Throttle Body Applications in Agricultural Vehicles

JUL 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution in Ag Vehicles

The evolution of throttle bodies in agricultural vehicles has been a significant aspect of engine technology advancement in the farming sector. Initially, mechanical throttle bodies were the standard, relying on direct linkages between the accelerator pedal and the throttle plate. These systems, while robust, lacked precision and adaptability to varying operating conditions.

The introduction of electronic throttle control (ETC) in the late 1990s marked a pivotal shift in throttle body technology for agricultural vehicles. ETC systems, also known as drive-by-wire, replaced mechanical linkages with sensors and actuators, allowing for more precise control of engine power and fuel efficiency. This transition enabled better integration with engine management systems, resulting in improved vehicle performance and reduced emissions.

As precision agriculture gained prominence in the early 2000s, throttle body technology in agricultural vehicles evolved to support more sophisticated engine control strategies. Advanced sensors were incorporated to monitor factors such as air temperature, pressure, and mass flow, enabling real-time adjustments to throttle position for optimal engine performance under varying load conditions.

The mid-2000s saw the integration of variable geometry throttle bodies in high-end agricultural vehicles. These systems could alter the shape of the throttle opening, optimizing airflow across different engine speeds and load conditions. This innovation contributed to enhanced fuel efficiency and power delivery, particularly beneficial for tractors and harvesters operating under diverse field conditions.

In recent years, the focus has shifted towards intelligent throttle body systems that leverage machine learning and IoT technologies. These advanced systems can predict optimal throttle positions based on historical data, current operating conditions, and even terrain information. Such predictive capabilities have further improved fuel efficiency and reduced wear on engine components.

The latest developments in throttle body technology for agricultural vehicles include the integration of hybrid and electric powertrain systems. These advancements have led to the development of throttle bodies that can seamlessly transition between different power sources, optimizing energy usage and reducing environmental impact.

Looking ahead, the evolution of throttle bodies in agricultural vehicles is likely to continue in the direction of increased electrification and automation. Future systems may incorporate AI-driven predictive maintenance capabilities, further enhancing reliability and reducing downtime for farmers. Additionally, as alternative fuels gain traction in the agricultural sector, throttle body designs are expected to adapt to accommodate these new energy sources, ensuring optimal performance and efficiency in the next generation of farm machinery.

The introduction of electronic throttle control (ETC) in the late 1990s marked a pivotal shift in throttle body technology for agricultural vehicles. ETC systems, also known as drive-by-wire, replaced mechanical linkages with sensors and actuators, allowing for more precise control of engine power and fuel efficiency. This transition enabled better integration with engine management systems, resulting in improved vehicle performance and reduced emissions.

As precision agriculture gained prominence in the early 2000s, throttle body technology in agricultural vehicles evolved to support more sophisticated engine control strategies. Advanced sensors were incorporated to monitor factors such as air temperature, pressure, and mass flow, enabling real-time adjustments to throttle position for optimal engine performance under varying load conditions.

The mid-2000s saw the integration of variable geometry throttle bodies in high-end agricultural vehicles. These systems could alter the shape of the throttle opening, optimizing airflow across different engine speeds and load conditions. This innovation contributed to enhanced fuel efficiency and power delivery, particularly beneficial for tractors and harvesters operating under diverse field conditions.

In recent years, the focus has shifted towards intelligent throttle body systems that leverage machine learning and IoT technologies. These advanced systems can predict optimal throttle positions based on historical data, current operating conditions, and even terrain information. Such predictive capabilities have further improved fuel efficiency and reduced wear on engine components.

The latest developments in throttle body technology for agricultural vehicles include the integration of hybrid and electric powertrain systems. These advancements have led to the development of throttle bodies that can seamlessly transition between different power sources, optimizing energy usage and reducing environmental impact.

Looking ahead, the evolution of throttle bodies in agricultural vehicles is likely to continue in the direction of increased electrification and automation. Future systems may incorporate AI-driven predictive maintenance capabilities, further enhancing reliability and reducing downtime for farmers. Additionally, as alternative fuels gain traction in the agricultural sector, throttle body designs are expected to adapt to accommodate these new energy sources, ensuring optimal performance and efficiency in the next generation of farm machinery.

