How to Develop Biodegradable Polycarbonate Blends?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable PC Blends: Background and Objectives

Polycarbonate (PC) has been a widely used engineering plastic for decades due to its excellent mechanical properties, transparency, and heat resistance. However, the growing concern over environmental sustainability has led to increased interest in developing biodegradable alternatives. The development of biodegradable polycarbonate blends represents a significant step towards addressing this challenge, aiming to combine the desirable properties of traditional PC with enhanced environmental friendliness.

The evolution of biodegradable polymers has seen significant progress over the past few decades, with materials such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) gaining prominence. However, these materials often lack the performance characteristics required for many applications where PC is currently used. The goal of developing biodegradable PC blends is to bridge this gap, creating materials that maintain the strength, durability, and optical clarity of PC while introducing biodegradability.

The primary objective of this research is to explore innovative approaches to synthesize and formulate biodegradable PC blends that can meet or exceed the performance standards of conventional PC. This involves investigating various biodegradable polymers that can be effectively blended with PC, as well as exploring chemical modifications that can enhance the biodegradability of the PC itself without significantly compromising its desirable properties.

Another crucial aspect of this research is to understand and optimize the degradation mechanisms of these blends under different environmental conditions. This includes studying the factors that influence biodegradation rates, such as temperature, humidity, and microbial activity, and developing strategies to control these processes to ensure that the materials degrade within acceptable timeframes after disposal.

Furthermore, the development of biodegradable PC blends aims to address the growing market demand for sustainable materials in various industries, including automotive, electronics, and packaging. As regulatory pressures increase and consumer awareness of environmental issues grows, there is a clear trend towards materials that can offer both high performance and reduced environmental impact.

The technical challenges in this field are significant and multifaceted. They include achieving a balance between biodegradability and material properties, ensuring compatibility between PC and biodegradable components, and developing cost-effective production methods that can be scaled up for industrial applications. Additionally, there is a need to establish standardized testing methods for assessing the biodegradability of these new materials under various conditions.

As we delve into this research, we will explore the current state of the art in biodegradable polymer technology, analyze the specific challenges associated with PC blends, and investigate promising approaches for overcoming these obstacles. The ultimate goal is to pave the way for a new generation of high-performance, environmentally friendly materials that can significantly reduce the environmental footprint of plastic products while maintaining their functionality and reliability.

The evolution of biodegradable polymers has seen significant progress over the past few decades, with materials such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) gaining prominence. However, these materials often lack the performance characteristics required for many applications where PC is currently used. The goal of developing biodegradable PC blends is to bridge this gap, creating materials that maintain the strength, durability, and optical clarity of PC while introducing biodegradability.

The primary objective of this research is to explore innovative approaches to synthesize and formulate biodegradable PC blends that can meet or exceed the performance standards of conventional PC. This involves investigating various biodegradable polymers that can be effectively blended with PC, as well as exploring chemical modifications that can enhance the biodegradability of the PC itself without significantly compromising its desirable properties.

Another crucial aspect of this research is to understand and optimize the degradation mechanisms of these blends under different environmental conditions. This includes studying the factors that influence biodegradation rates, such as temperature, humidity, and microbial activity, and developing strategies to control these processes to ensure that the materials degrade within acceptable timeframes after disposal.

Furthermore, the development of biodegradable PC blends aims to address the growing market demand for sustainable materials in various industries, including automotive, electronics, and packaging. As regulatory pressures increase and consumer awareness of environmental issues grows, there is a clear trend towards materials that can offer both high performance and reduced environmental impact.

The technical challenges in this field are significant and multifaceted. They include achieving a balance between biodegradability and material properties, ensuring compatibility between PC and biodegradable components, and developing cost-effective production methods that can be scaled up for industrial applications. Additionally, there is a need to establish standardized testing methods for assessing the biodegradability of these new materials under various conditions.

As we delve into this research, we will explore the current state of the art in biodegradable polymer technology, analyze the specific challenges associated with PC blends, and investigate promising approaches for overcoming these obstacles. The ultimate goal is to pave the way for a new generation of high-performance, environmentally friendly materials that can significantly reduce the environmental footprint of plastic products while maintaining their functionality and reliability.

