How Throttle Body Technology Supports Sustainable Transportation

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution

The throttle body has undergone significant evolution since its inception, playing a crucial role in the advancement of sustainable transportation. Initially designed as a simple mechanical device to control air intake in internal combustion engines, the throttle body has transformed into a sophisticated electronic component that optimizes fuel efficiency and reduces emissions.

In the early days of automotive engineering, throttle bodies were purely mechanical, utilizing a butterfly valve controlled by a cable connected to the accelerator pedal. This basic design, while functional, lacked precision and responsiveness, leading to inefficient fuel consumption and higher emissions. As environmental concerns grew and fuel economy became a priority, engineers began to explore ways to improve throttle body technology.

The introduction of electronic throttle control (ETC) in the 1980s marked a significant milestone in throttle body evolution. ETC replaced the mechanical linkage with sensors and actuators, allowing for more precise control of the throttle opening. This innovation enabled better integration with engine management systems, resulting in improved fuel efficiency and reduced emissions. The electronic throttle body also facilitated the implementation of advanced features such as cruise control and traction control systems.

Further advancements in throttle body technology focused on materials and design optimization. Lightweight materials like aluminum and composite plastics replaced heavier metals, contributing to overall vehicle weight reduction and improved fuel economy. Engineers also refined the aerodynamics of the throttle body interior, minimizing turbulence and maximizing airflow efficiency.

The integration of intelligent sensors and adaptive algorithms in modern throttle bodies has led to real-time adjustment capabilities. These systems can now respond to various factors such as engine temperature, altitude, and driving conditions, continuously optimizing air-fuel mixture for maximum efficiency and minimal emissions. This level of adaptability is particularly crucial for hybrid and electric vehicles, where precise energy management is essential for extending range and reducing environmental impact.

Recent developments in throttle body technology have focused on enhancing compatibility with alternative fuels and advanced powertrain systems. Manufacturers are designing throttle bodies that can seamlessly operate with biofuels, hydrogen, and other sustainable energy sources. Additionally, the integration of throttle bodies with regenerative braking systems in electric and hybrid vehicles has further improved energy recovery and overall vehicle efficiency.

As the automotive industry continues to prioritize sustainability, throttle body technology is evolving to meet the demands of next-generation powertrains. Research is ongoing into throttle-less engine designs and variable geometry intake systems, which promise even greater efficiency gains and emissions reductions. These innovations, coupled with advancements in materials science and electronic control systems, are paving the way for throttle bodies that will play an increasingly vital role in supporting sustainable transportation solutions.

In the early days of automotive engineering, throttle bodies were purely mechanical, utilizing a butterfly valve controlled by a cable connected to the accelerator pedal. This basic design, while functional, lacked precision and responsiveness, leading to inefficient fuel consumption and higher emissions. As environmental concerns grew and fuel economy became a priority, engineers began to explore ways to improve throttle body technology.

The introduction of electronic throttle control (ETC) in the 1980s marked a significant milestone in throttle body evolution. ETC replaced the mechanical linkage with sensors and actuators, allowing for more precise control of the throttle opening. This innovation enabled better integration with engine management systems, resulting in improved fuel efficiency and reduced emissions. The electronic throttle body also facilitated the implementation of advanced features such as cruise control and traction control systems.

Further advancements in throttle body technology focused on materials and design optimization. Lightweight materials like aluminum and composite plastics replaced heavier metals, contributing to overall vehicle weight reduction and improved fuel economy. Engineers also refined the aerodynamics of the throttle body interior, minimizing turbulence and maximizing airflow efficiency.

The integration of intelligent sensors and adaptive algorithms in modern throttle bodies has led to real-time adjustment capabilities. These systems can now respond to various factors such as engine temperature, altitude, and driving conditions, continuously optimizing air-fuel mixture for maximum efficiency and minimal emissions. This level of adaptability is particularly crucial for hybrid and electric vehicles, where precise energy management is essential for extending range and reducing environmental impact.

