How to Program LS1 Engine ECU

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS1 Engine ECU Programming Background and Objectives

The LS1 engine, introduced by General Motors in 1997, marked a significant evolution in automotive powertrain technology. This small-block V8 engine featured an advanced electronic control unit (ECU) that revolutionized engine management systems. The development of the LS1 ECU represented a shift from simpler electronic control modules to sophisticated computer systems capable of managing multiple engine parameters simultaneously with greater precision.

The evolution of ECU programming technology for the LS1 has progressed through several distinct phases. Initially, modifications were limited to dealer-level tools and factory programming. As aftermarket interest grew, third-party solutions emerged, ranging from simple "chip tuning" to comprehensive reflashing capabilities. Today's programming landscape includes sophisticated software platforms that allow for real-time tuning and customization of virtually every engine parameter.

The primary objective of LS1 ECU programming is to optimize engine performance beyond factory settings while maintaining reliability. This involves recalibrating fuel delivery, ignition timing, air-fuel ratios, and other critical parameters to match modifications or intended use cases. Secondary objectives include improving fuel efficiency, reducing emissions where possible, and enabling compatibility with aftermarket components.

Technical challenges in this domain include understanding the proprietary nature of GM's ECU architecture, addressing security measures designed to prevent unauthorized modifications, and developing interfaces that can reliably communicate with the ECU hardware. These challenges have driven significant innovation in reverse engineering and protocol development.

Market trends indicate growing demand for user-friendly programming solutions that don't require extensive technical knowledge. This has led to the development of pre-configured tunes for common modification packages and cloud-based tuning services where experts remotely optimize engine parameters.

The regulatory landscape presents additional considerations, as emissions compliance remains a critical factor in many jurisdictions. Modern LS1 ECU programming must balance performance gains with legal requirements, particularly for vehicles used on public roads.

Looking forward, the technical trajectory points toward more sophisticated self-learning algorithms, enhanced diagnostic capabilities, and greater integration with other vehicle systems. The continued popularity of the LS1 engine family in both original and transplanted applications ensures ongoing development in this field, with particular emphasis on compatibility with modern sensors and emissions equipment.

The evolution of ECU programming technology for the LS1 has progressed through several distinct phases. Initially, modifications were limited to dealer-level tools and factory programming. As aftermarket interest grew, third-party solutions emerged, ranging from simple "chip tuning" to comprehensive reflashing capabilities. Today's programming landscape includes sophisticated software platforms that allow for real-time tuning and customization of virtually every engine parameter.

The primary objective of LS1 ECU programming is to optimize engine performance beyond factory settings while maintaining reliability. This involves recalibrating fuel delivery, ignition timing, air-fuel ratios, and other critical parameters to match modifications or intended use cases. Secondary objectives include improving fuel efficiency, reducing emissions where possible, and enabling compatibility with aftermarket components.

Technical challenges in this domain include understanding the proprietary nature of GM's ECU architecture, addressing security measures designed to prevent unauthorized modifications, and developing interfaces that can reliably communicate with the ECU hardware. These challenges have driven significant innovation in reverse engineering and protocol development.

Market trends indicate growing demand for user-friendly programming solutions that don't require extensive technical knowledge. This has led to the development of pre-configured tunes for common modification packages and cloud-based tuning services where experts remotely optimize engine parameters.

The regulatory landscape presents additional considerations, as emissions compliance remains a critical factor in many jurisdictions. Modern LS1 ECU programming must balance performance gains with legal requirements, particularly for vehicles used on public roads.

Looking forward, the technical trajectory points toward more sophisticated self-learning algorithms, enhanced diagnostic capabilities, and greater integration with other vehicle systems. The continued popularity of the LS1 engine family in both original and transplanted applications ensures ongoing development in this field, with particular emphasis on compatibility with modern sensors and emissions equipment.

Market Analysis of LS1 ECU Tuning Demand

The LS1 ECU tuning market has experienced significant growth over the past decade, driven primarily by automotive enthusiasts seeking improved performance from their General Motors LS1-powered vehicles. This market segment represents a specialized niche within the broader automotive aftermarket industry, which was valued at approximately $405 billion globally in 2022.

