How to Enhance Electrical Properties of Polycarbonate?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Enhancement Goals

The enhancement of electrical properties in polycarbonate (PC) has become a critical focus in materials science and engineering. This pursuit aims to expand the application scope of PC beyond its traditional uses, particularly in the electronics and automotive industries. The primary goals for enhancing PC's electrical properties include improving its electrical conductivity, reducing static charge accumulation, and increasing its dielectric strength.

One of the key objectives is to develop PC composites with enhanced electrical conductivity. This involves incorporating conductive fillers such as carbon nanotubes, graphene, or metallic particles into the PC matrix. The challenge lies in achieving a uniform dispersion of these fillers without compromising the mechanical properties or optical clarity of the polymer. Researchers are exploring various methods, including melt blending, in-situ polymerization, and surface modification of fillers, to optimize the conductive network formation within the PC matrix.

Another important goal is to enhance the electrostatic dissipation (ESD) properties of PC. This is particularly crucial for applications in electronics packaging and components where static charge buildup can lead to device failure or safety hazards. Strategies to improve ESD properties include the incorporation of inherently dissipative polymers or antistatic additives into PC. The aim is to achieve a surface resistivity in the range of 10^6 to 10^9 ohms/square, which is considered optimal for ESD protection.

Increasing the dielectric strength of PC is another significant objective. This property is essential for applications in high-voltage insulation and capacitors. Researchers are investigating various approaches, such as the addition of nanofillers with high dielectric constants, surface modification of PC to enhance its interfacial properties, and the development of multi-layered PC composites. The goal is to achieve a dielectric strength exceeding 30 kV/mm while maintaining other desirable properties of PC.

Furthermore, there is a growing interest in developing PC with tunable electrical properties. This involves creating smart materials that can change their electrical characteristics in response to external stimuli such as temperature, light, or electric field. Such materials could find applications in sensors, actuators, and adaptive electronic components.

Lastly, enhancing the electromagnetic interference (EMI) shielding effectiveness of PC is becoming increasingly important with the proliferation of electronic devices. The goal is to develop PC composites that can effectively attenuate electromagnetic waves across a wide frequency range, typically aiming for shielding effectiveness of 20-30 dB or higher.

These enhancement goals are driven by the ever-evolving demands of industries such as electronics, automotive, aerospace, and healthcare. Achieving these objectives will not only expand the application range of PC but also contribute to the development of next-generation materials with advanced functionalities.

One of the key objectives is to develop PC composites with enhanced electrical conductivity. This involves incorporating conductive fillers such as carbon nanotubes, graphene, or metallic particles into the PC matrix. The challenge lies in achieving a uniform dispersion of these fillers without compromising the mechanical properties or optical clarity of the polymer. Researchers are exploring various methods, including melt blending, in-situ polymerization, and surface modification of fillers, to optimize the conductive network formation within the PC matrix.

Another important goal is to enhance the electrostatic dissipation (ESD) properties of PC. This is particularly crucial for applications in electronics packaging and components where static charge buildup can lead to device failure or safety hazards. Strategies to improve ESD properties include the incorporation of inherently dissipative polymers or antistatic additives into PC. The aim is to achieve a surface resistivity in the range of 10^6 to 10^9 ohms/square, which is considered optimal for ESD protection.

Increasing the dielectric strength of PC is another significant objective. This property is essential for applications in high-voltage insulation and capacitors. Researchers are investigating various approaches, such as the addition of nanofillers with high dielectric constants, surface modification of PC to enhance its interfacial properties, and the development of multi-layered PC composites. The goal is to achieve a dielectric strength exceeding 30 kV/mm while maintaining other desirable properties of PC.

Furthermore, there is a growing interest in developing PC with tunable electrical properties. This involves creating smart materials that can change their electrical characteristics in response to external stimuli such as temperature, light, or electric field. Such materials could find applications in sensors, actuators, and adaptive electronic components.

