How to Develop Sustainable Polycarbonate Alternatives?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sustainable PC Alternatives: Background and Objectives

Polycarbonate (PC) has been a widely used engineering plastic for decades due to its excellent mechanical properties, optical clarity, and heat resistance. However, growing environmental concerns have led to an urgent need for sustainable alternatives. The development of eco-friendly substitutes for polycarbonate is driven by several factors, including the desire to reduce reliance on fossil fuels, minimize environmental impact, and address health concerns associated with bisphenol A (BPA), a key component in traditional PC production.

The evolution of sustainable polycarbonate alternatives has been marked by significant milestones in materials science and polymer chemistry. Early efforts focused on finding BPA-free alternatives, which led to the development of copolyesters and other thermoplastic materials. As sustainability became a more pressing concern, research shifted towards bio-based and biodegradable options, exploring materials derived from renewable resources such as cellulose, starch, and plant-based oils.

The technical objectives in developing sustainable PC alternatives are multifaceted. Primarily, these new materials must match or exceed the performance characteristics of traditional polycarbonate, including impact resistance, transparency, and thermal stability. Additionally, they should offer improved environmental credentials, such as biodegradability, lower carbon footprint, and reduced toxicity throughout their lifecycle.

Another critical goal is to ensure that these alternatives are economically viable and can be integrated into existing manufacturing processes with minimal disruption. This includes developing materials that can be processed using conventional equipment and techniques, thereby reducing the barriers to adoption for manufacturers.

Furthermore, the development of sustainable PC alternatives aims to address specific application needs across various industries. For instance, in the automotive sector, there is a growing demand for lightweight, durable materials that can contribute to improved fuel efficiency and reduced emissions. In the electronics industry, the focus is on materials that can provide excellent flame retardancy without the use of harmful additives.

The pursuit of sustainable polycarbonate alternatives also aligns with broader global initiatives, such as the United Nations Sustainable Development Goals and various national and international regulations aimed at reducing plastic waste and promoting circular economy principles. As such, research in this field is not only driven by technological innovation but also by the need to comply with evolving environmental standards and consumer expectations for more sustainable products.

The evolution of sustainable polycarbonate alternatives has been marked by significant milestones in materials science and polymer chemistry. Early efforts focused on finding BPA-free alternatives, which led to the development of copolyesters and other thermoplastic materials. As sustainability became a more pressing concern, research shifted towards bio-based and biodegradable options, exploring materials derived from renewable resources such as cellulose, starch, and plant-based oils.

The technical objectives in developing sustainable PC alternatives are multifaceted. Primarily, these new materials must match or exceed the performance characteristics of traditional polycarbonate, including impact resistance, transparency, and thermal stability. Additionally, they should offer improved environmental credentials, such as biodegradability, lower carbon footprint, and reduced toxicity throughout their lifecycle.

Another critical goal is to ensure that these alternatives are economically viable and can be integrated into existing manufacturing processes with minimal disruption. This includes developing materials that can be processed using conventional equipment and techniques, thereby reducing the barriers to adoption for manufacturers.

Furthermore, the development of sustainable PC alternatives aims to address specific application needs across various industries. For instance, in the automotive sector, there is a growing demand for lightweight, durable materials that can contribute to improved fuel efficiency and reduced emissions. In the electronics industry, the focus is on materials that can provide excellent flame retardancy without the use of harmful additives.

The pursuit of sustainable polycarbonate alternatives also aligns with broader global initiatives, such as the United Nations Sustainable Development Goals and various national and international regulations aimed at reducing plastic waste and promoting circular economy principles. As such, research in this field is not only driven by technological innovation but also by the need to comply with evolving environmental standards and consumer expectations for more sustainable products.

Market Demand for Eco-friendly Plastics

The demand for eco-friendly plastics has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on plastic waste. This trend is particularly evident in the search for sustainable alternatives to polycarbonate, a widely used plastic known for its durability and optical clarity.

Consumer awareness of environmental issues has led to a significant shift in purchasing behavior. Many consumers now actively seek products made from sustainable materials, including eco-friendly plastics. This change in consumer preferences has prompted manufacturers across various industries to explore and adopt more environmentally friendly alternatives to traditional plastics like polycarbonate.

