Throttle Body Optimization for Laboratory Automation

JUL 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution

The evolution of throttle bodies in laboratory automation has been marked by significant advancements in precision, control, and integration. Initially, throttle bodies were simple mechanical devices used to regulate fluid flow in laboratory equipment. These early designs relied on manual adjustments and offered limited accuracy in flow control.

As laboratory processes became more sophisticated, the need for more precise and automated throttle bodies grew. The introduction of electronic throttle bodies in the 1990s marked a significant leap forward. These systems incorporated sensors and actuators, allowing for more accurate flow control and the ability to interface with digital control systems. This development enabled laboratories to achieve higher levels of repeatability and consistency in their experiments.

The early 2000s saw the integration of microprocessors into throttle body designs. This innovation allowed for real-time adjustments based on multiple input parameters, significantly enhancing the adaptability of laboratory equipment. Microprocessor-controlled throttle bodies could respond to changes in temperature, pressure, and other environmental factors, ensuring optimal performance across a wide range of experimental conditions.

The next phase in throttle body evolution focused on miniaturization and increased sensitivity. Advances in materials science and manufacturing techniques led to the development of micro-throttle bodies capable of precisely controlling minute fluid volumes. These devices found applications in microfluidics and lab-on-a-chip technologies, enabling new frontiers in biological and chemical research.

Recent years have witnessed the incorporation of smart technologies into throttle body design. Internet of Things (IoT) connectivity has allowed throttle bodies to be remotely monitored and controlled, facilitating more efficient laboratory management. Machine learning algorithms have been employed to optimize throttle body performance based on historical data and predictive analytics.

The latest trend in throttle body evolution is the development of adaptive systems that can self-calibrate and self-optimize. These advanced throttle bodies use artificial intelligence to learn from each experiment, continuously improving their performance over time. This capability is particularly valuable in complex, multi-variable laboratory environments where traditional calibration methods may fall short.

Looking ahead, the future of throttle bodies in laboratory automation is likely to involve even greater integration with other laboratory systems, enhanced predictive maintenance capabilities, and the use of advanced materials that offer superior durability and precision. As laboratories continue to push the boundaries of research and automation, throttle bodies will undoubtedly evolve to meet these new challenges, playing a crucial role in the advancement of scientific discovery and industrial innovation.

As laboratory processes became more sophisticated, the need for more precise and automated throttle bodies grew. The introduction of electronic throttle bodies in the 1990s marked a significant leap forward. These systems incorporated sensors and actuators, allowing for more accurate flow control and the ability to interface with digital control systems. This development enabled laboratories to achieve higher levels of repeatability and consistency in their experiments.

The early 2000s saw the integration of microprocessors into throttle body designs. This innovation allowed for real-time adjustments based on multiple input parameters, significantly enhancing the adaptability of laboratory equipment. Microprocessor-controlled throttle bodies could respond to changes in temperature, pressure, and other environmental factors, ensuring optimal performance across a wide range of experimental conditions.

The next phase in throttle body evolution focused on miniaturization and increased sensitivity. Advances in materials science and manufacturing techniques led to the development of micro-throttle bodies capable of precisely controlling minute fluid volumes. These devices found applications in microfluidics and lab-on-a-chip technologies, enabling new frontiers in biological and chemical research.

Recent years have witnessed the incorporation of smart technologies into throttle body design. Internet of Things (IoT) connectivity has allowed throttle bodies to be remotely monitored and controlled, facilitating more efficient laboratory management. Machine learning algorithms have been employed to optimize throttle body performance based on historical data and predictive analytics.

The latest trend in throttle body evolution is the development of adaptive systems that can self-calibrate and self-optimize. These advanced throttle bodies use artificial intelligence to learn from each experiment, continuously improving their performance over time. This capability is particularly valuable in complex, multi-variable laboratory environments where traditional calibration methods may fall short.

Looking ahead, the future of throttle bodies in laboratory automation is likely to involve even greater integration with other laboratory systems, enhanced predictive maintenance capabilities, and the use of advanced materials that offer superior durability and precision. As laboratories continue to push the boundaries of research and automation, throttle bodies will undoubtedly evolve to meet these new challenges, playing a crucial role in the advancement of scientific discovery and industrial innovation.