Market Analysis for Eco-Friendly Plastics

The market for eco-friendly plastics, particularly biodegradable polycarbonate blends, has been experiencing significant growth in recent years. This surge is driven by increasing environmental concerns, stringent regulations on plastic waste, and growing consumer awareness about sustainable products. The global biodegradable plastics market is projected to expand at a compound annual growth rate of 9.5% from 2021 to 2026, reaching a value of $7.1 billion by the end of the forecast period.

Biodegradable polycarbonate blends are gaining traction across various industries, including packaging, automotive, electronics, and consumer goods. The packaging sector, in particular, is expected to be the largest consumer of these materials, accounting for over 40% of the market share. This is primarily due to the increasing demand for sustainable packaging solutions in the food and beverage industry, as well as in e-commerce applications.

The automotive industry is another key market for biodegradable polycarbonate blends. As automakers strive to reduce vehicle weight and improve fuel efficiency, these materials offer a promising alternative to traditional plastics. The automotive sector is anticipated to witness the fastest growth rate in the adoption of biodegradable polycarbonate blends, with a projected CAGR of 11.2% from 2021 to 2026.

Geographically, Europe leads the market for eco-friendly plastics, followed by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, which has accelerated the adoption of biodegradable alternatives. The Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and India.

Consumer preferences are shifting towards sustainable products, with a recent survey indicating that 73% of consumers are willing to pay a premium for eco-friendly packaging. This trend is expected to further boost the demand for biodegradable polycarbonate blends across various end-use industries.

However, the market for biodegradable polycarbonate blends faces challenges such as higher production costs compared to conventional plastics and limited awareness about proper disposal methods. Addressing these issues through technological advancements and consumer education will be crucial for the continued growth of this market.

Biodegradable polycarbonate blends are gaining traction across various industries, including packaging, automotive, electronics, and consumer goods. The packaging sector, in particular, is expected to be the largest consumer of these materials, accounting for over 40% of the market share. This is primarily due to the increasing demand for sustainable packaging solutions in the food and beverage industry, as well as in e-commerce applications.

The automotive industry is another key market for biodegradable polycarbonate blends. As automakers strive to reduce vehicle weight and improve fuel efficiency, these materials offer a promising alternative to traditional plastics. The automotive sector is anticipated to witness the fastest growth rate in the adoption of biodegradable polycarbonate blends, with a projected CAGR of 11.2% from 2021 to 2026.

Geographically, Europe leads the market for eco-friendly plastics, followed by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, which has accelerated the adoption of biodegradable alternatives. The Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, driven by rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and India.

Consumer preferences are shifting towards sustainable products, with a recent survey indicating that 73% of consumers are willing to pay a premium for eco-friendly packaging. This trend is expected to further boost the demand for biodegradable polycarbonate blends across various end-use industries.

However, the market for biodegradable polycarbonate blends faces challenges such as higher production costs compared to conventional plastics and limited awareness about proper disposal methods. Addressing these issues through technological advancements and consumer education will be crucial for the continued growth of this market.

Current Challenges in Biodegradable PC Development

The development of biodegradable polycarbonate (PC) blends faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is achieving a balance between biodegradability and mechanical properties. Traditional polycarbonates are known for their excellent impact resistance, transparency, and thermal stability. However, introducing biodegradable components often compromises these desirable characteristics, resulting in materials with inferior performance compared to conventional PCs.

Another major challenge lies in controlling the degradation rate of biodegradable PC blends. The ideal material should maintain its structural integrity during its intended use but degrade rapidly once disposed of in the environment. Achieving this delicate balance requires precise control over the blend composition and the degradation mechanisms of individual components. Factors such as humidity, temperature, and microbial activity can significantly influence the degradation process, making it difficult to predict and standardize the material's behavior across different environments.

Cost-effectiveness remains a substantial hurdle in the development of biodegradable PC blends. The production of biodegradable polymers and their incorporation into PC matrices often involves complex processes and expensive raw materials. This increased cost of production makes it challenging for biodegradable PC blends to compete with traditional, non-biodegradable alternatives in the market. Scaling up production while maintaining consistent quality and properties is another cost-related challenge that researchers and manufacturers must address.