The automotive industry has emerged as a key driver in the demand for sustainable polycarbonate alternatives. With the push for lighter, more fuel-efficient vehicles, automakers are increasingly looking for materials that can reduce vehicle weight while maintaining safety standards. Eco-friendly plastics that can match or exceed the performance characteristics of polycarbonate are in high demand for applications such as headlamp lenses, interior components, and body panels.

The packaging industry is another significant market for sustainable plastic alternatives. As governments worldwide implement regulations to reduce single-use plastics, there is a growing need for biodegradable or easily recyclable materials that can replace polycarbonate in food packaging, beverage bottles, and other consumer goods packaging.

The electronics sector also presents a substantial market opportunity for eco-friendly plastics. With the rapid turnover of electronic devices and the resulting e-waste problem, manufacturers are under pressure to use more sustainable materials in their products. This includes finding alternatives to polycarbonate for casings, screens, and other components of smartphones, laptops, and other electronic devices.

The construction industry is showing increased interest in sustainable building materials, including eco-friendly alternatives to polycarbonate sheets used in roofing, skylights, and glazing applications. The demand is driven by green building certifications and the desire to reduce the carbon footprint of construction projects.

Market research indicates that the global bioplastics market, which includes many potential polycarbonate alternatives, is expected to grow significantly in the coming years. This growth is fueled by both consumer demand and regulatory pressures, with many countries implementing policies to promote the use of sustainable materials and reduce plastic waste.

Consumer awareness of environmental issues has led to a significant shift in purchasing behavior. Many consumers now actively seek products made from sustainable materials, including eco-friendly plastics. This change in consumer preferences has prompted manufacturers across various industries to explore and adopt more environmentally friendly alternatives to traditional plastics like polycarbonate.

The automotive industry has emerged as a key driver in the demand for sustainable polycarbonate alternatives. With the push for lighter, more fuel-efficient vehicles, automakers are increasingly looking for materials that can reduce vehicle weight while maintaining safety standards. Eco-friendly plastics that can match or exceed the performance characteristics of polycarbonate are in high demand for applications such as headlamp lenses, interior components, and body panels.

The packaging industry is another significant market for sustainable plastic alternatives. As governments worldwide implement regulations to reduce single-use plastics, there is a growing need for biodegradable or easily recyclable materials that can replace polycarbonate in food packaging, beverage bottles, and other consumer goods packaging.

The electronics sector also presents a substantial market opportunity for eco-friendly plastics. With the rapid turnover of electronic devices and the resulting e-waste problem, manufacturers are under pressure to use more sustainable materials in their products. This includes finding alternatives to polycarbonate for casings, screens, and other components of smartphones, laptops, and other electronic devices.

The construction industry is showing increased interest in sustainable building materials, including eco-friendly alternatives to polycarbonate sheets used in roofing, skylights, and glazing applications. The demand is driven by green building certifications and the desire to reduce the carbon footprint of construction projects.

Market research indicates that the global bioplastics market, which includes many potential polycarbonate alternatives, is expected to grow significantly in the coming years. This growth is fueled by both consumer demand and regulatory pressures, with many countries implementing policies to promote the use of sustainable materials and reduce plastic waste.

Current Challenges in Sustainable PC Development

The development of sustainable polycarbonate (PC) alternatives faces several significant challenges that hinder widespread adoption and commercialization. One of the primary obstacles is the difficulty in achieving comparable mechanical properties to traditional polycarbonates. Sustainable alternatives often struggle to match the high impact strength, heat resistance, and optical clarity that make polycarbonates so versatile and widely used in various industries.

Another major challenge lies in the cost-effectiveness of sustainable PC alternatives. The production processes for these materials are often more complex and expensive, making them less economically viable for large-scale manufacturing. This cost disparity creates a significant barrier to market entry and adoption, particularly in price-sensitive industries.

The limited availability of sustainable raw materials poses another hurdle. Many bio-based or recycled alternatives rely on specific feedstocks that may not be readily available in sufficient quantities to meet industrial demands. This scarcity can lead to supply chain instabilities and hinder the consistent production of sustainable PC alternatives.