The primary consumer base consists of performance-oriented vehicle owners, professional tuning shops, racing teams, and specialized automotive service centers. Market research indicates that LS1 ECU tuning demand is particularly strong in North America, where the LS1 engine has been widely deployed in various GM vehicles since its introduction in the 1997 Corvette C5.

Consumer motivation for LS1 ECU tuning typically falls into several categories: performance enhancement (horsepower and torque gains), fuel efficiency improvements, accommodation of aftermarket modifications, and customization of driving characteristics. Survey data suggests that performance enhancement remains the dominant driver, with approximately 78% of consumers citing increased horsepower as their primary motivation.

Market segmentation reveals distinct customer profiles: DIY enthusiasts who purchase tuning software and hardware for personal use; customers seeking professional tuning services; and racing teams requiring specialized competition-oriented calibrations. The DIY segment has shown particularly strong growth with the increasing availability of user-friendly tuning interfaces and educational resources.

Regional analysis demonstrates concentrated demand in traditional automotive strongholds including the Southern United States, Midwest, and California, with emerging markets in Australia, Europe, and the Middle East where GM LS-powered vehicles have gained popularity through imports and conversions.

Pricing analysis indicates a wide spectrum of market entry points, from basic handheld programmers starting around $300 to comprehensive professional tuning packages exceeding $2,000. Professional tuning services typically command $500-1,500 depending on complexity and customization requirements.

Market forecasts project continued growth at a compound annual rate of 6.8% through 2027, driven by the enduring popularity of LS-powered vehicles, the expanding ecosystem of aftermarket parts requiring ECU adjustments, and the increasing accessibility of tuning technology to non-specialist users.

Competitive analysis reveals a market dominated by established players like HP Tuners, EFILive, and Holley, alongside emerging companies offering specialized solutions for niche applications. The market structure suggests moderate concentration with opportunities for innovation in user interface design, remote tuning capabilities, and integration with mobile technologies.

The primary consumer base consists of performance-oriented vehicle owners, professional tuning shops, racing teams, and specialized automotive service centers. Market research indicates that LS1 ECU tuning demand is particularly strong in North America, where the LS1 engine has been widely deployed in various GM vehicles since its introduction in the 1997 Corvette C5.

Consumer motivation for LS1 ECU tuning typically falls into several categories: performance enhancement (horsepower and torque gains), fuel efficiency improvements, accommodation of aftermarket modifications, and customization of driving characteristics. Survey data suggests that performance enhancement remains the dominant driver, with approximately 78% of consumers citing increased horsepower as their primary motivation.

Market segmentation reveals distinct customer profiles: DIY enthusiasts who purchase tuning software and hardware for personal use; customers seeking professional tuning services; and racing teams requiring specialized competition-oriented calibrations. The DIY segment has shown particularly strong growth with the increasing availability of user-friendly tuning interfaces and educational resources.

Regional analysis demonstrates concentrated demand in traditional automotive strongholds including the Southern United States, Midwest, and California, with emerging markets in Australia, Europe, and the Middle East where GM LS-powered vehicles have gained popularity through imports and conversions.

Pricing analysis indicates a wide spectrum of market entry points, from basic handheld programmers starting around $300 to comprehensive professional tuning packages exceeding $2,000. Professional tuning services typically command $500-1,500 depending on complexity and customization requirements.

Market forecasts project continued growth at a compound annual rate of 6.8% through 2027, driven by the enduring popularity of LS-powered vehicles, the expanding ecosystem of aftermarket parts requiring ECU adjustments, and the increasing accessibility of tuning technology to non-specialist users.

Competitive analysis reveals a market dominated by established players like HP Tuners, EFILive, and Holley, alongside emerging companies offering specialized solutions for niche applications. The market structure suggests moderate concentration with opportunities for innovation in user interface design, remote tuning capabilities, and integration with mobile technologies.