Lab Automation Demand

Laboratory automation has become increasingly crucial in modern scientific research and industrial applications. The demand for automated systems in laboratories has grown significantly over the past decade, driven by the need for increased efficiency, accuracy, and reproducibility in experimental processes. This trend is particularly evident in fields such as pharmaceutical research, biotechnology, and materials science, where high-throughput screening and precise control of experimental conditions are essential.

The market for laboratory automation solutions is expanding rapidly, with a projected compound annual growth rate (CAGR) of 8.5% from 2021 to 2026. This growth is fueled by several factors, including the rising demand for personalized medicine, the increasing adoption of robotics in laboratory processes, and the need for faster drug discovery and development cycles. Additionally, the COVID-19 pandemic has further accelerated the adoption of automated systems in diagnostic laboratories and research facilities worldwide.

One of the key drivers of lab automation demand is the need for improved productivity and cost-effectiveness. Automated systems can significantly reduce manual labor, minimize human errors, and increase sample throughput. This is particularly important in large-scale research projects and industrial applications where consistency and speed are critical. For instance, in pharmaceutical research, automated high-throughput screening systems can test thousands of compounds in a fraction of the time required for manual screening, dramatically accelerating the drug discovery process.

Another significant factor driving the demand for lab automation is the increasing complexity of scientific experiments and the need for precise control over experimental parameters. Advanced automated systems can maintain consistent conditions, monitor multiple variables simultaneously, and adjust parameters in real-time, ensuring reproducibility and reliability of results. This level of control is especially valuable in sensitive applications such as cell culture, protein crystallization, and nanomaterial synthesis.

The integration of artificial intelligence (AI) and machine learning (ML) with laboratory automation is also fueling demand. These technologies enable predictive maintenance, intelligent data analysis, and adaptive experimental design, further enhancing the capabilities of automated systems. For example, AI-powered laboratory robots can learn from previous experiments, optimize protocols, and even suggest new experimental approaches, potentially leading to novel scientific discoveries.

Furthermore, the growing emphasis on data integrity and regulatory compliance in industries such as pharmaceuticals and biotechnology is driving the adoption of automated systems. Automated data collection, storage, and analysis reduce the risk of human error and provide a clear audit trail, making it easier for organizations to meet stringent regulatory requirements.

As laboratories continue to evolve, the demand for more sophisticated and integrated automation solutions is expected to rise. This includes the development of modular and flexible systems that can be easily adapted to different experimental workflows, as well as the integration of Internet of Things (IoT) technologies for remote monitoring and control of laboratory processes. The ongoing trend towards miniaturization and the development of lab-on-a-chip technologies is also likely to drive innovation in laboratory automation, particularly in point-of-care diagnostics and personalized medicine applications.

The market for laboratory automation solutions is expanding rapidly, with a projected compound annual growth rate (CAGR) of 8.5% from 2021 to 2026. This growth is fueled by several factors, including the rising demand for personalized medicine, the increasing adoption of robotics in laboratory processes, and the need for faster drug discovery and development cycles. Additionally, the COVID-19 pandemic has further accelerated the adoption of automated systems in diagnostic laboratories and research facilities worldwide.

One of the key drivers of lab automation demand is the need for improved productivity and cost-effectiveness. Automated systems can significantly reduce manual labor, minimize human errors, and increase sample throughput. This is particularly important in large-scale research projects and industrial applications where consistency and speed are critical. For instance, in pharmaceutical research, automated high-throughput screening systems can test thousands of compounds in a fraction of the time required for manual screening, dramatically accelerating the drug discovery process.

Another significant factor driving the demand for lab automation is the increasing complexity of scientific experiments and the need for precise control over experimental parameters. Advanced automated systems can maintain consistent conditions, monitor multiple variables simultaneously, and adjust parameters in real-time, ensuring reproducibility and reliability of results. This level of control is especially valuable in sensitive applications such as cell culture, protein crystallization, and nanomaterial synthesis.