Ensuring the long-term durability and performance of sustainable PC alternatives under various environmental conditions remains a challenge. These materials must withstand exposure to UV radiation, temperature fluctuations, and chemical interactions without significant degradation or loss of properties over time. Achieving this level of stability while maintaining sustainability is a complex balancing act.

Regulatory compliance and certification processes present additional obstacles. Sustainable PC alternatives must meet stringent safety and performance standards across different industries and geographical regions. The time and resources required for testing and approval can significantly delay market introduction and increase development costs.

The recyclability and end-of-life management of sustainable PC alternatives also pose challenges. While these materials aim to be more environmentally friendly, ensuring they can be effectively recycled or biodegraded without creating new environmental issues is crucial. Developing appropriate recycling infrastructure and processes for these novel materials is an ongoing challenge.

Lastly, overcoming market inertia and consumer skepticism towards new materials is a significant hurdle. Industries and consumers accustomed to traditional polycarbonates may be hesitant to adopt alternatives, particularly if they perceive any compromise in performance or reliability. Educating stakeholders and demonstrating the long-term benefits of sustainable alternatives is essential for market acceptance.

Another major challenge lies in the cost-effectiveness of sustainable PC alternatives. The production processes for these materials are often more complex and expensive, making them less economically viable for large-scale manufacturing. This cost disparity creates a significant barrier to market entry and adoption, particularly in price-sensitive industries.

The limited availability of sustainable raw materials poses another hurdle. Many bio-based or recycled alternatives rely on specific feedstocks that may not be readily available in sufficient quantities to meet industrial demands. This scarcity can lead to supply chain instabilities and hinder the consistent production of sustainable PC alternatives.

Ensuring the long-term durability and performance of sustainable PC alternatives under various environmental conditions remains a challenge. These materials must withstand exposure to UV radiation, temperature fluctuations, and chemical interactions without significant degradation or loss of properties over time. Achieving this level of stability while maintaining sustainability is a complex balancing act.

Regulatory compliance and certification processes present additional obstacles. Sustainable PC alternatives must meet stringent safety and performance standards across different industries and geographical regions. The time and resources required for testing and approval can significantly delay market introduction and increase development costs.

The recyclability and end-of-life management of sustainable PC alternatives also pose challenges. While these materials aim to be more environmentally friendly, ensuring they can be effectively recycled or biodegraded without creating new environmental issues is crucial. Developing appropriate recycling infrastructure and processes for these novel materials is an ongoing challenge.

Lastly, overcoming market inertia and consumer skepticism towards new materials is a significant hurdle. Industries and consumers accustomed to traditional polycarbonates may be hesitant to adopt alternatives, particularly if they perceive any compromise in performance or reliability. Educating stakeholders and demonstrating the long-term benefits of sustainable alternatives is essential for market acceptance.

Existing Sustainable PC Alternative Solutions

01 Bio-based alternatives to polycarbonate

Sustainable alternatives to polycarbonate are being developed using bio-based materials. These include polymers derived from renewable resources such as plant-based feedstocks. These materials aim to reduce environmental impact while maintaining similar properties to traditional polycarbonates.- Bio-based alternatives to polycarbonate: Sustainable alternatives to polycarbonate are being developed using bio-based materials. These include polymers derived from renewable resources such as plant-based feedstocks. These materials aim to reduce environmental impact while maintaining similar properties to traditional polycarbonates.

- Recycled and recyclable polycarbonate substitutes: Efforts are being made to create polycarbonate alternatives that are either made from recycled materials or are easily recyclable at the end of their life cycle. This approach aims to reduce waste and promote a circular economy in plastic production and use.

- Composite materials as sustainable alternatives: Composite materials combining different sustainable components are being explored as alternatives to polycarbonate. These may include natural fibers or other eco-friendly reinforcements to enhance performance while maintaining sustainability.

- Energy-efficient production of polycarbonate alternatives: Research is focused on developing production processes for polycarbonate alternatives that consume less energy and resources. This includes optimizing manufacturing techniques and exploring new synthesis methods that are more environmentally friendly.

- Biodegradable substitutes for polycarbonate: Development of biodegradable materials that can replace polycarbonate in certain applications is ongoing. These materials are designed to break down naturally in the environment, reducing long-term plastic pollution while still providing necessary performance characteristics.