Recent developments in throttle body technology have focused on enhancing compatibility with alternative fuels and advanced powertrain systems. Manufacturers are designing throttle bodies that can seamlessly operate with biofuels, hydrogen, and other sustainable energy sources. Additionally, the integration of throttle bodies with regenerative braking systems in electric and hybrid vehicles has further improved energy recovery and overall vehicle efficiency.

As the automotive industry continues to prioritize sustainability, throttle body technology is evolving to meet the demands of next-generation powertrains. Research is ongoing into throttle-less engine designs and variable geometry intake systems, which promise even greater efficiency gains and emissions reductions. These innovations, coupled with advancements in materials science and electronic control systems, are paving the way for throttle bodies that will play an increasingly vital role in supporting sustainable transportation solutions.

Sustainable Transport Market

The sustainable transport market has witnessed significant growth in recent years, driven by increasing environmental concerns and the global push towards reducing carbon emissions. This market encompasses various modes of transportation, including electric vehicles, hybrid vehicles, public transit systems, and alternative fuel vehicles. The throttle body technology plays a crucial role in supporting this market by enhancing fuel efficiency and reducing emissions in internal combustion engines.

Market demand for sustainable transportation solutions has been steadily rising, with governments worldwide implementing stricter emissions regulations and offering incentives for eco-friendly vehicles. This has led to a surge in consumer interest and adoption of more sustainable transport options. The global electric vehicle market, for instance, has experienced exponential growth, with sales increasing by over 40% annually in recent years.

The throttle body technology contributes to sustainable transportation by optimizing engine performance and fuel consumption. By precisely controlling the air intake into the engine, modern electronic throttle bodies can significantly improve fuel efficiency and reduce emissions. This technology aligns with the market's demand for more environmentally friendly vehicles without compromising performance.

In the context of hybrid vehicles, which represent a growing segment of the sustainable transport market, throttle body technology plays a vital role in seamlessly transitioning between electric and combustion power sources. This integration enhances overall vehicle efficiency and extends the range of hybrid vehicles, making them more attractive to consumers seeking sustainable transportation options.

The public transit sector has also embraced sustainable solutions, with many cities investing in electric and hybrid buses. Throttle body technology in these vehicles helps optimize fuel consumption during acceleration and deceleration, contributing to reduced operating costs and lower emissions in urban environments.

The market for alternative fuel vehicles, such as those powered by natural gas or hydrogen, is expanding as well. In these applications, advanced throttle body systems are essential for precise fuel metering and efficient combustion, supporting the broader adoption of these sustainable transport alternatives.

As the sustainable transport market continues to evolve, the demand for more advanced throttle body technologies is expected to grow. Manufacturers are investing in research and development to create more sophisticated electronic throttle control systems that can further improve fuel efficiency and reduce emissions. This ongoing innovation in throttle body technology is likely to play a significant role in supporting the sustainable transport market's expansion and meeting increasingly stringent environmental regulations.

Market demand for sustainable transportation solutions has been steadily rising, with governments worldwide implementing stricter emissions regulations and offering incentives for eco-friendly vehicles. This has led to a surge in consumer interest and adoption of more sustainable transport options. The global electric vehicle market, for instance, has experienced exponential growth, with sales increasing by over 40% annually in recent years.

The throttle body technology contributes to sustainable transportation by optimizing engine performance and fuel consumption. By precisely controlling the air intake into the engine, modern electronic throttle bodies can significantly improve fuel efficiency and reduce emissions. This technology aligns with the market's demand for more environmentally friendly vehicles without compromising performance.

In the context of hybrid vehicles, which represent a growing segment of the sustainable transport market, throttle body technology plays a vital role in seamlessly transitioning between electric and combustion power sources. This integration enhances overall vehicle efficiency and extends the range of hybrid vehicles, making them more attractive to consumers seeking sustainable transportation options.

The public transit sector has also embraced sustainable solutions, with many cities investing in electric and hybrid buses. Throttle body technology in these vehicles helps optimize fuel consumption during acceleration and deceleration, contributing to reduced operating costs and lower emissions in urban environments.