The integration of artificial intelligence (AI) and machine learning (ML) with laboratory automation is also fueling demand. These technologies enable predictive maintenance, intelligent data analysis, and adaptive experimental design, further enhancing the capabilities of automated systems. For example, AI-powered laboratory robots can learn from previous experiments, optimize protocols, and even suggest new experimental approaches, potentially leading to novel scientific discoveries.

Furthermore, the growing emphasis on data integrity and regulatory compliance in industries such as pharmaceuticals and biotechnology is driving the adoption of automated systems. Automated data collection, storage, and analysis reduce the risk of human error and provide a clear audit trail, making it easier for organizations to meet stringent regulatory requirements.

As laboratories continue to evolve, the demand for more sophisticated and integrated automation solutions is expected to rise. This includes the development of modular and flexible systems that can be easily adapted to different experimental workflows, as well as the integration of Internet of Things (IoT) technologies for remote monitoring and control of laboratory processes. The ongoing trend towards miniaturization and the development of lab-on-a-chip technologies is also likely to drive innovation in laboratory automation, particularly in point-of-care diagnostics and personalized medicine applications.

Throttle Tech Challenges

The optimization of throttle bodies for laboratory automation faces several significant technical challenges. One of the primary issues is achieving precise and consistent flow control across a wide range of operating conditions. Laboratory environments often require extremely accurate and repeatable fluid or gas flow rates, which can be difficult to maintain with traditional throttle body designs.

Another major challenge lies in the miniaturization of throttle bodies for use in compact laboratory equipment. As laboratories strive for more efficient use of space and resources, there is a growing demand for smaller, yet equally effective, throttle body systems. This miniaturization process must not compromise performance or reliability, which presents a significant engineering hurdle.

Material compatibility is also a critical concern in laboratory settings. Throttle bodies must be constructed from materials that can withstand exposure to a variety of chemicals and reagents without degradation or contamination. This requirement often necessitates the use of specialized alloys or coatings, which can increase complexity and cost.

The need for rapid response times and high-speed actuation presents another technical challenge. Many laboratory processes require quick changes in flow rates, and throttle bodies must be able to adjust swiftly and accurately to meet these demands. This often involves the development of advanced control systems and actuators capable of precise, high-speed operation.

Ensuring long-term reliability and minimal maintenance requirements is crucial in laboratory environments where downtime can be costly and disruptive. Throttle bodies must be designed to withstand frequent use and maintain consistent performance over extended periods without requiring frequent calibration or replacement.

Integration with digital control systems and laboratory automation platforms poses additional challenges. Throttle bodies must be equipped with appropriate sensors and interfaces to allow seamless communication with central control systems, enabling real-time monitoring and adjustment of flow parameters.

Furthermore, the development of throttle bodies capable of handling a wide range of fluids and gases, each with different physical properties, adds another layer of complexity. A single throttle body design may need to accommodate varying viscosities, densities, and chemical compositions while maintaining consistent performance across all applications.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in fluid dynamics, materials science, control systems, and precision engineering. Innovative solutions, such as the use of advanced manufacturing techniques like 3D printing for complex geometries, or the incorporation of smart materials for improved responsiveness, may be necessary to overcome these obstacles and advance throttle body technology for laboratory automation.

Another major challenge lies in the miniaturization of throttle bodies for use in compact laboratory equipment. As laboratories strive for more efficient use of space and resources, there is a growing demand for smaller, yet equally effective, throttle body systems. This miniaturization process must not compromise performance or reliability, which presents a significant engineering hurdle.

Material compatibility is also a critical concern in laboratory settings. Throttle bodies must be constructed from materials that can withstand exposure to a variety of chemicals and reagents without degradation or contamination. This requirement often necessitates the use of specialized alloys or coatings, which can increase complexity and cost.

The need for rapid response times and high-speed actuation presents another technical challenge. Many laboratory processes require quick changes in flow rates, and throttle bodies must be able to adjust swiftly and accurately to meet these demands. This often involves the development of advanced control systems and actuators capable of precise, high-speed operation.