Lastly, enhancing the electromagnetic interference (EMI) shielding effectiveness of PC is becoming increasingly important with the proliferation of electronic devices. The goal is to develop PC composites that can effectively attenuate electromagnetic waves across a wide frequency range, typically aiming for shielding effectiveness of 20-30 dB or higher.

These enhancement goals are driven by the ever-evolving demands of industries such as electronics, automotive, aerospace, and healthcare. Achieving these objectives will not only expand the application range of PC but also contribute to the development of next-generation materials with advanced functionalities.

Market Demand Analysis

The market demand for enhanced electrical properties in polycarbonate has been steadily growing across various industries. This demand is primarily driven by the increasing need for lightweight, durable, and electrically conductive materials in electronics, automotive, aerospace, and consumer goods sectors.

In the electronics industry, there is a significant push for miniaturization and improved performance of devices. Enhanced electrical properties in polycarbonate can lead to better electromagnetic interference (EMI) shielding, electrostatic discharge (ESD) protection, and improved thermal management in electronic components. This is particularly crucial for the development of next-generation smartphones, tablets, and wearable devices.

The automotive sector is another major driver of demand for electrically enhanced polycarbonate. With the rapid growth of electric vehicles (EVs) and advanced driver assistance systems (ADAS), there is an increasing need for lightweight materials that can provide electrical conductivity and EMI shielding. Polycarbonate with improved electrical properties can be used in various automotive applications, including battery casings, sensor housings, and interior components.

In the aerospace industry, the demand for lightweight materials with enhanced electrical properties is driven by the need to reduce fuel consumption and improve overall aircraft performance. Polycarbonate with improved electrical conductivity can be used in aircraft interiors, avionics housings, and other components where weight reduction and electrical functionality are critical.

The consumer goods sector is also showing increased interest in electrically enhanced polycarbonate. This demand is fueled by the growing market for smart home devices, IoT products, and wearable technology. These applications require materials that can provide both structural integrity and electrical functionality.

Market analysts predict that the global demand for electrically enhanced polycarbonate will continue to grow at a compound annual growth rate (CAGR) of 6-8% over the next five years. This growth is expected to be particularly strong in emerging economies, where rapid industrialization and increasing consumer electronics adoption are driving demand.

However, the market also faces challenges. The high cost of developing and manufacturing electrically enhanced polycarbonate compared to traditional materials remains a significant barrier to widespread adoption. Additionally, there is growing competition from alternative materials such as conductive polymers and carbon-fiber composites.

Despite these challenges, the overall market outlook for electrically enhanced polycarbonate remains positive. The material's unique combination of mechanical strength, optical clarity, and potential for improved electrical properties makes it an attractive option for many high-value applications. As research and development efforts continue to improve the electrical properties of polycarbonate while maintaining its other desirable characteristics, it is expected that new market opportunities will emerge, further driving demand for this innovative material.

In the electronics industry, there is a significant push for miniaturization and improved performance of devices. Enhanced electrical properties in polycarbonate can lead to better electromagnetic interference (EMI) shielding, electrostatic discharge (ESD) protection, and improved thermal management in electronic components. This is particularly crucial for the development of next-generation smartphones, tablets, and wearable devices.

The automotive sector is another major driver of demand for electrically enhanced polycarbonate. With the rapid growth of electric vehicles (EVs) and advanced driver assistance systems (ADAS), there is an increasing need for lightweight materials that can provide electrical conductivity and EMI shielding. Polycarbonate with improved electrical properties can be used in various automotive applications, including battery casings, sensor housings, and interior components.

In the aerospace industry, the demand for lightweight materials with enhanced electrical properties is driven by the need to reduce fuel consumption and improve overall aircraft performance. Polycarbonate with improved electrical conductivity can be used in aircraft interiors, avionics housings, and other components where weight reduction and electrical functionality are critical.

The consumer goods sector is also showing increased interest in electrically enhanced polycarbonate. This demand is fueled by the growing market for smart home devices, IoT products, and wearable technology. These applications require materials that can provide both structural integrity and electrical functionality.