The market for alternative fuel vehicles, such as those powered by natural gas or hydrogen, is expanding as well. In these applications, advanced throttle body systems are essential for precise fuel metering and efficient combustion, supporting the broader adoption of these sustainable transport alternatives.

As the sustainable transport market continues to evolve, the demand for more advanced throttle body technologies is expected to grow. Manufacturers are investing in research and development to create more sophisticated electronic throttle control systems that can further improve fuel efficiency and reduce emissions. This ongoing innovation in throttle body technology is likely to play a significant role in supporting the sustainable transport market's expansion and meeting increasingly stringent environmental regulations.

Throttle Tech Challenges

The throttle body, a critical component in internal combustion engines, faces several challenges in supporting sustainable transportation. One of the primary issues is achieving optimal fuel efficiency while maintaining performance. As environmental regulations become more stringent, throttle bodies must adapt to meet lower emissions standards without compromising engine power output.

Another significant challenge lies in the integration of electronic control systems. Modern throttle bodies are increasingly relying on electronic throttle control (ETC) systems, which replace mechanical linkages with sensors and actuators. While ETC offers improved precision and responsiveness, it also introduces complexity and potential reliability concerns. Ensuring the robustness and longevity of these electronic components in harsh automotive environments remains a persistent challenge.

Material selection presents another hurdle for throttle body technology. The need for lightweight yet durable materials that can withstand high temperatures and resist corrosion is crucial. Manufacturers must balance cost-effectiveness with performance, often exploring advanced alloys or composite materials to meet these requirements.

The advent of alternative fuel vehicles, particularly those using hydrogen or biofuels, poses additional challenges for throttle body design. These fuels may require different flow characteristics and materials compatibility, necessitating significant redesigns of traditional throttle body systems.

Miniaturization and packaging constraints also present ongoing difficulties. As engine compartments become more crowded with additional components for emissions control and performance enhancement, throttle bodies must become more compact without sacrificing functionality or ease of maintenance.

Furthermore, the throttle body's role in engine start-stop systems, which are increasingly common in hybrid and eco-friendly vehicles, presents unique challenges. These systems require throttle bodies to operate reliably under frequent cycling, potentially leading to increased wear and the need for more robust designs.

Lastly, the push towards connected and autonomous vehicles introduces new demands on throttle body technology. Integration with advanced driver assistance systems (ADAS) and vehicle-to-everything (V2X) communication platforms requires throttle bodies to interface seamlessly with a broader array of vehicle systems, adding layers of complexity to their design and operation.

Another significant challenge lies in the integration of electronic control systems. Modern throttle bodies are increasingly relying on electronic throttle control (ETC) systems, which replace mechanical linkages with sensors and actuators. While ETC offers improved precision and responsiveness, it also introduces complexity and potential reliability concerns. Ensuring the robustness and longevity of these electronic components in harsh automotive environments remains a persistent challenge.

Material selection presents another hurdle for throttle body technology. The need for lightweight yet durable materials that can withstand high temperatures and resist corrosion is crucial. Manufacturers must balance cost-effectiveness with performance, often exploring advanced alloys or composite materials to meet these requirements.

The advent of alternative fuel vehicles, particularly those using hydrogen or biofuels, poses additional challenges for throttle body design. These fuels may require different flow characteristics and materials compatibility, necessitating significant redesigns of traditional throttle body systems.

Miniaturization and packaging constraints also present ongoing difficulties. As engine compartments become more crowded with additional components for emissions control and performance enhancement, throttle bodies must become more compact without sacrificing functionality or ease of maintenance.

Furthermore, the throttle body's role in engine start-stop systems, which are increasingly common in hybrid and eco-friendly vehicles, presents unique challenges. These systems require throttle bodies to operate reliably under frequent cycling, potentially leading to increased wear and the need for more robust designs.

Lastly, the push towards connected and autonomous vehicles introduces new demands on throttle body technology. Integration with advanced driver assistance systems (ADAS) and vehicle-to-everything (V2X) communication platforms requires throttle bodies to interface seamlessly with a broader array of vehicle systems, adding layers of complexity to their design and operation.