02 Recycling and circular economy approaches

Efforts are being made to improve the recyclability of polycarbonate alternatives and implement circular economy principles. This includes developing materials that are easier to recycle, establishing efficient recycling processes, and creating closed-loop systems for material reuse.Expand Specific Solutions03 Energy-efficient production methods

Research is focused on developing energy-efficient production methods for polycarbonate alternatives. This includes optimizing manufacturing processes, reducing energy consumption, and minimizing waste generation to enhance the overall sustainability of these materials.Expand Specific Solutions04 Improved durability and longevity

Sustainable polycarbonate alternatives are being designed with improved durability and longevity. These materials aim to extend product lifespans, reduce the need for frequent replacements, and minimize overall resource consumption and waste generation.Expand Specific Solutions05 Integration of sustainable additives

Research is exploring the integration of sustainable additives into polycarbonate alternatives. These additives aim to enhance material properties, improve performance, and increase overall sustainability without compromising environmental friendliness.Expand Specific Solutions

Key Players in Sustainable Plastics Industry

The development of sustainable polycarbonate alternatives is currently in a transitional phase, with the market showing significant growth potential. The global market for bio-based and biodegradable plastics is expanding rapidly, driven by increasing environmental concerns and regulatory pressures. Companies like Toray Industries, Novomer, and SK Innovation are at the forefront of this technological shift, investing heavily in research and development of sustainable materials. The technology is maturing, with several companies moving from laboratory-scale production to commercial applications. However, challenges remain in scaling up production and achieving cost-competitiveness with traditional polycarbonates. Collaborations between industry leaders and research institutions, such as the École Polytechnique Fédérale de Lausanne and the University of California, are accelerating innovation in this field.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a bio-based polycarbonate alternative using isosorbide, a plant-derived monomer. Their process involves polymerizing isosorbide with other monomers to create a transparent, heat-resistant, and impact-resistant material. This bio-based polycarbonate exhibits properties comparable to traditional petroleum-based polycarbonates, with a glass transition temperature of around 150°C and high transparency[1]. Toray has also implemented a proprietary purification process for isosorbide to enhance the quality and consistency of the final product[2]. The company has successfully scaled up production and is now supplying this sustainable alternative to various industries, including automotive and electronics[3].

Strengths: Renewable sourcing, comparable performance to traditional polycarbonates, established production scale. Weaknesses: Potentially higher production costs, limited long-term performance data compared to traditional polycarbonates.

Novomer, Inc.

Technical Solution: Novomer has pioneered a CO2-based polycarbonate alternative called Converge® polyols. This innovative approach uses waste CO2 as a raw material, combining it with epoxides through a proprietary catalyst system to produce aliphatic polycarbonates. The resulting material contains up to 50% CO2 by weight, significantly reducing the carbon footprint[4]. Novomer's process operates at relatively low temperatures and pressures, making it energy-efficient. The Converge® polyols exhibit excellent chemical resistance, low viscosity, and can be tailored for various applications such as coatings, adhesives, and foams[5]. Recent advancements have allowed Novomer to produce higher molecular weight polycarbonates suitable for more demanding applications[6].

Strengths: Utilizes waste CO2, reducing greenhouse gas emissions; versatile product range. Weaknesses: May not fully replicate all properties of traditional polycarbonates; limited to certain application areas.

Innovative Approaches in Bio-based PC Research

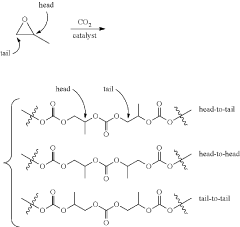

Eco-friendly synthesis of biodegradable polycarbonate from co2 and epoxide

PatentPendingIN202321017490A

Innovation

- The synthesis of biodegradable polycarbonate from carbon dioxide (CO2) and epoxide using a metal-organic framework (MOF) catalyst, which initiates a polymerization reaction that produces polycarbonates that can break down naturally, reducing waste and pollution.

