How to Improve Environmental Impact of Polycarbonate?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polycarbonate Sustainability Challenges and Objectives

Polycarbonate, a versatile thermoplastic polymer, has been widely used in various industries due to its exceptional properties. However, its environmental impact has become a growing concern in recent years. The primary objective of improving the environmental impact of polycarbonate is to address sustainability challenges while maintaining its desirable characteristics.

One of the main challenges in polycarbonate sustainability is its production process, which traditionally relies on bisphenol A (BPA) and phosgene. These chemicals have raised environmental and health concerns, prompting the need for alternative production methods. Researchers are exploring bio-based alternatives and greener synthesis routes to reduce the carbon footprint and potential toxicity associated with polycarbonate manufacturing.

Another significant challenge is the end-of-life management of polycarbonate products. While polycarbonate is technically recyclable, the recycling rates remain low due to various factors, including contamination, mixed plastic waste streams, and the lack of efficient recycling infrastructure. Improving the recyclability and establishing effective collection and sorting systems are crucial objectives in enhancing polycarbonate's environmental performance.

Energy consumption during production is also a key area of focus. The polymerization process of polycarbonate is energy-intensive, contributing to its overall environmental impact. Developing more energy-efficient production techniques and incorporating renewable energy sources in manufacturing facilities are important objectives in reducing the carbon footprint of polycarbonate.

Addressing the issue of additives and fillers used in polycarbonate formulations is another critical challenge. Some additives may hinder recyclability or pose environmental risks when the material is disposed of or incinerated. The objective is to develop eco-friendly additives that maintain or enhance polycarbonate's properties while minimizing negative environmental impacts.

Biodegradability is an area of growing interest in polycarbonate research. While traditional polycarbonate is not biodegradable, efforts are being made to develop biodegradable or compostable alternatives for specific applications. This approach aims to reduce the long-term environmental impact of polycarbonate products, particularly in single-use or short-lived applications.

Lastly, improving the durability and lifespan of polycarbonate products is a crucial objective in reducing their environmental impact. By enhancing resistance to weathering, UV radiation, and chemical degradation, the service life of polycarbonate products can be extended, reducing the need for frequent replacements and minimizing waste generation.

One of the main challenges in polycarbonate sustainability is its production process, which traditionally relies on bisphenol A (BPA) and phosgene. These chemicals have raised environmental and health concerns, prompting the need for alternative production methods. Researchers are exploring bio-based alternatives and greener synthesis routes to reduce the carbon footprint and potential toxicity associated with polycarbonate manufacturing.

Another significant challenge is the end-of-life management of polycarbonate products. While polycarbonate is technically recyclable, the recycling rates remain low due to various factors, including contamination, mixed plastic waste streams, and the lack of efficient recycling infrastructure. Improving the recyclability and establishing effective collection and sorting systems are crucial objectives in enhancing polycarbonate's environmental performance.

Energy consumption during production is also a key area of focus. The polymerization process of polycarbonate is energy-intensive, contributing to its overall environmental impact. Developing more energy-efficient production techniques and incorporating renewable energy sources in manufacturing facilities are important objectives in reducing the carbon footprint of polycarbonate.

Addressing the issue of additives and fillers used in polycarbonate formulations is another critical challenge. Some additives may hinder recyclability or pose environmental risks when the material is disposed of or incinerated. The objective is to develop eco-friendly additives that maintain or enhance polycarbonate's properties while minimizing negative environmental impacts.

Biodegradability is an area of growing interest in polycarbonate research. While traditional polycarbonate is not biodegradable, efforts are being made to develop biodegradable or compostable alternatives for specific applications. This approach aims to reduce the long-term environmental impact of polycarbonate products, particularly in single-use or short-lived applications.

Lastly, improving the durability and lifespan of polycarbonate products is a crucial objective in reducing their environmental impact. By enhancing resistance to weathering, UV radiation, and chemical degradation, the service life of polycarbonate products can be extended, reducing the need for frequent replacements and minimizing waste generation.

Market Demand for Eco-Friendly Polycarbonate Solutions

The market demand for eco-friendly polycarbonate solutions has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on plastic usage. Polycarbonate, a versatile thermoplastic polymer, is widely used in various industries due to its durability, transparency, and heat resistance. However, its environmental impact, particularly in terms of production processes and end-of-life disposal, has become a significant concern for both consumers and manufacturers.