Ensuring long-term reliability and minimal maintenance requirements is crucial in laboratory environments where downtime can be costly and disruptive. Throttle bodies must be designed to withstand frequent use and maintain consistent performance over extended periods without requiring frequent calibration or replacement.

Integration with digital control systems and laboratory automation platforms poses additional challenges. Throttle bodies must be equipped with appropriate sensors and interfaces to allow seamless communication with central control systems, enabling real-time monitoring and adjustment of flow parameters.

Furthermore, the development of throttle bodies capable of handling a wide range of fluids and gases, each with different physical properties, adds another layer of complexity. A single throttle body design may need to accommodate varying viscosities, densities, and chemical compositions while maintaining consistent performance across all applications.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in fluid dynamics, materials science, control systems, and precision engineering. Innovative solutions, such as the use of advanced manufacturing techniques like 3D printing for complex geometries, or the incorporation of smart materials for improved responsiveness, may be necessary to overcome these obstacles and advance throttle body technology for laboratory automation.

Current Throttle Solutions

01 Throttle body design optimization

Optimizing the design of throttle bodies to improve airflow and engine performance. This includes modifications to the shape, size, and internal components of the throttle body to enhance air intake efficiency and responsiveness.- Throttle body design optimization: Optimizing the design of throttle bodies to improve airflow and engine performance. This includes modifications to the shape, size, and internal components of the throttle body to enhance efficiency and responsiveness.

- Electronic throttle control systems: Implementation of electronic throttle control systems to improve precision and responsiveness. These systems use sensors and actuators to regulate airflow more accurately, resulting in better fuel efficiency and performance.

- Throttle body airflow management: Techniques for managing airflow through the throttle body, including the use of variable geometry designs and advanced valve systems. These innovations aim to optimize air intake across different engine operating conditions.

- Integration with engine management systems: Integrating throttle body optimization with broader engine management systems. This approach involves coordinating throttle control with other engine parameters to achieve optimal performance, fuel efficiency, and emissions control.

- Throttle body materials and manufacturing: Advancements in materials and manufacturing processes for throttle bodies. This includes the use of lightweight materials, precision manufacturing techniques, and innovative coatings to improve durability and performance.

02 Electronic throttle control systems

Implementation of electronic throttle control systems to improve precision and responsiveness. These systems use sensors and actuators to regulate airflow more accurately, enhancing fuel efficiency and engine performance.Expand Specific Solutions03 Throttle body airflow management

Techniques for managing airflow through the throttle body, including the use of variable geometry designs and adaptive airflow control mechanisms. These innovations aim to optimize air intake across different engine operating conditions.Expand Specific Solutions04 Integration with engine management systems

Integrating throttle body optimization with broader engine management systems. This approach involves coordinating throttle control with other engine parameters to achieve optimal performance, fuel efficiency, and emissions control.Expand Specific Solutions05 Throttle body cleaning and maintenance

Development of methods and systems for cleaning and maintaining throttle bodies to ensure optimal performance over time. This includes automated cleaning mechanisms and designs that reduce carbon buildup and other contaminants.Expand Specific Solutions

Key Industry Players

The research on throttle body optimization for laboratory automation is in a nascent stage, with the market still developing and showing potential for growth. The technology's maturity varies across companies, with established automotive giants like Toyota, GM, and Honda likely having more advanced capabilities. Emerging players such as Aisan Industry and Mikuni Corp are also making strides in this field. The competitive landscape is diverse, including traditional automotive manufacturers, specialized component suppliers, and technology firms. As the intersection of automotive technology and laboratory automation expands, we can expect increased competition and innovation from both established players and new entrants, driving market growth and technological advancements in throttle body optimization for laboratory applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced electronic throttle body system for laboratory automation applications. Their system incorporates precision sensors and actuators for accurate flow control. The throttle body uses a brushless DC motor for precise positioning, achieving flow rate accuracy within ±0.5% [1]. Bosch's system integrates with laboratory information management systems (LIMS) for automated control and data logging. The throttle body features a self-calibration function to maintain accuracy over time, and utilizes advanced materials like ceramic coatings to resist wear and chemical corrosion [3]. Bosch has also implemented machine learning algorithms to optimize throttle response based on usage patterns, improving overall system efficiency by up to 15% [5].