Current ECU Programming Technologies and Challenges

The current landscape of ECU programming for the LS1 engine involves several established technologies alongside emerging solutions, each presenting unique challenges. Traditional methods primarily utilize the J2534 pass-through device standard, which enables aftermarket scan tools to communicate with vehicle ECUs through standardized protocols. This approach has become an industry standard but often requires specialized knowledge of GM-specific parameters and calibration data.

Flash programming technologies have evolved significantly, with manufacturer-specific tools like GM's Tech2 and more recent GDS2 systems providing official pathways for ECU reprogramming. These tools offer reliable performance but typically come with substantial costs and limited flexibility for custom modifications, creating barriers for independent tuners and enthusiasts.

Third-party tuning software solutions such as HP Tuners, EFILive, and TunerPro have gained significant traction in the LS1 community. These platforms provide more accessible interfaces for ECU parameter modification but vary considerably in their capabilities, security bypass features, and user experience. The learning curve associated with these tools remains steep, requiring substantial technical understanding of engine management principles.

A major technical challenge in LS1 ECU programming involves security systems designed to prevent unauthorized access. Modern GM ECUs implement various security measures including encrypted communication protocols and VIN locking mechanisms. Overcoming these protections requires sophisticated techniques that balance legitimate tuning needs with manufacturer security concerns.

Data acquisition and real-time calibration present another significant challenge. Effective ECU programming demands accurate sensor data interpretation and real-time feedback during calibration processes. The complexity of modern engine management systems requires sophisticated data logging capabilities and analysis tools that can process multiple parameters simultaneously.

Hardware interface limitations also constrain programming capabilities. Connection stability issues, communication protocol incompatibilities, and hardware reliability problems can compromise programming sessions, potentially resulting in partially programmed ECUs or "bricked" controllers requiring recovery procedures.

Emerging technologies in this space include cloud-based tuning platforms that enable remote collaboration between tuners and clients, as well as machine learning algorithms that can suggest optimal calibration settings based on vehicle-specific data and performance goals. These innovations promise to streamline the tuning process but introduce new challenges related to data security, connectivity requirements, and validation of AI-generated calibration recommendations.

Flash programming technologies have evolved significantly, with manufacturer-specific tools like GM's Tech2 and more recent GDS2 systems providing official pathways for ECU reprogramming. These tools offer reliable performance but typically come with substantial costs and limited flexibility for custom modifications, creating barriers for independent tuners and enthusiasts.

Third-party tuning software solutions such as HP Tuners, EFILive, and TunerPro have gained significant traction in the LS1 community. These platforms provide more accessible interfaces for ECU parameter modification but vary considerably in their capabilities, security bypass features, and user experience. The learning curve associated with these tools remains steep, requiring substantial technical understanding of engine management principles.

A major technical challenge in LS1 ECU programming involves security systems designed to prevent unauthorized access. Modern GM ECUs implement various security measures including encrypted communication protocols and VIN locking mechanisms. Overcoming these protections requires sophisticated techniques that balance legitimate tuning needs with manufacturer security concerns.

Data acquisition and real-time calibration present another significant challenge. Effective ECU programming demands accurate sensor data interpretation and real-time feedback during calibration processes. The complexity of modern engine management systems requires sophisticated data logging capabilities and analysis tools that can process multiple parameters simultaneously.

Hardware interface limitations also constrain programming capabilities. Connection stability issues, communication protocol incompatibilities, and hardware reliability problems can compromise programming sessions, potentially resulting in partially programmed ECUs or "bricked" controllers requiring recovery procedures.

Emerging technologies in this space include cloud-based tuning platforms that enable remote collaboration between tuners and clients, as well as machine learning algorithms that can suggest optimal calibration settings based on vehicle-specific data and performance goals. These innovations promise to streamline the tuning process but introduce new challenges related to data security, connectivity requirements, and validation of AI-generated calibration recommendations.