Current Throttle Solutions

01 Sustainable materials for throttle body manufacturing

Utilizing eco-friendly and recyclable materials in the production of throttle bodies to reduce environmental impact. This includes the use of lightweight alloys, biodegradable plastics, and recycled metals to improve sustainability while maintaining performance and durability.- Sustainable materials for throttle body manufacturing: Utilizing eco-friendly and recyclable materials in the production of throttle bodies to reduce environmental impact. This includes the use of biodegradable plastics, recycled metals, and composite materials that offer durability while minimizing the carbon footprint of the manufacturing process.

- Energy-efficient throttle body designs: Developing throttle body designs that optimize fuel efficiency and reduce emissions. This involves creating aerodynamic shapes, implementing advanced flow control mechanisms, and integrating smart sensors to enhance overall engine performance while minimizing environmental impact.

- Sustainable manufacturing processes for throttle bodies: Implementing sustainable manufacturing processes for throttle bodies, including lean production techniques, waste reduction strategies, and the use of renewable energy sources in production facilities. This approach aims to minimize resource consumption and environmental impact throughout the manufacturing lifecycle.

- Throttle body recycling and end-of-life management: Developing strategies for the efficient recycling and proper disposal of throttle bodies at the end of their lifecycle. This includes designing for disassembly, implementing take-back programs, and exploring innovative recycling technologies to recover and reuse materials from old throttle bodies.

- Smart throttle bodies for improved sustainability: Integrating smart technologies into throttle bodies to enhance their sustainability performance. This includes incorporating IoT sensors, AI-driven control systems, and predictive maintenance capabilities to optimize fuel consumption, reduce emissions, and extend the lifespan of the throttle body and related engine components.

02 Energy-efficient throttle body designs

Developing throttle body designs that optimize airflow and reduce energy losses, leading to improved fuel efficiency and reduced emissions. This includes advanced aerodynamic shapes, precision-engineered components, and innovative sealing technologies.Expand Specific Solutions03 Smart throttle body systems for sustainability

Integrating intelligent control systems and sensors into throttle bodies to enhance engine performance and reduce fuel consumption. These smart systems can adapt to driving conditions, optimize air-fuel ratios, and provide real-time data for improved efficiency and reduced environmental impact.Expand Specific Solutions04 Throttle body maintenance and longevity

Developing throttle bodies with improved durability and easier maintenance to extend their lifespan and reduce waste. This includes self-cleaning mechanisms, corrosion-resistant coatings, and modular designs that allow for easy part replacement and refurbishment.Expand Specific Solutions05 Sustainable manufacturing processes for throttle bodies

Implementing eco-friendly manufacturing techniques for throttle body production, such as additive manufacturing, low-energy machining, and zero-waste production lines. These processes aim to reduce resource consumption, minimize waste, and lower the overall carbon footprint of throttle body manufacturing.Expand Specific Solutions

Key Throttle Manufacturers

The throttle body technology market for sustainable transportation is in a growth phase, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. The market size is expanding rapidly, with major automotive manufacturers and suppliers investing heavily in research and development. Companies like Honda, Toyota, and Bosch are at the forefront of innovation, developing advanced throttle body systems that improve engine performance and reduce emissions. The technology's maturity varies, with established players like Yamaha and Renault offering proven solutions, while newer entrants like Geely and Mazout Electric are pushing boundaries with electric and AI-enabled systems. Overall, the competitive landscape is dynamic, with a mix of traditional automotive giants and emerging tech-focused companies vying for market share.

Honda Motor Co., Ltd.

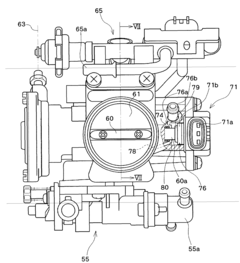

Technical Solution: Honda has innovated in throttle body technology to support sustainable transportation through their PGM-FI (Programmed Fuel Injection) system. This system incorporates an advanced electronic throttle body that works in conjunction with various sensors to optimize air-fuel mixture[1]. Honda's throttle bodies feature a throttle position sensor and idle air control valve, allowing for precise control of engine idle speed and smooth acceleration[2]. The company has also developed a multi-point injection system that works with the throttle body to improve fuel atomization, leading to more complete combustion and reduced emissions[3]. Honda's throttle body technology is designed to adapt to different driving conditions and altitudes, maintaining optimal performance while minimizing environmental impact[4].