Market analysts predict that the global demand for electrically enhanced polycarbonate will continue to grow at a compound annual growth rate (CAGR) of 6-8% over the next five years. This growth is expected to be particularly strong in emerging economies, where rapid industrialization and increasing consumer electronics adoption are driving demand.

However, the market also faces challenges. The high cost of developing and manufacturing electrically enhanced polycarbonate compared to traditional materials remains a significant barrier to widespread adoption. Additionally, there is growing competition from alternative materials such as conductive polymers and carbon-fiber composites.

Despite these challenges, the overall market outlook for electrically enhanced polycarbonate remains positive. The material's unique combination of mechanical strength, optical clarity, and potential for improved electrical properties makes it an attractive option for many high-value applications. As research and development efforts continue to improve the electrical properties of polycarbonate while maintaining its other desirable characteristics, it is expected that new market opportunities will emerge, further driving demand for this innovative material.

Current Limitations

Polycarbonate, a widely used engineering thermoplastic, faces several limitations in its electrical properties that hinder its broader application in electronic and electrical industries. One of the primary constraints is its relatively low dielectric constant, typically ranging from 2.8 to 3.0 at 1 MHz. This characteristic limits its effectiveness in applications requiring high capacitance or energy storage capabilities.

Another significant limitation is polycarbonate's moderate electrical resistivity, which falls in the range of 10^14 to 10^16 ohm-cm. While this resistivity is sufficient for many insulating applications, it falls short in scenarios demanding ultra-high insulation performance or in environments with extreme electrical stress.

The material's dielectric strength, although reasonably good at 15-67 kV/mm, still lags behind some high-performance polymers. This limitation becomes particularly apparent in high-voltage applications or in miniaturized electronic components where electrical breakdown resistance is crucial.

Polycarbonate also exhibits limitations in its frequency-dependent electrical properties. As the frequency of the applied electric field increases, the dielectric loss factor tends to rise, leading to increased energy dissipation and potential heating issues in high-frequency applications.

The temperature dependence of polycarbonate's electrical properties presents another challenge. At elevated temperatures, the material's electrical resistivity and dielectric strength tend to decrease, potentially compromising its performance in high-temperature electronic applications or in devices that generate significant heat during operation.

Polycarbonate's susceptibility to environmental factors such as humidity and chemical exposure can also affect its electrical properties over time. Moisture absorption, in particular, can lead to a decrease in surface resistivity and dielectric strength, potentially compromising the material's long-term electrical performance and reliability.

Lastly, the material's inherent inability to dissipate static charges effectively poses challenges in applications where electrostatic discharge (ESD) protection is critical. This limitation can lead to the accumulation of static charges on polycarbonate surfaces, potentially damaging sensitive electronic components or causing operational issues in certain devices.

Addressing these limitations is crucial for expanding polycarbonate's utility in advanced electrical and electronic applications, necessitating innovative approaches to enhance its electrical properties while maintaining its desirable mechanical and optical characteristics.

Another significant limitation is polycarbonate's moderate electrical resistivity, which falls in the range of 10^14 to 10^16 ohm-cm. While this resistivity is sufficient for many insulating applications, it falls short in scenarios demanding ultra-high insulation performance or in environments with extreme electrical stress.

The material's dielectric strength, although reasonably good at 15-67 kV/mm, still lags behind some high-performance polymers. This limitation becomes particularly apparent in high-voltage applications or in miniaturized electronic components where electrical breakdown resistance is crucial.

Polycarbonate also exhibits limitations in its frequency-dependent electrical properties. As the frequency of the applied electric field increases, the dielectric loss factor tends to rise, leading to increased energy dissipation and potential heating issues in high-frequency applications.

The temperature dependence of polycarbonate's electrical properties presents another challenge. At elevated temperatures, the material's electrical resistivity and dielectric strength tend to decrease, potentially compromising its performance in high-temperature electronic applications or in devices that generate significant heat during operation.

