mechanisms, advanced materials to manage heat transfer, and integrated sensors for real-time monitoring of airflow characteristics. These developments will need to be balanced against cost considerations and the need for reliability in diverse operating conditions.

Existing Knock Mitigation Strategies

01 Throttle body design modifications

Modifications to the throttle body design can help reduce knock tendency. This includes changes to the shape, size, and internal components of the throttle body to improve airflow and fuel mixture distribution. These modifications can lead to more efficient combustion and reduced likelihood of engine knock.- Throttle body design modifications: Modifications to the throttle body design can help reduce knock tendency. This includes changes to the shape, size, and internal components of the throttle body to improve airflow and fuel mixture distribution. These modifications can help prevent hot spots and uneven combustion that lead to engine knock.

- Sensor integration for knock detection: Integrating sensors into the throttle body or nearby components can help detect and prevent knock conditions. These sensors can monitor various parameters such as air pressure, temperature, and fuel mixture to adjust engine operation in real-time, reducing the likelihood of knock occurrence.

- Electronic throttle control systems: Implementing electronic throttle control systems can provide more precise management of air intake and fuel delivery. These systems can rapidly adjust throttle position based on various engine parameters, helping to maintain optimal combustion conditions and reduce knock tendency.

- Fuel injection optimization: Optimizing fuel injection in relation to throttle body operation can help reduce knock tendency. This includes adjusting injection timing, duration, and spray pattern to ensure proper fuel atomization and distribution within the combustion chamber, leading to more consistent and controlled combustion.

- Throttle body cooling and insulation: Implementing cooling mechanisms or improved insulation for the throttle body can help maintain consistent air intake temperatures. This can prevent heat soak and reduce the likelihood of pre-ignition or knock conditions, especially in high-performance or turbocharged engines.

02 Sensor integration for knock detection

Integrating sensors into the throttle body or nearby components can help detect and prevent knock conditions. These sensors can monitor various parameters such as air pressure, temperature, and fuel mixture to provide real-time data for engine management systems to adjust throttle position and fuel injection accordingly.Expand Specific Solutions03 Electronic throttle control systems

Implementing electronic throttle control systems can help mitigate knock tendency by providing more precise control over throttle position and air-fuel mixture. These systems can rapidly adjust throttle opening based on various engine parameters and driving conditions to optimize performance and reduce the risk of knock.Expand Specific Solutions04 Fuel injection optimization

Optimizing fuel injection in relation to throttle body operation can help reduce knock tendency. This involves adjusting fuel injection timing, duration, and spray pattern to ensure proper fuel atomization and distribution within the combustion chamber, leading to more efficient combustion and reduced likelihood of knock.Expand Specific Solutions05 Throttle body cooling and insulation

Implementing cooling and insulation techniques for the throttle body can help maintain optimal operating temperatures and reduce the risk of heat-induced knock. This may include the use of heat shields, improved airflow design, or integration of cooling channels to dissipate excess heat from the throttle body and surrounding components.Expand Specific Solutions

Key Players in Throttle Body Manufacturing

The competition landscape for throttle body design's impact on engine knock tendency is evolving rapidly. The market is in a growth phase, with increasing demand for fuel-efficient and high-performance engines driving innovation. Major players like Ford, Toyota, Honda, and Nissan are investing heavily in R&D to optimize throttle body designs. The market size is expanding, fueled by stringent emission regulations and consumer demand for improved engine performance. Technological maturity varies, with established companies like Bosch and Siemens leading in advanced electronic throttle control systems, while newer entrants like MotoCzysz and FEV Motorentechnik are pushing boundaries with innovative designs. The competition is fierce, with automotive giants and specialized component manufacturers vying for market share through continuous technological advancements.

Ford Global Technologies LLC

Technical Solution: Ford has implemented a variable geometry throttle body design that can dynamically adjust its shape to optimize airflow characteristics under different engine operating conditions. This system uses movable vanes or flaps within the throttle body that can alter the cross-sectional area and flow path of incoming air. By tailoring the airflow pattern, Ford's design can reduce turbulence and improve air-fuel mixture distribution, particularly at low engine speeds where knock is more likely to occur[2]. The system is integrated with Ford's EcoBoost technology, allowing for better synergy between turbocharging and throttle control to mitigate knock[4].

Strengths: Adaptive airflow optimization, improved low-speed performance, and compatibility with turbocharging. Weaknesses: Increased mechanical complexity and potential for higher maintenance requirements.

Toyota Motor Corp.

Technical Solution: Toyota has developed a throttle body design featuring an integrated air bypass system and a unique throttle plate profile. The air bypass system allows a controlled amount of air to flow around the throttle plate even when it's nearly closed, improving idle stability and reducing the likelihood of knock during sudden throttle openings[5]. The throttle plate itself has an asymmetrical profile that creates a more gradual increase in airflow as the throttle opens, providing smoother acceleration and better control over the air-fuel mixture. Toyota's design also incorporates a fast-response electric motor and high-resolution position sensor to enable precise throttle control[6].