Market Demand Analysis

The market demand for throttle body applications in agricultural vehicles has been steadily increasing in recent years, driven by the growing need for precision farming and improved fuel efficiency. Agricultural machinery manufacturers are increasingly incorporating advanced throttle body systems into their vehicles to meet the evolving requirements of modern farming practices.

The global agricultural machinery market, which includes tractors, harvesters, and other farm equipment, is projected to reach a substantial value in the coming years. This growth is largely attributed to the increasing mechanization of farming operations worldwide, particularly in developing countries. As a result, the demand for throttle bodies specifically designed for agricultural vehicles is expected to rise proportionally.

One of the key factors driving market demand is the push for enhanced fuel efficiency in agricultural vehicles. Farmers and agricultural businesses are constantly seeking ways to reduce operational costs, and fuel consumption represents a significant expense. Advanced throttle body systems offer precise control over engine performance, leading to optimized fuel usage and reduced emissions. This aligns well with the growing emphasis on sustainable farming practices and environmental regulations.

Another crucial aspect influencing market demand is the trend towards precision agriculture. Modern farming techniques rely heavily on data-driven decision-making and precise control of machinery. Throttle bodies play a vital role in this context by enabling fine-tuned engine performance, which is essential for tasks such as variable-rate application of fertilizers and pesticides. The ability to maintain consistent speed and power output across varying terrain and load conditions is highly valued in precision farming applications.

The increasing adoption of autonomous and semi-autonomous agricultural vehicles is also contributing to the demand for sophisticated throttle body systems. These advanced vehicles require precise control over engine performance to navigate fields efficiently and perform tasks with minimal human intervention. Throttle bodies that can integrate seamlessly with electronic control units and other autonomous systems are becoming increasingly sought after in the market.

Geographically, the demand for throttle body applications in agricultural vehicles varies across regions. Developed markets such as North America and Europe show a strong interest in high-end, technologically advanced throttle body systems that offer superior performance and integration with smart farming technologies. In contrast, emerging markets in Asia and Africa are experiencing rapid growth in basic and mid-range throttle body applications as mechanization efforts intensify.

The aftermarket segment for throttle bodies in agricultural vehicles is also showing promising growth. As existing machinery ages, there is an increasing need for replacement parts and upgrades. This presents opportunities for throttle body manufacturers to offer retrofit solutions that can improve the performance and efficiency of older agricultural vehicles.

The global agricultural machinery market, which includes tractors, harvesters, and other farm equipment, is projected to reach a substantial value in the coming years. This growth is largely attributed to the increasing mechanization of farming operations worldwide, particularly in developing countries. As a result, the demand for throttle bodies specifically designed for agricultural vehicles is expected to rise proportionally.

One of the key factors driving market demand is the push for enhanced fuel efficiency in agricultural vehicles. Farmers and agricultural businesses are constantly seeking ways to reduce operational costs, and fuel consumption represents a significant expense. Advanced throttle body systems offer precise control over engine performance, leading to optimized fuel usage and reduced emissions. This aligns well with the growing emphasis on sustainable farming practices and environmental regulations.

Another crucial aspect influencing market demand is the trend towards precision agriculture. Modern farming techniques rely heavily on data-driven decision-making and precise control of machinery. Throttle bodies play a vital role in this context by enabling fine-tuned engine performance, which is essential for tasks such as variable-rate application of fertilizers and pesticides. The ability to maintain consistent speed and power output across varying terrain and load conditions is highly valued in precision farming applications.

The increasing adoption of autonomous and semi-autonomous agricultural vehicles is also contributing to the demand for sophisticated throttle body systems. These advanced vehicles require precise control over engine performance to navigate fields efficiently and perform tasks with minimal human intervention. Throttle bodies that can integrate seamlessly with electronic control units and other autonomous systems are becoming increasingly sought after in the market.

Geographically, the demand for throttle body applications in agricultural vehicles varies across regions. Developed markets such as North America and Europe show a strong interest in high-end, technologically advanced throttle body systems that offer superior performance and integration with smart farming technologies. In contrast, emerging markets in Asia and Africa are experiencing rapid growth in basic and mid-range throttle body applications as mechanization efforts intensify.