Polycarbonate's susceptibility to environmental factors such as humidity and chemical exposure can also affect its electrical properties over time. Moisture absorption, in particular, can lead to a decrease in surface resistivity and dielectric strength, potentially compromising the material's long-term electrical performance and reliability.

Lastly, the material's inherent inability to dissipate static charges effectively poses challenges in applications where electrostatic discharge (ESD) protection is critical. This limitation can lead to the accumulation of static charges on polycarbonate surfaces, potentially damaging sensitive electronic components or causing operational issues in certain devices.

Addressing these limitations is crucial for expanding polycarbonate's utility in advanced electrical and electronic applications, necessitating innovative approaches to enhance its electrical properties while maintaining its desirable mechanical and optical characteristics.

Existing Enhancement Methods

01 Electrical conductivity enhancement

Polycarbonate compositions can be modified to enhance electrical conductivity. This is achieved by incorporating conductive additives or fillers, such as carbon nanotubes, graphene, or metal particles. These additives create conductive pathways within the polymer matrix, significantly improving the material's electrical properties while maintaining its mechanical strength and thermal stability.- Electrical conductivity enhancement: Various methods are employed to enhance the electrical conductivity of polycarbonate materials. These include incorporating conductive fillers, such as carbon nanotubes or metal particles, or applying conductive coatings. The improved conductivity makes polycarbonate suitable for applications requiring electrostatic discharge protection or electromagnetic shielding.

- Dielectric properties optimization: Techniques are developed to optimize the dielectric properties of polycarbonate materials. This involves modifying the polymer structure or adding specific additives to control the dielectric constant and loss tangent. These improvements make polycarbonate suitable for high-frequency electronic applications and insulation purposes.

- Thermal management for electrical applications: Strategies are implemented to enhance the thermal management capabilities of polycarbonate in electrical applications. This includes incorporating thermally conductive fillers or creating composite structures to improve heat dissipation. These modifications allow polycarbonate to be used in electrical components that generate significant heat during operation.

- Flame retardancy for electrical safety: Methods are developed to improve the flame retardancy of polycarbonate materials used in electrical applications. This involves incorporating flame retardant additives or modifying the polymer structure to enhance fire resistance. These improvements ensure that polycarbonate-based electrical components meet safety standards and regulations.

- Electrical property measurement and characterization: Techniques and devices are created for accurately measuring and characterizing the electrical properties of polycarbonate materials. These include methods for determining resistivity, dielectric strength, and other relevant electrical parameters. Such characterization is crucial for quality control and ensuring the suitability of polycarbonate for specific electrical applications.

02 Dielectric properties improvement

The dielectric properties of polycarbonate can be improved through various methods. This includes the addition of specific additives or the modification of the polymer structure. Enhanced dielectric properties result in better insulation characteristics, making the material suitable for high-frequency applications and electronic components where low dielectric loss is crucial.Expand Specific Solutions03 Electrostatic discharge (ESD) protection

Polycarbonate formulations can be developed to provide effective electrostatic discharge protection. This is typically achieved by incorporating antistatic agents or conductive fillers that allow for controlled dissipation of static charges. Such formulations are particularly useful in electronics packaging and components where ESD protection is critical.Expand Specific Solutions04 Flame retardancy with maintained electrical properties

Flame retardant additives can be incorporated into polycarbonate while maintaining or enhancing its electrical properties. This combination of flame retardancy and electrical performance is crucial for applications in electronics and electrical equipment where both safety and functionality are paramount.Expand Specific Solutions05 Tailoring electrical properties for specific applications

Polycarbonate's electrical properties can be tailored for specific applications through careful formulation and processing techniques. This includes adjusting the molecular weight, incorporating specific additives, or blending with other polymers. Such customization allows for the development of polycarbonate materials with optimized electrical characteristics for diverse applications, ranging from automotive components to medical devices.Expand Specific Solutions