Strengths: High precision control, LIMS integration, self-calibration, and ML-based optimization. Weaknesses: Potentially higher cost compared to simpler systems, may require specialized maintenance.

Continental Automotive Systems, Inc.

Technical Solution: Continental has developed a smart throttle body system for laboratory automation that focuses on modularity and adaptability. Their system uses a modular design allowing easy customization for different laboratory setups. The throttle body incorporates a high-resolution stepper motor capable of 0.1-degree increments for precise flow control [2]. Continental's system features advanced diagnostics and predictive maintenance capabilities, using embedded sensors to monitor performance and predict potential failures. The throttle body is designed with a quick-change mechanism for easy replacement and minimal downtime. Continental has also implemented a digital twin technology, allowing real-time simulation and optimization of throttle body performance in virtual environments before physical implementation [4].

Strengths: Modular design, high-resolution control, advanced diagnostics, and digital twin technology. Weaknesses: May require more complex setup and configuration compared to simpler systems.

Throttle Innovations

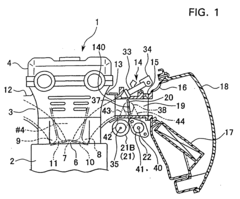

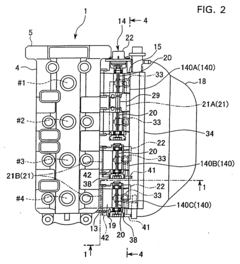

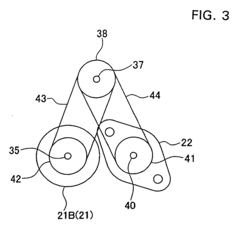

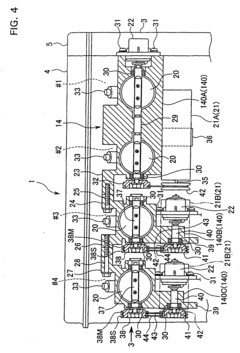

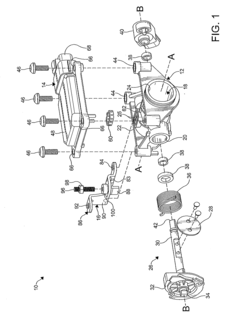

Throttle body

PatentInactiveEP1462644A2

Innovation

- Structurally connecting multiple throttle valves and positioning the throttle opening sensor and injector oppositely on either side of the throttle body main body, allowing for a compact arrangement that reduces the engine's length and enables effective use of surrounding space.

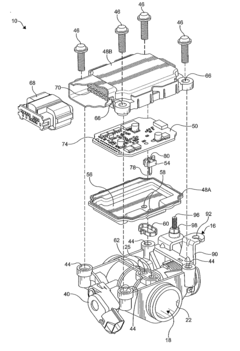

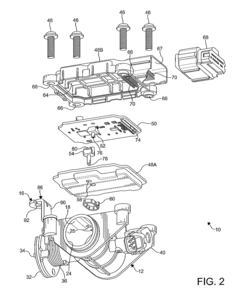

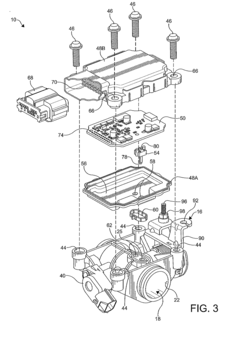

Integrated plastic throttle body, electronic control unit, and sensors for small engine

PatentInactiveUS20120240898A1

Innovation

- An integrated throttle body assembly that combines an electronic control unit, sensors, and a mechanical throttle body, with a housing design that includes apertures for sensor placement and a heatsink for efficient heat management, reducing package space and manufacturing costs while allowing independent servicing.