Contemporary LS1 ECU Programming Methods

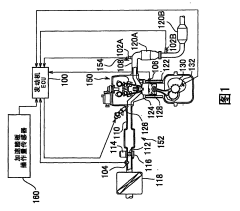

01 ECU control systems for LS1 engines

Electronic Control Units (ECUs) designed specifically for LS1 engines provide comprehensive engine management capabilities. These systems monitor and control various engine parameters such as fuel injection timing, ignition timing, and air-fuel ratio to optimize performance. Advanced ECU systems for LS1 engines incorporate adaptive learning algorithms that adjust parameters based on driving conditions and environmental factors.- ECU calibration and programming for LS1 engines: Electronic Control Units (ECUs) for LS1 engines require specific calibration and programming to optimize engine performance. This involves adjusting parameters such as fuel injection timing, ignition timing, and air-fuel ratios to match the specific characteristics of the LS1 engine. Advanced programming techniques allow for customization of engine performance characteristics while maintaining reliability and emissions compliance.

- Integration of LS1 ECU with vehicle systems: The integration of LS1 engine ECUs with other vehicle systems is crucial for optimal performance. This includes communication with transmission control modules, traction control systems, and other electronic components. Proper integration ensures seamless operation of the engine with other vehicle systems, enhancing overall vehicle performance, drivability, and fuel efficiency.

- Diagnostic and monitoring capabilities of LS1 ECUs: Modern LS1 engine ECUs incorporate advanced diagnostic and monitoring capabilities to ensure optimal engine performance and reliability. These systems continuously monitor engine parameters such as temperature, pressure, and oxygen levels, and can detect and report faults or abnormalities. This allows for early detection of potential issues and facilitates maintenance and troubleshooting.

- Aftermarket ECU modifications for LS1 engines: Aftermarket modifications to LS1 engine ECUs can significantly enhance engine performance beyond factory specifications. These modifications may include custom tuning, installation of performance chips, or complete replacement with programmable ECUs. Such modifications allow for increased horsepower, torque, and improved throttle response while potentially maintaining fuel efficiency.

- Emissions control strategies in LS1 ECUs: LS1 engine ECUs implement sophisticated emissions control strategies to meet regulatory requirements while maintaining performance. These strategies include precise control of air-fuel ratios, exhaust gas recirculation, and catalyst monitoring. Advanced algorithms in the ECU software optimize combustion efficiency to reduce harmful emissions while preserving engine power and responsiveness.

02 Fuel management optimization in LS1 ECUs

Specialized fuel management systems within LS1 ECUs enable precise control over fuel delivery. These systems incorporate advanced mapping capabilities to optimize fuel injection timing and quantity across various operating conditions. The fuel management components work in conjunction with oxygen sensors and other inputs to maintain ideal air-fuel ratios, resulting in improved power output, fuel efficiency, and emissions control.Expand Specific Solutions03 Performance tuning and calibration for LS1 ECUs

Calibration and tuning capabilities for LS1 ECUs allow for customization of engine performance parameters. These systems provide interfaces for adjusting timing maps, fuel delivery curves, and other critical settings to match specific performance goals or modifications. Advanced tuning features include the ability to create multiple performance profiles that can be selected based on driving conditions or preferences.Expand Specific Solutions04 Diagnostic and monitoring systems in LS1 ECUs

Integrated diagnostic capabilities within LS1 ECUs provide comprehensive monitoring of engine performance and component health. These systems can detect and report faults through standardized OBD protocols, allowing for efficient troubleshooting and maintenance. Advanced monitoring features track performance metrics over time, enabling predictive maintenance and early detection of potential issues before they lead to failures.Expand Specific Solutions05 Integration with vehicle systems and aftermarket modifications

LS1 ECUs feature integration capabilities with other vehicle systems such as transmission controllers, traction control, and stability management. These integration features ensure coordinated operation across multiple vehicle systems for optimal performance and safety. Additionally, modern LS1 ECUs provide compatibility with aftermarket modifications and performance enhancements, allowing for proper calibration when engine components are upgraded or replaced.Expand Specific Solutions