Key Industry Players

The market for enhancing electrical properties of polycarbonate is in a growth phase, driven by increasing demand in electronics, automotive, and aerospace industries. The global market size is estimated to be in the billions, with steady annual growth projected. Technologically, the field is moderately mature but continues to evolve with ongoing research and development. Key players like Covestro, SABIC, and Mitsubishi Engineering-Plastics are leading innovation, focusing on advanced formulations and composite materials. Emerging companies such as Kingfa Sci. & Tech. and Wanhua Chemical are also making significant strides, particularly in Asia. The competitive landscape is characterized by a mix of established chemical giants and specialized materials firms, with increasing emphasis on sustainable and high-performance solutions.

Covestro Deutschland AG

Technical Solution: Covestro has developed a novel approach to enhance the electrical properties of polycarbonate through the incorporation of conductive fillers and nanoparticles. Their method involves dispersing carbon nanotubes (CNTs) or graphene nanoplatelets uniformly throughout the polycarbonate matrix[1]. This results in a significant improvement in electrical conductivity while maintaining the polymer's mechanical properties. The company has also explored the use of surface modification techniques to improve the compatibility between the conductive fillers and the polycarbonate matrix, leading to better dispersion and enhanced electrical performance[2]. Additionally, Covestro has developed a proprietary process for creating polycarbonate composites with tailored electrical properties by controlling the orientation of conductive fillers during the molding process[3].

Strengths: Excellent balance between electrical conductivity and mechanical properties; Versatile applications in electronics and automotive industries. Weaknesses: Potential increase in production costs; Challenges in achieving uniform dispersion of conductive fillers at large scales.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a range of electrically enhanced polycarbonate materials under their LEXAN™ product line. Their approach involves the integration of conductive additives, such as carbon fibers and metal fibers, into the polycarbonate matrix[4]. SABIC's technology focuses on achieving a balance between electrical conductivity and mechanical properties, allowing for customization based on specific application requirements. They have also introduced a novel process for creating gradient conductivity in polycarbonate parts, enabling the production of components with varying electrical properties in different regions[5]. Furthermore, SABIC has developed a proprietary surface treatment technology that enhances the adhesion of conductive coatings to polycarbonate substrates, improving overall electrical performance and durability[6].

Strengths: Wide range of customizable solutions; Ability to create parts with gradient conductivity. Weaknesses: Potential trade-offs between electrical properties and optical clarity; Higher cost compared to standard polycarbonate.

Core Innovations Review

Electrically conductive polycarbonate

PatentInactiveEP0032379A3

Innovation

- Aromatic polycarbonate combined with carbon or graphite fibers having a length-to-cross-section ratio of at least 10:1, used in amounts of 0.01 to 3% by weight, to enhance electrical conductivity while maintaining or improving mechanical properties.

Polycarbonate composition with improved electrical properties containing carbon nanotubes

PatentInactiveEP2853560A1

Innovation

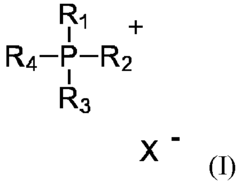

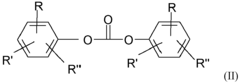

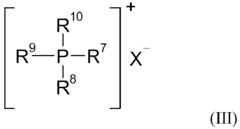

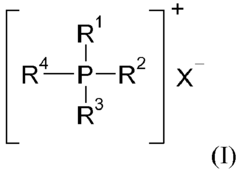

- A composition combining aromatic polycarbonate or copolycarbonate with 0.05 to 10% by weight of a phosphorus-containing ionic liquid and 0.05 to 10% by weight of carbon nanotubes, maintaining high melt stability for injection molding.

Environmental Impact

Enhancing the electrical properties of polycarbonate has significant environmental implications that must be carefully considered. The process of modifying polycarbonate to improve its electrical characteristics often involves the addition of conductive fillers or surface treatments, which can impact the material's overall environmental footprint.