The aftermarket segment for throttle bodies in agricultural vehicles is also showing promising growth. As existing machinery ages, there is an increasing need for replacement parts and upgrades. This presents opportunities for throttle body manufacturers to offer retrofit solutions that can improve the performance and efficiency of older agricultural vehicles.

Technical Challenges

The application of throttle bodies in agricultural vehicles presents several technical challenges that require innovative solutions. One of the primary issues is the harsh operating environment these vehicles encounter. Agricultural machinery often operates in dusty, humid, and extreme temperature conditions, which can significantly impact the performance and longevity of throttle body components.

Durability and reliability are crucial factors in this context. The throttle body must withstand prolonged exposure to dirt, debris, and moisture without compromising its functionality. This necessitates the development of robust sealing mechanisms and corrosion-resistant materials to protect sensitive electronic components and moving parts.

Another significant challenge is the need for precise control over engine performance across a wide range of operating conditions. Agricultural vehicles often require varying power outputs depending on the task at hand, from low-speed, high-torque operations to high-speed transport. The throttle body must be capable of delivering accurate and responsive throttle control to meet these diverse demands.

Fuel efficiency and emissions control pose additional technical hurdles. With increasing environmental regulations and the push for more sustainable farming practices, throttle bodies in agricultural vehicles must contribute to improved fuel economy and reduced emissions. This requires advanced electronic control systems and optimized airflow management to ensure efficient combustion across different engine loads and speeds.

The integration of throttle bodies with modern engine management systems presents another layer of complexity. Agricultural vehicles are increasingly equipped with sophisticated electronic control units (ECUs) that manage various aspects of engine performance. Ensuring seamless communication and coordination between the throttle body and these systems is essential for optimal vehicle operation.

Maintenance and serviceability are also critical considerations. Given the remote locations where agricultural vehicles often operate, throttle bodies must be designed for easy maintenance and troubleshooting. This includes developing diagnostic systems that can quickly identify issues and facilitate rapid repairs to minimize downtime during critical farming operations.

Furthermore, the diverse range of agricultural vehicles, from compact tractors to large harvesters, necessitates a flexible approach to throttle body design. Manufacturers must develop scalable solutions that can be adapted to different engine sizes and configurations while maintaining consistent performance and reliability across various applications.

Lastly, the cost-effectiveness of throttle body solutions remains a significant challenge. Agricultural equipment manufacturers must balance the implementation of advanced technologies with the need to keep vehicle prices competitive. This requires innovative engineering approaches to optimize performance while minimizing production costs.

Durability and reliability are crucial factors in this context. The throttle body must withstand prolonged exposure to dirt, debris, and moisture without compromising its functionality. This necessitates the development of robust sealing mechanisms and corrosion-resistant materials to protect sensitive electronic components and moving parts.

Another significant challenge is the need for precise control over engine performance across a wide range of operating conditions. Agricultural vehicles often require varying power outputs depending on the task at hand, from low-speed, high-torque operations to high-speed transport. The throttle body must be capable of delivering accurate and responsive throttle control to meet these diverse demands.

Fuel efficiency and emissions control pose additional technical hurdles. With increasing environmental regulations and the push for more sustainable farming practices, throttle bodies in agricultural vehicles must contribute to improved fuel economy and reduced emissions. This requires advanced electronic control systems and optimized airflow management to ensure efficient combustion across different engine loads and speeds.

The integration of throttle bodies with modern engine management systems presents another layer of complexity. Agricultural vehicles are increasingly equipped with sophisticated electronic control units (ECUs) that manage various aspects of engine performance. Ensuring seamless communication and coordination between the throttle body and these systems is essential for optimal vehicle operation.

Maintenance and serviceability are also critical considerations. Given the remote locations where agricultural vehicles often operate, throttle bodies must be designed for easy maintenance and troubleshooting. This includes developing diagnostic systems that can quickly identify issues and facilitate rapid repairs to minimize downtime during critical farming operations.

Furthermore, the diverse range of agricultural vehicles, from compact tractors to large harvesters, necessitates a flexible approach to throttle body design. Manufacturers must develop scalable solutions that can be adapted to different engine sizes and configurations while maintaining consistent performance and reliability across various applications.