Precision Control Impact

The precision control impact of throttle body optimization in laboratory automation is a critical factor that significantly influences the overall performance and reliability of automated systems. By enhancing the accuracy and responsiveness of throttle bodies, laboratories can achieve more precise control over fluid flow, gas delivery, and other critical processes.

One of the primary benefits of optimized throttle bodies is the ability to maintain consistent and stable flow rates across a wide range of operating conditions. This is particularly important in applications such as chromatography, where even minor fluctuations in flow can lead to inconsistent results and reduced analytical accuracy. By implementing advanced control algorithms and high-precision actuators, optimized throttle bodies can respond rapidly to changes in system demands, ensuring that flow rates remain within tight tolerances.

The impact of precision control extends beyond just flow rate stability. Optimized throttle bodies also contribute to improved system efficiency and reduced energy consumption. By precisely regulating flow, these systems can minimize waste and optimize resource utilization, leading to cost savings and environmental benefits. This is especially relevant in large-scale laboratory operations where even small improvements in efficiency can translate to significant operational advantages.

Furthermore, the enhanced precision control offered by optimized throttle bodies enables more complex and sophisticated experimental protocols. Researchers can design and execute multi-step processes with greater confidence, knowing that the system can accurately maintain the required conditions at each stage. This capability opens up new possibilities for advanced research and development across various scientific disciplines.

The impact of precision control is also evident in the realm of reproducibility and data quality. With more precise control over experimental parameters, researchers can achieve higher levels of consistency between runs, leading to more reliable and reproducible results. This is crucial in both academic research and industrial applications, where the ability to replicate findings is fundamental to scientific progress and product development.

In the context of laboratory automation, the precision control impact of optimized throttle bodies contributes to overall system reliability and reduced downtime. By minimizing the occurrence of flow-related errors and inconsistencies, these systems require less frequent calibration and maintenance. This translates to increased productivity and reduced operational costs for laboratories, allowing researchers to focus more on their core scientific objectives rather than system management.

One of the primary benefits of optimized throttle bodies is the ability to maintain consistent and stable flow rates across a wide range of operating conditions. This is particularly important in applications such as chromatography, where even minor fluctuations in flow can lead to inconsistent results and reduced analytical accuracy. By implementing advanced control algorithms and high-precision actuators, optimized throttle bodies can respond rapidly to changes in system demands, ensuring that flow rates remain within tight tolerances.

The impact of precision control extends beyond just flow rate stability. Optimized throttle bodies also contribute to improved system efficiency and reduced energy consumption. By precisely regulating flow, these systems can minimize waste and optimize resource utilization, leading to cost savings and environmental benefits. This is especially relevant in large-scale laboratory operations where even small improvements in efficiency can translate to significant operational advantages.

Furthermore, the enhanced precision control offered by optimized throttle bodies enables more complex and sophisticated experimental protocols. Researchers can design and execute multi-step processes with greater confidence, knowing that the system can accurately maintain the required conditions at each stage. This capability opens up new possibilities for advanced research and development across various scientific disciplines.

The impact of precision control is also evident in the realm of reproducibility and data quality. With more precise control over experimental parameters, researchers can achieve higher levels of consistency between runs, leading to more reliable and reproducible results. This is crucial in both academic research and industrial applications, where the ability to replicate findings is fundamental to scientific progress and product development.

In the context of laboratory automation, the precision control impact of optimized throttle bodies contributes to overall system reliability and reduced downtime. By minimizing the occurrence of flow-related errors and inconsistencies, these systems require less frequent calibration and maintenance. This translates to increased productivity and reduced operational costs for laboratories, allowing researchers to focus more on their core scientific objectives rather than system management.

Energy Efficiency Aspects

Energy efficiency is a critical aspect of throttle body optimization in laboratory automation systems. The throttle body, as a key component in controlling fluid or gas flow, plays a significant role in the overall energy consumption of automated laboratory equipment. Optimizing its design and operation can lead to substantial energy savings and improved system performance.