The compatibility between biodegradable components and polycarbonate matrices presents a significant technical challenge. Many biodegradable polymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHAs), have limited miscibility with polycarbonate. This incompatibility can lead to phase separation, resulting in poor mechanical properties and inconsistent degradation behavior. Developing effective compatibilization strategies or identifying novel biodegradable polymers with better compatibility is crucial for advancing biodegradable PC blends.

Regulatory compliance and standardization pose additional challenges in the development of biodegradable PC blends. The lack of universally accepted standards for biodegradability and compostability creates uncertainty in product development and marketing. Different regions and countries may have varying requirements, making it difficult for manufacturers to create globally compliant products. Additionally, the long-term environmental impact of degradation products from these blends requires thorough assessment to ensure they do not pose unforeseen ecological risks.

Lastly, the challenge of maintaining transparency in biodegradable PC blends is particularly significant for applications where optical clarity is crucial. Many biodegradable additives or polymers can introduce haziness or color to the final blend, limiting its use in applications that require high transparency, such as medical devices or electronic displays. Overcoming this challenge requires innovative approaches to blend design and processing techniques that can preserve the optical properties of polycarbonate while incorporating biodegradable components.

Another major challenge lies in controlling the degradation rate of biodegradable PC blends. The ideal material should maintain its structural integrity during its intended use but degrade rapidly once disposed of in the environment. Achieving this delicate balance requires precise control over the blend composition and the degradation mechanisms of individual components. Factors such as humidity, temperature, and microbial activity can significantly influence the degradation process, making it difficult to predict and standardize the material's behavior across different environments.

Cost-effectiveness remains a substantial hurdle in the development of biodegradable PC blends. The production of biodegradable polymers and their incorporation into PC matrices often involves complex processes and expensive raw materials. This increased cost of production makes it challenging for biodegradable PC blends to compete with traditional, non-biodegradable alternatives in the market. Scaling up production while maintaining consistent quality and properties is another cost-related challenge that researchers and manufacturers must address.

The compatibility between biodegradable components and polycarbonate matrices presents a significant technical challenge. Many biodegradable polymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHAs), have limited miscibility with polycarbonate. This incompatibility can lead to phase separation, resulting in poor mechanical properties and inconsistent degradation behavior. Developing effective compatibilization strategies or identifying novel biodegradable polymers with better compatibility is crucial for advancing biodegradable PC blends.

Regulatory compliance and standardization pose additional challenges in the development of biodegradable PC blends. The lack of universally accepted standards for biodegradability and compostability creates uncertainty in product development and marketing. Different regions and countries may have varying requirements, making it difficult for manufacturers to create globally compliant products. Additionally, the long-term environmental impact of degradation products from these blends requires thorough assessment to ensure they do not pose unforeseen ecological risks.

Lastly, the challenge of maintaining transparency in biodegradable PC blends is particularly significant for applications where optical clarity is crucial. Many biodegradable additives or polymers can introduce haziness or color to the final blend, limiting its use in applications that require high transparency, such as medical devices or electronic displays. Overcoming this challenge requires innovative approaches to blend design and processing techniques that can preserve the optical properties of polycarbonate while incorporating biodegradable components.

Existing Biodegradable PC Blend Formulations

01 Biodegradable polycarbonate blends composition

Biodegradable polycarbonate blends can be created by combining polycarbonates with other biodegradable polymers or additives. These blends often include aliphatic polyesters, starch, or natural fibers to enhance biodegradability while maintaining desirable mechanical properties. The composition of these blends is crucial in determining their overall biodegradability and performance characteristics.- Biodegradable polycarbonate blends composition: Biodegradable polycarbonate blends can be created by combining polycarbonates with other biodegradable polymers or additives. These blends often include aliphatic polyesters, starch-based materials, or natural fibers to enhance biodegradability while maintaining desirable mechanical properties.

- Enhancing biodegradability through additives: Additives such as pro-oxidants, enzymes, or microbial agents can be incorporated into polycarbonate blends to accelerate the biodegradation process. These additives help break down the polymer chains, making them more susceptible to microbial attack and environmental degradation.

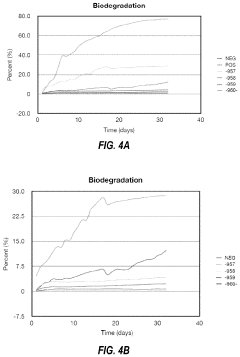

- Biodegradation testing methods: Various standardized testing methods are used to evaluate the biodegradability of polycarbonate blends. These may include composting tests, soil burial tests, or aqueous medium tests to assess the rate and extent of biodegradation under different environmental conditions.