Consumer awareness of environmental issues has led to a shift in preferences towards more sustainable products. This trend is particularly evident in sectors such as packaging, automotive, electronics, and construction, where polycarbonate is extensively used. Companies are now facing pressure from environmentally conscious consumers who demand products with reduced carbon footprints and improved recyclability.

In the packaging industry, there is a growing demand for eco-friendly polycarbonate alternatives that maintain the material's desirable properties while reducing environmental impact. Food and beverage containers, reusable water bottles, and storage solutions are key areas where consumers are actively seeking greener options.

The automotive sector is another major driver of demand for environmentally friendly polycarbonate solutions. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are looking for sustainable materials that can replace traditional polycarbonate components without compromising safety or performance.

In the electronics industry, the push for more sustainable products has led to increased interest in eco-friendly polycarbonate alternatives for device casings, screens, and other components. Manufacturers are exploring bio-based polycarbonates and recycled materials to meet this demand while maintaining the high-performance standards required in electronic devices.

The construction sector is also experiencing a surge in demand for sustainable building materials, including eco-friendly polycarbonate sheets and panels. These materials are sought after for their energy efficiency, durability, and potential for improved recyclability.

Regulatory pressures are further driving the market demand for eco-friendly polycarbonate solutions. Many countries and regions have implemented or are considering stricter regulations on plastic use, recycling, and disposal. This regulatory landscape is compelling manufacturers to invest in research and development of more sustainable polycarbonate alternatives to ensure compliance and maintain market access.

As a result of these market trends, there is a significant opportunity for companies that can develop and commercialize eco-friendly polycarbonate solutions. The demand spans across various applications, from consumer goods to industrial components, creating a diverse and growing market for innovative, sustainable materials that can match or exceed the performance of traditional polycarbonates while reducing environmental impact.

Consumer awareness of environmental issues has led to a shift in preferences towards more sustainable products. This trend is particularly evident in sectors such as packaging, automotive, electronics, and construction, where polycarbonate is extensively used. Companies are now facing pressure from environmentally conscious consumers who demand products with reduced carbon footprints and improved recyclability.

In the packaging industry, there is a growing demand for eco-friendly polycarbonate alternatives that maintain the material's desirable properties while reducing environmental impact. Food and beverage containers, reusable water bottles, and storage solutions are key areas where consumers are actively seeking greener options.

The automotive sector is another major driver of demand for environmentally friendly polycarbonate solutions. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are looking for sustainable materials that can replace traditional polycarbonate components without compromising safety or performance.

In the electronics industry, the push for more sustainable products has led to increased interest in eco-friendly polycarbonate alternatives for device casings, screens, and other components. Manufacturers are exploring bio-based polycarbonates and recycled materials to meet this demand while maintaining the high-performance standards required in electronic devices.

The construction sector is also experiencing a surge in demand for sustainable building materials, including eco-friendly polycarbonate sheets and panels. These materials are sought after for their energy efficiency, durability, and potential for improved recyclability.

Regulatory pressures are further driving the market demand for eco-friendly polycarbonate solutions. Many countries and regions have implemented or are considering stricter regulations on plastic use, recycling, and disposal. This regulatory landscape is compelling manufacturers to invest in research and development of more sustainable polycarbonate alternatives to ensure compliance and maintain market access.

As a result of these market trends, there is a significant opportunity for companies that can develop and commercialize eco-friendly polycarbonate solutions. The demand spans across various applications, from consumer goods to industrial components, creating a diverse and growing market for innovative, sustainable materials that can match or exceed the performance of traditional polycarbonates while reducing environmental impact.

Current Environmental Issues and Limitations of Polycarbonate

Polycarbonate, a widely used plastic material, faces significant environmental challenges that limit its sustainability. One of the primary issues is its production process, which relies heavily on fossil fuels and energy-intensive methods. The manufacturing of polycarbonate involves the use of bisphenol A (BPA), a chemical compound that has raised concerns due to its potential health and environmental impacts. This reliance on BPA not only poses risks to human health but also contributes to environmental pollution during production and disposal.