Lastly, the cost-effectiveness of throttle body solutions remains a significant challenge. Agricultural equipment manufacturers must balance the implementation of advanced technologies with the need to keep vehicle prices competitive. This requires innovative engineering approaches to optimize performance while minimizing production costs.

Current Throttle Solutions

01 Throttle body design and construction

Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Innovations in throttle body design focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.- Throttle body design and construction: Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Various designs focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.

- Electronic throttle control systems: Modern throttle bodies often incorporate electronic control systems, replacing traditional mechanical linkages. These systems use sensors and actuators to precisely control throttle position based on various engine parameters and driver input, improving fuel efficiency and responsiveness.

- Idle air control mechanisms: Throttle bodies may include idle air control mechanisms to regulate engine speed during idle conditions. These systems can bypass the main throttle plate to provide a controlled amount of air, maintaining stable idle speed and smooth engine operation.

- Throttle body cleaning and maintenance: Throttle bodies can accumulate carbon deposits and other contaminants over time, affecting performance. Various cleaning methods and maintenance procedures are developed to ensure optimal throttle body function, including specialized cleaning solutions and tools for removing buildup without damaging sensitive components.

- Integration with fuel injection systems: Throttle bodies are often integrated with fuel injection systems to optimize air-fuel mixture. This integration can involve positioning fuel injectors near the throttle body, incorporating fuel rails, or designing throttle bodies that work in conjunction with direct injection systems for improved atomization and combustion efficiency.

02 Electronic throttle control systems

Modern throttle bodies often incorporate electronic control systems, replacing traditional mechanical linkages. These systems use sensors and actuators to precisely control throttle position based on various engine parameters and driver input. This allows for improved fuel efficiency, smoother acceleration, and better integration with other engine management systems.Expand Specific Solutions03 Idle air control mechanisms

Throttle bodies may include integrated idle air control mechanisms to regulate engine idle speed. These systems bypass the main throttle plate to provide a controlled amount of air during idle conditions. Innovations in this area focus on improving idle stability, reducing emissions, and enhancing cold-start performance.Expand Specific Solutions04 Multi-valve throttle bodies

Some throttle body designs incorporate multiple valves or plates to provide more precise control over airflow across different engine operating conditions. These multi-valve configurations can offer improved throttle response, better low-end torque, and enhanced overall engine performance compared to traditional single-valve designs.Expand Specific Solutions05 Throttle body cleaning and maintenance

Throttle bodies can accumulate carbon deposits and other contaminants over time, affecting their performance. Innovations in this area include self-cleaning mechanisms, coatings to reduce deposit buildup, and improved designs that facilitate easier maintenance and cleaning procedures to ensure optimal throttle body operation throughout the engine's lifespan.Expand Specific Solutions

Key Industry Players

The throttle body applications in agricultural vehicles market is in a growth phase, driven by increasing mechanization in agriculture and demand for more efficient farming equipment. The market size is expanding, with projections indicating significant growth over the next decade. Technologically, throttle bodies for agricultural vehicles are evolving, with companies like AGCO Corp., Mahindra & Mahindra Ltd., and Deere & Co. leading innovations. These industry giants are investing in research and development to improve fuel efficiency, engine performance, and emissions control in agricultural machinery. Emerging players like LS Mtron Ltd. and TYM CORP. are also contributing to market competitiveness by introducing advanced throttle body technologies tailored for specific agricultural applications.

Mahindra & Mahindra Ltd.

Technical Solution: Mahindra & Mahindra Ltd. has focused on developing cost-effective throttle body solutions for agricultural vehicles in emerging markets. Their system utilizes a simplified electronic control unit that balances performance with affordability[10]. Mahindra's throttle bodies incorporate locally sourced components where possible, reducing costs and improving serviceability in rural areas[11]. The company has implemented a dual-mode throttle control that allows for both electronic and mechanical operation, providing redundancy and ease of maintenance in regions with limited access to advanced electronic diagnostics[12].

Strengths: Cost-effectiveness, serviceability in rural areas, dual-mode operation. Weaknesses: May lack some advanced features of premium systems, potential for reduced precision compared to more sophisticated designs.