Strengths: Adaptive technology, improved fuel efficiency, and reduced emissions. Weaknesses: System complexity may lead to higher maintenance costs over time.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced electronic throttle body systems that contribute to sustainable transportation. Their technology incorporates precise control algorithms and sensors to optimize fuel injection and air intake. This results in improved fuel efficiency and reduced emissions[1]. Bosch's throttle bodies feature a motorized valve controlled by the engine management system, allowing for real-time adjustments based on driving conditions and engine load[2]. The company has also integrated their throttle body technology with start-stop systems, further enhancing fuel economy in urban environments[3]. Additionally, Bosch has implemented materials and manufacturing processes that reduce the overall weight of the throttle body, contributing to vehicle lightweighting efforts[4].

Strengths: Precise control, integration with other systems, and contribution to overall vehicle efficiency. Weaknesses: Potentially higher initial cost compared to mechanical throttle bodies and reliance on complex electronic systems.

Throttle Body Innovations

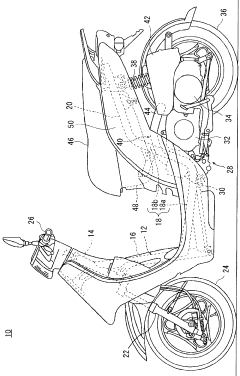

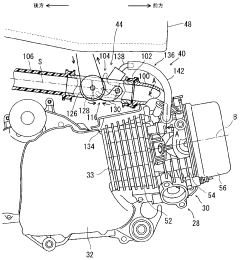

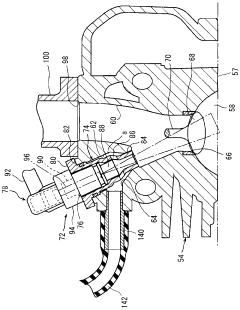

Throttle body having fuel return passage and vehicle

PatentInactiveUS7290526B2

Innovation

- A throttle body design with a fuel return passage that communicates the housing with the air intake passage, a pressure control chamber maintaining higher pressure than the air intake passage, and an air inflow passage connecting the housing with the pressure control chamber, creating a significant pressure difference to facilitate smooth fuel return and prevent water ingress.

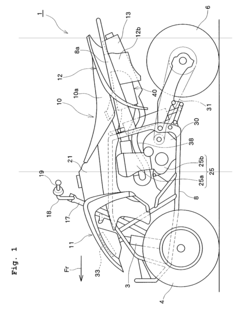

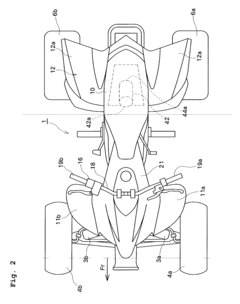

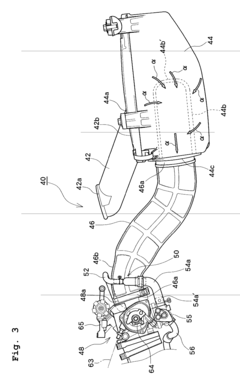

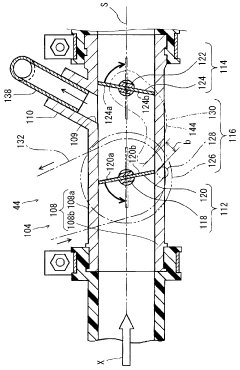

Throttle body and powered two-wheeled vehicle provided therewith

PatentWO2010113981A1

Innovation

- A throttle body design featuring butterfly-type first and second throttle valves with a tubular portion, through hole, and branch pipe to improve intake air flow between the valves, ensuring efficient air introduction into an auxiliary passage, which enhances fuel atomization and efficiency.