Strengths: Improved idle stability, smooth acceleration, and precise control. Weaknesses: More complex manufacturing process and potential for increased cost.

Innovative Throttle Body Designs for Knock Reduction

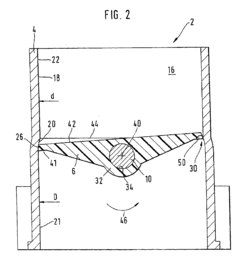

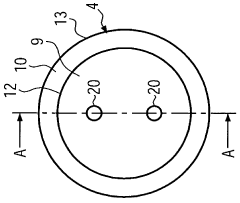

Throttle body for controlling the power of an engine

PatentInactiveEP1035312A3

Innovation

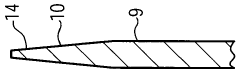

- A throttle body design with a narrowing gas duct wall and a spherical segment shape, where the axis of rotation is outside the plane of the throttle valve's circumference, allowing for a narrow gap and reduced leakage, and featuring adjustable depressions for precise control, minimizes air leakage and enhances sensitive control of engine power.

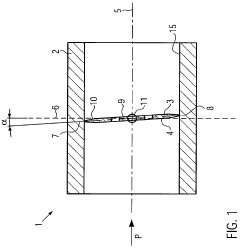

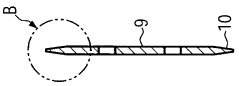

Combustion air guide device

PatentWO2009129969A1

Innovation

- A combustion air ducting device with a throttle valve body that tapers towards the outer contour, allowing a reduced flap base angle and minimizing unwanted torque increases, ensuring smooth power delivery and preventing throttle valve sticking.

Emissions Regulations Impact on Throttle Body Design

Emissions regulations have significantly influenced throttle body design in recent years, as automotive manufacturers strive to meet increasingly stringent environmental standards. These regulations, primarily focused on reducing harmful emissions and improving fuel efficiency, have led to substantial changes in throttle body technology and its integration with engine management systems.

One of the most notable impacts of emissions regulations on throttle body design has been the widespread adoption of electronic throttle control (ETC) systems. Unlike traditional mechanical throttle bodies, ETC systems use sensors and actuators to precisely control airflow into the engine. This level of control allows for more accurate fuel metering and improved emissions performance across various operating conditions.

The introduction of variable valve timing (VVT) and direct fuel injection systems has also necessitated changes in throttle body design. These technologies require throttle bodies to work in harmony with other engine components to optimize air-fuel mixture and combustion efficiency. As a result, throttle bodies now incorporate more sophisticated airflow management features, such as variable geometry designs and integrated sensors.

Emissions regulations have also driven the development of throttle bodies with improved sealing capabilities. Tighter seals help prevent uncontrolled air leaks, which can lead to inconsistent air-fuel ratios and increased emissions. Manufacturers have invested in advanced materials and manufacturing techniques to ensure precise fitment and long-term durability of throttle body components.

The need for more accurate airflow measurement has led to the integration of mass airflow sensors (MAF) directly into throttle body assemblies. This integration allows for real-time monitoring of intake air volume and density, enabling engine control units to make instantaneous adjustments to fuel delivery and ignition timing. Such precise control is crucial for maintaining optimal combustion and minimizing emissions across various engine operating conditions.

Furthermore, emissions regulations have prompted the development of throttle bodies with improved thermal management properties. Controlling the temperature of incoming air is essential for reducing the formation of nitrogen oxides (NOx) and other pollutants. As a result, some modern throttle bodies incorporate features such as integrated cooling passages or heat-dissipating materials to help regulate intake air temperature.

The push for reduced emissions has also led to the exploration of alternative throttle body designs, such as those incorporating active aerodynamic elements. These designs aim to optimize airflow characteristics under different engine loads and speeds, potentially improving combustion efficiency and reducing emissions without sacrificing performance.

One of the most notable impacts of emissions regulations on throttle body design has been the widespread adoption of electronic throttle control (ETC) systems. Unlike traditional mechanical throttle bodies, ETC systems use sensors and actuators to precisely control airflow into the engine. This level of control allows for more accurate fuel metering and improved emissions performance across various operating conditions.

The introduction of variable valve timing (VVT) and direct fuel injection systems has also necessitated changes in throttle body design. These technologies require throttle bodies to work in harmony with other engine components to optimize air-fuel mixture and combustion efficiency. As a result, throttle bodies now incorporate more sophisticated airflow management features, such as variable geometry designs and integrated sensors.