Mikuni Corp.

Technical Solution: Mikuni Corp. has leveraged its expertise in small engine components to develop specialized throttle body solutions for compact agricultural vehicles and equipment. Their throttle bodies feature a compact design with integrated fuel injection systems, optimizing space utilization in smaller engine compartments[13]. Mikuni has developed a proprietary coating technology for throttle body components that enhances wear resistance and reduces friction, extending service life in demanding agricultural applications[14]. The company's throttle control systems incorporate adaptive idle speed control algorithms that maintain stable engine operation across varying loads and environmental conditions[15].

Strengths: Compact design with integrated fuel injection, proprietary wear-resistant coatings, adaptive idle speed control. Weaknesses: May be limited to smaller agricultural vehicles and equipment, potential for higher cost due to specialized components.

Innovative Throttle Designs

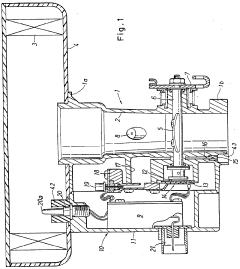

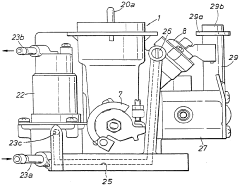

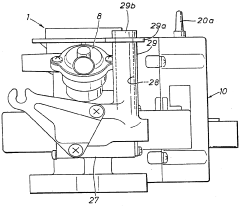

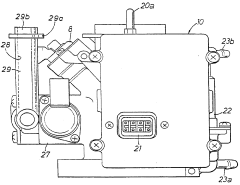

Throttle body assembly

PatentInactiveUS5094212A

Innovation

- A throttle body assembly with integrated components such as a fuel pump, fuel pressure control valve, by-pass air passage, and sensors directly mounted on the throttle body, eliminating the need for external tubing and simplifying the structure by incorporating a by-pass air control solenoid valve to prevent valve sticking in cold conditions and utilizing returned fuel for motor cooling.

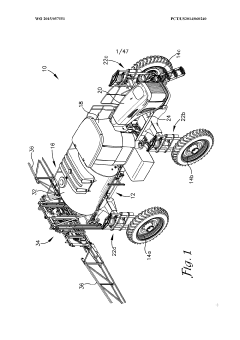

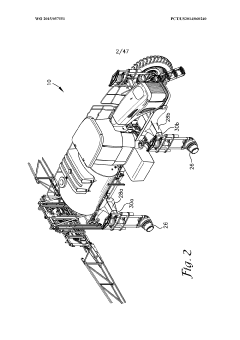

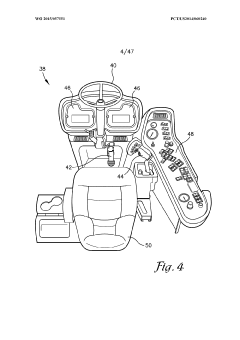

Vehicule suspension with height adjustment

PatentWO2015057551A1

Innovation

- A suspension system with a frame pivotably connected to the vehicle chassis, a wheel attachment component that pivots and adjusts in unison, and an adjustment actuator to regulate motion transfer, allowing for height adjustment and improved ground clearance without adding or removing vehicle equipment.

Emissions Regulations

Emissions regulations for agricultural vehicles have become increasingly stringent in recent years, driven by global efforts to reduce air pollution and combat climate change. These regulations directly impact the design and implementation of throttle bodies in agricultural vehicles, necessitating innovative solutions to meet compliance standards while maintaining vehicle performance and efficiency.

The United States Environmental Protection Agency (EPA) and the European Union's Euro emissions standards are at the forefront of setting emissions limits for non-road mobile machinery, including agricultural vehicles. These regulations typically focus on reducing emissions of particulate matter (PM), nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). As a result, manufacturers must adapt their throttle body designs to optimize fuel delivery and combustion processes.

One key aspect of emissions compliance for agricultural vehicles is the implementation of advanced electronic throttle control systems. These systems allow for more precise fuel metering and air-fuel ratio management, which is crucial for reducing emissions while maintaining engine performance. Electronic throttle bodies can respond more quickly to changing operating conditions, enabling better control over combustion processes and emissions output.