The durability of polycarbonate, while advantageous in many applications, becomes problematic at the end of its lifecycle. Polycarbonate products are not biodegradable and can persist in the environment for hundreds of years, contributing to the global plastic pollution crisis. Recycling polycarbonate presents significant challenges due to the presence of additives and the difficulty in separating it from other plastics in mixed waste streams. This results in a low recycling rate for polycarbonate products, with many ending up in landfills or incineration facilities.

Furthermore, the disposal of polycarbonate products through incineration can release toxic substances, including dioxins and furans, into the atmosphere. These emissions contribute to air pollution and pose potential health risks to nearby communities. The leaching of BPA and other additives from polycarbonate products in landfills or when exposed to environmental conditions is another concern, potentially contaminating soil and water sources.

The energy-intensive nature of polycarbonate production also contributes to its significant carbon footprint. The manufacturing process requires high temperatures and pressures, consuming substantial amounts of energy and resulting in greenhouse gas emissions. This energy consumption extends throughout the product lifecycle, from raw material extraction to processing and transportation.

Additionally, the use of polycarbonate in single-use or short-lived products exacerbates its environmental impact. The mismatch between the material's durability and the short lifespan of many polycarbonate products leads to unnecessary waste generation and resource depletion. This issue is particularly evident in packaging and consumer goods sectors, where alternatives with lower environmental impacts could be utilized.

The limitations in current recycling technologies for polycarbonate further compound its environmental issues. The lack of efficient and widespread recycling systems for this material means that valuable resources are lost, and the demand for virgin polycarbonate production remains high. This perpetuates the cycle of resource extraction and environmental degradation associated with polycarbonate manufacturing.

The durability of polycarbonate, while advantageous in many applications, becomes problematic at the end of its lifecycle. Polycarbonate products are not biodegradable and can persist in the environment for hundreds of years, contributing to the global plastic pollution crisis. Recycling polycarbonate presents significant challenges due to the presence of additives and the difficulty in separating it from other plastics in mixed waste streams. This results in a low recycling rate for polycarbonate products, with many ending up in landfills or incineration facilities.

Furthermore, the disposal of polycarbonate products through incineration can release toxic substances, including dioxins and furans, into the atmosphere. These emissions contribute to air pollution and pose potential health risks to nearby communities. The leaching of BPA and other additives from polycarbonate products in landfills or when exposed to environmental conditions is another concern, potentially contaminating soil and water sources.

The energy-intensive nature of polycarbonate production also contributes to its significant carbon footprint. The manufacturing process requires high temperatures and pressures, consuming substantial amounts of energy and resulting in greenhouse gas emissions. This energy consumption extends throughout the product lifecycle, from raw material extraction to processing and transportation.

Additionally, the use of polycarbonate in single-use or short-lived products exacerbates its environmental impact. The mismatch between the material's durability and the short lifespan of many polycarbonate products leads to unnecessary waste generation and resource depletion. This issue is particularly evident in packaging and consumer goods sectors, where alternatives with lower environmental impacts could be utilized.

The limitations in current recycling technologies for polycarbonate further compound its environmental issues. The lack of efficient and widespread recycling systems for this material means that valuable resources are lost, and the demand for virgin polycarbonate production remains high. This perpetuates the cycle of resource extraction and environmental degradation associated with polycarbonate manufacturing.

Existing Green Polycarbonate Manufacturing Methods

01 Recycling and biodegradability of polycarbonate

Efforts to improve the recyclability and biodegradability of polycarbonate materials are being made to reduce their environmental impact. This includes developing new recycling processes and creating biodegradable polycarbonate alternatives that can break down more easily in natural environments.- Recycling and biodegradability of polycarbonate: Polycarbonate recycling processes and methods to enhance biodegradability are being developed to reduce environmental impact. These include chemical recycling techniques, the use of additives to promote degradation, and the development of more easily recyclable polycarbonate formulations.

- Energy-efficient production methods: Innovative manufacturing processes are being implemented to reduce the energy consumption and carbon footprint associated with polycarbonate production. These methods include optimized reaction conditions, improved catalysts, and more efficient polymerization techniques.