Emissions Regulations

Emissions regulations play a crucial role in shaping the development and implementation of throttle body technology in sustainable transportation. These regulations, established by governmental bodies and environmental agencies, set strict limits on vehicle emissions to mitigate the environmental impact of transportation.

The evolution of emissions standards has been a driving force behind advancements in throttle body technology. Early regulations focused primarily on reducing carbon monoxide and hydrocarbon emissions. As scientific understanding of air pollution improved, regulations expanded to include nitrogen oxides, particulate matter, and greenhouse gases.

In recent years, emissions regulations have become increasingly stringent, pushing manufacturers to develop more sophisticated throttle body systems. These regulations vary by region, with some of the most stringent standards found in the European Union, California, and Japan. The differences in regional standards have led to the development of adaptive throttle body technologies that can meet diverse regulatory requirements.

One of the key impacts of emissions regulations on throttle body technology has been the shift towards electronic throttle control systems. These systems offer more precise control over fuel delivery and air intake, allowing for optimized combustion and reduced emissions. The integration of sensors and advanced control algorithms enables real-time adjustments to meet emissions targets under various driving conditions.

Emissions regulations have also driven the development of throttle body technologies that support alternative fuel systems. As regulations increasingly favor low-emission and zero-emission vehicles, throttle bodies have been adapted to work efficiently with hybrid, electric, and hydrogen fuel cell powertrains. This adaptation has led to the creation of specialized throttle bodies that can manage the unique air and fuel mixture requirements of these alternative propulsion systems.

The implementation of On-Board Diagnostics (OBD) systems, mandated by emissions regulations, has further influenced throttle body design. These systems continuously monitor vehicle emissions performance, including the functioning of the throttle body. This has led to the integration of self-diagnostic capabilities within throttle body assemblies, allowing for early detection of malfunctions that could lead to increased emissions.

Looking ahead, upcoming emissions regulations are expected to continue driving innovation in throttle body technology. The focus is likely to shift towards even more precise control of air-fuel mixtures, further reductions in cold-start emissions, and improved integration with hybrid and electric propulsion systems. These advancements will play a crucial role in supporting the transition to more sustainable transportation options while meeting increasingly stringent environmental standards.

The evolution of emissions standards has been a driving force behind advancements in throttle body technology. Early regulations focused primarily on reducing carbon monoxide and hydrocarbon emissions. As scientific understanding of air pollution improved, regulations expanded to include nitrogen oxides, particulate matter, and greenhouse gases.

In recent years, emissions regulations have become increasingly stringent, pushing manufacturers to develop more sophisticated throttle body systems. These regulations vary by region, with some of the most stringent standards found in the European Union, California, and Japan. The differences in regional standards have led to the development of adaptive throttle body technologies that can meet diverse regulatory requirements.

One of the key impacts of emissions regulations on throttle body technology has been the shift towards electronic throttle control systems. These systems offer more precise control over fuel delivery and air intake, allowing for optimized combustion and reduced emissions. The integration of sensors and advanced control algorithms enables real-time adjustments to meet emissions targets under various driving conditions.

Emissions regulations have also driven the development of throttle body technologies that support alternative fuel systems. As regulations increasingly favor low-emission and zero-emission vehicles, throttle bodies have been adapted to work efficiently with hybrid, electric, and hydrogen fuel cell powertrains. This adaptation has led to the creation of specialized throttle bodies that can manage the unique air and fuel mixture requirements of these alternative propulsion systems.

The implementation of On-Board Diagnostics (OBD) systems, mandated by emissions regulations, has further influenced throttle body design. These systems continuously monitor vehicle emissions performance, including the functioning of the throttle body. This has led to the integration of self-diagnostic capabilities within throttle body assemblies, allowing for early detection of malfunctions that could lead to increased emissions.

Looking ahead, upcoming emissions regulations are expected to continue driving innovation in throttle body technology. The focus is likely to shift towards even more precise control of air-fuel mixtures, further reductions in cold-start emissions, and improved integration with hybrid and electric propulsion systems. These advancements will play a crucial role in supporting the transition to more sustainable transportation options while meeting increasingly stringent environmental standards.