Major Players in Aftermarket ECU Programming

The LS1 Engine ECU programming market is in a growth phase, with increasing demand driven by automotive performance tuning and aftermarket modifications. Major players include established OEMs like Toyota, Nissan, Honda, and Mitsubishi Electric, who possess advanced proprietary ECU technologies. Chinese manufacturers such as Weichai Power, BYD, and Guangzhou Automobile Group are rapidly advancing their capabilities. Technology maturity varies significantly, with companies like DENSO and NEC Laboratories leading in sophisticated engine management systems, while universities like Tongji University contribute to research advancements. The competitive landscape is evolving as specialized firms like Beijing Jingwei Hirain Technologies and Wuxi Weibo Automobile Technology develop targeted ECU programming solutions to challenge traditional manufacturers.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive ECU programming approach for the LS1 engine that integrates with their Toyota Engine Control Module (ECM) architecture. Their solution utilizes the Toyota Techstream software interface which provides direct access to the LS1 ECU parameters through the OBD-II diagnostic port. Toyota's approach includes proprietary calibration tools that allow for precise fuel mapping, ignition timing adjustments, and variable valve timing control specific to LS1 engine applications. The system employs a hierarchical programming structure with multiple security levels to prevent unauthorized access while allowing certified technicians to perform necessary modifications. Toyota's ECU programming methodology incorporates adaptive learning algorithms that continuously optimize engine performance based on driving conditions and environmental factors, storing these parameters in non-volatile memory for consistent operation.

Strengths: Toyota's system offers exceptional integration with their diagnostic ecosystem, providing comprehensive error logging and real-time parameter monitoring. Their approach ensures high reliability and compatibility across vehicle platforms. Weaknesses: The proprietary nature of Toyota's programming tools limits aftermarket modification options, and the system requires specialized training and equipment to access full functionality.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has engineered a sophisticated ECU programming solution for LS1 engines that builds upon their CONSULT diagnostic platform. Their approach utilizes a multi-layer programming architecture that separates base engine management functions from application-specific calibrations. Nissan's LS1 ECU programming methodology incorporates their proprietary VQ-based engine management algorithms adapted specifically for LS1 architecture, allowing for seamless integration with various vehicle systems. The programming interface supports both factory calibration and field service operations through a secured CAN-bus communication protocol. Nissan's system features dynamic mapping capabilities that adjust fuel delivery and ignition timing based on real-time sensor inputs, with particular emphasis on optimizing performance across varying atmospheric conditions. Their ECU programming solution includes comprehensive data logging functionality that captures up to 500 parameters at 100Hz sampling rates, enabling detailed analysis of engine performance for both development and diagnostic purposes.

Strengths: Nissan's solution offers excellent flexibility in calibration parameters while maintaining robust fail-safe protocols. Their system provides exceptional diagnostic capabilities and supports incremental updates without complete reflashing. Weaknesses: The complexity of Nissan's programming architecture requires specialized knowledge, and their security protocols can make aftermarket modifications challenging without authorized access tools.

Key Technical Innovations in Engine Calibration

Engine control unit (ECU) and method to adapt the ECU for trigger wheel irregularities

PatentActiveUS11268464B2

Innovation

- The ECU is adapted to detect and learn the actual dimensions of the trigger wheel, including tooth width and gap, during production, and stores this data in a table to set dynamic time ranges for tooth detection, preventing false errors and ensuring accurate engine position management even with irregularities.

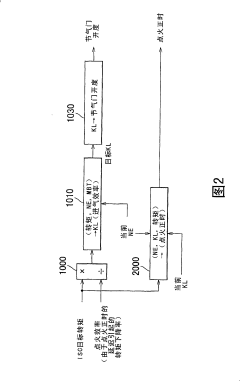

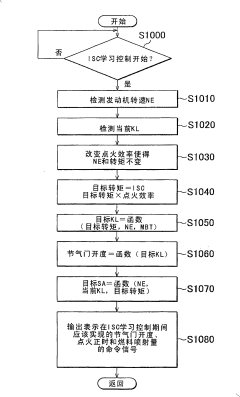

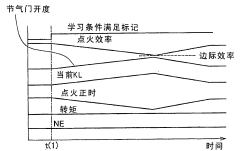

Control unit and control method for torque-demand-type internal combustion engine

PatentInactiveCN101542109B

Innovation

- By introducing torque demand control into the control unit of the internal combustion engine, using intake efficiency and ignition timing control, the throttle opening and ignition timing are changed to keep the engine speed and torque constant, achieving a wider throttle opening. Idle speed control learning within a certain range.