- Alternatives to bisphenol A in polycarbonate production: Research is focused on developing polycarbonate alternatives that do not rely on bisphenol A, addressing concerns about its potential environmental and health impacts. New monomers and copolymers are being explored to create more environmentally friendly polycarbonate materials.

- Life cycle assessment and environmental impact reduction: Comprehensive life cycle assessments are being conducted to evaluate and minimize the environmental impact of polycarbonate throughout its production, use, and disposal. This includes optimizing resource use, reducing emissions, and improving end-of-life management strategies.

- Polycarbonate in sustainable applications: Polycarbonate is being utilized in various sustainable applications, such as energy-efficient lighting, solar panels, and electric vehicle components. These applications leverage polycarbonate's properties to contribute to overall environmental sustainability despite its production impact.

02 Energy-efficient production methods

Research is focused on developing more energy-efficient methods for producing polycarbonate materials. These methods aim to reduce the carbon footprint associated with polycarbonate manufacturing by optimizing production processes and utilizing renewable energy sources.Expand Specific Solutions03 Reduction of harmful additives

Efforts are being made to reduce or eliminate the use of harmful additives in polycarbonate production. This includes finding safer alternatives to chemicals like bisphenol A (BPA) and developing new formulations that maintain the desirable properties of polycarbonate while minimizing environmental impact.Expand Specific Solutions04 Life cycle assessment and environmental impact analysis

Comprehensive life cycle assessments and environmental impact analyses are being conducted to better understand the overall environmental effects of polycarbonate materials. These studies consider factors such as raw material extraction, production, use, and disposal to identify areas for improvement in sustainability.Expand Specific Solutions05 Development of bio-based polycarbonates

Research is ongoing to develop bio-based polycarbonates derived from renewable resources. These materials aim to reduce dependence on fossil fuels and decrease the overall environmental impact of polycarbonate production by utilizing sustainable feedstocks.Expand Specific Solutions

Key Players in Sustainable Polycarbonate Industry

The environmental impact of polycarbonate is a growing concern in the mature plastics industry, with a global market size expected to reach $25 billion by 2027. The competitive landscape is characterized by established players like Covestro, SABIC, and LG Chem leading innovation efforts. These companies are investing in research and development to improve the sustainability of polycarbonate, focusing on bio-based alternatives, recycling technologies, and energy-efficient production processes. The technology is evolving rapidly, with emerging players such as Trinseo and Kingfa Sci. & Tech. also contributing to advancements in eco-friendly polycarbonate solutions. Collaboration between industry leaders and research institutions is accelerating progress towards more environmentally sustainable polycarbonate products.

Covestro Deutschland AG

Technical Solution: Covestro has developed a groundbreaking approach to improve the environmental impact of polycarbonate through their innovative CO2 technology. This method involves using carbon dioxide as a raw material in polycarbonate production, replacing up to 20% of fossil-based resources[1]. The process captures CO2 that would otherwise be emitted into the atmosphere and incorporates it into the polymer chain, creating a more sustainable product. Additionally, Covestro has implemented energy-efficient manufacturing processes and increased the use of renewable energy in their production facilities, further reducing the carbon footprint of their polycarbonate products[2]. The company has also focused on developing bio-based polycarbonates, utilizing plant-based raw materials to decrease reliance on fossil resources[3].

Strengths: Significant reduction in carbon footprint, innovative use of waste CO2, decreased reliance on fossil resources. Weaknesses: Limited percentage of CO2 incorporation, potential higher production costs, may require modifications to existing manufacturing infrastructure.

SABIC Global Technologies BV

Technical Solution: SABIC has introduced LEXAN™ polycarbonate resins with certified renewable content, derived from waste materials not competing with the food chain. These resins contain up to 60% certified renewable content, significantly reducing fossil-based resource consumption[4]. SABIC's approach involves a mass balance system to trace the flow of materials through the production process, ensuring the allocation of renewable content to the final product. The company has also developed LEXAN™ EXL copolymers with improved chemical resistance and durability, extending product lifespans and reducing waste[5]. Furthermore, SABIC has implemented energy-efficient production processes and increased the use of renewable energy in manufacturing, contributing to a lower overall environmental impact of their polycarbonate products.