One of the primary environmental concerns is the potential increase in energy consumption during the manufacturing process. The incorporation of conductive additives or the application of surface treatments may require additional processing steps, leading to higher energy demands. This increased energy usage contributes to greenhouse gas emissions and resource depletion, potentially offsetting some of the environmental benefits associated with improved electrical properties.

The choice of conductive additives also plays a crucial role in the environmental impact. Some additives, such as carbon nanotubes or metallic particles, may pose risks to ecosystems if released into the environment. Proper containment and disposal methods must be implemented to prevent these materials from entering water systems or soil, where they could potentially harm wildlife or accumulate in food chains.

Furthermore, the enhanced electrical properties of polycarbonate may affect its recyclability. The presence of conductive additives or surface treatments can complicate the recycling process, potentially reducing the material's ability to be reused or repurposed. This could lead to increased waste generation and the need for specialized recycling facilities, which may not be widely available.

On the positive side, improving the electrical properties of polycarbonate can lead to more efficient and durable electronic components. This enhanced performance may result in longer-lasting products, reducing the frequency of replacements and ultimately decreasing electronic waste. Additionally, better electrical properties could enable the development of more energy-efficient devices, potentially offsetting the initial environmental costs of production through reduced energy consumption during the product's lifetime.

The use of bio-based or renewable additives to enhance electrical properties presents an opportunity to mitigate some environmental concerns. Research into sustainable conductive materials derived from natural sources could provide a more environmentally friendly alternative to traditional synthetic additives. This approach aligns with the growing trend towards circular economy principles and could help reduce the overall environmental impact of electrically enhanced polycarbonate.

Lastly, the potential for improved electrical properties to enable new applications in renewable energy technologies should not be overlooked. Enhanced polycarbonate materials could contribute to the development of more efficient solar panels, energy storage systems, or other clean energy solutions. In this context, the environmental benefits of these applications could potentially outweigh the impacts associated with the material's production and modification processes.

One of the primary environmental concerns is the potential increase in energy consumption during the manufacturing process. The incorporation of conductive additives or the application of surface treatments may require additional processing steps, leading to higher energy demands. This increased energy usage contributes to greenhouse gas emissions and resource depletion, potentially offsetting some of the environmental benefits associated with improved electrical properties.

The choice of conductive additives also plays a crucial role in the environmental impact. Some additives, such as carbon nanotubes or metallic particles, may pose risks to ecosystems if released into the environment. Proper containment and disposal methods must be implemented to prevent these materials from entering water systems or soil, where they could potentially harm wildlife or accumulate in food chains.

Furthermore, the enhanced electrical properties of polycarbonate may affect its recyclability. The presence of conductive additives or surface treatments can complicate the recycling process, potentially reducing the material's ability to be reused or repurposed. This could lead to increased waste generation and the need for specialized recycling facilities, which may not be widely available.

On the positive side, improving the electrical properties of polycarbonate can lead to more efficient and durable electronic components. This enhanced performance may result in longer-lasting products, reducing the frequency of replacements and ultimately decreasing electronic waste. Additionally, better electrical properties could enable the development of more energy-efficient devices, potentially offsetting the initial environmental costs of production through reduced energy consumption during the product's lifetime.

The use of bio-based or renewable additives to enhance electrical properties presents an opportunity to mitigate some environmental concerns. Research into sustainable conductive materials derived from natural sources could provide a more environmentally friendly alternative to traditional synthetic additives. This approach aligns with the growing trend towards circular economy principles and could help reduce the overall environmental impact of electrically enhanced polycarbonate.

Lastly, the potential for improved electrical properties to enable new applications in renewable energy technologies should not be overlooked. Enhanced polycarbonate materials could contribute to the development of more efficient solar panels, energy storage systems, or other clean energy solutions. In this context, the environmental benefits of these applications could potentially outweigh the impacts associated with the material's production and modification processes.

Cost-Benefit Analysis

Enhancing the electrical properties of polycarbonate involves a careful consideration of costs and benefits. The implementation of various techniques to improve conductivity, dielectric strength, and other electrical characteristics often comes with significant financial implications.