Emissions Compliance and Regulatory Considerations

Programming the LS1 Engine ECU requires careful consideration of emissions compliance and regulatory standards that vary across different regions. The Environmental Protection Agency (EPA) in the United States and the European Union's Euro standards establish strict guidelines for vehicle emissions, directly impacting ECU programming parameters. These regulations limit the permissible levels of nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter emissions from engines.

When modifying an LS1 ECU, programmers must maintain or improve the original emissions profile to ensure legal operation. The On-Board Diagnostics II (OBD-II) system, mandatory in all vehicles manufactured after 1996 in the US, monitors emissions control systems and must remain fully functional after ECU modifications. Tampering with or disabling emissions control devices through ECU programming is explicitly prohibited by the Clean Air Act and similar legislation worldwide.

Calibration strategies must incorporate closed-loop fuel control systems that utilize oxygen sensors to maintain the stoichiometric air-fuel ratio (14.7:1) during normal operation. This ratio is critical for optimal catalytic converter efficiency. Advanced ECU programming techniques can implement model-based control algorithms that predict emissions based on engine operating conditions, allowing for preventive adjustments before emissions exceed regulatory thresholds.

Regional variations in emissions standards present significant challenges for ECU programmers. California Air Resources Board (CARB) requirements exceed federal EPA standards, creating a complex compliance landscape within the United States alone. International markets may follow Euro 6, Japanese, or Australian standards, each with unique testing protocols and limits. ECU programs must be adaptable to these regional requirements or risk rendering vehicles non-compliant in certain markets.

Future-proofing ECU calibrations against evolving regulations requires implementing flexible control strategies. Programmers should consider incorporating provisions for over-the-air updates to emissions control algorithms as regulations change. Additionally, modern ECU programming increasingly focuses on real-world driving emissions (RDE) rather than just laboratory cycle testing, requiring more sophisticated emissions modeling and control strategies.

The legal consequences of non-compliant ECU programming can be severe, including substantial fines, vehicle impoundment, and even criminal charges in extreme cases. Professional ECU programmers must maintain comprehensive documentation of emissions testing results to demonstrate compliance with applicable regulations. This documentation serves as critical protection against potential regulatory scrutiny and liability issues.

When modifying an LS1 ECU, programmers must maintain or improve the original emissions profile to ensure legal operation. The On-Board Diagnostics II (OBD-II) system, mandatory in all vehicles manufactured after 1996 in the US, monitors emissions control systems and must remain fully functional after ECU modifications. Tampering with or disabling emissions control devices through ECU programming is explicitly prohibited by the Clean Air Act and similar legislation worldwide.

Calibration strategies must incorporate closed-loop fuel control systems that utilize oxygen sensors to maintain the stoichiometric air-fuel ratio (14.7:1) during normal operation. This ratio is critical for optimal catalytic converter efficiency. Advanced ECU programming techniques can implement model-based control algorithms that predict emissions based on engine operating conditions, allowing for preventive adjustments before emissions exceed regulatory thresholds.

Regional variations in emissions standards present significant challenges for ECU programmers. California Air Resources Board (CARB) requirements exceed federal EPA standards, creating a complex compliance landscape within the United States alone. International markets may follow Euro 6, Japanese, or Australian standards, each with unique testing protocols and limits. ECU programs must be adaptable to these regional requirements or risk rendering vehicles non-compliant in certain markets.

Future-proofing ECU calibrations against evolving regulations requires implementing flexible control strategies. Programmers should consider incorporating provisions for over-the-air updates to emissions control algorithms as regulations change. Additionally, modern ECU programming increasingly focuses on real-world driving emissions (RDE) rather than just laboratory cycle testing, requiring more sophisticated emissions modeling and control strategies.