Exhaust gas recirculation (EGR) systems have also become a common feature in agricultural vehicles to meet emissions standards. EGR works in conjunction with the throttle body to reduce NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber. This process lowers combustion temperatures, thereby reducing NOx formation. Throttle bodies must be designed to accommodate the additional complexity introduced by EGR systems, including potential impacts on airflow and engine responsiveness.

Another significant development in emissions control for agricultural vehicles is the integration of selective catalytic reduction (SCR) technology. SCR systems use a urea-based solution (commonly known as diesel exhaust fluid or DEF) to convert NOx emissions into harmless nitrogen and water. While SCR primarily affects the exhaust system, it also influences throttle body design and operation, as the engine management system must coordinate fuel delivery and SCR operation to optimize emissions reduction.

The push for cleaner emissions has also led to the development of variable geometry turbochargers (VGTs) in agricultural vehicles. VGTs work in tandem with throttle bodies to improve engine efficiency and reduce emissions across a wide range of operating conditions. This technology allows for better control of exhaust gas flow, which in turn affects the throttle body's role in managing airflow into the engine.

As emissions regulations continue to evolve, manufacturers are exploring advanced materials and coatings for throttle bodies to improve durability and reduce friction, thereby enhancing overall engine efficiency and emissions performance. Additionally, the integration of sensors and actuators within the throttle body assembly is becoming more sophisticated, allowing for real-time adjustments to meet emissions targets under varying load conditions typical in agricultural applications.

The United States Environmental Protection Agency (EPA) and the European Union's Euro emissions standards are at the forefront of setting emissions limits for non-road mobile machinery, including agricultural vehicles. These regulations typically focus on reducing emissions of particulate matter (PM), nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC). As a result, manufacturers must adapt their throttle body designs to optimize fuel delivery and combustion processes.

One key aspect of emissions compliance for agricultural vehicles is the implementation of advanced electronic throttle control systems. These systems allow for more precise fuel metering and air-fuel ratio management, which is crucial for reducing emissions while maintaining engine performance. Electronic throttle bodies can respond more quickly to changing operating conditions, enabling better control over combustion processes and emissions output.

Exhaust gas recirculation (EGR) systems have also become a common feature in agricultural vehicles to meet emissions standards. EGR works in conjunction with the throttle body to reduce NOx emissions by recirculating a portion of the exhaust gases back into the combustion chamber. This process lowers combustion temperatures, thereby reducing NOx formation. Throttle bodies must be designed to accommodate the additional complexity introduced by EGR systems, including potential impacts on airflow and engine responsiveness.

Another significant development in emissions control for agricultural vehicles is the integration of selective catalytic reduction (SCR) technology. SCR systems use a urea-based solution (commonly known as diesel exhaust fluid or DEF) to convert NOx emissions into harmless nitrogen and water. While SCR primarily affects the exhaust system, it also influences throttle body design and operation, as the engine management system must coordinate fuel delivery and SCR operation to optimize emissions reduction.

The push for cleaner emissions has also led to the development of variable geometry turbochargers (VGTs) in agricultural vehicles. VGTs work in tandem with throttle bodies to improve engine efficiency and reduce emissions across a wide range of operating conditions. This technology allows for better control of exhaust gas flow, which in turn affects the throttle body's role in managing airflow into the engine.

As emissions regulations continue to evolve, manufacturers are exploring advanced materials and coatings for throttle bodies to improve durability and reduce friction, thereby enhancing overall engine efficiency and emissions performance. Additionally, the integration of sensors and actuators within the throttle body assembly is becoming more sophisticated, allowing for real-time adjustments to meet emissions targets under varying load conditions typical in agricultural applications.

Fuel Efficiency Impact

The implementation of throttle body technology in agricultural vehicles has a significant impact on fuel efficiency, contributing to both economic and environmental benefits. This impact is multifaceted, affecting various aspects of vehicle performance and operational costs.

Throttle bodies in agricultural vehicles play a crucial role in regulating air intake to the engine, directly influencing the air-fuel mixture. By precisely controlling this mixture, throttle bodies can optimize combustion efficiency, leading to improved fuel economy. In typical applications, the integration of advanced throttle body systems has shown potential fuel savings of 5-15% compared to traditional mechanical systems.