The primary cost factors in enhancing polycarbonate's electrical properties include research and development expenses, material costs for additives or fillers, and potential modifications to manufacturing processes. These costs can be substantial, especially when developing novel conductive composites or implementing advanced surface treatment techniques.

However, the benefits of improved electrical properties in polycarbonate can be considerable. Enhanced conductivity opens up new applications in electronics and automotive industries, potentially expanding market share and increasing revenue streams. Improved dielectric strength can lead to better insulation properties, making the material suitable for high-voltage applications and potentially reducing the need for additional insulating components in certain products.

From a manufacturing perspective, the cost-benefit analysis must consider the scalability of the chosen enhancement method. Some techniques, such as the incorporation of carbon nanotubes or graphene, may offer excellent electrical improvements but could be prohibitively expensive for large-scale production. On the other hand, more cost-effective methods like surface treatments or the use of less expensive conductive fillers might provide a better balance between performance enhancement and economic viability.

The long-term durability and stability of the enhanced polycarbonate must also be factored into the cost-benefit equation. If the electrical property improvements degrade over time or under certain environmental conditions, the initial benefits may be outweighed by increased maintenance or replacement costs for end-users.

Energy efficiency improvements resulting from enhanced electrical properties should be considered as well. Polycarbonate with better electrical characteristics may lead to more efficient electronic devices or electrical systems, potentially offering significant cost savings over the lifecycle of products incorporating the material.

Regulatory compliance and certification costs associated with introducing electrically enhanced polycarbonate products to the market must be accounted for. These expenses can be substantial but are often necessary to access certain industries or geographical markets.

Ultimately, the cost-benefit analysis for enhancing the electrical properties of polycarbonate must be conducted on a case-by-case basis, considering the specific application, target market, and available enhancement techniques. Companies must weigh the initial investment against potential long-term gains in market share, product performance, and customer satisfaction to determine the most economically viable approach to improving polycarbonate's electrical characteristics.

The primary cost factors in enhancing polycarbonate's electrical properties include research and development expenses, material costs for additives or fillers, and potential modifications to manufacturing processes. These costs can be substantial, especially when developing novel conductive composites or implementing advanced surface treatment techniques.

However, the benefits of improved electrical properties in polycarbonate can be considerable. Enhanced conductivity opens up new applications in electronics and automotive industries, potentially expanding market share and increasing revenue streams. Improved dielectric strength can lead to better insulation properties, making the material suitable for high-voltage applications and potentially reducing the need for additional insulating components in certain products.

From a manufacturing perspective, the cost-benefit analysis must consider the scalability of the chosen enhancement method. Some techniques, such as the incorporation of carbon nanotubes or graphene, may offer excellent electrical improvements but could be prohibitively expensive for large-scale production. On the other hand, more cost-effective methods like surface treatments or the use of less expensive conductive fillers might provide a better balance between performance enhancement and economic viability.

The long-term durability and stability of the enhanced polycarbonate must also be factored into the cost-benefit equation. If the electrical property improvements degrade over time or under certain environmental conditions, the initial benefits may be outweighed by increased maintenance or replacement costs for end-users.

Energy efficiency improvements resulting from enhanced electrical properties should be considered as well. Polycarbonate with better electrical characteristics may lead to more efficient electronic devices or electrical systems, potentially offering significant cost savings over the lifecycle of products incorporating the material.

Regulatory compliance and certification costs associated with introducing electrically enhanced polycarbonate products to the market must be accounted for. These expenses can be substantial but are often necessary to access certain industries or geographical markets.

Ultimately, the cost-benefit analysis for enhancing the electrical properties of polycarbonate must be conducted on a case-by-case basis, considering the specific application, target market, and available enhancement techniques. Companies must weigh the initial investment against potential long-term gains in market share, product performance, and customer satisfaction to determine the most economically viable approach to improving polycarbonate's electrical characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!