Sustainable polymer compositions and methods

PatentActiveUS20200062900A1

Innovation

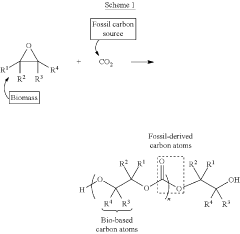

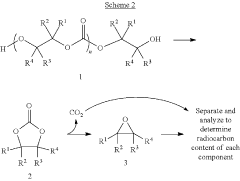

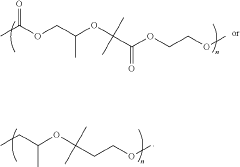

- The development of polymer compositions that incorporate both biobased and fossil-derived carbon atoms into polymer chains through epoxide-CO2 copolymerization, allowing for the predictable location of these atoms and the use of radiocarbon content analysis to determine the provenance of carbon atoms within the polymer chains.

Environmental Impact Assessment

The development of sustainable polycarbonate alternatives necessitates a comprehensive environmental impact assessment to ensure that proposed solutions genuinely contribute to reducing ecological footprints. This assessment begins with a life cycle analysis (LCA) of current polycarbonate production and usage, establishing a baseline for comparison. The LCA examines resource extraction, manufacturing processes, transportation, use phase, and end-of-life disposal, quantifying energy consumption, greenhouse gas emissions, water usage, and waste generation at each stage.

Potential alternative materials are then subjected to similar LCA scrutiny, with particular attention paid to biodegradability, recyclability, and overall carbon footprint. This analysis extends beyond the material itself to include the environmental implications of scaling up production, considering factors such as land use changes, impacts on local ecosystems, and potential for pollution during manufacturing.

The assessment also evaluates the durability and longevity of alternative materials compared to traditional polycarbonates. While a material may have a lower initial environmental impact, if it requires more frequent replacement, the cumulative effect could negate any benefits. Therefore, the analysis must account for the full service life of products made from these alternatives.

Water pollution potential is another critical aspect of the environmental impact assessment. This includes examining the leaching of chemicals or microplastics into aquatic environments during production, use, and disposal phases. The toxicity of any byproducts or degradation products must be thoroughly investigated to prevent unintended consequences on ecosystems and human health.

Energy efficiency in the production and processing of alternative materials is a key consideration. The assessment compares the energy requirements of new manufacturing processes with those of traditional polycarbonate production, factoring in the potential for using renewable energy sources to further reduce environmental impact.

The end-of-life scenario for these alternatives is particularly important. The assessment explores the feasibility of recycling or composting the materials, the energy recovery potential if incinerated, and the environmental consequences of landfill disposal. This includes an analysis of decomposition rates and the nature of any breakdown products.

Finally, the environmental impact assessment considers the broader implications of transitioning to sustainable polycarbonate alternatives. This includes evaluating the potential for these materials to displace other environmentally harmful substances, their role in promoting circular economy principles, and their capacity to drive innovation in green chemistry and sustainable manufacturing practices.

Potential alternative materials are then subjected to similar LCA scrutiny, with particular attention paid to biodegradability, recyclability, and overall carbon footprint. This analysis extends beyond the material itself to include the environmental implications of scaling up production, considering factors such as land use changes, impacts on local ecosystems, and potential for pollution during manufacturing.

The assessment also evaluates the durability and longevity of alternative materials compared to traditional polycarbonates. While a material may have a lower initial environmental impact, if it requires more frequent replacement, the cumulative effect could negate any benefits. Therefore, the analysis must account for the full service life of products made from these alternatives.

Water pollution potential is another critical aspect of the environmental impact assessment. This includes examining the leaching of chemicals or microplastics into aquatic environments during production, use, and disposal phases. The toxicity of any byproducts or degradation products must be thoroughly investigated to prevent unintended consequences on ecosystems and human health.

Energy efficiency in the production and processing of alternative materials is a key consideration. The assessment compares the energy requirements of new manufacturing processes with those of traditional polycarbonate production, factoring in the potential for using renewable energy sources to further reduce environmental impact.

The end-of-life scenario for these alternatives is particularly important. The assessment explores the feasibility of recycling or composting the materials, the energy recovery potential if incinerated, and the environmental consequences of landfill disposal. This includes an analysis of decomposition rates and the nature of any breakdown products.