The fuel efficiency gains are particularly notable during variable load conditions, which are common in agricultural operations. As tractors and other farm equipment frequently transition between high and low power demands, throttle bodies can rapidly adjust air intake to match these changing requirements. This dynamic response ensures that the engine operates at optimal efficiency across a wide range of working conditions, minimizing fuel waste during low-load periods and maximizing power delivery when needed.

Moreover, the integration of electronic throttle control (ETC) systems in agricultural vehicles further enhances fuel efficiency. ETC allows for more precise and responsive throttle management, eliminating the lag associated with mechanical linkages. This improved responsiveness not only contributes to fuel savings but also enhances overall vehicle performance, allowing for smoother operation and reduced operator fatigue.

The fuel efficiency impact of throttle body applications extends beyond direct consumption reduction. By optimizing engine performance, these systems can also reduce wear and tear on engine components, potentially extending engine life and reducing maintenance costs. This indirect benefit contributes to the overall economic efficiency of agricultural operations.

Environmental considerations are also significant when assessing the fuel efficiency impact of throttle body applications. Reduced fuel consumption directly correlates with lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations in the agricultural sector. Some studies suggest that advanced throttle body systems can contribute to a 10-20% reduction in carbon dioxide emissions from agricultural vehicles.

Furthermore, the improved fuel efficiency facilitated by throttle body technology enables agricultural vehicles to operate for longer periods between refueling. This increased operational range is particularly valuable in large-scale farming operations, where minimizing downtime for refueling can significantly enhance productivity.

As agricultural vehicle manufacturers continue to innovate, the integration of throttle body technology with other advanced systems, such as GPS-guided autonomous operation and precision farming techniques, promises to further amplify fuel efficiency gains. These synergies represent a key area for ongoing research and development in the pursuit of more sustainable and economically viable agricultural practices.

Throttle bodies in agricultural vehicles play a crucial role in regulating air intake to the engine, directly influencing the air-fuel mixture. By precisely controlling this mixture, throttle bodies can optimize combustion efficiency, leading to improved fuel economy. In typical applications, the integration of advanced throttle body systems has shown potential fuel savings of 5-15% compared to traditional mechanical systems.

The fuel efficiency gains are particularly notable during variable load conditions, which are common in agricultural operations. As tractors and other farm equipment frequently transition between high and low power demands, throttle bodies can rapidly adjust air intake to match these changing requirements. This dynamic response ensures that the engine operates at optimal efficiency across a wide range of working conditions, minimizing fuel waste during low-load periods and maximizing power delivery when needed.

Moreover, the integration of electronic throttle control (ETC) systems in agricultural vehicles further enhances fuel efficiency. ETC allows for more precise and responsive throttle management, eliminating the lag associated with mechanical linkages. This improved responsiveness not only contributes to fuel savings but also enhances overall vehicle performance, allowing for smoother operation and reduced operator fatigue.

The fuel efficiency impact of throttle body applications extends beyond direct consumption reduction. By optimizing engine performance, these systems can also reduce wear and tear on engine components, potentially extending engine life and reducing maintenance costs. This indirect benefit contributes to the overall economic efficiency of agricultural operations.

Environmental considerations are also significant when assessing the fuel efficiency impact of throttle body applications. Reduced fuel consumption directly correlates with lower greenhouse gas emissions, aligning with increasingly stringent environmental regulations in the agricultural sector. Some studies suggest that advanced throttle body systems can contribute to a 10-20% reduction in carbon dioxide emissions from agricultural vehicles.

Furthermore, the improved fuel efficiency facilitated by throttle body technology enables agricultural vehicles to operate for longer periods between refueling. This increased operational range is particularly valuable in large-scale farming operations, where minimizing downtime for refueling can significantly enhance productivity.

As agricultural vehicle manufacturers continue to innovate, the integration of throttle body technology with other advanced systems, such as GPS-guided autonomous operation and precision farming techniques, promises to further amplify fuel efficiency gains. These synergies represent a key area for ongoing research and development in the pursuit of more sustainable and economically viable agricultural practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!