Throttle Efficiency Metrics

Throttle efficiency metrics play a crucial role in evaluating the performance and sustainability of throttle body technology in modern transportation systems. These metrics provide quantitative measures to assess how effectively throttle bodies regulate airflow into the engine, impacting fuel consumption, emissions, and overall vehicle efficiency.

One key metric is throttle response time, which measures the delay between driver input and the actual change in engine power output. Faster response times contribute to improved drivability and potentially reduced fuel consumption in stop-and-go traffic conditions. Advanced throttle body designs incorporating electronic control systems have significantly reduced response times compared to traditional mechanical linkages.

Airflow accuracy is another critical metric, indicating how precisely the throttle body can control the amount of air entering the engine. Higher accuracy leads to more optimal air-fuel ratios, resulting in better combustion efficiency and reduced emissions. Modern throttle bodies utilize sophisticated sensors and algorithms to achieve airflow accuracies within 1-2% of the target value across various operating conditions.

Throttle position resolution is a metric that quantifies the granularity of throttle control. Higher resolution allows for finer adjustments in airflow, enabling smoother acceleration and more precise engine management. State-of-the-art throttle bodies can achieve resolutions of up to 0.1 degrees, allowing for exceptionally precise control over engine performance.

Energy efficiency of the throttle body itself is an often-overlooked metric that has gained importance in electric and hybrid vehicles. This metric measures the power consumption of the throttle actuator and control electronics. Lower energy consumption by the throttle system contributes to extended battery range in electric vehicles and improved overall efficiency in hybrids.

Durability and reliability metrics, such as mean time between failures (MTBF) and cycle life, are essential for assessing the long-term performance of throttle bodies. These metrics directly impact maintenance requirements and the overall lifespan of the vehicle, contributing to sustainability by reducing the need for replacement parts and associated manufacturing processes.

Emissions reduction potential is a critical metric that links throttle body performance to environmental impact. By optimizing airflow and enabling more precise engine control, advanced throttle bodies can contribute to significant reductions in harmful emissions. This metric is typically measured as a percentage improvement in emissions levels compared to baseline configurations.

One key metric is throttle response time, which measures the delay between driver input and the actual change in engine power output. Faster response times contribute to improved drivability and potentially reduced fuel consumption in stop-and-go traffic conditions. Advanced throttle body designs incorporating electronic control systems have significantly reduced response times compared to traditional mechanical linkages.

Airflow accuracy is another critical metric, indicating how precisely the throttle body can control the amount of air entering the engine. Higher accuracy leads to more optimal air-fuel ratios, resulting in better combustion efficiency and reduced emissions. Modern throttle bodies utilize sophisticated sensors and algorithms to achieve airflow accuracies within 1-2% of the target value across various operating conditions.

Throttle position resolution is a metric that quantifies the granularity of throttle control. Higher resolution allows for finer adjustments in airflow, enabling smoother acceleration and more precise engine management. State-of-the-art throttle bodies can achieve resolutions of up to 0.1 degrees, allowing for exceptionally precise control over engine performance.

Energy efficiency of the throttle body itself is an often-overlooked metric that has gained importance in electric and hybrid vehicles. This metric measures the power consumption of the throttle actuator and control electronics. Lower energy consumption by the throttle system contributes to extended battery range in electric vehicles and improved overall efficiency in hybrids.

Durability and reliability metrics, such as mean time between failures (MTBF) and cycle life, are essential for assessing the long-term performance of throttle bodies. These metrics directly impact maintenance requirements and the overall lifespan of the vehicle, contributing to sustainability by reducing the need for replacement parts and associated manufacturing processes.

Emissions reduction potential is a critical metric that links throttle body performance to environmental impact. By optimizing airflow and enabling more precise engine control, advanced throttle bodies can contribute to significant reductions in harmful emissions. This metric is typically measured as a percentage improvement in emissions levels compared to baseline configurations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!