Emissions regulations have also driven the development of throttle bodies with improved sealing capabilities. Tighter seals help prevent uncontrolled air leaks, which can lead to inconsistent air-fuel ratios and increased emissions. Manufacturers have invested in advanced materials and manufacturing techniques to ensure precise fitment and long-term durability of throttle body components.

The need for more accurate airflow measurement has led to the integration of mass airflow sensors (MAF) directly into throttle body assemblies. This integration allows for real-time monitoring of intake air volume and density, enabling engine control units to make instantaneous adjustments to fuel delivery and ignition timing. Such precise control is crucial for maintaining optimal combustion and minimizing emissions across various engine operating conditions.

Furthermore, emissions regulations have prompted the development of throttle bodies with improved thermal management properties. Controlling the temperature of incoming air is essential for reducing the formation of nitrogen oxides (NOx) and other pollutants. As a result, some modern throttle bodies incorporate features such as integrated cooling passages or heat-dissipating materials to help regulate intake air temperature.

The push for reduced emissions has also led to the exploration of alternative throttle body designs, such as those incorporating active aerodynamic elements. These designs aim to optimize airflow characteristics under different engine loads and speeds, potentially improving combustion efficiency and reducing emissions without sacrificing performance.

Cost-Benefit Analysis of Advanced Throttle Bodies

The cost-benefit analysis of advanced throttle bodies is a crucial consideration for automotive manufacturers and engine designers. Advanced throttle bodies offer several potential benefits that can justify their higher initial costs. These benefits include improved fuel efficiency, enhanced engine performance, and reduced emissions. By optimizing airflow into the engine, advanced throttle bodies can contribute to more precise fuel metering and combustion control, potentially leading to a reduction in engine knock tendency.

One of the primary advantages of advanced throttle bodies is their ability to provide more accurate and responsive throttle control. This can result in improved drivability and a more refined driving experience for consumers. Additionally, the enhanced precision in air intake management can lead to better fuel economy, which is an increasingly important factor for both consumers and regulatory compliance. The potential fuel savings over the lifetime of a vehicle can offset the higher upfront costs associated with advanced throttle body technology.

From an emissions perspective, advanced throttle bodies can play a significant role in meeting stringent environmental regulations. By enabling more precise control over the air-fuel mixture, these components can help reduce harmful emissions, particularly during cold starts and transient operating conditions. This benefit not only contributes to environmental protection but also helps manufacturers avoid potential fines and penalties associated with non-compliance.

However, the implementation of advanced throttle bodies also comes with challenges. The increased complexity of these components can lead to higher manufacturing costs and potentially more frequent maintenance requirements. There may also be additional costs associated with integrating advanced throttle bodies into existing engine management systems, including software development and calibration expenses.

When considering the long-term benefits, it's important to factor in the potential reduction in warranty claims and customer satisfaction improvements that may result from the enhanced reliability and performance of advanced throttle bodies. These indirect benefits can contribute significantly to a manufacturer's reputation and market position, potentially leading to increased sales and brand loyalty.

In conclusion, while advanced throttle bodies may require a higher initial investment, their potential to improve engine efficiency, reduce emissions, and enhance overall vehicle performance can provide substantial long-term value. Manufacturers must carefully weigh these benefits against the increased costs to determine the most appropriate implementation strategy for their specific product lines and target markets.

One of the primary advantages of advanced throttle bodies is their ability to provide more accurate and responsive throttle control. This can result in improved drivability and a more refined driving experience for consumers. Additionally, the enhanced precision in air intake management can lead to better fuel economy, which is an increasingly important factor for both consumers and regulatory compliance. The potential fuel savings over the lifetime of a vehicle can offset the higher upfront costs associated with advanced throttle body technology.

From an emissions perspective, advanced throttle bodies can play a significant role in meeting stringent environmental regulations. By enabling more precise control over the air-fuel mixture, these components can help reduce harmful emissions, particularly during cold starts and transient operating conditions. This benefit not only contributes to environmental protection but also helps manufacturers avoid potential fines and penalties associated with non-compliance.

However, the implementation of advanced throttle bodies also comes with challenges. The increased complexity of these components can lead to higher manufacturing costs and potentially more frequent maintenance requirements. There may also be additional costs associated with integrating advanced throttle bodies into existing engine management systems, including software development and calibration expenses.

When considering the long-term benefits, it's important to factor in the potential reduction in warranty claims and customer satisfaction improvements that may result from the enhanced reliability and performance of advanced throttle bodies. These indirect benefits can contribute significantly to a manufacturer's reputation and market position, potentially leading to increased sales and brand loyalty.

In conclusion, while advanced throttle bodies may require a higher initial investment, their potential to improve engine efficiency, reduce emissions, and enhance overall vehicle performance can provide substantial long-term value. Manufacturers must carefully weigh these benefits against the increased costs to determine the most appropriate implementation strategy for their specific product lines and target markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!