- Environmental impact and applications: Biodegradable polycarbonate blends are being developed for various applications, including packaging, disposable products, and agricultural films. These materials aim to reduce environmental impact by offering improved end-of-life options compared to traditional non-biodegradable polycarbonates.

- Balancing biodegradability and performance: Researchers are working on optimizing the balance between biodegradability and mechanical performance in polycarbonate blends. This involves careful selection of blend components and processing techniques to achieve desired biodegradation rates while maintaining strength, durability, and other essential properties for specific applications.

02 Biodegradation mechanisms of polycarbonate blends

The biodegradation of polycarbonate blends involves various mechanisms, including hydrolysis, enzymatic degradation, and microbial action. The presence of biodegradable components in the blend facilitates the breakdown of the polymer matrix. Factors such as temperature, humidity, and microbial activity in the environment influence the rate and extent of biodegradation.Expand Specific Solutions03 Improving biodegradability of polycarbonate blends

Techniques to enhance the biodegradability of polycarbonate blends include incorporating biodegradation-promoting additives, optimizing blend ratios, and modifying the polymer structure. These methods aim to increase the susceptibility of the blends to environmental degradation while maintaining their functional properties during use.Expand Specific Solutions04 Testing and evaluation of biodegradability

Various standardized tests and methods are used to assess the biodegradability of polycarbonate blends. These include composting tests, soil burial tests, and enzymatic degradation assays. The evaluation typically involves measuring weight loss, CO2 evolution, and changes in mechanical properties over time to determine the extent and rate of biodegradation.Expand Specific Solutions05 Applications of biodegradable polycarbonate blends

Biodegradable polycarbonate blends find applications in various industries, including packaging, agriculture, and consumer goods. These materials offer a balance between performance and environmental sustainability, making them suitable for products where end-of-life biodegradability is desirable. The specific applications depend on the blend composition and its resulting properties.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The development of biodegradable polycarbonate blends is in a growth phase, with increasing market demand driven by environmental concerns. The global market for biodegradable plastics is expanding rapidly, expected to reach $7.8 billion by 2025. Technologically, the field is advancing but still maturing. Companies like BASF, Novamont, and CJ CheilJedang are leading innovation, while academic institutions such as Wuhan University and Tongji University contribute significant research. The involvement of major chemical companies and specialized bioplastic firms like BioLogiQ indicates growing industry interest and investment in this area, suggesting a competitive landscape with potential for further technological breakthroughs and market expansion.

BASF Corp.

Technical Solution: BASF has developed a novel approach to biodegradable polycarbonate blends using their ecovio® technology. This involves blending polylactic acid (PLA) with their biodegradable copolyester ecoflex®. The resulting material combines the high mechanical strength and thermal stability of polycarbonate with the biodegradability of PLA and ecoflex®. BASF's process includes a compatibilizer to improve the miscibility of the components, resulting in a homogeneous blend with enhanced properties[1][3]. The company has also incorporated nanoclay particles to further improve the material's barrier properties and mechanical strength[2].

Strengths: Leverages existing ecovio® technology, combines high performance with biodegradability, and offers customizable properties. Weaknesses: May be more expensive than traditional polycarbonates, and biodegradation rates can vary depending on environmental conditions.

Novamont SpA

Technical Solution: Novamont has pioneered the development of MATER-BI®, a family of biodegradable and compostable bioplastics that can be used in polycarbonate blends. Their approach involves blending their proprietary starch-based polymers with polycarbonate and other biodegradable polyesters. Novamont's technology utilizes a multi-phase system where the starch component forms a continuous matrix, enhancing the overall biodegradability of the blend[4]. The company has also developed a patented process for creating nanostructured blends, which improves the material's mechanical properties and biodegradation rate[5]. Novamont's blends have shown biodegradation rates of up to 90% within 180 days in industrial composting conditions[6].

Strengths: Established technology with proven biodegradability, versatile applications, and renewable content. Weaknesses: May have lower heat resistance compared to pure polycarbonates, and performance can be affected by moisture absorption.