Strengths: High percentage of renewable content, improved durability for longer product life, established traceability system. Weaknesses: Potential limitations in material properties compared to traditional polycarbonates, higher production costs, reliance on availability of suitable waste materials.

Innovative Approaches to Reduce Polycarbonate Environmental Impact

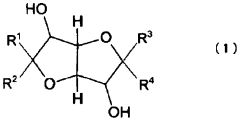

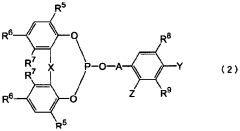

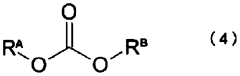

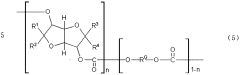

Polycarbonate having plant-derived component and method for producing the same

PatentWO2009044907A1

Innovation

- A polycarbonate produced using plant-derived components, specifically anhydrosugar alcohols like isosorbide and glycols, with added cyclic phosphites and metal elements as stabilizers, to improve hue and stability, and a method involving melt polycondensation with nitrogen-containing basic compounds as catalysts.

Process for producing high-performance biodegradable polycarbonates from carbon dioxide and epoxide using novel catalysts

PatentPendingIN202341024559A

Innovation

- Utilization of CO2 and epoxide as feedstocks for producing biodegradable polycarbonates, offering a sustainable alternative to conventional methods.

- Employment of novel catalyst systems, including metal-organic frameworks (MOFs), to initiate the polymerization reaction efficiently.

- Integration of co-catalysts, both organic and inorganic, to enhance the synthesis process and improve the properties of the resulting biodegradable polycarbonates.

Life Cycle Assessment of Polycarbonate Products

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of polycarbonate products throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to end-of-life disposal, providing valuable insights into the overall sustainability of these materials.

The production phase of polycarbonate typically involves energy-intensive processes, contributing significantly to its environmental footprint. Raw material extraction, primarily bisphenol A and phosgene, requires substantial energy inputs and may lead to resource depletion. The polymerization process itself consumes considerable energy and often relies on fossil fuel-based sources, resulting in greenhouse gas emissions.

During the use phase, polycarbonate products generally exhibit favorable environmental performance due to their durability and longevity. This extended lifespan reduces the need for frequent replacements, potentially offsetting the initial production impacts. Additionally, the lightweight nature of polycarbonate can contribute to energy savings in transportation applications.

End-of-life management presents both challenges and opportunities for improving the environmental impact of polycarbonate. While recycling technologies for polycarbonate exist, the current recycling rates remain relatively low. Incineration with energy recovery is another disposal option, but it may release harmful emissions if not properly controlled. Landfilling, though still common, is the least preferable option due to the material's slow degradation rate and potential for leaching chemicals into the environment.

To enhance the environmental performance of polycarbonate products, several strategies can be employed throughout the lifecycle. Increasing the use of renewable energy sources in production processes can significantly reduce carbon emissions. Implementing more efficient manufacturing techniques and optimizing material usage can minimize waste and resource consumption.

Improving the recyclability of polycarbonate products is crucial for closing the loop in their lifecycle. This can be achieved through better product design, enhancing collection and sorting systems, and developing advanced recycling technologies. Additionally, exploring bio-based alternatives for polycarbonate precursors could potentially reduce reliance on fossil-based raw materials.

Conducting comprehensive LCAs for specific polycarbonate applications can identify hotspots in the lifecycle where environmental improvements can be most impactful. This data-driven approach enables informed decision-making and targeted interventions to minimize the overall environmental footprint of polycarbonate products.

The production phase of polycarbonate typically involves energy-intensive processes, contributing significantly to its environmental footprint. Raw material extraction, primarily bisphenol A and phosgene, requires substantial energy inputs and may lead to resource depletion. The polymerization process itself consumes considerable energy and often relies on fossil fuel-based sources, resulting in greenhouse gas emissions.

During the use phase, polycarbonate products generally exhibit favorable environmental performance due to their durability and longevity. This extended lifespan reduces the need for frequent replacements, potentially offsetting the initial production impacts. Additionally, the lightweight nature of polycarbonate can contribute to energy savings in transportation applications.