Finally, the environmental impact assessment considers the broader implications of transitioning to sustainable polycarbonate alternatives. This includes evaluating the potential for these materials to displace other environmentally harmful substances, their role in promoting circular economy principles, and their capacity to drive innovation in green chemistry and sustainable manufacturing practices.

Regulatory Framework for Sustainable Plastics

The regulatory framework for sustainable plastics plays a crucial role in shaping the development and adoption of sustainable polycarbonate alternatives. As governments and international organizations increasingly recognize the environmental impact of traditional plastics, they are implementing stricter regulations and guidelines to promote sustainability in the plastics industry.

One of the key aspects of this regulatory framework is the emphasis on lifecycle assessment (LCA) for new materials. Manufacturers developing sustainable polycarbonate alternatives are required to conduct comprehensive LCAs to evaluate the environmental impact of their products from production to disposal. This includes assessing factors such as carbon footprint, water usage, and potential for biodegradation or recycling.

Many countries have introduced or are in the process of introducing extended producer responsibility (EPR) schemes for plastics. These regulations hold manufacturers accountable for the entire lifecycle of their products, including collection and recycling after use. This has significant implications for the development of sustainable polycarbonate alternatives, as it incentivizes the creation of materials that are easier to recycle or biodegrade.

The European Union's Circular Economy Action Plan is a prime example of a comprehensive regulatory framework that impacts the development of sustainable plastics. It sets targets for plastic recycling and aims to make all plastic packaging recyclable or reusable by 2030. This has spurred innovation in the field of sustainable polycarbonate alternatives, pushing manufacturers to develop materials that align with these circular economy principles.

In addition to recycling and circularity, regulations are also addressing the chemical composition of plastics. Many jurisdictions have banned or restricted the use of certain additives and chemicals in plastics, particularly those known to be harmful to human health or the environment. This has led to increased research into safer, more sustainable additives for polycarbonate alternatives.

The regulatory landscape also includes standards and certifications for sustainable plastics. Organizations such as ASTM International and the International Organization for Standardization (ISO) have developed standards for biobased and biodegradable plastics. These standards provide a framework for assessing the sustainability claims of new materials and help ensure consistency across the industry.

Furthermore, regulations are evolving to address the issue of microplastics. As awareness of the environmental impact of microplastic pollution grows, some jurisdictions are implementing regulations to limit the release of microplastics from products. This is driving research into polycarbonate alternatives that do not contribute to microplastic pollution, either through improved durability or biodegradability.

One of the key aspects of this regulatory framework is the emphasis on lifecycle assessment (LCA) for new materials. Manufacturers developing sustainable polycarbonate alternatives are required to conduct comprehensive LCAs to evaluate the environmental impact of their products from production to disposal. This includes assessing factors such as carbon footprint, water usage, and potential for biodegradation or recycling.

Many countries have introduced or are in the process of introducing extended producer responsibility (EPR) schemes for plastics. These regulations hold manufacturers accountable for the entire lifecycle of their products, including collection and recycling after use. This has significant implications for the development of sustainable polycarbonate alternatives, as it incentivizes the creation of materials that are easier to recycle or biodegrade.

The European Union's Circular Economy Action Plan is a prime example of a comprehensive regulatory framework that impacts the development of sustainable plastics. It sets targets for plastic recycling and aims to make all plastic packaging recyclable or reusable by 2030. This has spurred innovation in the field of sustainable polycarbonate alternatives, pushing manufacturers to develop materials that align with these circular economy principles.

In addition to recycling and circularity, regulations are also addressing the chemical composition of plastics. Many jurisdictions have banned or restricted the use of certain additives and chemicals in plastics, particularly those known to be harmful to human health or the environment. This has led to increased research into safer, more sustainable additives for polycarbonate alternatives.

The regulatory landscape also includes standards and certifications for sustainable plastics. Organizations such as ASTM International and the International Organization for Standardization (ISO) have developed standards for biobased and biodegradable plastics. These standards provide a framework for assessing the sustainability claims of new materials and help ensure consistency across the industry.

Furthermore, regulations are evolving to address the issue of microplastics. As awareness of the environmental impact of microplastic pollution grows, some jurisdictions are implementing regulations to limit the release of microplastics from products. This is driving research into polycarbonate alternatives that do not contribute to microplastic pollution, either through improved durability or biodegradability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!