Innovative Approaches in PC Biodegradability

Eco-friendly synthesis of biodegradable polycarbonate from co2 and epoxide

PatentPendingIN202321017490A

Innovation

- The synthesis of biodegradable polycarbonate from carbon dioxide (CO2) and epoxide using a metal-organic framework (MOF) catalyst, which initiates a polymerization reaction that produces polycarbonates that can break down naturally, reducing waste and pollution.

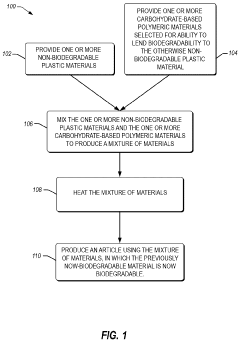

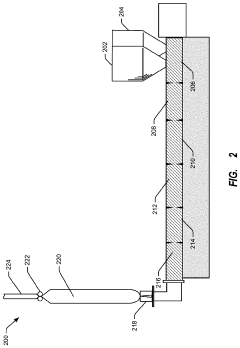

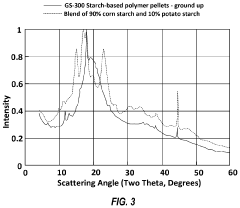

Methods for lending biodegradability to non-biodegradable polyolefin and nylon materials

PatentActiveUS11840623B2

Innovation

- Incorporating a carbohydrate-based polymeric material, such as Eco Starch Resin, into non-biodegradable plastics to create a blend that can be molded and processed into biodegradable products, including films, bottles, and bags, which can fully degrade into natural components under landfill or compost conditions.

Environmental Impact Assessment

The development of biodegradable polycarbonate blends presents a significant opportunity to address environmental concerns associated with traditional plastics. This environmental impact assessment evaluates the potential effects of these innovative materials on ecosystems, resource consumption, and waste management.

Biodegradable polycarbonate blends offer a promising solution to reduce plastic pollution, particularly in marine environments. These materials are designed to decompose naturally under specific conditions, potentially mitigating the accumulation of plastic waste in oceans and landfills. The degradation process typically results in the formation of non-toxic byproducts, such as water, carbon dioxide, and biomass, which can be assimilated into natural ecosystems without causing harm.

The production of biodegradable polycarbonate blends may have a lower carbon footprint compared to conventional plastics. Many biodegradable polymers are derived from renewable resources, such as plant-based materials, which can reduce dependence on fossil fuels. This shift towards bio-based feedstocks can contribute to a decrease in greenhouse gas emissions associated with plastic production.

However, it is crucial to consider the entire life cycle of these materials when assessing their environmental impact. The cultivation and processing of bio-based raw materials may require significant land and water resources, potentially competing with food production or leading to deforestation if not managed sustainably. Additionally, the energy requirements for manufacturing biodegradable polycarbonate blends should be carefully evaluated to ensure they do not offset the environmental benefits gained from biodegradability.

Waste management systems play a critical role in realizing the full environmental potential of biodegradable polycarbonate blends. These materials often require specific conditions, such as industrial composting facilities, to degrade effectively. Without proper infrastructure and consumer education, biodegradable plastics may end up in conventional recycling streams or landfills, where they may not degrade as intended and could potentially contaminate recycling processes.

The introduction of biodegradable polycarbonate blends may also influence consumer behavior. While these materials offer an environmentally friendly alternative, there is a risk that they could inadvertently encourage increased consumption or improper disposal if consumers perceive them as completely harmless to the environment. Public awareness campaigns and clear labeling are essential to ensure responsible use and disposal of these materials.

In conclusion, biodegradable polycarbonate blends have the potential to significantly reduce the environmental impact of plastic products. However, their successful implementation requires a holistic approach that considers production methods, waste management infrastructure, and consumer education. Ongoing research and life cycle assessments are necessary to fully understand and optimize the environmental benefits of these innovative materials.

Biodegradable polycarbonate blends offer a promising solution to reduce plastic pollution, particularly in marine environments. These materials are designed to decompose naturally under specific conditions, potentially mitigating the accumulation of plastic waste in oceans and landfills. The degradation process typically results in the formation of non-toxic byproducts, such as water, carbon dioxide, and biomass, which can be assimilated into natural ecosystems without causing harm.