One of the primary considerations in throttle body energy efficiency is the reduction of pressure drop across the device. By minimizing pressure losses, less energy is required to maintain the desired flow rates, resulting in lower power consumption for pumps or compressors. Advanced computational fluid dynamics (CFD) simulations are increasingly being employed to analyze and optimize throttle body geometries, identifying designs that offer the best balance between flow control precision and energy efficiency.

Material selection also plays a crucial role in energy efficiency. The use of low-friction materials for throttle body components can reduce wear and energy losses due to friction. Additionally, lightweight materials can contribute to faster response times and lower inertia, potentially reducing the energy required for actuation and control.

Smart control systems are being integrated into modern throttle bodies to enhance energy efficiency. These systems utilize real-time data and adaptive algorithms to optimize throttle position based on current system demands, ensuring that energy is not wasted through unnecessary flow restrictions or excessive openings. The implementation of predictive control strategies can further improve efficiency by anticipating changes in flow requirements and adjusting the throttle body preemptively.

The incorporation of energy recovery mechanisms is an emerging trend in throttle body design for laboratory automation. In systems where pressure reduction is necessary, micro-turbines or other energy harvesting devices can be integrated to capture some of the energy that would otherwise be lost during throttling processes. This recovered energy can be used to power sensors, control systems, or other auxiliary components, reducing the overall energy footprint of the laboratory equipment.

Thermal management is another important consideration in throttle body energy efficiency. Efficient designs minimize heat generation and dissipation, reducing the need for cooling systems and preventing energy losses through thermal radiation. This is particularly important in temperature-sensitive laboratory environments where precise thermal control is crucial for experimental accuracy.

As laboratory automation systems become more complex and energy-intensive, the focus on throttle body optimization for energy efficiency is likely to intensify. Future developments may include the use of advanced materials such as shape-memory alloys or piezoelectric actuators that offer improved energy efficiency in throttle body operation. Additionally, the integration of throttle bodies with other system components through the Internet of Things (IoT) and artificial intelligence could lead to holistic energy optimization strategies that consider the entire laboratory automation ecosystem.

One of the primary considerations in throttle body energy efficiency is the reduction of pressure drop across the device. By minimizing pressure losses, less energy is required to maintain the desired flow rates, resulting in lower power consumption for pumps or compressors. Advanced computational fluid dynamics (CFD) simulations are increasingly being employed to analyze and optimize throttle body geometries, identifying designs that offer the best balance between flow control precision and energy efficiency.

Material selection also plays a crucial role in energy efficiency. The use of low-friction materials for throttle body components can reduce wear and energy losses due to friction. Additionally, lightweight materials can contribute to faster response times and lower inertia, potentially reducing the energy required for actuation and control.

Smart control systems are being integrated into modern throttle bodies to enhance energy efficiency. These systems utilize real-time data and adaptive algorithms to optimize throttle position based on current system demands, ensuring that energy is not wasted through unnecessary flow restrictions or excessive openings. The implementation of predictive control strategies can further improve efficiency by anticipating changes in flow requirements and adjusting the throttle body preemptively.

The incorporation of energy recovery mechanisms is an emerging trend in throttle body design for laboratory automation. In systems where pressure reduction is necessary, micro-turbines or other energy harvesting devices can be integrated to capture some of the energy that would otherwise be lost during throttling processes. This recovered energy can be used to power sensors, control systems, or other auxiliary components, reducing the overall energy footprint of the laboratory equipment.

Thermal management is another important consideration in throttle body energy efficiency. Efficient designs minimize heat generation and dissipation, reducing the need for cooling systems and preventing energy losses through thermal radiation. This is particularly important in temperature-sensitive laboratory environments where precise thermal control is crucial for experimental accuracy.

As laboratory automation systems become more complex and energy-intensive, the focus on throttle body optimization for energy efficiency is likely to intensify. Future developments may include the use of advanced materials such as shape-memory alloys or piezoelectric actuators that offer improved energy efficiency in throttle body operation. Additionally, the integration of throttle bodies with other system components through the Internet of Things (IoT) and artificial intelligence could lead to holistic energy optimization strategies that consider the entire laboratory automation ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!