The legal consequences of non-compliant ECU programming can be severe, including substantial fines, vehicle impoundment, and even criminal charges in extreme cases. Professional ECU programmers must maintain comprehensive documentation of emissions testing results to demonstrate compliance with applicable regulations. This documentation serves as critical protection against potential regulatory scrutiny and liability issues.

Performance Testing and Validation Methodologies

Performance testing and validation methodologies for LS1 Engine ECU programming require systematic approaches to ensure optimal engine performance and reliability. The validation process begins with bench testing, where the ECU is connected to specialized hardware simulators that mimic engine sensors and actuators. This controlled environment allows programmers to verify basic functionality and calibration parameters without risking actual engine hardware.

Dynamometer testing represents the next critical phase, where the programmed ECU controls a real LS1 engine under various load conditions. Modern dynamometers can simulate different driving scenarios while measuring power output, torque curves, fuel consumption, and emissions. Advanced facilities incorporate environmental chambers to test ECU performance across temperature extremes from -40°F to 185°F, ensuring the programming remains stable under all operating conditions.

On-road testing complements laboratory validation by exposing the ECU programming to real-world variables impossible to fully simulate. Test vehicles equipped with data acquisition systems record comprehensive performance metrics during various driving conditions. These tests typically follow standardized protocols covering urban driving, highway cruising, mountain ascents, and high-temperature operation in desert environments.

Emissions compliance testing has become increasingly important in ECU validation. Modern testing methodologies utilize specialized equipment to measure exhaust gases under standardized test cycles, ensuring the ECU programming meets regulatory requirements while maintaining performance targets. This often requires sophisticated trade-off optimization between power, fuel economy, and emissions.

Durability validation represents perhaps the most time-consuming aspect of ECU programming validation. Accelerated aging tests subject the engine and ECU to thousands of hours of operation under stress conditions to verify long-term reliability. These tests often include rapid thermal cycling, vibration exposure, and extended operation at maximum power to identify potential failure modes in the programming.

Statistical analysis of test data forms the foundation of modern validation methodologies. Advanced analytics tools process terabytes of performance data to identify anomalies, optimization opportunities, and potential failure scenarios. Machine learning algorithms increasingly supplement traditional analysis by detecting subtle patterns that might indicate future performance issues before they manifest in obvious ways.

Dynamometer testing represents the next critical phase, where the programmed ECU controls a real LS1 engine under various load conditions. Modern dynamometers can simulate different driving scenarios while measuring power output, torque curves, fuel consumption, and emissions. Advanced facilities incorporate environmental chambers to test ECU performance across temperature extremes from -40°F to 185°F, ensuring the programming remains stable under all operating conditions.

On-road testing complements laboratory validation by exposing the ECU programming to real-world variables impossible to fully simulate. Test vehicles equipped with data acquisition systems record comprehensive performance metrics during various driving conditions. These tests typically follow standardized protocols covering urban driving, highway cruising, mountain ascents, and high-temperature operation in desert environments.

Emissions compliance testing has become increasingly important in ECU validation. Modern testing methodologies utilize specialized equipment to measure exhaust gases under standardized test cycles, ensuring the ECU programming meets regulatory requirements while maintaining performance targets. This often requires sophisticated trade-off optimization between power, fuel economy, and emissions.

Durability validation represents perhaps the most time-consuming aspect of ECU programming validation. Accelerated aging tests subject the engine and ECU to thousands of hours of operation under stress conditions to verify long-term reliability. These tests often include rapid thermal cycling, vibration exposure, and extended operation at maximum power to identify potential failure modes in the programming.

Statistical analysis of test data forms the foundation of modern validation methodologies. Advanced analytics tools process terabytes of performance data to identify anomalies, optimization opportunities, and potential failure scenarios. Machine learning algorithms increasingly supplement traditional analysis by detecting subtle patterns that might indicate future performance issues before they manifest in obvious ways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!