The production of biodegradable polycarbonate blends may have a lower carbon footprint compared to conventional plastics. Many biodegradable polymers are derived from renewable resources, such as plant-based materials, which can reduce dependence on fossil fuels. This shift towards bio-based feedstocks can contribute to a decrease in greenhouse gas emissions associated with plastic production.

However, it is crucial to consider the entire life cycle of these materials when assessing their environmental impact. The cultivation and processing of bio-based raw materials may require significant land and water resources, potentially competing with food production or leading to deforestation if not managed sustainably. Additionally, the energy requirements for manufacturing biodegradable polycarbonate blends should be carefully evaluated to ensure they do not offset the environmental benefits gained from biodegradability.

Waste management systems play a critical role in realizing the full environmental potential of biodegradable polycarbonate blends. These materials often require specific conditions, such as industrial composting facilities, to degrade effectively. Without proper infrastructure and consumer education, biodegradable plastics may end up in conventional recycling streams or landfills, where they may not degrade as intended and could potentially contaminate recycling processes.

The introduction of biodegradable polycarbonate blends may also influence consumer behavior. While these materials offer an environmentally friendly alternative, there is a risk that they could inadvertently encourage increased consumption or improper disposal if consumers perceive them as completely harmless to the environment. Public awareness campaigns and clear labeling are essential to ensure responsible use and disposal of these materials.

In conclusion, biodegradable polycarbonate blends have the potential to significantly reduce the environmental impact of plastic products. However, their successful implementation requires a holistic approach that considers production methods, waste management infrastructure, and consumer education. Ongoing research and life cycle assessments are necessary to fully understand and optimize the environmental benefits of these innovative materials.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in shaping the development and adoption of biodegradable polycarbonate blends. As environmental concerns continue to grow, governments and international organizations have implemented various regulations and standards to ensure the proper production, use, and disposal of biodegradable plastics.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard defines the characteristics that a material must have to be considered "compostable" and provides a framework for testing and certification. Similarly, the ASTM D6400 standard in the United States outlines the specifications for compostable plastics.

The ISO 17088 international standard provides specifications for compostable plastics, including biodegradation, disintegration during composting, negative effects on the composting process and facility, and negative effects on the quality of the resulting compost. These standards help ensure that biodegradable polycarbonate blends meet specific environmental and performance criteria.

Regulatory bodies such as the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) oversee the registration and evaluation of chemical substances used in biodegradable plastics. These agencies assess the potential risks associated with new materials and their environmental impact.

Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize the development of more sustainable materials, such as biodegradable polycarbonate blends.

Labeling requirements for biodegradable plastics vary across jurisdictions. The EU, for instance, has strict guidelines on environmental claims, requiring clear and accurate information about a product's biodegradability and compostability. In the United States, the Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability.

As the field of biodegradable plastics continues to evolve, regulatory frameworks are likely to adapt and become more comprehensive. Researchers and manufacturers developing biodegradable polycarbonate blends must stay informed about current and emerging regulations to ensure compliance and market acceptance of their products.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard defines the characteristics that a material must have to be considered "compostable" and provides a framework for testing and certification. Similarly, the ASTM D6400 standard in the United States outlines the specifications for compostable plastics.

The ISO 17088 international standard provides specifications for compostable plastics, including biodegradation, disintegration during composting, negative effects on the composting process and facility, and negative effects on the quality of the resulting compost. These standards help ensure that biodegradable polycarbonate blends meet specific environmental and performance criteria.

Regulatory bodies such as the European Chemicals Agency (ECHA) and the U.S. Environmental Protection Agency (EPA) oversee the registration and evaluation of chemical substances used in biodegradable plastics. These agencies assess the potential risks associated with new materials and their environmental impact.

Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize the development of more sustainable materials, such as biodegradable polycarbonate blends.

Labeling requirements for biodegradable plastics vary across jurisdictions. The EU, for instance, has strict guidelines on environmental claims, requiring clear and accurate information about a product's biodegradability and compostability. In the United States, the Federal Trade Commission (FTC) provides guidelines for environmental marketing claims, including those related to biodegradability.

As the field of biodegradable plastics continues to evolve, regulatory frameworks are likely to adapt and become more comprehensive. Researchers and manufacturers developing biodegradable polycarbonate blends must stay informed about current and emerging regulations to ensure compliance and market acceptance of their products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!