End-of-life management presents both challenges and opportunities for improving the environmental impact of polycarbonate. While recycling technologies for polycarbonate exist, the current recycling rates remain relatively low. Incineration with energy recovery is another disposal option, but it may release harmful emissions if not properly controlled. Landfilling, though still common, is the least preferable option due to the material's slow degradation rate and potential for leaching chemicals into the environment.

To enhance the environmental performance of polycarbonate products, several strategies can be employed throughout the lifecycle. Increasing the use of renewable energy sources in production processes can significantly reduce carbon emissions. Implementing more efficient manufacturing techniques and optimizing material usage can minimize waste and resource consumption.

Improving the recyclability of polycarbonate products is crucial for closing the loop in their lifecycle. This can be achieved through better product design, enhancing collection and sorting systems, and developing advanced recycling technologies. Additionally, exploring bio-based alternatives for polycarbonate precursors could potentially reduce reliance on fossil-based raw materials.

Conducting comprehensive LCAs for specific polycarbonate applications can identify hotspots in the lifecycle where environmental improvements can be most impactful. This data-driven approach enables informed decision-making and targeted interventions to minimize the overall environmental footprint of polycarbonate products.

Regulatory Framework for Sustainable Plastics Production

The regulatory framework for sustainable plastics production plays a crucial role in improving the environmental impact of polycarbonate. Governments and international organizations have been implementing increasingly stringent regulations to address the environmental concerns associated with plastic production and disposal.

In the European Union, the Circular Economy Action Plan sets ambitious targets for plastic recycling and reuse. This plan includes measures to reduce single-use plastics and promote the use of recycled materials in new products. The EU has also introduced the Plastic Waste Directive, which aims to reduce the environmental impact of certain plastic products and promote a circular economy approach to plastic production.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for sustainable plastics production under the Pollution Prevention Act. These guidelines encourage manufacturers to adopt cleaner production processes, reduce waste generation, and increase the use of recycled materials in their products.

Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These programs incentivize companies to design products with improved recyclability and reduced environmental impact.

International standards, such as ISO 14001 for environmental management systems, provide a framework for organizations to implement sustainable practices in their production processes. These standards help companies identify and manage their environmental impacts, including those related to polycarbonate production.

The regulatory landscape also includes restrictions on hazardous substances used in plastic production. For example, the EU's REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals) aims to protect human health and the environment by regulating the use of chemicals in various industries, including plastics manufacturing.

To address the specific environmental concerns related to polycarbonate, some jurisdictions have implemented regulations targeting bisphenol A (BPA), a key component in polycarbonate production. These regulations range from bans on BPA in certain products to requirements for labeling and disclosure of BPA content.

As the focus on sustainability intensifies, regulatory bodies are exploring new approaches to promote eco-friendly plastics production. This includes incentives for the development of bio-based and biodegradable alternatives to traditional polycarbonate, as well as support for research into more sustainable production methods and recycling technologies.

In the European Union, the Circular Economy Action Plan sets ambitious targets for plastic recycling and reuse. This plan includes measures to reduce single-use plastics and promote the use of recycled materials in new products. The EU has also introduced the Plastic Waste Directive, which aims to reduce the environmental impact of certain plastic products and promote a circular economy approach to plastic production.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for sustainable plastics production under the Pollution Prevention Act. These guidelines encourage manufacturers to adopt cleaner production processes, reduce waste generation, and increase the use of recycled materials in their products.

Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These programs incentivize companies to design products with improved recyclability and reduced environmental impact.

International standards, such as ISO 14001 for environmental management systems, provide a framework for organizations to implement sustainable practices in their production processes. These standards help companies identify and manage their environmental impacts, including those related to polycarbonate production.

The regulatory landscape also includes restrictions on hazardous substances used in plastic production. For example, the EU's REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals) aims to protect human health and the environment by regulating the use of chemicals in various industries, including plastics manufacturing.

To address the specific environmental concerns related to polycarbonate, some jurisdictions have implemented regulations targeting bisphenol A (BPA), a key component in polycarbonate production. These regulations range from bans on BPA in certain products to requirements for labeling and disclosure of BPA content.

As the focus on sustainability intensifies, regulatory bodies are exploring new approaches to promote eco-friendly plastics production. This includes incentives for the development of bio-based and biodegradable alternatives to traditional polycarbonate, as well as support for research into more sustainable production methods and recycling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!